When I first started TIG welding thin aluminum, I quickly realized it wasn’t like tackling thicker steel. It demands precision, control, and the right equipment to prevent warping and burn-through. After countless hours in the shop, testing different machines and techniques, I’ve seen firsthand how crucial an AC/DC TIG welder with advanced features like pulse and fine-tuned controls is for getting those clean, precise welds on delicate aluminum alloys. This guide is built from that hands-on experience, helping you navigate the options to find the best TIG welder for thin aluminum that truly delivers.

Contents

- Biscuits Welding Practice Aluminum Parts – 5052 Aluminum

- Sunstac 250A AC/DC Aluminum TIG Welder with Pulse

- YESWELDER 200A AC/DC Aluminum Tig Welder with Pulse Large

- YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

- ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse, Aluminum TIG

- AZZUNO AC/DC TIG Welder 200A with Pulse 110V/220V, Aluminum

- TOOLIOM 200A AC/DC TIG Welder with Pulse, Dual Voltage

- Helpful Comparison Short Insights

- Final Verdict

- Best TIG Welder For Thin Aluminum FAQs

- Q1: What makes AC TIG essential for welding thin aluminum?

- Q2: Why is “Pulse TIG” important for thin aluminum?

- Q3: What is “AC Balance” and how does it affect thin aluminum welding?

- Q4: Which filler rod is best for general-purpose thin aluminum TIG welding?

- Q5: How does a “Square Wave” or “Triangular Wave” AC setting help with thin aluminum?

- Q6: What amperage should I look for in a TIG welder for thin aluminum?

- Q7: What are some tips for preventing distortion when TIG welding thin aluminum?

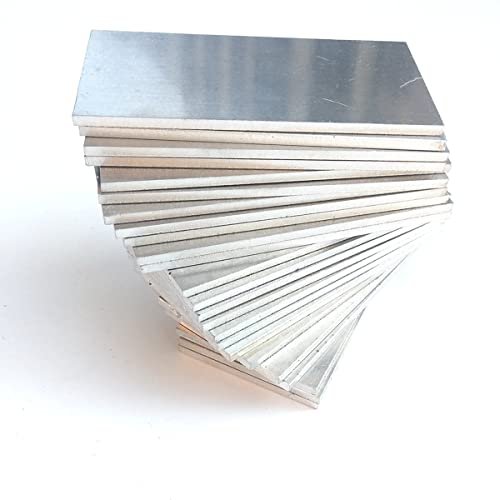

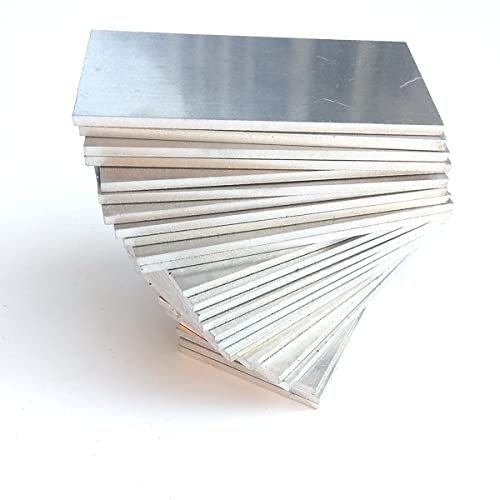

Biscuits Welding Practice Aluminum Parts – 5052 Aluminum

Before you even touch a live arc to your project, you need to hone your skills, especially with thin aluminum. These practice parts are a fantastic resource for any TIG welder, particularly beginners. Made from common 5052 aluminum, they provide a realistic material to practice your bead consistency, heat control, and puddle manipulation, which are all critical for successful thin aluminum TIG welding. Using these regularly can significantly improve your technique and confidence on delicate materials.

Key features that stand out:

– Material: 5052 Aluminum Welding Coupons, a common alloy for practice.

– Size: 2 inches * 4 inches* 0.125 thickness, ideal for simulating thin aluminum projects.

– Quantity: 24 pieces, ample material for extensive practice sessions.

– Versatility: Suitable for beginners to practice and training for MIG, TIG, Stick, Arc, Gas, and Braz, though particularly valuable for TIG.

Pros:

– Excellent for developing precise heat and puddle control.

– Provides a consistent, realistic practice material.

– Ample quantity for extended training.

– Helps build confidence before working on actual projects.

Cons:

– Not a welding machine, but an essential accessory for skill development.

Best for: TIG welding beginners and experienced welders looking to refine their thin aluminum technique.

Expert Opinion: These aluminum practice pieces are invaluable. TIG welding thin aluminum is all about muscle memory and immediate feedback. Having dedicated coupons lets you make mistakes and learn without ruining an actual project, making your investment in a good TIG welder truly pay off.

Sunstac 250A AC/DC Aluminum TIG Welder with Pulse

The Sunstac 250A AC/DC TIG Welder is truly born for aluminum welding, offering a robust feature set that makes working with thin aluminum not just possible, but enjoyable. Its AC TIG mode, combined with high-frequency start and a powerful 250A output, ensures clean, controlled arcs on aluminum and its alloys. The modern LCD screen simplifies parameter adjustments, while pulse and spot TIG functions provide the nuanced control needed to prevent distortion and achieve pristine welds on even the thinnest materials.

Key features that stand out:

– Born for Aluminum Welding: AC TIG mode specifically optimized for aluminum and aluminum alloy.

– AC/DC Professional TIG Welder: Offers High-Frequency AC/DC, Pulsed AC/DC, AC/DC SPOT, and STICK modes.

– LCD Digital Screen: All-new, easy-to-read screen for precise parameter access, even with a helmet on.

– Smart TIG Welding Machine: Minimizes material distortion with Pulse TIG for precise control and Spot TIG for reinforcement.

– Intelligent Parameter Saving Function: Automatically restores previous welding settings.

– Dual Voltage: 110V/220V, providing flexibility for different power sources.

Pros:

– High amperage (250A) handles a wide range of tasks, including thin materials.

– Advanced control with pulse and spot TIG for precise work.

– User-friendly LCD screen and intelligent features enhance efficiency.

– Versatile for welding various metals beyond just aluminum.

Cons:

– Foot pedal remote control is not included.

Best for: Professional welders and advanced hobbyists needing high power and precise control for diverse aluminum projects.

Expert Opinion: This machine is a powerhouse for aluminum. The combination of 250A and precise pulse control means you can tackle thin sections confidently, knowing you have enough heat for quick starts but also the ability to back off to prevent burn-through. The parameter saving is a huge time-saver.

YESWELDER 200A AC/DC Aluminum Tig Welder with Pulse Large

The YESWELDER 200A AC/DC TIG Welder is an excellent choice for anyone needing a capable and user-friendly machine for thin aluminum. Its large LED display makes parameter settings crystal clear, and features like Easy Start with Hot Start streamline the welding process, especially for beginners. Weighing in at a mere 16.47lb, its portability is unmatched, making it ideal for mobile jobs or small workshops. The square wave AC mode is specifically optimized to provide cleaner and more precise aluminum welds, ensuring quality results on thin gauges.

Key features that stand out:

– Large LED Display: Enhanced visibility for clear display of welding parameters and settings.

– Easy to use: Easy Start with Hot Start prevents sticking, Auto Memory saves settings.

– More Powerful: 200 amps for effective welding of most metal thicknesses, with HF non-touch starting for aluminum.

– 6-in-1 Exceptional Versatility: Combines STICK, AC TIG, DC TIG, AC Pulse TIG, DC Pulse TIG, and Spot Welding.

– ACDC Pulsed TIG Welder: Software-controlled Square Wave AC/DC TIG inverter, with AC mode optimized for aluminum.

– Lightweight: Only 7.47kg (16.47lb), highly portable.

Pros:

– Extremely lightweight and portable for on-the-go welding.

– User-friendly interface with auto-memory and easy start features.

– Square wave AC provides excellent control for thin aluminum.

– Versatile with 6 welding modes for different materials.

Cons:

– Max amperage is 200A, which might be limiting for very thick aluminum.

Best for: Hobbyists, small workshops, and welders prioritizing portability and user-friendliness for thin aluminum.

Expert Opinion: For its size and weight, the YESWELDER 200A punches above its class. The auto-memory and large display are excellent for consistency, and the square wave AC is crucial for getting those clean, crisp beads on thin aluminum without excessive heat input.

YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

While not a welder itself, the YESWELDER Aluminum TIG Welding Rod ER4043 is an absolutely essential component for TIG welding thin aluminum. This ER4043 rod, also known as “AlSi5″ due to its 5% silicon content, is one of the most widely used and versatile aluminum filler metals. The silicon additions significantly improve fluidity, making it a preferred choice for TIG welders working on delicate materials where good puddle control and minimal cracking are paramount. It’s compatible with many common aluminum alloys, making it a staple in any TIG welder’s arsenal for thin gauge work.

Key features that stand out:

– ER4043 Composition: 5% silicon for improved fluidity and reduced cracking.

– Shielding Gas: Usually 100% Argon, Helium, or mix, standard for aluminum TIG.

– Excellence: Improved fluidity and less sensitive to weld cracking, producing brighter welds.

– Multiple Usage: Can be used on weld forge and casting materials, suitable where base metal requires thermal treatment.

– Application: Suitable for 3003, 3004, 5052, 6061, 6063, common aluminum alloys used in thin applications.

Pros:

– Excellent fluidity makes it easier to work with on thin materials.

– Reduces sensitivity to weld cracking, promoting stronger joints.

– Versatile for many common aluminum alloys.

– Produces visually appealing, brighter welds.

Cons:

– Not suitable for aluminum alloys that will be anodized after welding.

Best for: General-purpose TIG welding of most common thin aluminum alloys.

Expert Opinion: You can have the best TIG welder, but without the right filler rod, your thin aluminum welds will suffer. ER4043 is a go-to for a reason – its flow characteristics are ideal for precise, low-heat input welding, crucial for avoiding burn-through and distortion on thin stock.

ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse, Aluminum TIG

The ARCCAPTAIN TIG Welder stands out with its POWERFUL 7-IN-1 capability and advanced waveform control, making it a top contender for precise thin aluminum welding. What truly sets it apart is the inclusion of Square and Triangular waveforms in its AC TIG mode. The triangular wave specifically reduces heat input, causing the weld to form rapidly and effectively preventing material distortion on extremely thin metals. Coupled with a large LED display and extensive digital parameter adjustments, this machine offers unparalleled control and performance for delicate aluminum projects.

Key features that stand out:

– POWERFUL 7-IN-1 TIG WELDER AC/DC: Comprehensive modes including AC/DC TIG, Pulse TIG, STICK, SPOT TIG, and unique Square/Triangular Waveforms.

– LARGE LED DISPLAY: Clear visibility of welding parameters for precise control.

– PULSE & SQUARE & TRIANGULAR WAVEFORM: Triangular wave specifically reduces heat input for thin metal, Square wave provides cleaning action.

– DIGITAL WEDLING PARAMETER SET: MCU Digital control system allows easy adjustment of pre-flow, peak current, AC frequency, AC balance, and more.

– Thin Aluminum Welding Capability: Can weld 0.5MM-5MM (1/5“-1.97”) aluminum effectively.

– Lightweight: Only 12 kg (26.5lb), enhancing portability.

Pros:

– Advanced waveform options (Triangular wave) are exceptional for controlling heat on thin aluminum.

– Extensive digital parameter control offers maximum precision.

– Highly versatile with 7 welding methods.

– Good portability and a long 5-year quality service.

Cons:

– Foot pedal remote control is not included in the package.

Best for: Welders who demand the highest level of precision and heat control for very thin and delicate aluminum fabrication.

Expert Opinion: The triangular waveform is a game-changer for super thin aluminum. It reduces the total heat input, allowing the puddle to freeze faster and minimizing warpage. This machine truly shines when you need absolute control over your arc and heat.

AZZUNO AC/DC TIG Welder 200A with Pulse 110V/220V, Aluminum

The AZZUNO AC/DC TIG Welder offers an impressive blend of versatility, precision, and convenience, making it an excellent option for thin aluminum. Its 7-in-1 multifunctional design covers every TIG welding need, from AC Pulse TIG for aluminum to DC Pulse TIG for steel. The advanced MCU Digital control system ensures every critical parameter can be finely tuned, and the seamless parameter persistence (auto-save function) is a huge time-saver. What truly makes this a standout for beginners and those looking for immediate usability is its comprehensive accessory package, including a TIG torch, regulator, electrodes, and more.

Key features that stand out:

– 7-IN-1 MULTIFUNCTIONAL TIG WELDER: AC TIG, AC Pulsed TIG, DC TIG, DC Pulsed TIG, Spot TIG, Stick, and Spot Stick.

– MASTER THE PULSE: PULSE TIG function for greater precision and cleaner aluminum welds.

– PRECISION PARAMETER SETTINGS: Advanced MCU Digital control system for effortless adjustment of crucial parameters.

– SEAMLESS PARAMETER PERSISTENCE: Intelligent automatic save function restores previous welding parameters.

– COMPREHENSIVE PACKAGE INCLUDES: TIG Torch (WP-26), Electrode Holder, Ground Clamp, Brush/hammer, 110V/220V Adapter Cord, Argon Gas Regulator and Hose, Nozzles, Collets, Tungsten Electrodes.

– Lightweight: N.W.: 17LBS, good portability.

Pros:

– Highly versatile with 7 welding functions.

– Exceptional parameter control with auto-save for convenience.

– Comes with a complete set of essential accessories, making it ready to use.

– Excellent for aluminum, stainless steel, and carbon steel.

Cons:

– Foot pedal remote control is sold separately.

Best for: Beginners and experienced welders seeking a feature-rich, versatile TIG welder with a complete accessory package for thin aluminum.

Expert Opinion: The AZZUNO’s real strength lies in its ready-to-weld package and intelligent features. For someone starting with thin aluminum, having the regulator and electrodes included is a huge plus. The auto-save function is invaluable when switching between different projects.

TOOLIOM 200A AC/DC TIG Welder with Pulse, Dual Voltage

The TOOLIOM 200A AC/DC TIG Welder offers a reliable and versatile solution for various welding tasks, particularly shining when it comes to aluminum. With its 6-in-1 welding modes, including AC Pulsed TIG, it provides the flexibility needed for thin materials. The large digital display screen gives clear feedback on parameters, while its software-controlled square wave AC/DC inverter with unique fish-scale waveform feature ensures both high performance and visually appealing welds. This focus on aesthetic weld quality, alongside precise control, makes it a strong contender for those who care about both functionality and finish on their thin aluminum projects.

Key features that stand out:

– 6-in-1 Welding Modes: AC TIG, DC TIG, AC Pulsed TIG, DC Pulsed TIG, Stick, and TIG Spot Welding.

– Foot Pedal Function: Compatible with a foot pedal (not included) for precise current control.

– Large Digital Display Screen: Clear view of key parameters for monitoring and adjustments.

– Aluminum TIG Welder: Capable of welding most metals, including aluminum up to 3/16″ (5mm) @ 220V.

– ACDC PULSED TIG WELDER: Software Controlled Square Wave AC/DC TIG inverter with a unique fish-scale waveform for excellent weld quality and visual appeal.

– Dual Voltage: 110V/220V, offering flexibility for power sources.

Pros:

– Versatile with 6 welding modes for diverse applications.

– Unique fish-scale waveform enhances weld aesthetics.

– Clear digital display for easy monitoring and adjustments.

– Good capability for precision welding of thinner aluminum.

Cons:

– Foot pedal must be purchased separately.

Best for: Welders who prioritize versatility, precise control, and visually appealing welds on thin aluminum.

Expert Opinion: The TOOLIOM is a solid performer for thin aluminum. The pulse features and square wave control are essential, but the added benefit of the ‘fish-scale’ waveform for visual appeal is a nice touch for those fabricating projects where aesthetics matter as much as strength.

Helpful Comparison Short Insights

When looking for the best TIG welder for thin aluminum, specific features really set machines apart. The Sunstac 250A offers the highest amperage, making it suitable for a broader range of aluminum thicknesses, but still excels at thin with its precise controls. For ultimate portability, the YESWELDER 200A stands out due to its incredibly low weight, making it perfect for small shops or mobile work. The ARCCAPTAIN 200Amp takes precision to another level with its triangular waveform, which is a significant advantage for extremely thin aluminum, effectively reducing heat input and distortion.

If you’re a beginner or prefer a comprehensive package, the AZZUNO 200A offers a fantastic deal by including many essential accessories right out of the box, saving you additional purchases. The TOOLIOM 200A focuses on not just strong welds but also beautiful ones with its unique fish-scale waveform, appealing to those who value aesthetics. And remember, no matter which welder you choose, skill practice with items like the Biscuits Welding Practice Aluminum Parts and using the right filler metal like the YESWELDER Aluminum TIG Welding Rod ER4043 are equally crucial for achieving top-tier results on thin aluminum.

Final Verdict

Choosing the best TIG welder for thin aluminum boils down to your specific needs, skill level, and budget.

For the serious hobbyist or professional who needs maximum control and power for diverse thin aluminum projects, the Sunstac 250A AC/DC Aluminum TIG Welder with Pulse is a phenomenal choice, offering high amperage and advanced features.

If portability and user-friendliness are your top priorities, the YESWELDER 200A AC/DC Aluminum Tig Welder with Pulse Large is an unbeatable option, especially with its lightweight design and auto-memory functions.

For those demanding the absolute finest heat control for delicate, super-thin aluminum, the ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse and its unique triangular waveform is the standout performer.

And for beginners looking for an all-inclusive setup to get started right away with excellent control for thin aluminum, the AZZUNO AC/DC TIG Welder 200A with Pulse provides incredible value with its complete accessory package.

Remember to also factor in essential accessories like Biscuits Welding Practice Aluminum Parts for skill development and the YESWELDER Aluminum TIG Welding Rod ER4043 for optimal filler metal. With any of these top contenders, you’ll be well-equipped to lay down those beautiful, strong beads on thin aluminum.

Best TIG Welder For Thin Aluminum FAQs

Q1: What makes AC TIG essential for welding thin aluminum?

A: AC (Alternating Current) TIG is crucial for aluminum because it provides a “cleaning action” that breaks up the aluminum oxide layer on the surface. This oxide melts at a much higher temperature than the base aluminum, so the AC current’s alternating positive and negative cycles effectively scour it away, allowing for a clean, penetrating weld puddle. Without it, you’d struggle to get proper fusion on aluminum.

Q2: Why is “Pulse TIG” important for thin aluminum?

A: Pulse TIG cycling between a high peak current and a lower background current. This feature is a game-changer for thin aluminum as it allows you to control the heat input more precisely. The peak current creates the puddle, and the background current allows it to cool slightly, preventing burn-through and reducing distortion. It helps maintain a stable arc and achieve more consistent, aesthetically pleasing welds on delicate materials.

Q3: What is “AC Balance” and how does it affect thin aluminum welding?

A: AC Balance, often expressed as a percentage, controls the proportion of electrode negative (EN) to electrode positive (EP) in the AC cycle. More EN provides deeper penetration and a narrower bead, while more EP (cleaning action) helps remove the oxide layer but can overheat the tungsten. For thin aluminum, finding the right balance is key to getting adequate cleaning without excessive heat, which could lead to burn-through or warping.

Q4: Which filler rod is best for general-purpose thin aluminum TIG welding?

A: The ER4043 aluminum TIG welding rod (like the YESWELDER one reviewed) is widely considered the best general-purpose option. Its 5% silicon content improves fluidity, reduces weld cracking, and creates bright, clean welds. It’s suitable for a broad range of common aluminum alloys used in thin applications, such as 3003, 3004, 5052, 6061, and 6063.

Q5: How does a “Square Wave” or “Triangular Wave” AC setting help with thin aluminum?

A: These waveform shapes in AC TIG welding offer superior arc control compared to older sine wave machines. A square wave allows for rapid polarity changes, providing a crisp, stable arc and excellent cleaning action for aluminum. A triangular wave, offered by machines like the ARCCAPTAIN, is even more advanced for thin material. It further reduces the heat input, causing the weld puddle to solidify faster, which dramatically minimizes distortion and burn-through on very thin gauges.

Q6: What amperage should I look for in a TIG welder for thin aluminum?

A: While thin aluminum welding often uses lower amperages (e.g., 20-80 amps for 1/16″ or thinner), it’s beneficial to have a machine with a higher maximum output (like 200A or 250A) for versatility. A higher maximum amperage ensures the machine isn’t strained, provides better arc stability at lower settings, and allows you to tackle occasional thicker aluminum projects or other metals. Look for welders that offer fine amperage control throughout their range.

Q7: What are some tips for preventing distortion when TIG welding thin aluminum?

A: Preventing distortion on thin aluminum is crucial. Key tips include:

1. Use Pulse TIG: As mentioned, this minimizes heat input.

2. Proper AC Balance: Optimize cleaning without excessive heat.

3. Fast Travel Speed: Get in and out quickly to limit heat saturation.

4. Tack Welding: Use frequent tacks to hold the pieces in place before running a full bead.

5. Back-purging with Argon: For very critical or thinner welds, this prevents sugaring on the backside.

6. Heat Sinks: Using copper or aluminum backing plates can draw heat away from the weld.

7. Choose the Right Tungsten: A smaller diameter tungsten (e.g., 3/32″ or 1/16″) with a sharpened point for AC can help focus the arc.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.