As a gearhead who’s spent my fair share of weekends under various vehicles, I know the sinking feeling of hearing that tell-tale hiss or rumble that signals an exhaust leak. It’s not just annoying; it can be bad for your car’s performance and even your health. That’s why I started digging into the best JB Weld for exhaust leak repairs. There are several options out there, each with its own strengths, and I’m here to walk you through my top picks, based on what I’ve seen work effectively for various situations, from small cracks to larger holes in your muffler or tailpipe.

Contents

- J-B Weld 37901 ExtremeHeat High Temperature Resistant…

- J-B Weld MufflerSeal Muffler Cement Plastic Tube 12 oz.,…

- J-B Weld ExhaustWeld 2″ x 72″ Repair Wrap, White

- J-B Weld MufflerSeal Muffler Cement Plastic Tube 6 oz….

- J-B Weld 8297 HighHeat 500 Degree Epoxy Putty Stick -…

- J-B Weld 38237 FiberWeld 2 in. W x 36 in….

- J-B Weld FiberWeld 2” Pipe Repair Cast 2×60 Inch -…

- Comparison Short Insights

- Final Verdict: Your Exhaust Leak Solution

- Best JB Weld For Exhaust Leak: Your Questions Answered

- Q1: Can J-B Weld really fix an exhaust leak permanently?

- Q2: What’s the most important factor to consider when choosing JB Weld for an exhaust leak?

- Q3: How do I prepare the exhaust surface before applying J-B Weld?

- Q4: Can I use J-B Weld for a crack in the exhaust manifold?

- Q5: How long does J-B Weld take to cure on an exhaust?

- Q6: Is J-B Weld a good temporary fix or a permanent solution for muffler repair?

- Q7: Can I paint over J-B Weld after it cures on my exhaust?

- Q8: What if my exhaust leak is too large for J-B Weld?

J-B Weld 37901 ExtremeHeat High Temperature Resistant…

This J-B Weld ExtremeHeat is a go-to for serious high-temperature repairs. It’s specifically formulated to handle the intense heat of exhaust systems, making it incredibly durable for iron, steel, and metal components. Once it sets, it forms a bond that’s impressively strong and can even be drilled or machined, giving you a really professional finish for your exhaust manifold repair or pipe connection fix.

Key features that stand out:

– High-Temperature Resistance: Withstands up to 1000°F (537°C) continuously.

– Permanent, Strong Bond: Creates a bond stronger than steel when fully cured.

– Versatile Application: Ideal for exhaust manifolds, mufflers, catalytic converters, and more.

– Easy to Work With: Can be drilled, machined, or sanded after curing.

Pros:

– Excellent temperature rating suitable for the hottest exhaust parts.

– Provides a very durable, long-lasting repair that can be shaped.

– No solvents or VOCs, making it safer to use.

Cons:

– Requires a longer curing time for full strength compared to some other options.

Best for: High-temperature applications like exhaust manifolds or catalytic converters where maximum heat resistance and a permanent, machineable fix are needed.

Expert Opinion: This is the heavyweight champion for extreme heat. If you’re dealing with a leak close to the engine or any part of the exhaust that gets scorching hot, this is your best bet for a robust, lasting repair.

J-B Weld MufflerSeal Muffler Cement Plastic Tube 12 oz.,…

When you’re facing a leak in your muffler or a loose pipe joint, J-B Weld MufflerSeal is a fantastic solution. This iron-reinforced paste is designed specifically for these kinds of fixes, resisting temperatures up to 700°F. I’ve found it’s really effective for patching smaller holes or sealing seams where exhaust gases might be escaping. You can either let it air cure or speed things up with a bit of heat.

Key features that stand out:

– Iron Reinforced Paste: Specially formulated to seal mufflers, pipe joints, and exhaust systems.

– Good Heat Resistance: Withstands temperatures up to 700°F.

– Flexible Cure Process: Can be air-cured (up to 24 hours) or heat-cured for faster results.

– Specifically for Exhaust: Ideal for muffler and pipe joint repairs.

Pros:

– Easy to apply directly to leaks and cracks in exhaust pipes and mufflers.

– Cures to a hard, durable seal.

– Can be accelerated with heat.

Cons:

– Not suitable for the absolute highest temperature parts of the exhaust.

Best for: Sealing small holes, cracks, and pipe joints on mufflers and mid-section exhaust pipes.

Expert Opinion: For general muffler and exhaust pipe sealing, this paste does a solid job. It’s easy to apply and, with the option to heat cure, you can get back on the road quicker, making it a reliable exhaust pipe sealer.

J-B Weld ExhaustWeld 2″ x 72″ Repair Wrap, White

This J-B Weld ExhaustWeld wrap is a lifesaver for larger cracks or holes that a paste just won’t cut. It’s a fiberglass wrap impregnated with a resin designed for high-temperature repairs, capable of resisting up to 1100°F. I’ve used wraps like this on older, rustier pipes where the metal might be a bit thin, and it provides a strong, structural repair. The fact that it can cure with or without heat is a huge bonus, offering flexibility depending on your situation.

Key features that stand out:

– High-Strength Fiberglass Wrap: Impregnated with a specialized high-temperature resin.

– Superior Heat Resistance: Withstands up to 1100°F once fully cured.

– Fast Curing Options: Sets in 20 minutes with or without heat; cures in 2 hours without heat, or faster with heat.

– Versatile Applications: Great for manifolds, catalytic converters, mufflers, and tailpipes.

Pros:

– Provides a strong, structural repair for larger holes or weakened sections.

– Excellent temperature resistance for the entire exhaust system.

– Quick setting and curing, especially with heat.

Cons:

– Application requires careful wrapping to ensure a smooth, effective seal.

Best for: Reinforcing and repairing larger holes or weakened sections of exhaust pipes, catalytic converters, and mufflers where a structural patch is needed.

Expert Opinion: When a simple patch won’t cut it, this wrap is incredibly effective. It’s like giving your exhaust a new, tough skin, especially good for catalytic converter repair or significant muffler damage.

J-B Weld MufflerSeal Muffler Cement Plastic Tube 6 oz….

This is essentially the smaller, more convenient version of the 12 oz. MufflerSeal. It’s the same iron-reinforced paste designed to seal mufflers, pipe joints, and exhaust systems, resisting temperatures up to 700°F. For smaller jobs or if you just need enough for one quick repair, this 6 oz. tube is perfect. It works just as well for patching those annoying small leaks.

Key features that stand out:

– Iron Reinforced Paste: Specifically designed for sealing mufflers, pipe joints, and exhaust systems.

– Reliable Heat Resistance: Endures temperatures up to 700°F.

– Dual Cure Process: Air-cures (up to 24 hours) or can be expedited with heat.

– Convenient Size: Ideal for single repairs or smaller projects.

Pros:

– Easy and straightforward application for minor exhaust leaks.

– Effective for sealing pipe joints and small cracks.

– Compact size is great for keeping in your garage for emergencies.

Cons:

– Limited quantity for larger repair jobs.

Best for: Quick, smaller fixes on mufflers and exhaust pipe joints, or as a convenient size for single-use applications.

Expert Opinion: The 6 oz. tube is a smart choice for anyone wanting to tackle minor exhaust issues without buying more product than they need. It’s the same reliable muffler cement, just in a more manageable size.

J-B Weld 8297 HighHeat 500 Degree Epoxy Putty Stick -…

J-B Weld HighHeat is a fantastic hand-mixable epoxy putty stick, which I personally find incredibly versatile for quick, on-the-spot repairs. It’s formulated to handle high temperatures – continuous heat up to 450°F and intermittent heat up to 500°F – making it great for various automotive applications beyond just the tailpipe. You just knead it together, apply it, and it sets fast, curing to a machine grey finish that’s 3x stronger at higher temps than regular epoxy.

Key features that stand out:

– Hand Mixable Epoxy Putty: Two-part formula that you knead by hand.

– High-Temperature Endurance: Withstands continuous heat up to 450°F and intermittent heat up to 500°F.

– Fast Setting & Curing: Sets in 1 hour, cures in 8 hours.

– Strong & Durable: 800 PSI strength (room temp), 600 PSI (400°F), can be tapped and drilled.

– Versatile Use: Ideal for exhaust manifolds, tailpipes, mufflers, engine blocks, and more.

Pros:

– Easy to apply directly to the repair area, even odd shapes.

– Very strong and durable, can be machined after curing.

– Good temperature resistance for many exhaust components.

Cons:

– Requires thorough hand-mixing, which can be messy if not careful.

Best for: Repairing odd-shaped holes, cracks, or rebuilding small sections on exhaust manifolds, tailpipes, and mufflers where a moldable, high-strength solution is needed. It’s a great DIY exhaust repair option.

Expert Opinion: This putty stick is a true workhorse. Its moldable nature is excellent for patching irregular shapes or even rebuilding small missing pieces of metal. Plus, its strength and heat resistance make it a very dependable high heat epoxy.

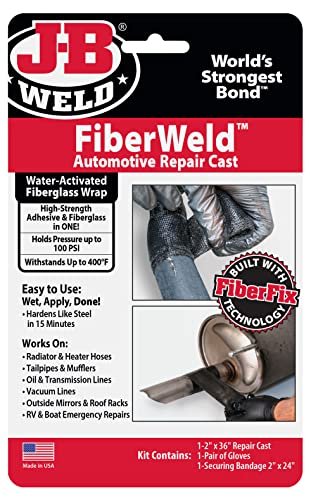

J-B Weld 38237 FiberWeld 2 in. W x 36 in….

The J-B Weld FiberWeld Automotive Repair Cast is another excellent wrap option, specifically designed for automotive repairs. It’s a high-strength fiberglass wrap that becomes incredibly tough like steel within 15 minutes when activated by water. I’ve used this for radiator hoses and mufflers, and it forms a really strong, permanent bond. While its temperature resistance is up to 400°F, which is lower than some others, it’s still suitable for many sections of the exhaust system further down the line, and holds water pressure too!

Key features that stand out:

– Water-Activated Fiberglass Wrap: Hardens like steel in just 15 minutes when dipped in water.

– Permanent, Strong Bond: Forms a robust, durable repair.

– Temperature & Pressure Resistant: Withstands up to 400°F and 100 PSI water pressure.

– Versatile Automotive Applications: Great for radiator hoses, tailpipes, mufflers, and oil lines.

– Kit Includes: Gloves and a securing bandage for convenience.

Pros:

– Extremely fast curing time for quick repairs.

– Provides a very strong, steel-like structural patch.

– Versatile for various automotive repairs, not just exhaust.

Cons:

– Lower heat resistance compared to products specifically designed for extreme exhaust temperatures.

Best for: Quick, strong repairs on tailpipes, mufflers, and other mid-to-lower exhaust components that don’t reach extreme temperatures, especially good for tailpipe patch or muffler patch.

Expert Opinion: For rapid, strong, and permanent repairs on components that don’t experience the absolute highest exhaust temperatures, this FiberWeld wrap is fantastic. Its quick set time is a huge advantage for urgent fixes.

J-B Weld FiberWeld 2” Pipe Repair Cast 2×60 Inch -…

This J-B Weld FiberWeld Pipe Repair Cast is very similar to the automotive repair cast but with a slightly different focus. It’s a high-strength, single-use fiberglass wrap pre-impregnated with a specialized anti-corrosive resin. Just like its sibling, you wet it, wrap it, and it hardens like steel in 15 minutes. This version is particularly good for creating a permanent, protective adhesion on a wide variety of pipes. While specific temperature resistance isn’t listed, its pipe repair focus suggests it’s designed for durability in challenging environments.

Key features that stand out:

– Water-Activated Fiberglass Wrap: Hardens like steel in 15 minutes after activation.

– Anti-Corrosive Resin: Provides permanent and protective adhesion.

– Single-Use Format: Convenient for one-time pipe repairs.

– Versatile Pipe Repair: Suitable for a wide variety of pipes.

Pros:

– Quick and easy application for fast pipe repairs.

– Forms a strong, steel-like, anti-corrosive bond.

– Effective for general pipe sealing and reinforcement.

Cons:

– Specific high-temperature rating for exhaust use isn’t explicitly stated, so less suited for manifold areas.

Best for: General pipe repair where a strong, quick-setting, and anti-corrosive wrap is needed, especially for tailpipes or less hot exhaust sections.

Expert Opinion: If you’re looking for a quick and incredibly strong solution for general pipe reinforcement or patching, this wrap is a solid choice. The anti-corrosive resin is a nice bonus for longevity, especially in areas prone to rust.

Comparison Short Insights

When picking the best JB Weld for exhaust leak, it really boils down to the specific repair needed. For the absolute highest temperatures, like near the engine or catalytic converter, the J-B Weld ExtremeHeat with its 1000°F rating is unmatched. If you’re dealing with a small crack or seam leak on your muffler or a less intense part of the pipe, either the J-B Weld MufflerSeal (6 oz. or 12 oz. tubes) offers a great paste solution with 700°F resistance and easy application.

For larger holes or weakened sections that need structural reinforcement, you’ll want a wrap. The J-B Weld ExhaustWeld wrap boasts an impressive 1100°F resistance and can handle the entire exhaust system. If you need a quick, steel-hard fix on parts that aren’t quite as hot (up to 400°F), the J-B Weld FiberWeld Automotive Repair Cast is a fantastic, fast-curing option. Finally, for oddly shaped damage or rebuilding small missing pieces, the J-B Weld HighHeat Epoxy Putty Stick (500°F intermittent) is incredibly versatile and moldable. Each product serves a distinct purpose, offering varying degrees of temperature resistance, application methods, and curing times.

Final Verdict: Your Exhaust Leak Solution

So, which JB Weld reigns supreme for your exhaust leak? It’s not a one-size-fits-all answer, but rather about matching the product to the problem.

For extreme high-temperature repairs and professional-grade durability on manifolds and catalytic converters, J-B Weld ExtremeHeat is the clear winner. If you’re just patching smaller holes and sealing joints on mufflers and tailpipes, the J-B Weld MufflerSeal in either size will serve you well. When structural integrity is compromised by a larger hole or weakened pipe, the J-B Weld ExhaustWeld wrap offers supreme heat resistance, while the J-B Weld FiberWeld Automotive Repair Cast is perfect for a rapid, steel-hard fix on mid-to-lower sections. And don’t forget the J-B Weld HighHeat Epoxy Putty Stick for those tricky, irregular repairs where you need to mold the solution.

Ultimately, by understanding the specific demands of your exhaust leak – its location, size, and the heat it endures – you can confidently pick the right J-B Weld product to get your vehicle quiet and running efficiently again.

Best JB Weld For Exhaust Leak: Your Questions Answered

Q1: Can J-B Weld really fix an exhaust leak permanently?

A1: While J-B Weld products are designed for extremely durable and long-lasting repairs, calling them “permanent” depends on the severity of the original damage, proper application, and how long the repair holds up against constant vibration, temperature changes, and rust. For many common leaks, they offer a very effective and lasting solution, often extending the life of your exhaust system significantly.

Q2: What’s the most important factor to consider when choosing JB Weld for an exhaust leak?

A2: The most crucial factor is temperature resistance. Different parts of your exhaust system experience vastly different temperatures. An exhaust manifold near the engine gets much hotter than a tailpipe. Ensure the J-B Weld product you choose can withstand the maximum temperature of the specific repair area.

Q3: How do I prepare the exhaust surface before applying J-B Weld?

A3: Proper surface preparation is key for any effective repair. You should thoroughly clean the area, removing all rust, grease, and loose debris. Sanding or wire brushing the metal to create a rough surface helps the J-B Weld adhere better. Degreasing with a suitable cleaner is also highly recommended.

Q4: Can I use J-B Weld for a crack in the exhaust manifold?

A4: Yes, certain J-B Weld products, particularly J-B Weld ExtremeHeat and J-B Weld HighHeat Epoxy Putty Stick, are specifically formulated for the extreme temperatures found in exhaust manifolds. These products offer the high heat resistance and strong bond necessary for such a critical repair.

Q5: How long does J-B Weld take to cure on an exhaust?

A5: Cure times vary significantly by product. Some pastes and putties might set in minutes but require hours (e.g., 8-24 hours) for a full cure. Wraps like FiberWeld can harden like steel in 15 minutes. Always check the product’s specific instructions for set and full cure times. Heat can often accelerate the curing process for many exhaust-specific J-B Weld products.

Q6: Is J-B Weld a good temporary fix or a permanent solution for muffler repair?

A6: For many typical muffler holes and cracks, J-B Weld offers a very robust and often long-term solution, making it more than just a temporary fix. With proper application and the right product, it can save you from a costly muffler replacement, functioning as a reliable muffler patch.

Q7: Can I paint over J-B Weld after it cures on my exhaust?

A7: Yes, once fully cured, many J-B Weld products, especially the epoxies and putties, can be sanded, drilled, and painted. This allows you to achieve a clean, professional-looking finish that blends with your exhaust system.

Q8: What if my exhaust leak is too large for J-B Weld?

A8: While J-B Weld offers solutions for a wide range of sizes, extremely large holes, severely rusted-through sections, or completely separated pipes might require professional welding or replacement. Wraps like ExhaustWeld or FiberWeld can handle significant damage, but there’s a limit to what an adhesive can repair structurally.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.