As someone who’s spent countless hours under the hood, I know that tackling structural steel projects demands not just skill, but also the right equipment. Getting those strong, reliable welds on beams, frames, or heavy-duty fabrication is crucial, and a good MIG setup is often the backbone of such work. When we talk about the best MIG welder for structural steel, we’re looking for power, precision, and durability. In this guide, I’ll share my insights on some key pieces of gear, including a versatile MIG machine, specialized wires, and essential tools, to help you make informed choices for your next heavy-duty structural project.

Contents

- Product Reviews

- Helpful Comparison Short Insights

- Final Verdict

- Best MIG Welder For Structural Steel: Your Questions Answered

- What’s the best type of MIG wire for structural steel?

- Can a 120V MIG welder handle structural steel?

- Why are welding pliers considered essential for structural steel MIG welding?

- When should I use flux core wire versus solid wire for structural steel?

- Is stainless steel MIG wire suitable for all structural steel applications?

- What are key considerations for safety when welding structural steel?

Product Reviews

ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L,…

When you’re working with stainless steel structural components, especially in demanding environments like food service or medical facilities, you need a wire that delivers both strength and superior corrosion resistance. This ARCCAPTAIN ER308L wire is a top-tier choice, designed to minimize carbon precipitation and give you clean, precise welds. It’s highly compatible with various stainless steel grades, making it incredibly versatile for specialized fabrication.

Key features that stand out:

– Premium Low Carbon Content: Minimizes carbide precipitation for enhanced corrosion resistance.

– Versatile Stainless Steel Compatibility: Works with 304, 304L, 308, 308L, 321, and 347 stainless steels.

– Precision and Control: Offers superior arc control and minimal splatter for clean welds.

– Durable Construction: Crafted from high-grade stainless steel for longevity.

Pros:

– Excellent corrosion resistance for specific applications

– Low carbon content enhances weld integrity

– Minimal spatter for cleaner finished products

– Compatible with a wide range of stainless steel types

Cons:

– Requires specific shielding gas (argon/helium) for optimal performance.

Best for: Specialized structural applications using stainless steel where corrosion resistance is paramount.

Expert Opinion: This isn’t your everyday mild steel wire, it’s a specialty item. When you need to weld stainless steel for structural integrity and high-grade finish, especially in hygienic or corrosive environments, this ER308L wire is a professional’s choice for its precise properties and reliability.

ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6…

For general structural steel welding, particularly with mild carbon steel, the ARCCAPTAIN ER70S-6 solid MIG wire is a fantastic workhorse. This wire ensures consistent performance and superior strength, which is exactly what you need for load-bearing structures. Its smooth feeding characteristics mean less fuss and more consistent bead appearance, helping you achieve high-quality welds with excellent penetration.

Key features that stand out:

– High-Quality ER70S-6 Standard: Meets industry standards for consistent performance and superior strength.

– TÜV Tested and Approved: Rigorously tested for quality and reliability.

– Smooth Weld Bead: Ensures proper molten metal flow for visually appealing welds with minimal cleanup.

– Optimal Performance: Excellent arc characteristics with minimal spatter.

Pros:

– Ensures consistent strength and penetration

– Smooth feeding for hassle-free operation

– Produces clean, visually appealing weld beads

– User-friendly for both beginners and experienced welders

Cons:

– Requires external shielding gas, limiting outdoor use.

Best for: General purpose MIG welding of mild carbon structural steel indoors, where strength and a smooth finish are important.

Expert Opinion: For robust structural steel jobs, especially when working with mild steel, the ER70S-6 is a staple. This particular ARCCAPTAIN wire delivers on reliability and consistency, which translates directly to strong, dependable welds – exactly what you need when you’re building something that needs to hold up.

8″MIG Welding Pliers, Multi-functional Carbon Steel MIG…

While not a welder itself, having the right tools makes all the difference when you’re working with a MIG welder for structural steel. These 8″ MIG welding pliers are an absolute essential for any fabricator. Often called “welpers,” they’re a multi-functional tool designed to handle nearly every torch maintenance task, from cutting wire to cleaning nozzles, ensuring your MIG setup performs optimally on those critical structural welds.

Key features that stand out:

– High-Quality Construction: Made from premium carbon steel for sturdiness and durability.

– Multi-Functional Design: Features built-in wire cutters, metal wire cutting blades, and serrated holes for nozzle rotation.

– Strong Clamping: Long serrated jaws provide exceptional grip for various workpieces.

– Comfortable Handle: User-friendly design with a spring mechanism to reduce fatigue.

Pros:

– All-in-one tool for MIG torch maintenance

– Durable construction for long-lasting use

– Reduces hand fatigue with spring mechanism

– Essential for clean wire cuts and nozzle care

Cons:

– The rust-proof oil coating needs wiping before first use.

Best for: Every MIG welding setup, an indispensable tool for maintaining the torch and preparing wire for structural projects.

Expert Opinion: You might not think much about pliers, but these are a lifesaver. When you’re in the middle of a big structural project, you don’t want to stop for fiddly torch maintenance. These pliers make everything quick and easy, which means more arc time and less frustration. Definitely a must-have for efficiency and safety.

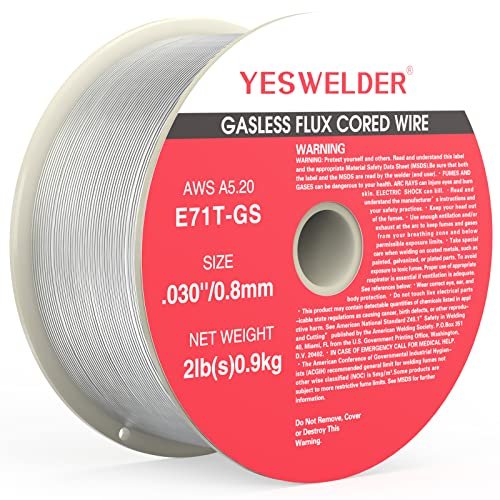

YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon…

For structural steel projects that demand flexibility, especially when you’re working outdoors or don’t have access to shielding gas, the YESWELDER Flux Core Gasless MIG Wire is an excellent choice. This self-shielding E71T-GS wire eliminates the need for an external gas cylinder, making your MIG setup highly portable. It’s designed to perform well in windy conditions and through light rust, ensuring reliable welds on carbon steel and low-alloy structural steel.

Key features that stand out:

– E71T-GS Flux Core Wire: Self-shielding design for gasless welding.

– Excellent Performance: Low spatter, easy slag removal, porosity-free deposits.

– Versatile Applications: Ideal for outdoor, windy conditions and all-position welding.

– Material Compatibility: Suitable for carbon steel and low-alloy structural steel.

Pros:

– No need for shielding gas, enhancing portability

– Great for outdoor and windy conditions

– Produces strong, reliable welds on various steels

– Low spatter and good bead appearance

Cons:

– Creates more slag than solid wire, requiring more post-weld cleanup.

Best for: Structural steel welding outdoors, on-site, or in situations where portability and gasless operation are crucial.

Expert Opinion: Flux core wire like this is a game-changer for on-site structural work. I’ve used it countless times when a gas bottle just isn’t practical, and it consistently delivers strong, dependable welds even in less-than-ideal conditions. It’s incredibly versatile for repair and fabrication away from the shop.

Eastwood 140 Amp 120V MIG Welder Machine for Sheet Metal…

When it comes to the best MIG welder for structural steel that offers a balance of power and portability for hobbyists and serious DIYers, the Eastwood 140 Amp 120V MIG Welder is a standout. This machine is lightweight and operates on standard 120V power, making it incredibly versatile for workshops and home garages. It’s capable of welding mild and stainless steel up to 3/16″ thick, which covers a significant range of structural projects like automotive frames, gates, and small building components.

Key features that stand out:

– Portable Welder: Lightweight (less than 25 lbs) and runs on 120V, maximizing usability.

– Latest IGBT Inverter Technology: Offers a 30-140 amp welding range for versatile applications.

– Metal Drive Motor: Ensures smooth wire feeding for consistent operation.

– 2T/4T Modes: Provides comfort for long welds, and compatible with Flux-Core welding.

Pros:

– Highly portable for various work locations

– Versatile amperage range for different thicknesses

– Can weld mild and stainless steel

– Includes 2T/4T modes for user comfort during long welds

– Excellent customer support and warranty from Eastwood

Cons:

– 3/16″ thickness limit might be insufficient for very heavy structural steel.

Best for: Hobbyists, DIY enthusiasts, and small fabrication shops needing a portable, capable MIG welder for structural steel up to 3/16″.

Expert Opinion: This Eastwood 140 Amp unit is an excellent entry point into structural steel welding for anyone without industrial power. It handles a good range of thicknesses for most home and hobby projects, and the inverter technology means it’s pretty efficient. Pairing this with the right wire, you’ll be surprised at what you can accomplish.

Helpful Comparison Short Insights

When picking your gear for structural steel welding, it’s all about matching the tool to the task. For any robust structural steel projects, you’ll primarily rely on a capable MIG machine like the Eastwood 140 Amp, which forms the core of your welding setup. Complementing this, your choice of wire is critical.

For most mild carbon steel structural work indoors, where precision and strength are paramount, the ARCCAPTAIN ER70S-6 solid wire is your go-to, delivering strong, smooth beads. However, if you need portability and often weld outdoors or on-site, the YESWELDER Flux Core wire becomes invaluable, as its self-shielding nature eliminates the need for external gas and performs well in windy conditions.

For projects requiring specialized corrosion resistance, especially with stainless steel structural elements in specific industries like food or medical, the ARCCAPTAIN ER308L stainless steel wire is the precise, high-grade solution.

Regardless of your machine or wire choice, having dedicated MIG welding pliers is an absolute must-have. These multi-functional tools are essential for torch maintenance, wire cutting, and nozzle care, ensuring your entire MIG setup runs efficiently and your workflow stays smooth through every structural weld.

Final Verdict

For the aspiring fabricator or dedicated DIYer tackling structural steel, the Eastwood 140 Amp MIG Welder stands out as the core machine you need, offering a great balance of power and portability for various projects up to 3/16″. Complementing this, your choice of wire is critical. If you’re primarily working with mild steel indoors and prioritize consistent, strong welds, the ARCCAPTAIN ER70S-6 solid wire delivers exactly that. For outdoor work or maximum portability without the hassle of a gas bottle, the YESWELDER Flux Core wire is an invaluable asset. And for those specialized stainless steel structural components requiring corrosion resistance, the ARCCAPTAIN ER308L offers precise, high-grade joints. Finally, don’t underestimate the utility of the 8″ MIG Welding Pliers – they’re not optional, they’re essential for efficient, safe operations. Ultimately, the best setup for your structural steel projects will involve selecting the right combination of these tools and consumables based on your specific material, environment, and desired finish.

Best MIG Welder For Structural Steel: Your Questions Answered

What’s the best type of MIG wire for structural steel?

For mild structural steel, ER70S-6 solid wire (like the ARCCAPTAIN ER70S-6) is a common and excellent choice for its strength and smooth bead. If you’re welding outdoors or need portability without gas, E71T-GS flux core wire (like the YESWELDER Flux Core) is highly effective. For stainless steel structural components, specialized wires like ER308L are necessary for corrosion resistance.

Can a 120V MIG welder handle structural steel?

Yes, a 120V MIG welder like the Eastwood 140 Amp can definitely handle structural steel, especially for thicknesses up to 3/16″ (about 4.8mm). While it won’t weld incredibly thick steel (like 1/2″ or more) as quickly as a 240V machine, it’s perfect for many common structural projects such as gates, railings, vehicle frames, and light fabrication. Always check the machine’s capacity and duty cycle for your specific project.

Why are welding pliers considered essential for structural steel MIG welding?

Welding pliers, or “welpers,” are indispensable because they streamline crucial MIG torch maintenance. They allow you to quickly cut welding wire, remove and install contact tips, clean spatter from nozzles, and even hammer when needed. This multi-functionality ensures your equipment is always in top shape, leading to better, more consistent welds on your structural steel projects and preventing costly downtime.

When should I use flux core wire versus solid wire for structural steel?

You should use flux core wire (like the E71T-GS) when working outdoors or in windy conditions, or when you need maximum portability without a shielding gas tank. It’s self-shielding and penetrates well, even through light rust. Use solid wire (like ER70S-6) for indoor structural work where you can maintain a consistent gas shield. Solid wire generally produces less spatter and a cleaner bead, with less post-weld cleanup required.

Is stainless steel MIG wire suitable for all structural steel applications?

No, stainless steel MIG wire like ER308L is specifically designed for welding stainless steel alloys. It’s chosen for its corrosion resistance and specific mechanical properties, making it ideal for structural applications where hygiene or resistance to rust is critical. For welding common carbon steel or low-alloy structural steel, you’ll need mild steel wires like ER70S-6 or flux core wires. Using the wrong wire for the base metal can lead to weak or brittle welds.

What are key considerations for safety when welding structural steel?

Safety is paramount when using a MIG welder for structural steel. Always wear appropriate Personal Protective Equipment (PPE), including a high-quality welding helmet with the correct shade lens, flame-resistant jacket, heavy-duty gloves, and steel-toed boots. Ensure good ventilation to avoid inhaling fumes, especially in enclosed spaces. Protect others nearby from arc flash with welding screens. Be aware of fire hazards and have a fire extinguisher ready. Always follow your welder’s manual for safe operation and maintenance.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.