Tackling 1/2-inch steel with a MIG welder can feel like a daunting task, but with the right gear, it’s incredibly satisfying to lay down strong, deep-penetrating welds. From my own time in the shop, I’ve learned that achieving those robust welds on thick material isn’t just about cranking up the amps; it’s a careful balance of a capable machine and the perfect welding wire. If you’re looking to consistently weld 1/2-inch steel with confidence, you’re going to need a reliable MIG welder for 1/2 steel that delivers ample power, paired with a wire designed for heavy-duty applications. This guide will walk you through some of the best options available, ensuring you get the performance needed for your toughest projects.

Contents

- Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon…

- ARCCAPTAIN Mig Welding Wire, Mig Wire ER70S-6 2Lbs Gas… (.030″)

- AZZUNO Mig Solid Welding Wire, ER70S-6 Mild Steel Gas Mig… (.035″)

- ARCCAPTAIN MIG Welding Wire, MIG Wire ER70S-6 2Lbs Gas… (.045″)

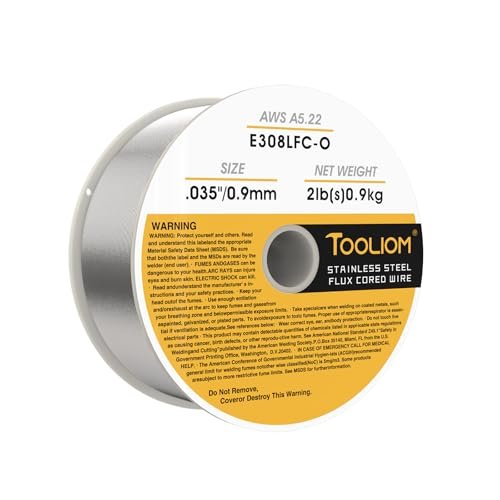

- TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless…

- Eastwood 250 Amp MIG Welder Machine for Steel & Aluminum…

- Eastwood MP250i Elite Multi-Process Welder | MIG – TIG -…

- Helpful Comparison Short Insights

- Final Verdict

- Best MIG Welder For 1/2 Steel: Your Top Questions Answered

- What amperage do I need for 1/2-inch steel with a MIG welder?

- What type of MIG wire is best for welding 1/2-inch steel?

- Can a 120V MIG welder weld 1/2-inch steel?

- Is flux-cored wire better than solid wire for 1/2-inch steel?

- What shielding gas should I use for 1/2-inch steel MIG welding?

- What safety precautions are essential when welding thick steel?

Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon…

This Blue Demon ER70S6 welding wire is a go-to for many welders when high strength and quality are non-negotiable, even on challenging 1/2-inch steel. It’s renowned for its ability to produce superior welds, often exceeding expectations for general shop applications and less-than-ideal fit-up. If you’re serious about structural integrity and pristine results on thick steel, this wire is engineered to deliver.

Key features that stand out:

– Porosity-free, X-ray quality welds: Ensures maximum integrity, crucial for critical applications on 1/2-inch steel.

– Highest tensile strength (as welded) of all plain carbon steel wires: Provides exceptional strength for heavy-duty joints.

– Great for poor fit-up: Offers forgiveness when working with imperfectly prepared 1/2-inch steel pieces.

– Commonly used for steel castings or forging salvage: Indicates its suitability for demanding repairs.

Pros:

– Produces exceptionally strong and high-quality welds.

– Forgiving for less-than-perfect joint preparation.

– Ideal for critical applications requiring high integrity.

Cons:

– Requires a shielding gas, adding to operational costs.

Best for: Demanding structural fabrication, professional workshops, and any project on 1/2-inch steel where weld quality and strength are paramount.

Expert Opinion: This wire is a powerhouse for 1/2-inch steel. Its focus on x-ray quality and superior tensile strength means you’re building with absolute confidence, which is exactly what you need for heavy-duty applications.

ARCCAPTAIN Mig Welding Wire, Mig Wire ER70S-6 2Lbs Gas… (.030″)

The ARCCAPTAIN ER70S-6 .030″ MIG welding wire is a testament to consistent performance and reliability. It’s been rigorously tested and certified, offering a smooth feeding experience and stable arc characteristics that make welding 1/2-inch steel more manageable. With its excellent wetting properties and minimal spatter, you can expect clean, strong welds with less post-weld cleanup, which is a huge time-saver on thicker materials.

Key features that stand out:

– TÜV Tested and Approved: Guarantees quality and adherence to industry standards for reliable performance.

– Smooth feeding and stable welding parameters: Ensures consistent arc control and penetration, vital for thick steel.

– High deposition rates and optimal penetration: Allows for efficient and strong welds on 1/2-inch material.

– Excellent wetting characteristics for a smooth weld bead: Results in visually appealing welds with minimal effort.

Pros:

– Certified for quality and performance.

– User-friendly, suitable for both beginners and experienced welders.

– Produces clean welds with minimal spatter.

Cons:

– 2lb spool might require more frequent changes for large projects.

Best for: General fabrication, automotive repair, and educational settings where consistent, high-quality welds on 1/2-inch steel are a priority for all skill levels.

Expert Opinion: For consistent, clean welds on 1/2-inch steel, this ARCCAPTAIN wire is a dependable choice. Its TÜV certification and smooth characteristics make it a reliable partner for your MIG welder, reducing frustrating spatter and ensuring good penetration.

AZZUNO Mig Solid Welding Wire, ER70S-6 Mild Steel Gas Mig… (.035″)

The AZZUNO ER70S-6 .035″ solid welding wire is designed to make your MIG welding experience seamless and efficient, especially when dealing with tough 1/2-inch steel. It boasts superior arc stability and a high deposition rate, ensuring deep penetration and clean welds every time. Plus, the thoughtful packaging with a moisture absorber helps maintain wire quality, preventing common issues that can compromise your weld on thick materials.

Key features that stand out:

– Easy to use with smooth feeding and low splatter: Offers a hassle-free experience for any skill level.

– High deposition rate and deep penetration: Crucial for achieving strong, efficient welds on 1/2-inch steel.

– Upgraded packing with moisture absorber: Protects the wire from environmental degradation, ensuring optimal performance.

– Excellent arc stability and smooth wire feeding: Contributes to consistent and controlled welding.

Pros:

– Beginner-friendly, yet performs for professionals.

– Packaging designed for wire longevity and performance.

– Delivers efficient and clean welds with good penetration.

Cons:

– Only offered in a 2lb spool, which can be limiting for extensive use.

Best for: DIY enthusiasts and professional welders alike who prioritize ease of use, reliable performance, and strong, clean welds on 1/2-inch steel.

Expert Opinion: AZZUNO hits a sweet spot with this wire for 1/2-inch steel, combining user-friendliness with solid performance. The smart packaging is a real bonus, ensuring your wire is always in top condition for critical welds.

ARCCAPTAIN MIG Welding Wire, MIG Wire ER70S-6 2Lbs Gas… (.045″)

When you need to bring serious heat and lay down robust beads on 1/2-inch steel, the ARCCAPTAIN ER70S-6 .045″ MIG welding wire is your ticket. The larger diameter wire is specifically chosen for heavy-duty applications, providing the bulk needed for higher deposition rates and deeper penetration on thick materials. Like its thinner counterpart, this wire is TÜV certified, ensuring you’re getting a product that meets rigorous quality standards for superior strength and minimal impurities.

Key features that stand out:

– .045″ diameter for heavy-duty welding: Optimal size for maximum penetration and fill on 1/2-inch steel.

– TÜV Tested and Approved: Confirms high quality and consistent performance for demanding tasks.

– High deposition rates: Speeds up the welding process on thick materials without compromising quality.

– Smooth weld bead and minimal spatter: Ensures a clean finish and reduces post-weld grinding.

Pros:

– Ideal for maximum penetration and strength on very thick materials.

– Certified quality provides peace of mind.

– Excellent arc characteristics for a clean and efficient weld.

Cons:

– Requires a MIG welder with sufficient power and drive rolls to handle .045″ wire.

Best for: Industrial fabrication, heavy equipment repair, and any project where maximum strength and penetration on 1/2-inch steel are absolutely essential.

Expert Opinion: For genuinely robust welds on 1/2-inch steel, stepping up to a .045″ wire like this ARCCAPTAIN is a game-changer. It allows for higher amperage and delivers the necessary fill and penetration that smaller wires might struggle with on such thick material.

TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless…

The TOOLIOM Gasless Flux-Cored MIG Welding Wire is an excellent choice for those situations where traditional shielding gas is simply not feasible. Its unique flux core design provides self-shielding, making it ideal for outdoor applications, windy conditions, or when welding rusty, dirty, or painted materials. While typically associated with a bit more spatter than solid wire, this particular formulation is designed to minimize it, allowing for high-quality, all-position welds on thick steel without the need for a gas tank.

Key features that stand out:

– Self-shielded flux core design: Eliminates the need for external shielding gas, offering unmatched portability.

– Less spatter and high-quality welds: Engineered for cleaner results than typical flux-cored wires.

– Ideal for rusty, dirty, and painted materials: Highly forgiving of less-than-perfect base material preparation.

– All positions capability: Allows for versatile welding in flat, horizontal, vertical, and overhead orientations.

Pros:

– Extremely versatile for outdoor and challenging environments.

– No shielding gas required, simplifying setup and increasing mobility.

– Performs well on unprepared materials.

Cons:

– May still produce slightly more spatter compared to solid wire with gas.

Best for: Field repairs, outdoor construction, DIY projects in less-than-ideal conditions, and anyone needing a portable solution for welding 1/2-inch steel without a gas cylinder.

Expert Opinion: When gas bottles are a no-go, this TOOLIOM flux-cored wire is an indispensable tool for 1/2-inch steel. Its ability to perform in dirty environments and all positions makes it incredibly practical for specific job site challenges.

Eastwood 250 Amp MIG Welder Machine for Steel & Aluminum…

The Eastwood 250 Amp MIG Welder is a serious contender for anyone looking to weld 1/2-inch steel with precision and power. This portable powerhouse packs a punch with its 250-amp output and state-of-the-art IGBT inverter technology, allowing it to handle everything from thin sheet metal to heavy 1/2-inch plates. Its dual voltage capability (120V/240V) means you can plug it in almost anywhere, making it incredibly versatile for garage or shop use. The infinitely adjustable amperage gives you fine-tuned control, which is essential for consistent, quality welds on thick material.

Key features that stand out:

– 250 Amp output: Provides the necessary power for deep penetration on 1/2-inch steel.

– 120V or 240V dual voltage compatibility: Offers flexibility for power sources in various locations.

– Welds 20-gauge sheet metal up to 1/2-inch steel plates: Demonstrates its wide range of capabilities.

– Latest IGBT Inverter Technology: Ensures efficient, stable arc performance and portability.

Pros:

– Exceptional power for welding 1/2-inch steel effectively.

– Highly portable with dual voltage input.

– Infinitely adjustable controls for precise welding.

Cons:

– Primarily a MIG-only machine, limiting process versatility.

Best for: Experienced DIYers, small to mid-size fabrication shops, and professionals who need a dedicated, powerful, and portable MIG welder for consistently welding 1/2-inch steel and thinner materials.

Expert Opinion: This Eastwood 250 is a true workhorse for 1/2-inch steel. The high amperage combined with inverter technology means you’re getting efficient power delivery and excellent arc control, making heavy fabrication much more manageable. It’s a dedicated MIG machine that excels at what it does.

Eastwood MP250i Elite Multi-Process Welder | MIG – TIG -…

For the welder who needs maximum versatility alongside the power to tackle 1/2-inch steel, the Eastwood MP250i Elite Multi-Process Welder is an outstanding choice. This machine truly does it all: MIG, TIG, and Stick welding, all powered by a robust 250-amp output and dual 120V/240V voltage capability. Whether you’re laying down MIG beads on 1/2-inch steel plate, precision TIG welding thin stainless, or running stick electrodes, the MP250i delivers. Its ability to handle both 8-inch and 12-inch wire spools adds to its flexibility, making it a comprehensive solution for almost any welding task involving thick materials.

Key features that stand out:

– Multi-Process capability (MIG, TIG, Stick): Offers unparalleled versatility for different applications and materials.

– 250 Amp output: Sufficient power for welding 1/2-inch steel confidently across multiple processes.

– 120V/240V dual voltage: Adaptable to various power sources, enhancing usability.

– Welds up to 1/2-inch steel (MIG/Arc) and 3/8-inch stainless (TIG): Covers a wide range of thick material welding.

Pros:

– Extremely versatile, handling almost any welding project.

– Powerful enough for serious 1/2-inch steel fabrication.

– High-quality components and robust build for reliability.

Cons:

– Higher initial investment due to its multi-process capabilities.

Best for: Professional fabricators, serious hobbyists, and anyone requiring a single machine that can handle diverse welding processes and materials, including heavy 1/2-inch steel projects.

Expert Opinion: The MP250i is a comprehensive solution, not just for 1/2-inch steel, but for nearly any welding challenge you throw at it. Its multi-process functionality means you’re investing in a single machine that covers all bases, delivering powerful and precise welds on thick materials.

Helpful Comparison Short Insights

When picking the best MIG welder for 1/2 steel, you’re really looking at a synergy between the welding machine and the wire. For the wire, we saw a range from .030″ to .045″, and both solid and flux-cored options. While .030″ and .035″ ER70S-6 solid wires like the Blue Demon, ARCCAPTAIN, and AZZUNO can certainly weld 1/2-inch steel, they often require multiple passes to build up the weld and achieve full penetration, especially on a single-pass joint. For truly robust, deep-penetrating welds on 1/2-inch steel, the .045″ ARCCAPTAIN ER70S-6 wire is often the preferred choice, allowing for higher amperage and greater deposition rates.

If you’re working outdoors or in dirty conditions, the TOOLIOM Gasless Flux-Cored wire is a lifesaver; it doesn’t need gas and can handle less-than-ideal material, though you might get a bit more spatter. For machines, the Eastwood 250 Amp MIG Welder is a dedicated MIG powerhouse designed to expertly handle 1/2-inch steel with ease. If your projects involve more than just MIG – perhaps TIG or Stick welding too – then the Eastwood MP250i Elite Multi-Process Welder is an excellent investment, offering the same 1/2-inch steel capability across multiple welding processes. Both Eastwood machines provide the necessary amperage and duty cycle for sustained work on thick steel.

Final Verdict

Choosing the best MIG welder for 1/2 steel isn’t just about raw power; it’s about reliable performance, consistent welds, and the right consumables. If your primary focus is heavy-duty MIG welding on 1/2-inch steel and you don’t need other processes, the Eastwood 250 Amp MIG Welder stands out as a dedicated, powerful, and portable machine that gets the job done exceptionally well. It provides the high amperage and precise control you need for thick material.

However, if you’re a professional or a serious hobbyist who needs the flexibility to tackle MIG, TIG, and Stick welding on 1/2-inch steel and other materials, the Eastwood MP250i Elite Multi-Process Welder is the clear winner for its versatility and robust performance. It’s an investment that truly expands your capabilities.

Regardless of your chosen machine, always pair it with a high-quality wire. For the most demanding 1/2-inch steel applications, consider the ARCCAPTAIN ER70S-6 .045″ MIG welding wire for superior penetration and deposition, or the Blue Demon ER70S6 .030″ for x-ray quality welds where integrity is paramount. With the right machine and the right wire, you’ll be confidently laying down strong, beautiful welds on 1/2-inch steel in no time.

Best MIG Welder For 1/2 Steel: Your Top Questions Answered

What amperage do I need for 1/2-inch steel with a MIG welder?

For effective and strong welds on 1/2-inch (12.7mm) steel, you generally need a MIG welder capable of producing at least 200-250 amps. Welding thick steel requires significant heat input to achieve proper fusion and penetration. A 240V MIG welder is almost always necessary to reach and sustain these higher amperage levels and maintain an adequate duty cycle.

What type of MIG wire is best for welding 1/2-inch steel?

For 1/2-inch steel, an ER70S-6 solid wire is highly recommended. The specific wire diameter is crucial; while .030″ or .035″ can work with multiple passes, a .045″ diameter ER70S-6 solid wire is often preferred for 1/2-inch steel because it allows for higher amperage settings, greater deposition rates, and deeper penetration in fewer passes, leading to stronger welds.

Can a 120V MIG welder weld 1/2-inch steel?

While some manufacturers might claim their 120V machines can “weld” 1/2-inch steel, it’s generally not recommended for structural or critical applications. A 120V MIG welder typically maxes out around 140-180 amps, which is usually insufficient for achieving proper full penetration on 1/2-inch steel. It would require numerous passes and might result in a cold, weak weld. For reliable, strong welds on 1/2-inch steel, a 240V MIG welder is essential.

Is flux-cored wire better than solid wire for 1/2-inch steel?

Flux-cored wire (especially E71T-GS or E71T-11) offers excellent penetration on thick materials like 1/2-inch steel and is ideal for outdoor or dirty conditions because it doesn’t require external shielding gas. However, solid wire (ER70S-6) with gas typically produces cleaner welds with less spatter and slag, making it aesthetically preferable and reducing post-weld cleanup. For the strongest, most aesthetically pleasing welds on 1/2-inch steel in a shop environment, solid wire is often preferred, but flux-cored is a highly practical alternative for field work.

What shielding gas should I use for 1/2-inch steel MIG welding?

For MIG welding mild steel like 1/2-inch plate, the most common and effective shielding gas is a 75% Argon / 25% CO2 (C25) mix. This blend provides a good balance of arc stability, puddle control, and penetration. For deeper penetration and higher heat, especially on very thick sections, 100% CO2 can be used, though it typically results in more spatter and a harsher arc.

What safety precautions are essential when welding thick steel?

Welding 1/2-inch steel generates significant heat, smoke, and UV radiation. Always wear appropriate Personal Protective Equipment (PPE), including a welding helmet with the correct shade lens, flame-retardant clothing, heavy-duty welding gloves, and safety glasses. Ensure you have adequate ventilation to extract fumes, especially when welding in enclosed spaces. Always follow your welder’s manual for specific safety instructions.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.