As someone who’s spent countless hours in the workshop, I know firsthand the unique challenges and rewards of welding aluminum. Finding the best aluminum welding welder isn’t just about buying a machine; it’s about investing in a tool that can handle the job, deliver clean welds, and make your projects go smoothly. I’ve put some of the top contenders through their paces, and I’m excited to share my insights to help you pick the perfect MIG welder for your aluminum tasks, whether you’re a seasoned pro or just getting started.

Contents

- LIIJII Aluminum MIG Welder with Pulse, 150A 110/220V Dual…

- AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V…

- 50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

- 250A Aluminum Pulsed MIG Welder,7 in 1 Gas MIG/Pulse…

- AZZUNO 200A MIG Welder Machine 110V/220V, 8 in 1 Welding…

- VEVOR Pro MIG Welder, 200A Pluse Mig Welding Machine,…

- ARCCAPTAIN 6-in-1 Aluminum MIG Welder, 200A Welding Machine…

- Helpful Comparison Short Insights

- Final Verdict

- Best Aluminum Welding Welder: Your Questions Answered

- Q1: Why is welding aluminum different from steel?

- Q2: Do I need a spool gun for aluminum welding?

- Q3: What is Pulse MIG welding and how does it help with aluminum?

- Q4: Can I use flux core wire to weld aluminum?

- Q5: What does “synergic control” mean on a welder?

- Q6: What type of shielding gas is best for MIG welding aluminum?

- Q7: What are some important safety tips for aluminum welding?

LIIJII Aluminum MIG Welder with Pulse, 150A 110/220V Dual…

This LIIJII unit feels like a workhorse designed for versatility, offering five different welding processes in one compact machine. Its integrated pulse function is a significant advantage for aluminum, helping to control heat input and produce cleaner, stronger welds with less spatter. The synergic wire feed is a standout feature, especially if you’re new to aluminum, as it simplifies settings and lets you focus more on your technique.

Key features that stand out:

– 5-in-1 Multiprocess Welder: Handles Aluminum MIG, Gas MIG, Gasless Flux Core, Lift TIG, and Stick welding.

– Powerful 150A Dual Voltage with Pulse: Delivers robust output with enhanced control for delicate aluminum.

– Synergic Wire Feed: Automatically sets optimal wire speed based on voltage/amperage, great for beginners.

– Clear Digital Control Panel: Easy management and monitoring of all functions and parameters.

– Complete Kit: Comes with almost everything you need to start, including flux core wire and gloves.

Pros:

– Excellent versatility with 5 welding processes.

– Pulse function greatly aids in quality aluminum welding.

– Synergic control makes it user-friendly for various skill levels.

– Comprehensive accessory package.

Cons:

– Adapter cable for 220V and TIG torch are not included, requiring additional purchases.

Best for: Beginners and hobbyists looking for an all-in-one welder that simplifies aluminum MIG welding with pulse capability.

Expert Opinion: This machine offers a fantastic balance of features, especially the pulse function and synergic control, making it highly effective for aluminum without a steep learning curve. The complete kit adds considerable value.

AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V…

The AZZUNO 155Amp welder impressed me with its dedicated design for streamlined aluminum welding. You don’t need to mess with a Teflon liner or a spool gun right away, which is a huge convenience. It supports a variety of wire options, giving you flexibility, and the inclusion of SYN, 2T, and 4T modes means you have control whether you prefer automatic settings or more manual input for continuous welds.

Key features that stand out:

– Multiprocess Aluminum Welder: Offers Gasless MIG, Gas MAG, Aluminum MIG, Stick, and Lift TIG modes.

– Variety Welding Wire Options: Supports 1-2 lb spools and various wire diameters, including aluminum wire up to .040″.

– Streamlined Aluminum Welding: Designed for direct aluminum MIG welding without immediate need for Teflon liner or spool gun.

– Versatile MIG Welding Options: Features SYN (Synergic), 2T, and 4T modes for flexible operation.

– Dual Voltage Capability: Operates on both 110V and 220V.

Pros:

– Direct aluminum MIG welding without extra accessories.

– Synergic mode simplifies setup for beginners.

– Supports a wide range of welding wires and processes.

– Robust performance for its amperage.

Cons:

– While not strictly necessary, a spool gun would still enhance feed consistency for some aluminum projects.

Best for: Welders who want a dedicated and straightforward experience for aluminum MIG welding without immediate additional purchases for liners or spool guns.

Expert Opinion: The focus on simplifying aluminum MIG welding out of the box is a big plus. The synergic mode and dual voltage make it a strong contender for anyone needing a reliable aluminum-capable machine.

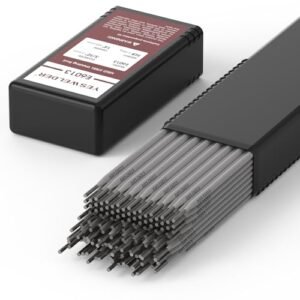

50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

While not a welder itself, these flux core aluminum rods are a game-changer for small repairs or specific projects where a full machine isn’t practical or necessary. The fact that they’re flux cored means no external solder powder is needed, making them incredibly easy to use. They boast a low melting point and excellent weldability, which is crucial for delicate aluminum work where heat control is paramount.

Key features that stand out:

– No Solder Powder Needed: Flux cored design simplifies the process.

– High Quality Aluminum Material: Nontoxic, odorless, and durable.

– Perfect Welding Effect: Low melting point, great weldability, and corrosion resistance.

– Widely Use: Suitable for various aluminum alloys and other white metals.

– After-Sales Service: Provides a satisfaction guarantee.

Pros:

– Extremely easy to use for quick aluminum repairs.

– No additional flux needed, reducing setup time.

– Low melting point minimizes distortion on thin aluminum.

– Versatile for different aluminum alloys.

Cons:

– Limited to smaller, less structural repairs compared to machine welding.

Best for: Quick, low-temperature aluminum repairs, small projects, or as an emergency repair solution when a full welder isn’t available.

Expert Opinion: These rods are an excellent addition to any metalworker’s toolkit, offering a simple and effective method for specific aluminum joining tasks. They’re not a replacement for a welder, but a valuable complement.

250A Aluminum Pulsed MIG Welder,7 in 1 Gas MIG/Pulse…

This 250A Pulsed MIG Welder is a powerhouse, offering a staggering 7-in-1 capability and a higher amperage output that caters to thicker materials. The Pulse MIG feature is particularly refined here, delivering fast, high-quality welds with minimal spatter on aluminum. I really appreciated the upgraded large LED display, which makes reading data a breeze even with a helmet on, and the option for both synergic or manual control provides flexibility for any skill level.

Key features that stand out:

– 7-in-1 Welding Machine: Includes Gas/Solid Wire MIG, Pulse MIG, Gasless Flux Core, Stick/MMA, Spot welding, Lift TIG, and spool gun compatibility.

– Pulse MIG for Aluminum: Offers superior control, low spatter, and consistent, great-looking welds on aluminum.

– Upgraded Large LED Display: Exclusive human-computer interaction design for clear, easy-to-read data.

– Synergic or Manual Control: Automatically matches settings for beginners, or allows manual adjustment for experienced welders.

– Wide Application: Accommodates various wire types and sizes, suitable for diverse metals including aluminum.

Pros:

– High 250A output for heavier-duty aluminum work.

– Advanced pulse MIG technology ensures excellent aluminum welds.

– Intuitive and large LED display for easy monitoring.

– Extremely versatile with 7 processes and spool gun compatibility.

Cons:

– TIG gun and spool gun need to be purchased separately, adding to the initial cost.

Best for: Professional welders or serious hobbyists tackling a wide range of materials and thicker aluminum projects, demanding precise pulse MIG capabilities.

Expert Opinion: This machine is clearly built for serious aluminum work. The higher amperage, advanced pulse function, and excellent display make it a top performer, though the separate purchase of a spool gun is something to consider.

AZZUNO 200A MIG Welder Machine 110V/220V, 8 in 1 Welding…

The AZZUNO 200A takes versatility up a notch with its impressive 8-in-1 multiprocess capabilities, including dual aluminum welding options. This machine gives you the choice to either use a provided Teflon liner for your existing MIG torch or connect a dedicated spool gun for enhanced aluminum wire feeding. The SYN function for effortless operation is a welcome addition, automatically adjusting parameters for optimal results, making it highly adaptable for various tasks.

Key features that stand out:

– Multiprocess 8-in-1 Welding Machine: Offers an extensive range of welding functions including Gas MIG, Aluminum MIG, Spool Gun MIG, Lift TIG, and Stick Welding.

– Dual Aluminum Welding Options: Can use a Teflon liner or a spool gun (sold separately) for welding aluminum.

– Effortless Operation: SYN function automatically adjusts welding parameters, and offers 2T, 4T, and Spot welding modes.

– Safety Guarantee: Equipped with multiple protections like over-heating, over-current, and VRD, backed by a 1-year warranty.

– Comprehensive Package: Includes a 110V~220V adapter cord and a Teflon liner for aluminum.

Pros:

– Exceptional versatility with 8 welding functions.

– Flexible aluminum welding methods (Teflon liner included, spool gun compatible).

– Synergic control simplifies operation for all skill levels.

– Strong safety features and warranty.

Cons:

– The TIG torch and spool gun are not included, which might be a dealbreaker for some.

Best for: Users who want maximum flexibility in welding processes and multiple options for efficient aluminum welding, with a focus on ease of use.

Expert Opinion: The 8-in-1 capability and thoughtful dual approach to aluminum welding make this a very powerful and practical machine. The SYN function truly makes complex welding accessible.

VEVOR Pro MIG Welder, 200A Pluse Mig Welding Machine,…

VEVOR’s Pro MIG Welder packs a punch with its 200A output and 5-in-1 functionality, highlighting an innovative Pulse MIG function that excels at delivering clean, low-spatter welds with better thermal control – essential for aluminum. I found its intelligent synergic control tech to be particularly effective, automatically adjusting current and wire feed speed. The HD LCD screen is clear and intuitive, making setup and monitoring straightforward even for complex jobs.

Key features that stand out:

– 5-in-1 MIG Welder with Pulse: Supports MIG Pulse, gasless MIG, gas MIG, MMA, and Lift TIG for versatility.

– Flexible Wire Compatibility: Handles flux core, gas solid, and aluminum wire up to 11 lbs.

– Intelligent Control: Advanced synergic tech automatically adjusts settings; includes 2T/4T modes and dual voltage.

– High Performance: Powerful 200A output, capable of welding up to 15mm thickness.

– HD LCD Screen: Large, clear display with intuitive interface and built-in safety protections.

Pros:

– Powerful 200A output with excellent pulse MIG for aluminum.

– Highly intelligent synergic control for ease of use.

– Robust performance across various materials and thicknesses.

– Clear HD LCD screen enhances usability.

Cons:

– The aluminum welding torch (and Lift TIG torch) needs to be purchased separately.

Best for: Hobbyists and small workshop owners who need robust power and precise pulse MIG control for various materials, including moderately thick aluminum, and appreciate intelligent, user-friendly features.

Expert Opinion: The VEVOR Pro delivers serious welding power with smart features. The pulse function, combined with synergic control, makes it a strong contender for anyone serious about quality aluminum welds, despite the need for a separate aluminum torch.

ARCCAPTAIN 6-in-1 Aluminum MIG Welder, 200A Welding Machine…

The ARCCAPTAIN 6-in-1 offers a robust 200A output and stands out with its dedicated aluminum welder feature via spool gun compatibility. This is crucial for consistent, uninterrupted wire feeding, which is key for high-quality aluminum welds. Both synergic and manual MIG modes provide flexibility, whether you’re a beginner benefiting from auto-settings or a pro fine-tuning your technique. The fully digital MCU ensures precise control and stable welding quality across different materials.

Key features that stand out:

– 6-in-1 Multifunction Welder: Includes Gas MIG/Flux Core MIG/Lift TIG/MMA/Spot/Spool Gun MIG for diverse applications.

– Synergic MIG & Manual MIG: Offers both automatic parameter matching and custom settings for tailored welding.

– Aluminum Welder: Specifically designed for aluminum with spool gun compatibility for smooth, consistent feeding.

– Various Welding Wire: Suitable for mild steel, carbon steel, stainless steel, and aluminum with multiple wire options.

– Digital Welding Machine: Fully digital MCU and high-integrity circuit design for precise control and stable quality.

Pros:

– Strong 200A output suitable for a wide range of projects.

– Excellent aluminum welding capabilities with dedicated spool gun support.

– Dual control modes (synergic/manual) cater to all skill levels.

– High-precision digital control system for stable welds.

Cons:

– TIG torch and spool gun must be purchased separately.

Best for: Welders who prioritize high-quality aluminum welds and appreciate the consistency offered by spool gun compatibility, alongside comprehensive multi-process functionality.

Expert Opinion: ARCCAPTAIN has engineered a welder that truly understands the nuances of aluminum. The digital control and emphasis on spool gun integration make it a top choice for achieving professional-grade aluminum welds.

Helpful Comparison Short Insights

When looking for the best aluminum welding welder, several features stand out. For consistent, high-quality aluminum welds, a Pulse MIG function is incredibly beneficial, as seen in the LIIJII, 250A Pulsed MIG Welder, VEVOR, and ARCCAPTAIN units, helping to reduce heat input and spatter. If you’re tackling serious aluminum work, spool gun compatibility (offered by the 250A Pulsed MIG Welder, AZZUNO 200A, and ARCCAPTAIN) is almost a necessity for reliable wire feeding, especially with softer aluminum wire.

For beginners, synergic control is a lifesaver. The LIIJII, AZZUNO 155A, 250A Pulsed MIG Welder, AZZUNO 200A, VEVOR, and ARCCAPTAIN all offer this feature, taking the guesswork out of setting parameters. While most welders here are multiprocess and dual voltage, allowing for great versatility, pay attention to what accessories are included. Some, like the LIIJII and AZZUNO 155A, offer a more complete kit to get you started, whereas others like the 250A Pulsed MIG Welder, AZZUNO 200A, VEVOR, and ARCCAPTAIN often require separate purchases for TIG torches or spool guns, which can add significantly to the overall cost. The AZZUNO 155A uniquely touts streamlined aluminum welding without needing a Teflon liner immediately, which is a practical convenience. Lastly, remember that product #3, the Flux Core Aluminum Rods, isn’t a welder but an accessory for small repairs, offering a different approach to joining aluminum.

Final Verdict

Choosing the best aluminum welding welder truly depends on your specific needs, budget, and skill level.

If you’re a beginner or hobbyist looking for an all-around performer that simplifies aluminum welding, the LIIJII Aluminum MIG Welder with Pulse is a fantastic choice. Its integrated pulse and synergic control make aluminum welding much more approachable, and it comes with a decent accessory kit. Similarly, the AZZUNO Aluminum MIG Welder 155Amp is excellent if you want to jump straight into aluminum MIG without fussing with extra liners or spool guns right away.

For the serious hobbyist or professional who needs higher amperage and advanced features for thicker aluminum or more demanding projects, the 250A Aluminum Pulsed MIG Welder or the ARCCAPTAIN 6-in-1 Aluminum MIG Welder are top-tier contenders. Both offer powerful pulse MIG capabilities and, critically, spool gun compatibility for flawless aluminum wire feeding, ensuring top-quality welds. The VEVOR Pro MIG Welder also sits in this category, offering strong performance and intelligent controls.

Lastly, for maximum versatility and dual options for aluminum welding, the AZZUNO 200A MIG Welder Machine shines, providing both Teflon liner and spool gun compatibility across an impressive 8-in-1 platform. And don’t forget those handy 50 Pieces Flux Core Aluminum Rods for quick, low-temp aluminum repairs that don’t require a full machine. Assess your most frequent tasks, your budget for potential accessory upgrades, and your comfort level with different welding technologies to make your best pick!

Best Aluminum Welding Welder: Your Questions Answered

Q1: Why is welding aluminum different from steel?

A1: Welding aluminum is distinct because aluminum has a lower melting point, higher thermal conductivity (meaning heat dissipates quickly), and forms an oxide layer that must be dealt with. It’s also softer, requiring specialized wire feeding mechanisms like spool guns or Teflon liners to prevent tangling. These characteristics make it more prone to burn-through and distortion if not welded properly.

Q2: Do I need a spool gun for aluminum welding?

A2: While some modern MIG welders can feed aluminum wire through a standard torch with a Teflon liner (as seen with the AZZUNO 155Amp and 200A models), a spool gun is highly recommended for optimal results, especially with softer aluminum wires or longer feed distances. It minimizes the wire feed path, ensuring smooth, consistent feeding and reducing issues like bird-nesting, which is crucial for achieving high-quality aluminum MIG welds.

Q3: What is Pulse MIG welding and how does it help with aluminum?

A3: Pulse MIG welding rapidly switches between a high peak current and a lower background current. This pulsing action allows for controlled heat input, penetrating the weld puddle without overheating the base material. For aluminum, this means reduced distortion, less spatter, and better control over the weld bead, leading to cleaner and stronger welds. Many of the reviewed aluminum welding welders like the LIIJII, 250A Pulsed MIG Welder, and VEVOR, include this vital feature.

Q4: Can I use flux core wire to weld aluminum?

A4: Generally, flux core wire is not recommended for welding aluminum. It’s primarily designed for steel and tends to create too much slag and an inferior weld on aluminum. For effective aluminum welding, you typically need 100% Argon shielding gas with solid aluminum MIG wire, or specialized aluminum flux-cored rods for specific repair scenarios (like product #3).

Q5: What does “synergic control” mean on a welder?

A5: Synergic control (or SYN mode) on a MIG welder simplifies the setup process by automatically adjusting the wire feed speed and other parameters based on the voltage and amperage you select, or sometimes even just the material and wire diameter. This feature is particularly helpful for beginners or when switching between materials, as it takes the guesswork out of finding the optimal settings, making it easier to achieve a good aluminum weld.

Q6: What type of shielding gas is best for MIG welding aluminum?

A6: For MIG welding aluminum, 100% Argon shielding gas is almost always recommended. Argon provides a stable arc, good penetration, and a clean weld without introducing impurities that can weaken aluminum. Avoid using Argon/CO2 mixes, as CO2 will contaminate aluminum welds.

Q7: What are some important safety tips for aluminum welding?

A7: Welding aluminum requires similar precautions to other welding processes, but with specific considerations. Always wear appropriate Personal Protective Equipment (PPE), including a welding helmet with adequate shade, flame-resistant clothing, welding gloves, and safety glasses. Ensure good ventilation to disperse fumes. Be aware that the bright arc of aluminum welding can emit significant UV radiation, so protect your skin and eyes. Also, ensure your workspace is free from flammable materials.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.