When I’m in the workshop tackling projects with 1/8-inch steel, choosing the right welding rod can make all the difference between a frustrating mess and a clean, strong weld. I’ve spent countless hours laying beads, and I can tell you firsthand that for 1/8 steel welding, the electrode you pick really impacts arc stability, penetration, and overall weld quality. This guide will walk you through some top contenders, helping you find the ideal stick welding rod for your next project, whether it’s mild steel or a specialized stainless application.

Contents

- YesRight 1/8″ Stick Welding Electrode Rods J422 Carbon

- WeldingCity 1-Lb ER308L Stainless Steel 308 TIG Welding Rod

- Sunstac E7018 Welding Rod 1/8″ 5LB Carbon Steel Stick

- Blue Demon ER316L X 1/8″ X 36″ X 1LB Tube

- YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rod For 1/8 Steel: Your Top Questions Answered

- Q1: What is the best all-around welding rod for 1/8 inch mild steel?

- Q2: Can I use E7018 rods on 1/8 inch thin steel?

- Q3: What amperage settings should I use for 1/8 inch welding rods on 1/8 inch steel?

- Q4: Why is a low-hydrogen welding rod important for 1/8 steel?

- Q5: What’s the difference between a stick welding rod and a TIG welding rod for 1/8 steel?

- Q6: Can I use a 3/32 inch welding rod instead of 1/8 inch for 1/8 inch steel?

YesRight 1/8″ Stick Welding Electrode Rods J422 Carbon

The YesRight J422 rods are a fantastic go-to for general-purpose welding on 1/8-inch carbon steel, especially if you’re working with AC power. I’ve found these electrodes incredibly forgiving, producing a strong arc force that drives deep into the metal, which is exactly what you need for consistent penetration on thinner sections. Their ability to handle less-than-perfect surfaces like dirty or rusty steel is a huge time-saver.

Key features that stand out:

– 1/8″ Carbon Steel Rod for AC Power: Specifically designed for common household welding machines.

– Good Welding Usability: Offers a stable arc, minimal spatter, and easy slag removal, making it user-friendly.

– Efficient and Reliable: Excellent for all-position welding and fast freezing, even on dirty or painted materials.

– Multipurpose Welding Rod: Ideal for construction, fabrication, automotive, and general repair tasks.

Pros:

– Very forgiving on less-than-clean surfaces.

– Provides deep penetration crucial for 1/8″ steel.

– Excellent arc stability and easy re-strike.

– Versatile for various applications and welding positions.

Cons:

– May not offer the highest tensile strength compared to low-hydrogen rods.

Best for: General fabrication, repair work on mild steel, and beginners using AC stick welders on dirty or rusty material.

Expert Opinion: “The YesRight J422 is a solid choice for workshops where cleanliness isn’t always pristine. Its robust arc and deep penetration characteristics make it very effective for joining 1/8″ mild steel with ease, particularly for those relying on AC machines.”

WeldingCity 1-Lb ER308L Stainless Steel 308 TIG Welding Rod

Now, if your 1/8-inch material is stainless steel and you’re planning on TIG welding, the WeldingCity ER308L rods are definitely worth considering. These aren’t stick welding electrodes, but premium TIG filler rods designed for specific stainless steel grades. I’ve used ER308L for stainless exhaust work and know how crucial it is for maintaining corrosion resistance. The “L” indicates low carbon, which is key to preventing carbide precipitation and maintaining the integrity of your stainless weld.

Key features that stand out:

– Premium Quality ER308L Stainless Steel: Specifically formulated for TIG welding stainless steels.

– Low Carbon Content (0.02% C): Reduces the possibility of intergranular carbide precipitation, crucial for corrosion resistance.

– Versatile Stainless Steel Applications: Perfect for joining 304, 304L, 308, 308L, 321, and 347 stainless.

– Cryogenic Temperature Applications: Suitable for use in environments with very low temperatures.

Pros:

– Excellent for maintaining corrosion resistance in stainless steel welds.

– Ideal for a wide range of common stainless steel alloys.

– High quality and reliable for TIG applications.

– Available in various package sizes for convenience.

Cons:

– Requires a TIG welder and shielding gas, not for stick welding.

Best for: TIG welding 1/8-inch stainless steel projects where corrosion resistance and specific alloy compatibility are critical.

Expert Opinion: “For anyone TIG welding 1/8-inch stainless, the ER308L is a standard for a reason. Its low carbon content is vital for preventing weld decay, making it suitable for applications ranging from food-grade equipment to marine components. Just remember, this is a TIG filler, not a stick rod.”

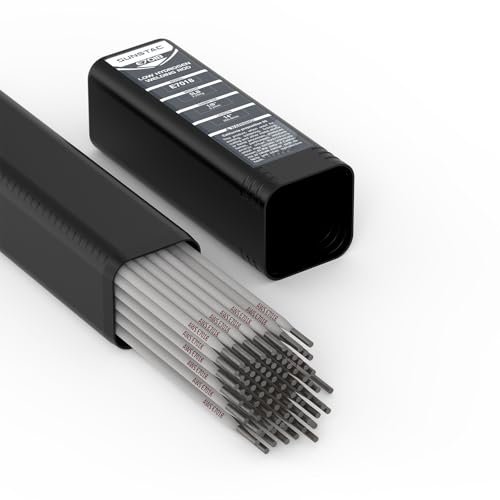

Sunstac E7018 Welding Rod 1/8″ 5LB Carbon Steel Stick

When I need serious strength and integrity in my 1/8-inch steel welds, I reach for an E7018. The Sunstac E7018 rod is a prime example of a low-hydrogen electrode that delivers exceptional weld quality. Its special coating and added rare earth elements like Yttrium Oxide mean less porosity and a super stable arc, even when I’m tackling complex joints or welding in tight, all-position scenarios. This is the rod for projects where failure isn’t an option.

Key features that stand out:

– E7018 Low-Hydrogen Coating: Contains minerals, ferroalloys, and arc stabilizers for enhanced weld performance and protection.

– Rare Earth Element Additives: Yttrium Oxide reduces porosity, while LiF and MgO stabilize the arc and reduce spatter.

– All-Position Welding: Capable of welding in horizontal, vertical, and overhead positions, even in complex structures.

– Heavy-Duty Welding Applications: Suited for high-strength scenarios like bridges, ships, pressure vessels, and structural steel.

Pros:

– Produces very strong, ductile welds with excellent impact toughness.

– Low-hydrogen coating significantly reduces cracking risk.

– Excellent arc stability and reduced spatter due to additives.

– Highly versatile for all welding positions and heavy-duty applications.

Cons:

– Requires proper storage (dry) to maintain low-hydrogen properties.

Best for: Structural welding, heavy equipment repair, pressure vessels, and any high-strength application on 1/8-inch low-carbon or low-alloy steel where weld integrity is paramount.

Expert Opinion: “The Sunstac E7018 is a workhorse for professional welders. Its low-hydrogen properties are non-negotiable for critical applications on 1/8″ steel where crack resistance and high strength are required. The rare earth additives are a welcome bonus, making for a smoother, cleaner weld bead.”

Blue Demon ER316L X 1/8″ X 36″ X 1LB Tube

Here’s another specialized option for stainless steel, specifically the Blue Demon ER316L TIG rod. Similar to the ER308L, this is a TIG filler metal, not a stick electrode. I’ve used 316L when working with applications requiring superior corrosion resistance, especially against pitting in chloride environments. It’s the go-to for welding molybdenum-bearing austenitic alloys like 316 or 316L stainless steel, common in marine or chemical processing industries.

Key features that stand out:

– Low Carbon ER316L Alloy: Designed for welding low carbon molybdenum bearing austenitic alloys.

– AWS A5.9 Specification: Meets industry standards for TIG welding filler metals.

– DCEN Welding Current: Primarily used with DC electrode negative current for TIG applications.

– Enhanced Corrosion Resistance: Ideal for environments where resistance to pitting and crevice corrosion is critical.

Pros:

– Excellent for welding 316L stainless steel for improved corrosion resistance.

– Low carbon content prevents sensitization and intergranular corrosion.

– High-quality filler metal from a reputable brand.

– Suitable for specific industrial applications requiring 316L properties.

Cons:

– Limited to TIG welding and specific stainless steel alloys.

Best for: TIG welding 1/8-inch 316L or similar molybdenum-bearing stainless steels in marine, chemical, or pharmaceutical environments where superior corrosion resistance is a must.

Expert Opinion: “For specialized stainless steel TIG welding on 1/8″ material, particularly 316L, the Blue Demon ER316L is an essential choice. Its inherent resistance to chloride corrosion makes it invaluable for specific industrial uses, ensuring weld integrity in challenging environments. Again, this is a TIG filler, requiring a TIG setup.”

YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon

Rounding out our stick welding options for 1/8-inch steel is another excellent E7018 from YESWELDER. This rod is known for producing high-quality, X-ray-grade welds, which means it’s super reliable. From my experience, the steady arc and low spatter on these rods make for a very pleasant welding experience. It’s particularly good for working with medium-grade carbon steels without needing to preheat, and it shines on cold-rolled steels where other rods might struggle with porosity.

Key features that stand out:

– E7018 Low-Hydrogen Iron Powder Electrode: Delivers high-quality, X-ray-grade welds.

– All-Position Welding (AC or DC Reverse Polarity): Versatile for various welding scenarios and machine types.

– Excellent Performance: Offers a steady arc, low spatter, outstanding re-striking ability, and high deposition efficiency.

– Wide Application Range: Suitable for low-alloy structurals, various carbon steels, offshore rigs, power plants, and tack welds.

Pros:

– Produces extremely high-quality, defect-free welds.

– Handles medium-grade carbon steels well without preheating.

– Excellent for preventing porosity on cold-rolled steels.

– Very stable arc and minimal cleanup required.

Cons:

– Like all E7018, needs dry storage to maintain performance.

Best for: Critical structural welds, fabrication of medium-grade carbon steels, and applications requiring X-ray quality welds on 1/8-inch material, including cold-rolled steel.

Expert Opinion: “The YESWELDER E7018 is a fantastic all-around low-hydrogen rod for 1/8″ steel. Its ability to produce X-ray quality welds and perform consistently across different steel types and positions makes it a top pick for both professional welders and serious hobbyists demanding the best in weld integrity.”

Helpful Comparison Short Insights

When picking the best welding rod for 1/8 steel, it really boils down to your material and welding process. For general stick welding mild steel, the YesRight J422 is excellent for its forgiveness on less-than-perfect surfaces and strong arc with AC machines. If you’re tackling more critical or heavy-duty carbon steel projects where strength and minimal porosity are key, both the Sunstac E7018 and YESWELDER E7018 are superior choices due to their low-hydrogen properties and rare earth additives for arc stability. They are also great for all-position welding. Remember, E7018 rods generally require a dry environment to maintain their effectiveness.

Now, if you’re dealing with 1/8-inch stainless steel, the game changes completely. The WeldingCity ER308L and Blue Demon ER316L are specifically TIG welding filler rods, not stick electrodes. The ER308L is your general-purpose stainless steel TIG rod for 304/308 series, while the ER316L is tailored for molybdenum-bearing alloys like 316L, offering enhanced corrosion resistance, especially in chloride environments. It’s crucial to understand this distinction; you can’t use these with a stick welder.

Final Verdict

For most hobbyists and general fabricators working on 1/8-inch mild steel with a stick welder, I’d lean towards the YesRight 1/8″ Stick Welding Electrode Rods J422 Carbon. It’s incredibly forgiving, performs well on AC, and delivers consistent results even on less-than-ideal surfaces. It’s a fantastic all-rounder.

However, if your projects demand the absolute highest strength, crack resistance, and X-ray quality welds on carbon or low-alloy steels, the YESWELDER E7018 1/8” 5LB Welding Rod (or the Sunstac E7018) is my top recommendation. These low-hydrogen rods excel in critical applications and offer superior weld integrity.

And for those specialized tasks involving 1/8-inch stainless steel and a TIG welder, the WeldingCity 1-Lb ER308L is your standard workhorse for general stainless, while the Blue Demon ER316L is the go-to for enhanced corrosion resistance in specific applications. Always match your filler metal to your base metal precisely for stainless.

Best Welding Rod For 1/8 Steel: Your Top Questions Answered

Q1: What is the best all-around welding rod for 1/8 inch mild steel?

A1: For general-purpose stick welding of 1/8 inch mild steel, an E6013 or E7014 rod is often recommended for its ease of use, smooth arc, and good appearance. However, for slightly more demanding applications or dirtier material, an E6011 or J422 carbon steel rod like the YesRight reviewed, provides deeper penetration and can burn through contaminants more effectively. If you prioritize strength and quality, an E7018 low-hydrogen rod is superior but requires a cleaner surface and proper storage.

Q2: Can I use E7018 rods on 1/8 inch thin steel?

A2: Yes, you can use E7018 welding rods on 1/8 inch steel, especially when high strength, ductility, and X-ray quality welds are required. They are excellent for structural work and critical applications. However, because E7018 runs hotter and has a thicker slag, it can be a bit more challenging for beginners on thinner material compared to E6013, requiring good technique to avoid burn-through.

Q3: What amperage settings should I use for 1/8 inch welding rods on 1/8 inch steel?

A3: Amperage settings for 1/8 inch welding rods typically range from 90 to 130 amps, depending on the specific rod type, material thickness, welding position, and your machine. For E6011, you might be around 75-125A; for E7018, often 115-165A. Always start with the manufacturer’s recommended range, test on scrap metal, and adjust until you achieve good penetration and a stable arc without excessive spatter or burn-through.

Q4: Why is a low-hydrogen welding rod important for 1/8 steel?

A4: A low-hydrogen welding rod (like E7018) is crucial for 1/8 inch steel when you need maximum weld strength and crack resistance. Hydrogen can get trapped in the weld, leading to hydrogen embrittlement and delayed cracking, especially in thicker or harder steels. For critical structural applications, pressure vessels, or high-carbon steels, using a low-hydrogen rod significantly reduces this risk, resulting in a much more sound and durable weld.

Q5: What’s the difference between a stick welding rod and a TIG welding rod for 1/8 steel?

A5: The main difference lies in their application. A stick welding rod (electrode) carries current and provides both filler metal and a flux coating to shield the weld. It’s used with an SMAW (Shielded Metal Arc Welding) process. A TIG welding rod (filler metal) does not carry current; it’s a bare wire added manually to the weld puddle, which is shielded by an inert gas (usually argon) from a TIG torch. Stick rods are self-shielding, while TIG rods require an external gas supply for shielding. The TIG rods like ER308L stainless steel or ER316L are specifically for TIG welding stainless steels and cannot be used for stick welding.

Q6: Can I use a 3/32 inch welding rod instead of 1/8 inch for 1/8 inch steel?

A6: Yes, you can use a 3/32 inch welding rod for welding 1/8 inch steel. A 3/32 inch rod will typically run at lower amperages and produce a smaller, more focused weld puddle. This can be beneficial for beginners, for out-of-position welding (vertical up, overhead), or when trying to minimize heat input to prevent warping on slightly thinner sections of the 1/8 inch material. However, it might require more passes to achieve the same fill and strength as a 1/8 inch rod.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.