As someone who’s spent my fair share of time in the field, I know how crucial it is to choose the right tools, especially when you’re dealing with something as demanding as drill stem pipe. The integrity of these pipes depends heavily on strong, durable welds. This guide is built from practical insights to help you find the best welding rod for drill stem pipe, focusing on options that deliver reliable joint strength and overall durability for your critical projects. Let’s dive into some top contenders that can stand up to the challenge.

Contents

- Tandefio 24pcs Low Temperature Universal Welding Rod Sticks

- Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon

- WISUNO Welding Rods,E7018 3/32’’ 1LB,Carbon Steel Stick

- YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon

- Bernzomatic PC3 Copper-Phosphorous Brazing/Welding Rods

- LesNau Pipe Drill Jig For Cylinders & Pipes Guide Centers

- Comparison Short Insights

- Final Verdict

- Best Welding Rod For Drill Stem Pipe: Your Questions Answered

- Q1: What’s the main difference between 6010 and 7018 welding rods for drill stem pipe applications?

- Q2: Can I use low-temperature universal welding rods, like the Tandefio, on drill stem pipe?

- Q3: Why is low hydrogen important when selecting a welding rod for critical applications like drill stem pipe?

- Q4: What diameter welding rod is best for drill stem pipe?

- Q5: Are there any special preparations needed before welding drill stem pipe?

- Q6: What does “X-ray quality welds” mean for drill stem pipe, and why is it important?

- Q7: How can a drill jig, like the LesNau, be useful when working with drill stem pipe if it’s not a welding rod?

Tandefio 24pcs Low Temperature Universal Welding Rod Sticks

This Tandefio package offers a versatile solution for various repair tasks, making it a handy kit to have in your toolbox for lighter-duty or multi-metal applications. These rods boast a low melting point and are designed for low-temperature welding, allowing for quick repairs without specialized equipment. Made with quality tin and aluminum powder, they incorporate solvent and flux to ensure a smooth welding process. While convenient for universal use, it’s important to understand their specific applications versus heavy-duty structural pipe welding.

Key features that stand out:

– Comprehensive Welding Package: Comes with 24 rods, ensuring you’re stocked for various projects.

– Low Temperature Welding: Designed to melt at lower temperatures, even with just an ordinary lighter for some applications.

– Quality Material: Fabricated with quality tin and aluminum powder, including integrated solvent and flux.

– Wide Range of Applications: Suitable for electronic circuits, copper, aluminum, stainless steel, and PVC pipes.

Pros:

– Extremely easy to use, even for beginners, due to low melting point.

– Versatile for repairing various metals and components.

– No need for external solder powder or specialized equipment.

Cons:

– Material can be brittle, and might not offer the tensile strength required for critical drill stem pipe applications.

Best for: Light-duty repairs on a variety of metals, small component work, and situations where traditional high-heat welding isn’t feasible or necessary.

Expert Opinion: These rods are excellent for quick, low-strength repairs on non-ferrous metals like aluminum and copper. However, for the high-strength, structural demands of drill stem pipe, they are generally not suitable as a primary welding solution due to their lower tensile strength and different metallurgical properties. They’re more akin to brazing or soldering for repairs.

Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube

When it comes to pipe welding, the Blue Demon 6010 is often a go-to choice. This rod is engineered to produce X-ray quality welds in all positions, making it exceptionally reliable for critical applications. Developed specifically for the pipe welding industry, it’s highly recommended for joining API grades A25, A, B, and X42 pipe, which are commonly found in drill stem applications. Its deep penetration capabilities and strong, consistent arc make it a favorite for root passes and general structural fabrication where robust joints are paramount.

Key features that stand out:

– X-ray Quality Welds: Capable of producing welds that pass stringent quality inspections.

– All-Position Welding: Excellent performance in flat, horizontal, overhead, vertical-up, and vertical-down positions.

– Pipe Welding Specific: Developed with the unique demands of the pipe welding industry in mind.

– Wide Application: Ideal for general purpose fabrication, maintenance welding, construction, and shipbuilding.

Pros:

– Exceptional for root passes and deep penetration, crucial for pipe integrity.

– Known for its strong, digging arc, making it effective on dirty or rusty surfaces.

– Delivers high-quality welds across all positions.

Cons:

– Produces more spatter compared to some other rod types, requiring more cleanup.

Best for: Root pass welding on drill stem pipe, general structural pipe fabrication, and critical applications requiring X-ray quality welds.

Expert Opinion: The 6010 rod is a workhorse for pipe welders, especially for the root pass where deep penetration and solid fusion are non-negotiable. Its ability to handle less-than-ideal surface conditions makes it incredibly practical in field environments. For drill stem pipe, it’s an essential tool for achieving robust initial joints.

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon

The ARCCAPTAIN E7018 rod is a staple for welders needing high-strength, low-hydrogen welds for demanding applications like drill stem pipe. This iron powder electrode delivers high-quality X-ray welds and boasts exceptional tensile strength and good resistance to cracking. It’s suitable for all welding positions using AC or DC reverse polarity, offering great flexibility. With its high melting efficiency and smooth, stable arc, it minimizes spatter and ensures high-quality, defect-free welds crucial for high-pressure pipelines and structural components.

Key features that stand out:

– E7018 Low Hydrogen Electrode: Designed for high-quality, crack-resistant welds.

– Outstanding X-ray Values: Meets stringent inspection standards for weld integrity.

– High Tensile Strength: Ensures strong, durable joints in critical applications.

– Versatile Use: Suitable for all positions and compatible with AC or DC reverse polarity.

Pros:

– Produces very strong, ductile welds with excellent crack resistance.

– Ideal for critical applications like high-pressure pipelines and heavy structural components.

– Smooth and stable arc with low spatter for cleaner welds.

Cons:

– Requires proper storage (baking) to maintain low hydrogen properties.

Best for: Fill and cap passes on drill stem pipe, welding low, medium, and high carbon steels, structural components, and high-pressure applications where strength and crack resistance are paramount.

Expert Opinion: E7018 is indispensable for critical structural and pipe welding where hydrogen embrittlement is a concern. For the fill and cap passes on drill stem pipe, its strength and X-ray quality are unmatched. Always ensure these rods are properly stored and baked before use to maintain their low-hydrogen benefits.

WISUNO Welding Rods,E7018 3/32’’ 1LB,Carbon Steel Stick

The WISUNO E7018 welding rod offers an accessible option for those seeking the benefits of a low-hydrogen electrode in a smaller package. It’s designed for both AC and DC applications and provides easy arc initiation with a super stable arc, which can lead to beautiful weld seams and easy slag removal. While suitable for low carbon steel structures, its emphasis on a smooth weld surface and excellent mechanical properties makes it a reliable choice for various repair and fabrication tasks. Remember the crucial pre-welding precautions, like baking the electrode, to ensure optimal performance.

Key features that stand out:

– E7018 Versatility: Suitable for AC and DC applications and all-position welding.

– User-Friendly Performance: Offers easy arc initiation, a stable arc, and minimal spatter.

– Quality Weld Seam: Designed for beautiful, smooth weld surfaces with easy slag removal.

– Strict Quality Control: Deposited metal’s chemical composition and mechanical performance meet high standards.

Pros:

– Excellent for achieving aesthetically pleasing welds on low carbon steel.

– User-friendly with stable arc and easy slag removal.

– Good for both thin plate and cover welding.

Cons:

– Requires meticulous pre-welding preparation (baking, cleaning) for best results.

Best for: Smaller structural repairs on low carbon steel, cover passes where aesthetics are important, and welders who prioritize ease of use with an E7018 rod.

Expert Opinion: This E7018 variant provides reliable performance for various carbon steel applications. Its ease of use is a plus, but the strict adherence to pre-welding steps like baking is critical to leverage its low-hydrogen properties, especially for any part of a drill stem pipe repair, even if it’s not the primary choice for the most critical passes.

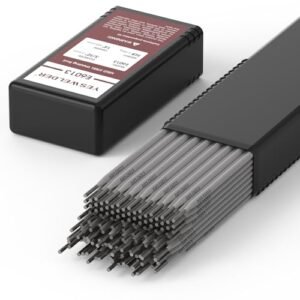

YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon

YESWELDER’s E7018 rod offers another robust low-hydrogen option, specifically highlighted for its ability to produce high-quality X-ray welds and prevent excessive porosity when welding on cold rolled steels. This iron powder electrode maintains a steady arc with low spatter and boasts excellent re-striking ability, contributing to higher deposition efficiency. Its versatility extends to all positions on AC or DC reverse polarity, making it highly adaptable. Recommended for medium grade carbon steels without preheat and critical applications like offshore rigs and power plants, it’s a solid choice for the demanding environment of drill stem pipe work.

Key features that stand out:

– E7018 Low Hydrogen: Designed for X-ray quality welds and crack resistance.

– Prevents Porosity: Recommended for cold rolled steels which can be prone to porosity.

– Excellent Arc Performance: Features a steady arc, low spatter, and superior re-striking ability.

– High Deposition Efficiency: Helps to complete welds faster.

Pros:

– Effectively prevents porosity on challenging materials like cold rolled steel.

– Offers excellent re-striking capabilities, improving workflow efficiency.

– Suitable for a wide range of carbon steels and heavy industrial applications.

Cons:

– Like all E7018 rods, proper storage and baking are essential to maintain its integrity.

Best for: Welding medium carbon steels, structural fabrications, offshore rigs, and any application where preventing porosity and achieving high deposition efficiency are key, including critical drill stem pipe repairs.

Expert Opinion: The YESWELDER E7018 is a strong contender for its consistent performance, particularly its ability to mitigate porosity. The higher deposition efficiency is a bonus for larger projects or multiple passes on thick-walled pipe. It’s a reliable choice for structural integrity on drill stem pipe.

Bernzomatic PC3 Copper-Phosphorous Brazing/Welding Rods

The Bernzomatic PC3 rods are a specialized product, designed specifically for brazing copper to copper without flux and copper to copper alloys (like brass and bronze) with flux. These copper-phosphorous rods are ideal for applications in refrigeration, electrical, and plumbing jobs where copper piping is prevalent. While they offer a tensile strength of 40,000 psi and operate at a working temperature of 1,310-1,475°F, it’s crucial to understand that these are brazing rods, not welding rods for steel. They are not intended for joining steel drill stem pipe.

Key features that stand out:

– Copper-Phosphorous Composition: Specifically formulated for brazing copper and its alloys.

– Fluxless for Copper-to-Copper: Simplifies the process when joining pure copper.

– Versatile Brazing: Suitable for refrigeration, electrical, and plumbing applications.

– Reliable Tensile Strength: Provides 40,000 psi for brazed joints in appropriate materials.

Pros:

– Excellent for brazing copper, creating strong, leak-free joints in non-ferrous systems.

– Eliminates the need for external flux when joining copper to copper.

– Ideal for specialized HVAC, electrical, and plumbing repairs.

Cons:

– Completely unsuitable for welding steel drill stem pipe as it’s a brazing product, not a steel welding rod.

Best for: Brazing copper pipes in HVAC, refrigeration, electrical, and plumbing systems, not for welding steel drill stem pipe.

Expert Opinion: These Bernzomatic rods are top-notch for their intended purpose: brazing copper. They create reliable, strong joints for copper lines. However, they should never be considered a substitute for steel welding rods when working with drill stem pipe. Using them on steel would result in a bond that lacks the strength and metallurgical compatibility required.

LesNau Pipe Drill Jig For Cylinders & Pipes Guide Centers

While not a welding rod, the LesNau Pipe Drill Jig is an incredibly useful accessory for anyone working with pipes, including drill stem pipe. This jig is designed to accurately drill holes into cylindrical objects, ensuring precise hole alignment and preventing the drill bit from wandering. Made from hard 304 stainless steel, it’s built for wear and rust resistance, promising a long service life. Its unique bridge triangle structure and cutout window provide stability and visibility, making drilling tasks more efficient and precise for plumbing, metal fabrication, and DIY projects.

Key features that stand out:

– Accurate Hole Drilling: Ensures precise alignment and prevents drill bit wandering on pipes.

– Unique Bridge Triangle Design: Provides stability and clear operation visualization.

– Durable Construction: Made from hard 304 stainless steel for wear and rust resistance.

– Versatile Hole Sizes: Features 6 different diameter drill holes to suit various needs.

Pros:

– Greatly improves accuracy and efficiency when drilling into pipes.

– Extremely durable and portable for field use.

– Prevents costly mistakes from off-center or wandering drill bits.

Cons:

– It’s a drilling accessory, not a welding rod, so it won’t help with the welding process itself.

Best for: Precisely drilling holes into cylindrical objects like drill stem pipes for tasks such as installing fittings, making modifications, or preparing for subsequent welding repairs.

Expert Opinion: Even though it’s not a welding rod, this drill jig is a smart addition to any pipe worker’s toolkit. Accurate hole placement is often a prerequisite for quality fabrication and repair, and this tool significantly reduces errors. It’s an investment in precision and efficiency that complements welding work on drill stem pipe.

Comparison Short Insights

When choosing the best welding rod for drill stem pipe, it primarily comes down to Blue Demon 6010 and E7018 rods from ARCCAPTAIN, WISUNO, or YESWELDER. The 6010 is king for the root pass due to its deep penetration and ability to burn through contaminants, ensuring a solid foundation. For the fill and cap passes, an E7018 rod is ideal, offering superior strength, ductility, and crack resistance thanks to its low-hydrogen properties. While the Tandefio low-temperature rods are great for multi-metal repairs, they lack the structural integrity for drill stem pipe. Similarly, the Bernzomatic PC3 rods are specifically for brazing copper and are entirely unsuitable for steel pipe. Finally, the LesNau Drill Jig, though not a rod, is a valuable precision tool for pipe preparation, making your work more accurate before welding begins.

Final Verdict

When it comes down to securing those critical drill stem pipe joints, you generally won’t find a single “best” rod for all passes. Instead, the most reliable approach combines two powerhouses: the Blue Demon 6010 for your root pass and any of the E7018 rods (ARCCAPTAIN, WISUNO, or YESWELDER) for your fill and cap passes.

For the absolute strongest and most reliable drill stem pipe welds, I’d personally lean towards starting with the Blue Demon 6010 for that crucial, deep-penetrating root pass. Then, I’d follow up with the ARCCAPTAIN E7018 Low Hydrogen Carbon for the fill and cap. This combination leverages the 6010’s excellent fusion and the 7018’s high tensile strength, crack resistance, and X-ray quality. The YESWELDER E7018 is also an excellent contender, particularly if you’re dealing with cold-rolled steels prone to porosity.

The other options, like the Tandefio universal rods or Bernzomatic brazing rods, simply aren’t designed for the structural demands of drill stem pipe. However, tools like the LesNau Pipe Drill Jig can be incredibly valuable for ensuring precise preparation, which is just as important as the weld itself. Invest in the right rods for each pass, and you’ll build connections that truly hold up under pressure.

Best Welding Rod For Drill Stem Pipe: Your Questions Answered

Q1: What’s the main difference between 6010 and 7018 welding rods for drill stem pipe applications?

A: The primary difference lies in their characteristics and typical use. 6010 rods are known for their deep penetration, strong, forceful arc, and ability to burn through rust and contaminants, making them ideal for root passes on drill stem pipe. They are also excellent for all-position welding. 7018 rods, on the other hand, are low-hydrogen electrodes that produce high-strength, ductile, and crack-resistant welds with excellent X-ray quality. They are preferred for fill and cap passes where strength and minimal defects are crucial.

Q2: Can I use low-temperature universal welding rods, like the Tandefio, on drill stem pipe?

A: Generally, no. Low-temperature universal rods, often designed for multi-metal repairs on aluminum, copper, or thin materials, do not provide the necessary tensile strength or metallurgical compatibility required for the demanding structural integrity of steel drill stem pipe. Using them on drill stem pipe would result in a weak, unreliable joint that could fail under stress.

Q3: Why is low hydrogen important when selecting a welding rod for critical applications like drill stem pipe?

A: Low hydrogen is critical because it significantly reduces the risk of hydrogen embrittlement, a phenomenon where hydrogen becomes trapped in the weld, making the steel brittle and prone to cracking, especially in high-strength steels. E7018 rods are specifically designed to have low hydrogen content, making them ideal for preventing cracks and ensuring long-term durability in high-stress environments like drill stem pipe.

Q4: What diameter welding rod is best for drill stem pipe?

A: The best rod diameter depends on the pipe’s thickness, the specific pass (root, fill, cap), and your amperage capabilities. For a root pass, smaller diameters like 3/32″ or 1/8″ are common with 6010 to ensure deep penetration. For fill and cap passes with 7018, 1/8″ or 5/32″ are frequently used to build up material efficiently and achieve desired weld profiles. Always refer to the pipe’s specifications and your welding procedure.

Q5: Are there any special preparations needed before welding drill stem pipe?

A: Yes, proper preparation is crucial for quality pipe welding. This includes thoroughly cleaning the pipe surface to remove all rust, oil, paint, and other contaminants. Depending on the pipe’s material and thickness, preheating may be required to prevent cracking. Additionally, if using low-hydrogen rods like E7018, they must be baked at specified temperatures before use to drive out any moisture that could introduce hydrogen into the weld.

Q6: What does “X-ray quality welds” mean for drill stem pipe, and why is it important?

A: “X-ray quality welds” means the welds are so clean and defect-free that they would pass a radiographic (X-ray) inspection, which is a stringent non-destructive testing method. For drill stem pipe, this is vital because it signifies maximum structural integrity, absence of internal flaws (like porosity, inclusions, or lack of fusion), and reliable performance under extreme pressures and stresses. Welds that are X-ray quality ensure the pipe connections won’t fail prematurely.

Q7: How can a drill jig, like the LesNau, be useful when working with drill stem pipe if it’s not a welding rod?

A: A drill jig, while not directly involved in the welding process, is incredibly useful for pre-welding fabrication and modification of drill stem pipe. It ensures precise alignment and accurate hole drilling into the cylindrical surface, which is crucial when installing fittings, sensors, or preparing the pipe for subsequent welding repairs. By preventing wandering drill bits and ensuring correct hole placement, it significantly improves the overall quality and efficiency of your pipework, complementing your welding efforts.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.