Getting a ding or a crack on your car’s plastic parts, like a bumper or an interior console, can be super frustrating. I’ve been there, staring at a split bumper, wondering if it meant a costly trip to the body shop. But over time, I discovered that plastic welding for cars is an incredibly effective and often DIY-friendly solution for these kinds of fixes. It’s not just about hiding a crack; it’s about restoring strength and integrity, making it one of the best types of welding for car repairs when dealing with plastics. This guide will walk you through some of the top tools and accessories that make these repairs possible.

Contents

- Sandfren Car Plastic Welder, Vehicle Plastic Bumper Crack…

- Allturn Plastic Welder 2 in 1, Plastic Welding Kit Car…

- 1200 Plastic Welder Staples – 6 Types Hot and Wave…

- Plastic Welder, 2 in 1 Plastic Welding Kit, SONNLER…

- 106pcs Plastic Welding Rods ABS PP PU PE PA PC…

- Helpful Comparison Short Insights

- Final Verdict

- Best Type Of Welding For Cars: Your Questions Answered

- Q1: What is the best type of welding for car plastic repairs?

- Q2: Can I use a regular metal welder for car plastic?

- Q3: How durable are plastic welded repairs on car parts?

- Q4: What tools do I need for basic car bumper crack repair?

- Q5: Do I need different welding rods for different types of plastic?

- Q6: Is plastic welding a safe DIY car repair?

- Q7: Can plastic welding fix broken interior plastic parts in a car?

Sandfren Car Plastic Welder, Vehicle Plastic Bumper Crack…

This Sandfren automotive plastic welding kit is a fantastic entry point for anyone looking to tackle car bumper cracks or other plastic damage. I found it incredibly straightforward to use, making quick work of common issues like broken tabs or dashboard fractures. It heats up rapidly thanks to its pure copper transformer, ensuring the heat is evenly distributed for a strong, reliable weld every time. The comprehensive package means you’re ready to go right out of the box, with a variety of staples for different repair needs.

Key features that stand out:

– High Quality Material: Features a pure copper transformer for quick, even heating and a durable plastic shell.

– Wide Application: Universal compatibility for most vehicle plastic products, including bumpers, lamp housings, and interior parts.

– Practical Function: Accurately repairs a variety of plastic parts like front bumpers, rear guards, and dashboard elements.

– Easy Installation: Simple plug-and-play operation; just insert the welding nail, plug into a 220V outlet, and weld.

– Complete Package: Comes with a main unit, four types of nails (50 of each), and pliers, all stored in a convenient white plastic box.

Pros:

– Very easy to set up and use, perfect for beginners.

– Heats up fast and evenly for efficient repairs.

– Comes with a comprehensive set of staples and tools.

– Portable storage case enhances convenience.

Cons:

– Requires a 220V outlet, which might not be standard in all garages.

Best for: Beginners and DIY enthusiasts looking for an all-in-one, easy-to-use solution for general car plastic repairs.

Expert Opinion: This kit excels in user-friendliness and provides a solid foundation for tackling common automotive plastic damage without needing extensive prior welding experience.

Allturn Plastic Welder 2 in 1, Plastic Welding Kit Car…

The Allturn Plastic Welder stands out with its robust performance and user-centric design. If you’re frequently repairing vehicle plastic parts, this tool is a solid choice. It’s a powerful hot stapler that speeds up your repair process, allowing you to fix everything from radiators to dashboards with ease. What I particularly appreciate is its ergonomic design; the rubber handle makes it comfortable for extended use, and the built-in overheating protection adds a crucial layer of safety. This truly restores broken parts, giving them a new lease on life against shock and twist.

Key features that stand out:

– Powerful Plastic Welder: Designed for faster and more efficient plastic repairs.

– Versatile Repair Tool: Fixes car bumpers, dashboards, lamp holders, plastic rings, radiators, and more.

– Strong and Durable: Creates repairs that can withstand shock and twist, extending part lifespan.

– Comfortable and Easy to Use: Ergonomic design with a rubber handle for comfortable, long-term grip, no special training required.

– Safe and Patented Design: Features internal overheating protection and a patented appearance for safety and distinctiveness.

Pros:

– Delivers strong, durable repairs that resist further damage.

– Ergonomic design enhances comfort during prolonged use.

– Overheating protection provides an important safety feature.

– Versatile for a wide range of automotive and household plastic items.

Cons:

– May be an overkill for very occasional, light repairs.

Best for: Mechanics and dedicated DIYers who perform frequent plastic repairs and prioritize durability, comfort, and safety.

Expert Opinion: The Allturn offers a blend of power, versatility, and safety, making it an excellent choice for those who demand reliable and comfortable use for various plastic repair tasks.

1200 Plastic Welder Staples – 6 Types Hot and Wave…

While not a welder itself, these 1200 Plastic Welder Staples are an absolute game-changer for strengthening any plastic repair done with a hot stapler. Think of them as the rebar for your plastic welds – they provide structural integrity that a simple plastic-to-plastic weld can’t match. Made from high-quality stainless steel, these staples are anti-corrosion and ensure a long-lasting hold. With six different shapes, you’re equipped for various crack configurations, making sure your repair is as strong as possible. They are pre-cut, saving you time and effort.

Key features that stand out:

– Quality Material: Made of high-hardness, anti-corrosion stainless steel for lasting repairs.

– Versatile Plastic Welding Staples: Includes 1200 staples in 6 different shapes for various repair needs.

– For Welding: Helps to lap cracked parts together, suitable for ABS, PVC, nylon, and other plastics.

– Simple To Operate: Can be used directly with most plastic welders/hot staplers and are pre-cut for convenience.

– Wide Practicality: Ideal for repairing bumpers, dashboards, radiators, kayaks, and various daily plastic supplies.

Pros:

– Essential for reinforcing plastic welds for maximum strength.

– Wide variety of shapes addresses different crack types.

– High-quality stainless steel resists corrosion.

– Pre-cut for quick and easy integration into repairs.

Cons:

– This is an accessory, not a standalone welding tool.

Best for: Anyone performing hot stapler plastic repairs who needs to ensure maximum strength and durability for their welds.

Expert Opinion: These staples are non-negotiable for professional-grade plastic repairs. They significantly enhance the structural integrity of a weld, ensuring the repair holds up over time, which is critical for automotive plastic welding.

Plastic Welder, 2 in 1 Plastic Welding Kit, SONNLER…

The SONNLER Plastic Welder is an impressive tool for quickly and effectively dealing with unsightly cracks and broken plastic parts. What really caught my attention was its incredible heating speed – just 2-3 seconds to reach 400°C/752°F! This rapid heat-up time means you can tackle your DIY car repair projects much faster. The kit is comprehensive, including 1000 hot staplers and various accessories, offering excellent value. It also features a safety light on the front, which is a thoughtful addition for improved visibility and safer operation, especially in tricky spots.

Key features that stand out:

– Quick and Efficient Solution: Repairs various plastic materials from automotive bumpers to household items.

– Perfect Match: Includes high-quality hot staplers and accessories, seamlessly fusing different plastic types.

– 1000pcs Hot Stapler & Many Accessories: Sufficient accessories for diverse plastic welding projects, offering great value.

– 100w Plastic Bumper Repair Kit: Heats up very quickly (2-3 seconds to 400°C/752°F) for fast repairs.

– Safety Design: Equipped with a front light for safer and more convenient operation, plus a one-year quality guarantee.

Pros:

– Extremely fast heat-up time boosts repair efficiency.

– Generous supply of staples and accessories included.

– Integrated safety light improves visibility and precision.

– Backed by a one-year quality guarantee for peace of mind.

Cons:

– The high heat-up speed requires careful handling to prevent over-melting.

Best for: DIYers and professionals who need a fast-acting, versatile plastic repair kit with abundant consumables, especially for bumper repair.

Expert Opinion: The SONNLER kit’s blistering heat-up time and thoughtful safety features make it a highly efficient choice for quick turnaround repairs, perfect for busy garages or ambitious home mechanics.

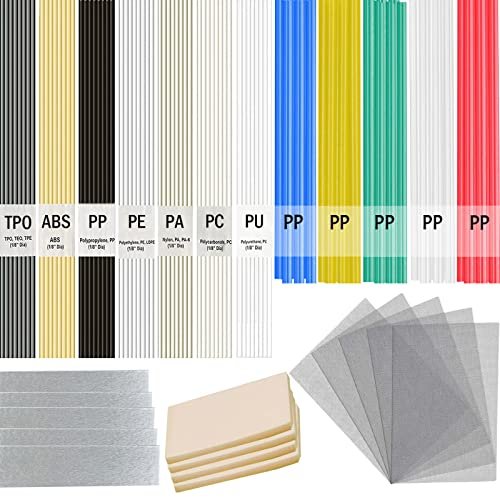

106pcs Plastic Welding Rods ABS PP PU PE PA PC…

This plastic welding kit with rods is an absolute necessity if you’re dealing with specific types of plastic that require material-matched repairs, not just stapling. I can’t stress enough the importance of matching your rod material to your base plastic – this kit provides 12-color plastic welding rods covering seven common types (PP, PU, PE, PC, PA, ABS, TPO). This allows for a much stronger, more seamless bond when you’re actually melting plastic. The inclusion of reinforcing stainless steel mesh and foil tape takes your repairs to the next level, adding serious strength and integrity, especially for load-bearing areas on vehicle plastic parts.

Key features that stand out:

– Plastic Welding Kit with Rods: 106 pieces of 12-color plastic welding rods, including 7 common plastic types.

– Welding Rods Good Performance: Rods have good toughness and stable moisture-proof insulation, suitable for repairing damaged plastic parts.

– Reinforcing Stainless Steel Mesh: Increases strength and durability of welds, can be cut to size and melted into the repair.

– Multiple Plastic Types: ABS/PP/PU/PE/PA/PC/TPO rods to repair car bumpers, kayaks, lawnmowers, water tanks, etc.

– Foil Tape and Sponge: Auxiliary foil tape for temporary repair and positioning, and a sponge for cleaning the welding surface.

Pros:

– Offers a wide variety of plastic types for accurate material-matched repairs.

– Stainless steel mesh provides significant structural reinforcement.

– Rods are clearly labeled for easy identification.

– Includes essential auxiliary tools like foil tape and a cleaning sponge.

Cons:

– Requires a separate plastic welder (hot air or soldering iron type) to use the rods effectively.

Best for: Anyone performing advanced plastic repairs where material matching and maximum structural integrity are crucial, especially for different plastic types on automotive components.

Expert Opinion: For genuine plastic fusion and the strongest possible repairs, especially on diverse automotive plastics, these welding rods are indispensable. The added mesh and variety of plastics ensure professional-level results.

Helpful Comparison Short Insights

When looking for the best type of welding for cars, especially for plastic repairs, it’s crucial to understand the tools available. For fundamental crack repair and reinforcement, hot staplers like the Sandfren, Allturn, and SONNLER kits are your primary tools. They excel at bridging cracks by embedding metal staples, offering a quick and strong solution. The SONNLER stands out for its lightning-fast heating, making it incredibly efficient, while the Allturn offers superior ergonomic comfort and robust construction for heavy use. The Sandfren is a great all-rounder for beginners, providing a complete package with ease of use.

However, a hot stapler alone isn’t always enough for the best car welding results on plastics. That’s where accessories like the 1200 Plastic Welder Staples and the 106pcs Plastic Welding Rods become vital. The staples are paramount for reinforcing stapler welds, providing the internal skeleton that prevents future cracking. Meanwhile, the welding rods allow for true plastic fusion – melting new plastic into a crack to create a seamless, material-matched repair. This is especially important when you need to fill gaps or rebuild missing pieces of plastic. The rods are essential for advanced repairs and when the specific plastic type matters for a lasting bond. Pairing a good hot stapler with the right reinforcing staples and material-matched welding rods will give you the most comprehensive and durable plastic repair kit for cars.

Final Verdict

Deciding on the best type of welding for cars primarily boils down to the type of repair you’re undertaking on plastic components.

- If you’re a beginner or tackling general cracks and breaks on car bumpers or interior trim, the Sandfren Car Plastic Welder is an excellent starting point. It’s user-friendly, comprehensive, and gets the job done reliably.

- For those needing speed and efficiency in their repairs, the SONNLER Plastic Welder is a fantastic choice with its rapid heat-up time and generous accessory count, perfect for quick fixes on car bodywork.

- If durability, comfort, and safety are your top priorities for frequent use, the Allturn Plastic Welder 2 in 1 provides a robust solution with its ergonomic design and overheating protection, making it ideal for the serious DIYer or professional.

- Regardless of which hot stapler you choose, the 1200 Plastic Welder Staples are an indispensable accessory for reinforcing your plastic welds. They transform a temporary fix into a long-lasting, structurally sound repair.

- For advanced repairs, material-matched fusion, or rebuilding missing plastic pieces, the 106pcs Plastic Welding Rods are a must-have. When combined with a suitable heating tool, they offer the ultimate in seamless, strong repairs across various plastic types.

Ultimately, for the most comprehensive and strongest plastic welding for cars, a combination approach is often the best. Start with a quality hot stapler, ensure you have plenty of reinforcing staples, and for specific, high-stress repairs, integrate the correct plastic welding rods to achieve truly professional and lasting results.

Best Type Of Welding For Cars: Your Questions Answered

Q1: What is the best type of welding for car plastic repairs?

A1: For plastic car components like bumpers, dashboards, and interior trims, plastic welding is the best type of repair. This typically involves either hot stapling (reinforcing cracks with metal staples melted into the plastic) or plastic rod fusion (melting new plastic filler rods into the damaged area for a seamless bond). Hot staplers are excellent for structural reinforcement, while plastic welding rods are ideal for material-matched repairs and filling gaps.

Q2: Can I use a regular metal welder for car plastic?

A2: No, absolutely not. A regular metal welder (like MIG or TIG) operates at much higher temperatures and is designed to melt and fuse metal. Using it on plastic would simply burn and destroy the plastic, releasing toxic fumes, and could be extremely dangerous. Always use specialized plastic welding tools for plastic repairs.

Q3: How durable are plastic welded repairs on car parts?

A3: When done correctly, plastic welded repairs can be incredibly durable and long-lasting, often restoring the original strength and flexibility of the component. The key is to use the right tools, proper technique, and reinforcing materials like hot staples and material-matched welding rods. A well-executed repair can withstand impacts and vibrations, making it a reliable car repair solution.

Q4: What tools do I need for basic car bumper crack repair?

A4: For basic bumper crack repair on a car, you’ll primarily need a hot stapler plastic welding kit. These kits usually include the main welding gun, various types of metal staples, and sometimes a cutting tool. For added strength, having extra staples (like the 1200 Plastic Welder Staples reviewed) is highly recommended.

Q5: Do I need different welding rods for different types of plastic?

A5: Yes, absolutely. For optimal strength and a seamless bond, you should always try to use plastic welding rods that match the specific type of plastic you are repairing. Common car plastics include ABS, PP (polypropylene), PE (polyethylene), PU (polyurethane), and PC (polycarbonate). Many plastic welding kits with rods (like the 106pcs Plastic Welding Rods reviewed) offer a variety of materials. Matching the plastic type ensures proper fusion and durability for your vehicle plastic parts.

Q6: Is plastic welding a safe DIY car repair?

A6: Plastic welding can be a safe DIY car repair if you take proper precautions. Always work in a well-ventilated area to avoid inhaling fumes. Wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety glasses. Ensure your tools have safety features like overheating protection (as seen in the Allturn welder). Following instructions carefully will help ensure a safe and effective repair for your automotive plastic welding projects.

Q7: Can plastic welding fix broken interior plastic parts in a car?

A7: Yes, plastic welding is highly effective for repairing various broken interior plastic parts in a car, such as dashboards, door panels, center consoles, and even small tabs. The precision of hot staplers and the ability to fusion-weld with plastic rods make it possible to fix cracks, reattach broken pieces, and reinforce weak points, offering an alternative to costly replacements for your vehicle plastic parts.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.