When I first started dabbling in sheet metal projects, I quickly realized that finding the best cheap welder for sheet metal wasn’t just about the machine itself. It’s also about having the right accessories and materials to make that budget setup truly effective. This comprehensive guide will walk you through essential tools and even a handy portable spot welder that are vital for achieving clean, strong welds on thin materials without emptying your wallet. Let’s dive into some practical options and insights to help you get the job done right.

Contents

- Product Reviews

- Wire/Metal Sheet Thickness Gauge 229895 Welding Gage Plated…

- Tzwhwcx Metal Gauge Thickness Tool, 3PCS Stainless Steel…

- YESWELDER Round Dual Sided Metal Sheet Gage & Metal Sheet…

- Debaishi Wire/Metal Sheet Thickness Gauge Stainless Steel…

- DGOL Stainless Steel Mini Portable Metal Sheet Thickness…

- Spot Welder, Handheld Spot Welder LCD 99 Gear Adjustable,…

- Weewooday 3 Pcs Wire/Metal Sheet Thickness Gauge Metal Tool…

- Mardatt 5Pcs Welding Coupons, 11 Gauge 2″ x 6″ Steel…

- 12 Pack 3×3 18 Gauge Sheet Cold Rolled Metal Welding…

- Alffun 2 Pcs 16 Gauge Sheet Metal, 12″ x 8″…

- Helpful Comparison Insights

- Final Verdict

- Best Cheap Welder For Sheet Metal: FAQ Section

- Q1: What kind of welder is generally best for sheet metal, especially if I’m on a budget?

- Q2: Why are metal thickness gauges so important for welding sheet metal with a cheap welder?

- Q3: Can I use a flux-core welder for sheet metal, and is it considered a cheap option?

- Q4: What’s the best way to practice welding sheet metal with a budget welder?

- Q5: Is the handheld spot welder reviewed suitable for automotive body repair on thin sheet metal?

- Q6: What accessories should I prioritize when buying a cheap welder for sheet metal projects?

- Q7: How important is gas for welding thin sheet metal with a MIG welder?

Product Reviews

Wire/Metal Sheet Thickness Gauge 229895 Welding Gage Plated…

This thickness gauge quickly became a staple in my toolbox for sheet metal work. Its clear, laser-engraved scales mean no more guessing the material thickness, which is crucial when you’re trying to set your cheap welder just right to avoid burn-through on thin sheet metal. The built-in ruler is a nice bonus for quick measurements.

Key features that stand out:

– Updated Miller 229895 Design: Improved clarity and readability.

– Durable Stainless Steel: Resists rust for long-term use.

– Laser Engraving: Scales won’t wear off easily.

– Keychain Design: Easy to carry and hard to lose.

– Integrated Ruler: Adds versatility for quick measurements.

Pros:

– Very accurate for identifying metal thickness.

– Scales are clear and won’t fade.

– Compact and easy to carry on a keychain.

Cons:

– Limited to specific gauge measurements, not a universal ruler.

Best for: Beginners and experienced welders needing precise sheet metal thickness identification before welding.

Expert Opinion: This gauge is an absolute must-have for anyone working with thin gauge metals. Properly identifying your material thickness is the first step to setting your welding machine accurately, preventing common issues like burn-through or weak welds, especially when using an affordable welding setup.

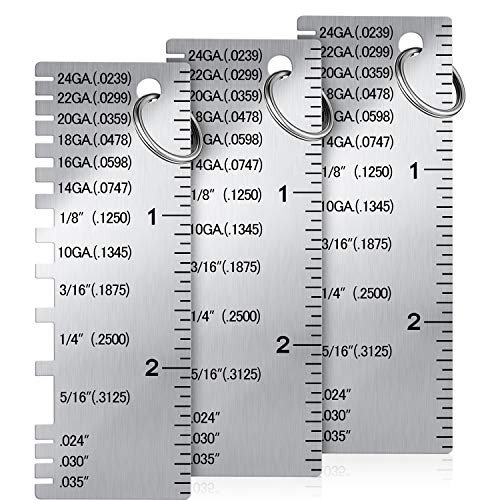

Tzwhwcx Metal Gauge Thickness Tool, 3PCS Stainless Steel…

Having a pack of these metal thickness gauges is incredibly useful, especially if you have multiple workstations or tend to misplace small tools like I do. Made from spring steel, they feel robust and provide consistent, accurate measurements. They’re perfect for quick checks on various sheet metal fabrication projects.

Key features that stand out:

– Precision Measurement: Made from spring steel with a fine brushed finish for accuracy.

– Portable Design: Compact size with a keyring, ideal for on-site use.

– 3-Pack Set: Great value, ensuring you always have one handy.

– Multi-Functional: Suitable for welding inspection, metalworking, and DIY repairs.

– Durable & Rust-Resistant: Spring steel with anti-oxidation coating for longevity.

Pros:

– Excellent precision for welding inspection.

– Very portable and comes in a convenient 3-pack.

– Durable construction, built to last.

Cons:

– Scales might be slightly smaller than single, larger gauges.

Best for: Teams or individuals who need multiple reliable metal thickness gauges for various projects or to keep in different toolboxes.

Expert Opinion: These multi-packs are fantastic for professional settings or for hobbyists who frequently move their workspace. Consistent thickness verification is non-negotiable for quality sheet metal welding, and these gauges deliver that reliability on a budget.

YESWELDER Round Dual Sided Metal Sheet Gage & Metal Sheet…

YESWELDER provides a versatile combo with both a round wire gauge and a traditional sheet metal thickness gauge, all neatly packaged in leather. This set is fantastic for welders who encounter a variety of material types, from metal sheets to wires, ensuring you always have the right gauge for the job.

Key features that stand out:

– High-Quality Stainless Steel: Anti-rust and corrosion-resistant for long-term durability.

– Dual-Sided Round Wire Gauge: Measures wire, plate iron, steel, leather, and more.

– Easy to Use: Simple press-and-match contouring for quick measurements.

– Wide Application: Suitable for diverse materials beyond just sheet metal.

– Leather Packaging: Provides protection and enhances portability.

Pros:

– Offers two essential gauges in one package.

– High-quality, durable stainless steel construction.

– Handy for measuring various material types and wire diameters.

Cons:

– The round gauge can be a bit bulkier in a pocket.

Best for: Welders who work with a diverse range of materials, including both sheet metal and wires, and appreciate a bundled, protective solution.

Expert Opinion: This combo pack is a smart buy for versatile fabricators. Accurately gauging both wire and sheet metal is fundamental to selecting the correct consumables and settings for your affordable welder, ensuring clean welds on thin sheet metal.

Debaishi Wire/Metal Sheet Thickness Gauge Stainless Steel…

Much like the first product, this Debaishi gauge stands out for its clarity and robust construction. I appreciate that it’s an updated version of the classic Miller 229895, making the scales even easier to read—a huge plus when you’re quickly checking sheet metal thickness on a project. The ruler on the back is genuinely helpful.

Key features that stand out:

– Metal Thickness Gauge Function: Helps check metal sheet thickness or wire diameter.

– Updated 229895 Design: Clearer, easier-to-read laser-engraved scales.

– Premium Stainless Steel: Rust-resistant and durable.

– Keychain Design: Convenient for carrying and preventing loss.

– Laser Engraving: Scales won’t wear off, ensuring long-term readability.

Pros:

– Exceptional clarity with laser-engraved scales.

– Durable stainless steel build for longevity.

– Practical ruler on the backside.

Cons:

– Essentially a single-purpose tool, though it does its job well.

Best for: Welders who prioritize highly legible and durable thickness gauges for consistent accuracy in sheet metal welding.

Expert Opinion: Readability is key, especially when you’re under the hood or in varying light conditions. This gauge’s laser-engraved scales make it incredibly user-friendly for quickly determining sheet metal thickness, which directly impacts your welding machine settings and bead quality.

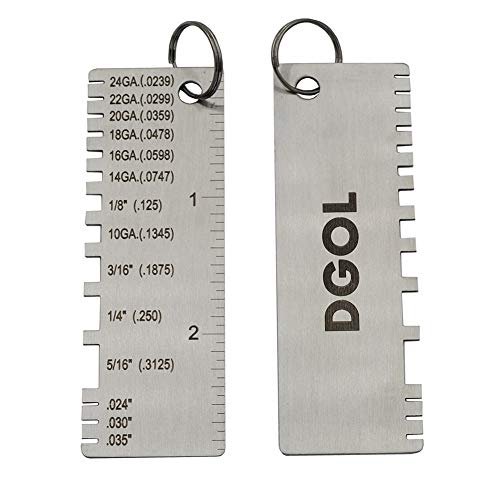

DGOL Stainless Steel Mini Portable Metal Sheet Thickness…

This DGOL mini gauge is my go-to for quick, on-the-spot measurements. Its compact size means it easily slips into a pocket, making it super convenient. Don’t let its small size fool you; the stainless steel construction and clear markings make it a reliable tool for gauging non-ferrous metals and uncoated steel sheets.

Key features that stand out:

– Stainless Steel Material: Ensures durability and rust resistance.

– Clear & Easy-to-Read: Numbers and letters are distinct and bright.

– Mini Portable Size: Extremely compact (2.88″ x 1″) for easy carrying.

– Quick & Accurate Measuring: Provides fast and reliable thickness readings.

– Versatile Gauging: Suitable for non-ferrous wire, copper, brass, and uncoated sheets.

Pros:

– Exceptionally portable and lightweight.

– Clear, shining numbers and letters.

– Quick and accurate for small tasks.

Cons:

– Its small size might not be ideal for larger hands.

Best for: Welders who need an ultra-portable, reliable metal thickness gauge for quick checks on thin sheet metal and other materials.

Expert Opinion: Sometimes the smallest tools make the biggest difference. This mini gauge is ideal for those who need a constant companion for thickness checks, ensuring they’re always prepared to set their cheap welder correctly for the specific sheet metal gauge at hand.

Spot Welder, Handheld Spot Welder LCD 99 Gear Adjustable,…

[This is the only actual welder in the list.]

Now, for an actual welding machine! This handheld spot welder is a game-changer for specific sheet metal fabrication tasks, especially when working with thin materials or battery packs. I was impressed by its portability and the 99 adjustable gears, allowing for precise control on delicate jobs. It’s truly a cheap welder option for specific applications.

Key features that stand out:

– Portable & Cordless Design: Lightweight and handheld, perfect for outdoor or mobile use.

– Powerful Double Pulse: 99 adjustable gears, welding thickness up to 0.25mm.

– LCD Display: Color display shows temperature, mode, preheat, trigger time, and power.

– Manual/Automatic Modes: Offers flexibility for different welding scenarios.

– Multi-function: Ideal for battery assembly, cell phone repair, and small DIY welding.

Pros:

– Highly portable and cordless.

– Excellent for very thin materials and battery tab welding.

– Precise control with 99 adjustable gears.

– Clear LCD display provides crucial information.

Cons:

– Limited to spot welding, not suitable for continuous seams.

Best for: Hobbyists, electronics repairers, and small-scale sheet metal projects requiring precise, localized welds on very thin materials or battery assemblies.

Expert Opinion: While not a traditional arc welder, this portable spot welder excels in its niche, particularly for joining thin metal tabs or specific sheet metal repairs where speed and minimal heat distortion are paramount. It’s a surprisingly capable cheap welder for certain thin gauge metal applications.

Weewooday 3 Pcs Wire/Metal Sheet Thickness Gauge Metal Tool…

Another excellent multi-pack of metal thickness gauges, these stainless steel tools are a lifesaver for anyone regularly tackling sheet metal welding. Having three means you can keep one at your workbench, one in your mobile kit, and one for a friend. They’re quick, easy to use, and more accurate than a tape measure for gauging thin materials.

Key features that stand out:

– Portable: Quicker and easier than a tape measure for metal thickness.

– Quality Stainless Steel: Anti-rust and corrosion-resistant for long service life.

– 3-Piece Package: Offers great value and convenience.

– Practical Handy Tool: Helps determine material thickness before welding or processing.

– Must-Have Accessory: Useful for checking metal sheet wire size quickly and accurately.

Pros:

– Great value with a 3-pack.

– Durable stainless steel construction.

– Essential for accurate pre-welding measurements.

Cons:

– Design is basic, lacking extra features like an integrated ruler.

Best for: Workshops or individuals who need multiple, reliable, and straightforward sheet metal thickness gauges for everyday use.

Expert Opinion: Stocking up on these gauges is a smart move. They eliminate guesswork, which is vital when optimizing settings on any cheap welder to prevent material damage on thin sheet metal. Consistency in measurement leads directly to consistency in weld quality.

Mardatt 5Pcs Welding Coupons, 11 Gauge 2″ x 6″ Steel…

You can’t get good at welding sheet metal without practice, and these welding coupons are perfect for that! Made from 11 gauge hot-rolled mild steel, they provide a realistic practice surface. They’re well-cut with smooth edges, making them safe and ready for you to hone your skills with your cheap welder.

Key features that stand out:

– 5-Piece Set: Sufficient quantity for extensive practice.

– Premium Hot Rolled Mild Steel: High hardness, wear-resistant, and suitable for welding.

– High Performance: Excellent welding and electroplating characteristics.

– Perfect for Novice Practice: Ideal for beginners to improve welding skills.

– Wide Application: Useful for various metal fabrication and DIY projects.

Pros:

– Great for practicing bead control and settings.

– High-quality, laser-cut mild steel.

– Sufficient quantity for multiple practice sessions.

Cons:

– Only one specific gauge (11 gauge) which might be thicker than some ultra-thin sheet metal.

Best for: Beginners learning sheet metal welding and experienced welders practicing new techniques or settings with their budget welder.

Expert Opinion: Practice coupons like these are indispensable. Before tackling a critical project with your cheap welder for sheet metal, always run some test beads on identical material. These provide a perfect starting point for developing muscle memory and fine-tuning your machine settings.

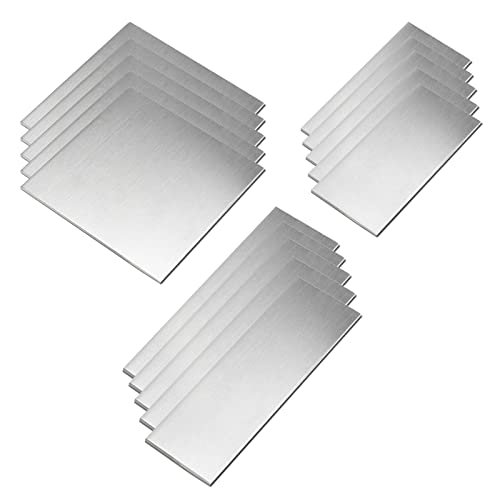

12 Pack 3×3 18 Gauge Sheet Cold Rolled Metal Welding…

This pack of 18 gauge cold-rolled mild steel sheets is excellent for small fabrication projects or for more realistic sheet metal welding practice. The precision laser cut edges ensure consistency, and having multiple pieces allows for various small repairs or custom parts.

Key features that stand out:

– 12-Pack: Ample material for multiple small projects or extensive practice.

– 18 Gauge Cold Rolled Mild Steel: Common thickness for various sheet metal applications.

– Precision Laser Cut: Ensures clean, accurate edges for easy use.

– Versatile: Suitable for any DIY, home, or commercial project.

– Manufactured in America: Quality assurance for materials.

Pros:

– Ideal for small sheet metal projects and practice.

– Consistent 18 gauge thickness.

– Clean, laser-cut edges.

Cons:

– Size might be too small for larger projects.

Best for: Hobbyists and DIY enthusiasts tackling small sheet metal projects or needing ample material for practicing with a cheap welder.

Expert Opinion: Working with actual sheet metal of varying gauges is crucial for developing proficiency. 18 gauge is a common thickness, making these pieces perfect for practical application and understanding how your cheap welder behaves on typical thin metal.

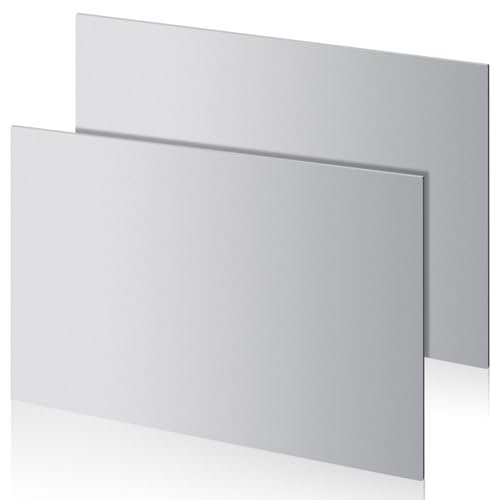

Alffun 2 Pcs 16 Gauge Sheet Metal, 12″ x 8″…

Having these 16 gauge cold-rolled steel plates on hand is fantastic for a variety of sheet metal fabrication needs, from automotive repairs to custom brackets. They strike a good balance between workability and structural integrity, making them suitable for many projects where you need slightly thicker thin metal.

Key features that stand out:

– 2-Piece Package: Provides a decent amount of material for projects.

– 16 Gauge Cold-Rolled Steel: Good balance of strength, durability, and weldability.

– Easy to Process: Supports cutting, drilling, welding, and bending.

– Flat and Smooth: Burr-free edges and smooth finish for safe handling and easy prep.

– Wide Applications: Versatile for automotive, DIY metalwork, home reinforcement, and industrial maintenance.

Pros:

– Excellent weldability and ductility.

– Flat and smooth, ready for use or painting.

– Versatile for various projects.

Cons:

– Only two pieces, so not ideal for very large or numerous projects.

Best for: Those needing slightly thicker sheet metal for repairs, custom parts, or practice, offering a good balance of strength and ease of processing with a budget welder.

Expert Opinion: 16 gauge is a common and forgiving thickness for many sheet metal welding tasks. These plates are excellent for practicing more robust welds or fabricating parts that require a bit more structural integrity than lighter gauges. They allow you to test the limits of your cheap welder effectively.

Helpful Comparison Insights

When looking for the best cheap welder for sheet metal, remember that the accessories are just as crucial as the machine. Metal thickness gauges are non-negotiable; getting a pack like the Tzwhwcx or Weewooday ensures you always have one handy, while the Debaishi or Wire/Metal Sheet Thickness Gauge offer excellent single-tool precision. The YESWELDER combo is great for those who also deal with wire. Knowing the exact gauge of your sheet metal dictates your welder’s settings, preventing frustration and wasted material.

For actual welding, the Spot Welder stands out as the only true welder reviewed here. It’s ideal for very thin materials and quick, localized joins, but it’s important to recognize its limitations for continuous seams. If your projects involve continuous welds on thin sheet metal, you’d typically look at entry-level MIG or even TIG welders, which are often a higher price point than this spot welder.

Finally, having welding coupons like Mardatt’s and varied sheet metal packs (18 gauge or 16 gauge) is fundamental for practice. Practicing on the same material you’ll use for your project is key to mastering your cheap welder‘s settings and technique. Don’t skip this step!

Final Verdict

Navigating the world of cheap welders for sheet metal can feel daunting, but it’s truly about assembling the right toolkit. While this guide focused heavily on indispensable sheet metal welding accessories and materials, the portable spot welder we reviewed stands out as a unique and affordable welding solution for very specific tasks like battery assembly or joining super thin metal tabs. It’s important to understand that for more traditional, continuous sheet metal welding (like car bodywork or custom fabrication), a budget-friendly MIG or TIG machine would typically be the go-to choice, though these often represent a slightly larger initial investment than a spot welder.

Ultimately, the true “best cheap welder for sheet metal” isn’t just one machine; it’s a combination of an appropriate, affordable welding machine (whether it’s a spot welder, a small MIG, or a TIG unit) combined with essential tools like accurate thickness gauges and plenty of practice metal. By investing wisely in these supporting items, you can maximize the effectiveness of any budget welder and achieve impressive results on your thin metal projects. Your journey into sheet metal fabrication will be much smoother and more successful with these foundations in place.

Best Cheap Welder For Sheet Metal: FAQ Section

Q1: What kind of welder is generally best for sheet metal, especially if I’m on a budget?

A1: For general sheet metal welding, particularly for continuous seams, a MIG welder (GMAW) is often considered the best choice, even for beginners, due to its ease of use and ability to handle thin gauge metals. You can find cheap MIG welders that are very capable for hobbyist and DIY sheet metal projects. For very thin and precise work where aesthetics are paramount, a TIG welder (GTAW) is superior but typically costs more and has a steeper learning curve. The handheld spot welder reviewed here is excellent for specific, localized joins.

Q2: Why are metal thickness gauges so important for welding sheet metal with a cheap welder?

A2: Metal thickness gauges are crucial because the settings on your welding machine (amperage, voltage, wire speed) depend heavily on the material’s thickness. With thin sheet metal, using incorrect settings can easily lead to burn-through, warping, or weak welds. An affordable welder might have less fine-tuned control, making accurate measurement with a gauge even more critical to dial in the correct settings and achieve strong, clean welds.

Q3: Can I use a flux-core welder for sheet metal, and is it considered a cheap option?

A3: Yes, flux-core welders are generally among the cheapest welding machine options. While they can be used for sheet metal, they produce more spatter and a rougher finish than MIG welders with gas, and the heat input can be harder to control on very thin gauge metals. For hobbyists and non-critical applications, a small flux-core welder might be an affordable welding solution, but for cleaner, more precise sheet metal fabrication, a gas MIG is preferred.

Q4: What’s the best way to practice welding sheet metal with a budget welder?

A4: The best way to practice sheet metal welding is by using welding coupons or scrap pieces of sheet metal that are the same gauge as your project material. Start with your cheap welder on its lowest settings and gradually increase until you get good penetration without burn-through. Focus on consistent travel speed and proper torch angle. Practicing lap joints, butt joints, and corner joints will build your skills.

Q5: Is the handheld spot welder reviewed suitable for automotive body repair on thin sheet metal?

A5: The handheld spot welder reviewed is excellent for very specific, small-scale automotive repairs or joining thin tabs. However, for larger areas of body repair or structural components, traditional spot welders found in auto body shops or a MIG welder are generally more appropriate for creating stronger, continuous welds. Its portability makes it great for small, targeted thin metal repairs, but it’s not a full-scale bodywork solution.

Q6: What accessories should I prioritize when buying a cheap welder for sheet metal projects?

A6: Beyond the cheap welder itself, prioritize metal thickness gauges for accurate measurement, good quality welding wire (for MIG/flux-core), proper safety gear (helmet, gloves, jacket), and plenty of practice metal (welding coupons or scrap sheets). A good set of clamps and a metal cutting tool are also invaluable for sheet metal fabrication.

Q7: How important is gas for welding thin sheet metal with a MIG welder?

A7: Using shielding gas (typically C25, a mix of Argon and CO2) is highly important for welding thin sheet metal with a MIG welder. Gas provides a cleaner weld, less spatter, and better control over the weld puddle, which is crucial for preventing burn-through and achieving strong, aesthetically pleasing welds on thin gauge metals. While flux-core doesn’t require gas, it’s generally not recommended for the best results on sheet metal.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.