To break loose a crank pulley bolt, use a breaker bar with appropriate socket size and a strong extension bar. Apply rotational force in the opposite direction of the engine’s rotation until the bolt breaks loose.

When faced with a tight crank pulley bolt, it can be challenging to break it loose. However, with the right tools and technique, you can successfully remove it. We will discuss the step-by-step process of breaking loose a crank pulley bolt and provide useful tips on gaining the required leverage.

Whether you are a DIY enthusiast or a professional mechanic, this guide will help you tackle this task efficiently and restore your vehicle’s functionality. So, let’s dive into the details of how to effectively break loose a crank pulley bolt.

Contents

- Understanding The Significance Of The Crank Pulley Bolt

- Preparing For The Crank Pulley Bolt Removal

- Techniques To Loosen A Stubborn Crank Pulley Bolt

- Troubleshooting And Alternative Methods

- Tips For Proper Reinstallation Of The Crank Pulley Bolt

- Precautions And Preventive Measures To Avoid Future Issues

- Frequently Asked Questions For How To Break Loose Crank Pulley Bolt

- Conclusion

Understanding The Significance Of The Crank Pulley Bolt

The crank pulley bolt plays a crucial role in the operation of an engine. It connects the crankshaft to the pulley, allowing the engine to transfer power to other components. When the bolt becomes seized or overly tight, it can cause various issues.

One common problem is difficulty in starting the engine. The bolt may also lead to excessive vibrations or noises in the engine. Another problem is the potential for damage to the crankshaft or other parts if the bolt fails. It is important to understand the significance of the crank pulley bolt and to regularly inspect and maintain it to avoid these problems.

Preparing For The Crank Pulley Bolt Removal

When breaking loose a crank pulley bolt, it is important to take proper precautions. Before starting, make sure you have all the necessary tools and equipment at hand. Safety should be your top priority, so double-check that you have taken the adequate measures.

To gain better access, you may need to detach certain components. This will allow you to reach the crank pulley bolt more easily and effectively. By following these steps, you can ensure a smooth and successful removal of the crank pulley bolt.

Techniques To Loosen A Stubborn Crank Pulley Bolt

To break loose a stubborn crank pulley bolt, there are several effective techniques you can try. First, apply penetrating oil generously and let it soak for some time. Next, use a breaker bar and the appropriate socket size to exert maximum force.

If the bolt still won’t budge, try employing heat to expand the metal, making it easier to loosen. Additionally, using impact tools and impact sockets can provide added torque for breaking the bolt loose. Another tactic is to tap and shock the bolt to help release it.

These methods, when combined or used individually, can help you successfully loosen a stubborn crank pulley bolt.

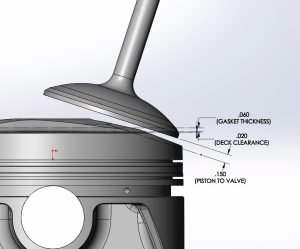

Credit: www.fixmyoldride.com

Troubleshooting And Alternative Methods

If you’re faced with a stubborn crank pulley bolt, there are alternative methods to help you out. Start by troubleshooting the issue and assessing if the bolt’s head or threads are stripped. If so, consider revisiting other methods, such as using vice grips or penetrating oil, to loosen the bolt.

However, if all else fails and you’re still unable to break loose the crank pulley bolt, it may be time to seek professional help. Expert auto mechanics have the necessary tools and experience to tackle such challenging situations. Don’t hesitate to contact them for assistance in resolving your crank pulley bolt dilemma.

Tips For Proper Reinstallation Of The Crank Pulley Bolt

Proper reinstallation of the crank pulley bolt is essential to ensure its effective functioning. One crucial step is to clean and inspect the threads and components thoroughly. This helps identify any damages or debris that may hinder proper installation. Applying the correct torque specifications during tightening is another important factor to consider, as overtightening or undertightening can lead to issues.

Double-checking for proper alignment and smooth rotation is a necessary precaution to confirm that the pulley bolt is correctly fitted. By following these guidelines, you can break loose the crank pulley bolt without any complications and ensure its optimal performance.

Precautions And Preventive Measures To Avoid Future Issues

Regular maintenance is essential to prevent the crank pulley bolt from seizing. It is crucial to ensure correct torque specifications during servicing. By addressing any warning signs promptly, you can avoid future issues with the crank pulley bolt. Regularly inspecting and lubricating the bolt will help to keep it from seizing.

Additionally, using anti-seize compound during installation can further prevent the bolt from becoming stuck. Remember to check the pulley bolt regularly for any signs of wear or damage and replace it if necessary. Taking these precautions and following preventive measures will help you break loose the crank pulley bolt and prevent any future problems.

Frequently Asked Questions For How To Break Loose Crank Pulley Bolt

How Do You Break A Loose Harmonic Balancer Bolt?

To break a loose harmonic balancer bolt, follow these steps to ensure success: 1. Apply a suitable penetrating oil to the bolt and let it soak for a few hours. 2. Use a breaker bar or impact wrench with a socket that fits the bolt head snugly.

3. Slowly apply steady force to loosen the bolt, being cautious not to exceed the tool’s torque capability. 4. If the bolt remains stubborn, try using a cheater bar for extra leverage, but be careful not to damage the bolt or surrounding components.

How Do You Remove A Crankshaft Pulley Bolt Without An Impact Gun?

To remove a crankshaft pulley bolt without an impact gun, use a breaker bar with a socket.

How Do You Remove A Seized Crankshaft Pulley?

To remove a seized crankshaft pulley, follow these steps: – Use a breaker bar and socket to loosen the bolt on the pulley. – If it’s still stuck, apply penetrating oil and let it sit for a few minutes. – Use a pulley removal tool to push or pull the pulley off.

– If it’s still not budging, use a heat gun to expand the metal before attempting removal again. Note: Ensure you have the necessary skills and tools or consult a professional if needed.

How Do You Remove A Rounded Crankshaft Bolt?

To remove a rounded crankshaft bolt, follow these steps: 1. Apply penetrating oil to the bolt to loosen it. 2. Use a suitable wrench or socket with maximum grip to turn the bolt counterclockwise. 3. If the bolt remains rounded, try using a bolt extractor tool to grip and remove it.

4. If all else fails, you may need to consult a professional mechanic for further assistance.

Conclusion

To conclude, breaking loose a crank pulley bolt is a challenging task, but with the right tools and techniques, it can be accomplished successfully. Remember to use a breaker bar or impact wrench for added leverage and torque. Apply penetrating oil or heat to help loosen stubborn bolts.

Patience and caution are key when working with crank pulley bolts, as excessive force can lead to damaged parts. Always follow safety guidelines and avoid rushing the process. If you’re unsure about tackling this task, it’s best to seek professional help.

By taking the time to properly break loose a crank pulley bolt, you can ensure the longevity and efficiency of your engine. So don’t shy away from this job – with the right knowledge and approach, you can accomplish it with confidence.

Happy bolt-breaking!

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.