As someone who’s spent my fair share of time under the hood, I know that mastering stick welding techniques (also known as SMAW) can feel like a daunting task, especially when you’re just starting out. It’s a skill that combines art and science, requiring precision, practice, and the right resources. This guide dives into some of the top picks available today, from comprehensive instructional books to essential welding rods, helping you refine your arc welding abilities and achieve cleaner, stronger welds.

Contents

- Stick Welding and the ART of SMAW (Shielded Metal Arc…

- Basic Welding for Farm and Ranch: Essential Tools and…

- Stick Welding : SMAW Complete Guide for Beginners

- Welding Know-how: Tips & Techniques of Master Welders

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

- Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

- YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

- Comparison Insights

- Final Verdict

- Best Stick Welding Techniques: FAQ Section

- Q1: What makes E7018 welding rods so popular for stick welding techniques?

- Q2: How important is proper rod storage for low hydrogen electrodes like E7018?

- Q3: Can beginner welders effectively use E7018 rods for learning stick welding techniques?

- Q4: What are the benefits of using “low temperature universal welding rods” compared to traditional stick welding electrodes?

- Q5: How do books on stick welding techniques improve practical skills?

- Q6: What should I look for in an introductory book on SMAW for beginners?

- Q7: Are there specific stick welding techniques for repairing different types of steel, like low carbon vs. high carbon?

Stick Welding and the ART of SMAW (Shielded Metal Arc…

This book really dives deep into the nuances of Shielded Metal Arc Welding (SMAW), presenting it as both a craft and a technical skill. It’s written in a way that helps you understand the “why” behind different stick welding techniques, not just the “how.” You’ll find it incredibly useful for understanding electrode types, arc control, and proper joint preparation.

Key features that stand out:

– In-depth coverage of SMAW principles

– Focus on the artistic aspect of welding

– Detailed explanations of arc manipulation and puddle control

Pros:

– Excellent for understanding theoretical concepts

– Helps develop a deeper appreciation for the craft

– Good for intermediate welders looking to refine their skills

Cons:

– Might be a bit advanced for absolute beginners without some prior exposure.

Best for: Welders looking to elevate their understanding beyond basic operation to truly master the art of stick welding.

Expert Opinion: This resource is fantastic for developing a strong theoretical foundation, which is crucial for troubleshooting and adapting to different welding scenarios.

Basic Welding for Farm and Ranch: Essential Tools and…

If you’re out on the farm or ranch, you know practical, durable repairs are key. This book is tailor-made for those situations, focusing on real-world stick welding techniques for agricultural environments. It cuts through the jargon and gets straight to what you need to know to fix equipment quickly and effectively, emphasizing common welding tools and materials.

Key features that stand out:

– Practical, hands-on approach for farm and ranch repairs

– Focus on essential tools and equipment

– Covers common welding challenges in agricultural settings

Pros:

– Extremely practical for specific use cases

– Simple, easy-to-follow instructions

– Helps identify and use basic, essential welding gear

Cons:

– Less theoretical depth compared to other comprehensive guides.

Best for: Farmers, ranchers, and anyone needing practical, immediate welding solutions for heavy equipment and outdoor repairs.

Expert Opinion: A solid pick for practical application; it prioritizes getting the job done safely and effectively in specific, demanding environments.

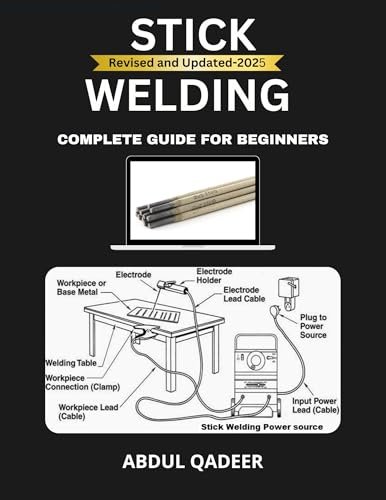

Stick Welding : SMAW Complete Guide for Beginners

This guide is exactly what it sounds like – a comprehensive starting point for anyone new to stick welding. It breaks down complex SMAW techniques into manageable steps, making it less intimidating for newcomers. From setting up your machine to striking your first arc, it walks you through everything you need to know to get started with confidence.

Key features that stand out:

– Comprehensive guide specifically for beginners

– Step-by-step instructions for initial setup and welding

– Covers fundamental SMAW concepts in an easy-to-understand way

Pros:

– Ideal for absolute beginners

– Builds confidence with foundational knowledge

– Easy to read and follow

Cons:

– May not offer advanced insights for experienced welders.

Best for: Newcomers to stick welding who need a clear, structured path to learning the basics.

Expert Opinion: A must-have for anyone just dipping their toes into stick welding; it lays a solid foundation for future learning.

Welding Know-how: Tips & Techniques of Master Welders

This book is a goldmine for anyone wanting to learn from the pros. It doesn’t just cover basic stick welding techniques; it dives into advanced welding tips and tricks used by experienced welders. The inclusion of 600 clear & detailed line drawings is a huge plus, making complex procedures much easier to visualize and understand.

Key features that stand out:

– 600 clear & detailed line drawings for visual learning

– Step-by-step instructions for dozens of projects

– Includes silver & bronze brazing techniques

– Covers bending & straightening methods

– Well-indexed for easy reference

Pros:

– Highly visual, great for understanding complex steps

– Expands knowledge beyond basic welding to other fabrication techniques

– Offers practical project ideas

Cons:

– The broad scope might be overwhelming for a complete beginner focused solely on stick.

Best for: Welders of all levels looking to broaden their fabrication skills and learn advanced techniques from seasoned professionals.

Expert Opinion: The visual aids in this book are unparalleled, making it an excellent reference for anyone looking to master various fabrication processes, not just welding.

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

When it comes to essential stick welding techniques, having the right electrode is paramount. These ARCCAPTAIN E7018 welding rods are a professional’s choice for a reason. Their low hydrogen content helps prevent cracking, making them ideal for critical structural welds where high quality is a must. I’ve found them to deliver a smooth and stable arc with minimal spatter, which is always a bonus.

Key features that stand out:

– E7018 Welding Rod: 3/32” diameter, 5 lb pack.

– Low hydrogen content: Delivers high-quality, X-ray welds.

– Outstanding X-ray values and high tensile strength: Good resistance to cracking.

– Smooth and stable arc with less spatter: High melting efficiency.

– Widely used: Ideal for various carbon steels and structural components.

Pros:

– Produces very high-quality, strong welds

– Excellent for critical applications and structural work

– Performs well in various positions with AC or DC reverse polarity

Cons:

– Requires proper storage to maintain low hydrogen properties.

Best for: Professional welders and those undertaking critical structural repairs where weld quality and strength are paramount.

Expert Opinion: E7018 rods are a workhorse in the industry for their reliability and strength. These are a solid choice for demanding applications.

Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

These Tandefio low temperature universal welding rods offer a unique approach to repairs, especially for thinner materials. The convenience of being able to use an ordinary lighter to light them up for some applications is genuinely impressive. They’re designed for speed and have a low melting point, making them versatile for repairs on a wide range of metallic and non-metallic materials like aluminum and PVC pipes.

Key features that stand out:

– 24 low temperature universal welding rods in a package.

– Ideal size for versatility: 3.07 inches/ 78 mm for easy handling.

– Quality material: Fabricated with tin powder and aluminum powder, with integrated solvent and flux.

– Low temperature welding capability: Can be lit with an ordinary lighter (for specific applications).

– Wide range of applications: Suitable for stainless steel, iron, copper, aluminum, and PVC pipes.

Pros:

– Extremely versatile for multi-material repairs

– Low melting point and quick welding speed

– Convenient for small, localized repairs without needing a full welding setup

Cons:

– Material is relatively brittle and might break during transit, though still usable.

Best for: DIY enthusiasts and those needing quick, versatile repairs on various materials, especially aluminum, without a traditional welding machine.

Expert Opinion: These rods are more akin to brazing or soldering for lighter repairs, offering incredible convenience for quick fixes where traditional stick welding might be overkill or impractical.

YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

Another excellent choice for robust stick welding techniques is the YESWELDER E7018 welding rod. Similar to the ARCCAPTAIN, these are low hydrogen iron powder electrodes, known for producing high-quality, X-ray welds. I’ve found them to have a steady arc, low spatter, and excellent re-striking ability, making them user-friendly even for less experienced hands tackling critical joints. They’re great for structural work and offshore rigs.

Key features that stand out:

– E7018 low-hydrogen iron powder electrode: Produces high quality x-ray welds.

– All position welding: Usable on AC or DC reverse polarity.

– Steady arc, low spatter, excellent re-striking ability: High deposition efficiency.

– Application: Ideal for low, medium, and high carbon steels, offshore rigs, and power plants.

– Specification: 1/8” diameter, 5LB weight. Recommended Amperages: 115A-165A.

Pros:

– Reliable for high-strength, crack-resistant welds

– Good performance in all positions

– User-friendly with excellent re-striking capabilities

Cons:

– Again, proper storage is essential to maintain performance.

Best for: Welders working on critical structural components, marine applications, or power plant equipment who need reliable, high-quality welds.

Expert Opinion: This specific size (1/8”) is very common and versatile for many projects, and YESWELDER is a reputable brand, making these a solid, trustworthy option for serious welders.

Comparison Insights

When looking at these diverse picks for stick welding techniques, we can see a clear split: instructional resources and actual welding materials. The books like “Stick Welding and the ART of SMAW” and “Stick Welding : SMAW Complete Guide for Beginners” offer invaluable theoretical and practical knowledge, essential for anyone wanting to truly understand and improve their SMAW skills. They represent an investment in your personal expertise. “Welding Know-how: Tips & Techniques of Master Welders” stands out with its visual richness and broader scope, useful for expanding into other fabrication areas. Meanwhile, “Basic Welding for Farm and Ranch” targets a very specific, practical need with straightforward advice.

On the materials side, the ARCCAPTAIN E7018 and YESWELDER E7018 rods are champions for high-strength, low-hydrogen welding, crucial for structural integrity and meeting strict code requirements. They offer superior weld quality and crack resistance, making them the go-to for critical applications. In contrast, the Tandefio low temperature rods offer a unique, multi-material repair solution for lighter tasks where traditional stick welding isn’t feasible or necessary. The key takeaway is to match the product to your specific learning goal or welding project – knowledge for skill, and the right rod for the job.

Final Verdict

Navigating the world of stick welding techniques can be challenging, but with the right guidance and materials, you’ll be laying down strong beads in no time. If you’re an absolute beginner, starting with “Stick Welding : SMAW Complete Guide for Beginners” is a smart move to build foundational knowledge. For those looking to master the artistic and technical nuances, “Stick Welding and the ART of SMAW” offers a deeper dive. When it comes to consumables, for critical structural work and robust repairs, you can’t go wrong with either the ARCCAPTAIN E7018 or YESWELDER E7018 rods – they consistently deliver high-quality, dependable welds. For incredibly versatile, quick repairs on a variety of materials, especially aluminum, the Tandefio low temperature rods present a practical, unique solution. Ultimately, combining a solid instructional resource with appropriate, high-quality welding rods will empower you to tackle almost any arc welding challenge with confidence.

Best Stick Welding Techniques: FAQ Section

Q1: What makes E7018 welding rods so popular for stick welding techniques?

A1: E7018 rods are highly valued for their low hydrogen content, which significantly reduces the risk of cracking in welds, especially on high-strength steels. They produce high-quality, X-ray clean welds with excellent tensile strength, making them ideal for critical structural applications and heavy fabrication where weld integrity is paramount.

Q2: How important is proper rod storage for low hydrogen electrodes like E7018?

A2: Proper storage is crucial for maintaining the performance of low hydrogen electrodes. These rods are designed to have minimal moisture absorption, but if exposed to humidity, they can absorb moisture, losing their low hydrogen properties. This can lead to hydrogen-induced cracking in welds. Always store them in a dry, heated environment, often in a rod oven, to ensure optimal performance.

Q3: Can beginner welders effectively use E7018 rods for learning stick welding techniques?

A3: While E7018 rods are excellent for critical applications, some beginners might find them slightly trickier to start and run smoothly compared to more forgiving rods like E6010 or E6011. However, with guidance from a comprehensive SMAW guide and some practice, beginners can certainly learn to use them, especially given their steady arc and low spatter characteristics.

Q4: What are the benefits of using “low temperature universal welding rods” compared to traditional stick welding electrodes?

A4: Low temperature universal welding rods, like the Tandefio ones reviewed, are typically used for brazing-like applications rather than true arc welding. Their main benefits include low melting points, versatility across multiple materials (like aluminum, copper, and even some plastics), and the ability to be used with simpler heat sources like a torch or even a lighter for very small tasks. They are excellent for quick repairs and DIY projects where a full welding setup isn’t practical or necessary.

Q5: How do books on stick welding techniques improve practical skills?

A5: Books provide the foundational knowledge that complements hands-on practice. They teach you about electrode selection, machine setup, proper joint preparation, arc length control, and different welding positions. Understanding the principles behind arc welding helps you diagnose issues, correct mistakes, and adapt your technique to various materials and scenarios, ultimately leading to better practical skills and stronger welds.

Q6: What should I look for in an introductory book on SMAW for beginners?

A6: For an introductory book on SMAW for beginners, look for clear, step-by-step instructions, easily understandable language, and comprehensive coverage of basic safety, equipment setup, and fundamental stick welding techniques. Visual aids, like diagrams and photos, are incredibly helpful. A focus on common mistakes and how to avoid them is also a valuable feature.

Q7: Are there specific stick welding techniques for repairing different types of steel, like low carbon vs. high carbon?

A7: Yes, different stick welding techniques and electrodes are often recommended for varying carbon steel types. For low carbon steels, many general-purpose electrodes work well. For medium to high carbon steels, which are more prone to cracking, low hydrogen electrodes (like E7018) are typically preferred. These steels may also require pre-heating and post-weld heat treatment to prevent cracking, emphasizing the importance of understanding the material you’re working with through resources like welding know-how guides.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.