When I was setting up my last 12 Valve Cummins build, aiming for maximum efficiency and serious horsepower with a powerful compound turbo arrangement, I quickly realized that true performance isn’t just about bolting on large turbos. It starts deep inside the engine. Achieving peak cylinder sealing is absolutely critical before you introduce the heavy boost associated with a high-quality best compound turbo setup for 12 valve. That preparation requires meticulous attention to detail, especially ensuring the valve seats are perfectly matched to the valves. I’ve gathered and reviewed the essential grinding and lapping tools you’ll need to properly prepare your cylinder head for high-boost, high-performance applications.

Contents

- Permatex 80037 Valve Grinding Compound, 3 oz.

- weyleity Automotive Valve Spring Compressor Tool | Valve Lapping Compound Kit, 10pcs C Clamp Tool Set for Motorcycle, ATV, Car, Small Engine Vehicle Equipment

- LZVXTYM Valve Lapping Tool Kit, Valve Lapping Tool & Compound Kit with 5 Suction Plates, 1000rpm to 1250rpm Working Speed Valve Grinding Compound, Valve Lap Tool Attachment Kit for Motorc, Grey

- J-B Weld Valve Grinding Compound Carded 1.5 oz.

- Valve Grinding Lapping Compound Kit Fine and Coarse Grade Bundle with Capners Creations Valve Grinding Compound Tool Guide and One Pair of Black Gloves

- Valve Lapping Tool Kit, valve lapping tool and compound kit with 5 Suction Plates 1000rpm to 1250rpm Working Speed valve grinding Compound Valve Lap Tool Attachment Kit for Motorc

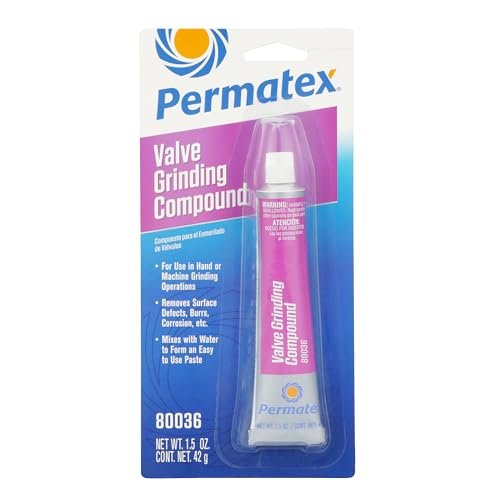

- Permatex 80036 Valve Grinding Compound, 1.5 oz.

- Comparison Short Insights

- Final Verdict

- Common Questions About best compound turbo setup for 12 valve Preparation Tools

- Why is valve lapping important when installing a best compound turbo setup for 12 valve?

- Can I skip lapping if my valves are new or my seats are freshly cut?

- What’s the difference between coarse and fine lapping compound grades?

- Are motorized valve lapping tools better than manual tools?

- What kind of maintenance does a 12 valve Cummins need before a high boost compound turbo setup?

- Do I need a special valve spring compressor for diesel engines?

Permatex 80037 Valve Grinding Compound, 3 oz.

This 3-ounce can of Permatex compound is a long-standing favorite in garages for good reason. It’s designed specifically to aid in seating valves and correcting minor surface irregularities, which is a crucial step before installing any performance engine component. The compound is abrasive and mixes easily with water, forming a simple paste that makes the lapping process straightforward. I found that this formulation works well for removing light corrosion and carbon buildup, ensuring a tight seal necessary to handle the pressure from a best compound turbo setup for 12 valve.

Key features that stand out:

– Fit Type: Universal Fit, making it suitable for almost any engine, including the 12 Valve.

– Mixes with water to form an easy-to-use paste.

– Removes burrs, surface defects, carbon, gum and corrosion, promoting superior sealing.

– Suggested Applications: Seat valves and sharpen tools.

Pros:

– Excellent value for the amount of compound provided.

– Water-soluble formulation makes cleanup simple.

– Effective for light-to-medium pitting and surface correction.

Cons:

– Only provides one grade of abrasive, limiting its use for heavy repair work.

Best for: General maintenance, final seating checks, and light surface cleanup on fresh valve jobs.

Expert Opinion: For 12 Valve builders focused on maximizing compression integrity, this Permatex paste is the industry standard. It’s simple, effective, and delivers a highly polished seat surface when used correctly with a manual lapper.

weyleity Automotive Valve Spring Compressor Tool | Valve Lapping Compound Kit, 10pcs C Clamp Tool Set for Motorcycle, ATV, Car, Small Engine Vehicle Equipment

While not a lapping compound itself, this kit is an essential tool for the preparatory stages of the 12 Valve engine build. You can’t seat the valves or check spring tension until you can easily remove and reinstall the valve springs. This robust C-Clamp style compressor is built from high-quality, black-oxide finished metal, promising great durability and corrosion resistance. Its versatile collection of collet pusher adapters means it can handle the various valve sizes found in many small and medium-sized diesel engines.

Key features that stand out:

– Premium Durability: Constructed from high-quality metal with a black-oxide finish for longevity.

– Robust C Clamp Design: Heat-treated steel resists bending under pressure.

– Versatile Application: Includes 5 collect adapters (16mm up to 30mm) fitting a wide range of vehicles.

– Package Content: Includes the C clamp, extension screws, and multiple adapters for comprehensive use.

Pros:

– Highly durable construction capable of handling stiff diesel valve springs.

– Comprehensive set of adapters increases versatility across different builds.

– Makes valve removal and installation hassle-free.

Cons:

– The C-clamp style may require removal of the cylinder head for easiest use.

Best for: Engine builders who frequently disassemble cylinder heads and require a heavy-duty, versatile valve spring compression solution.

Expert Opinion: If you’re performing a full head rebuild to prepare for a powerful best compound turbo setup for 12 valve, this compressor kit is mandatory. It ensures quick and safe spring management, allowing you to access the valves for grinding and lapping.

LZVXTYM Valve Lapping Tool Kit, Valve Lapping Tool & Compound Kit with 5 Suction Plates, 1000rpm to 1250rpm Working Speed Valve Grinding Compound, Valve Lap Tool Attachment Kit for Motorc, Grey

This kit moves beyond manual lapping and offers a drill attachment solution, significantly increasing productivity—a real time-saver when dealing with larger, heavier valves like those on a 12 Valve Cummins. The main component is a specialized grinder attachment that works with your existing power drill (not included) at speeds between 1000rpm and 1250rpm. It even features an automatic direction change function to ensure even wear and a precise seal.

Key features that stand out:

– Main Function: Corrects surface irregularities and ensures valves fit accurately into the valve guide.

– Working Speed: Optimal operating range of 1000rpm to 1250rpm.

– Automatic Direction Change: Facilitates accurate valve insertion and even grinding.

– 5 Suction Plate Sizes: Includes a wide range of synthetic rubber cups (up to 45mm) resistant to oil and UV exposure.

Pros:

– Reduces user fatigue compared to manual lapping tools.

– Wide variety of suction cup sizes ensures compatibility with most engine valves.

– Automatic direction shifting helps create an even, precise seating surface.

Cons:

– Requires a separate abrasive compound and power drill to operate.

Best for: Professional shops or frequent engine builders looking for speed and efficiency in preparing multiple valve seats for high-performance applications.

Expert Opinion: Using a drill attachment like this speeds up the process dramatically. The automatic directional change is a standout feature, ensuring you get a concentric pattern, which is vital for maintaining the high cylinder pressures generated by a best compound turbo setup for 12 valve.

J-B Weld Valve Grinding Compound Carded 1.5 oz.

Known primarily for their epoxy, J-B Weld also offers a reliable valve grinding compound. This 1.5 oz. carded paste is designed specifically for valve faces and seats. What sets the J-B Weld offering apart is its water-based, odorless formula, making it much more pleasant to work with in a closed environment compared to older oil-based formulas. It is highly effective at tackling the usual culprits of poor compression: burrs, surface defects, and general corrosion.

Key features that stand out:

– Water-Based Odorless Abrasive Paste: Comfortable and safer to use.

– Valve Grinder Focus: Specifically formulated for valve faces and seats.

– Removes Defects: Effective at taking out burrs, surface defects, and corrosion.

Pros:

– Odorless and easy to clean up due to its water base.

– Fine grit formulation is excellent for finishing and achieving a factory-tight seal.

– Compact size is perfect for single-use jobs or field repairs.

Cons:

– The smaller quantity is not ideal for full head rebuilds requiring extensive lapping.

Best for: Quick touch-ups, minor valve seat adjustments, or small engine maintenance where minimal product is needed.

Expert Opinion: This is a great, reliable alternative to the traditional compounds. If you’re simply checking the seat pattern on a newly cut 12 Valve head before bolting it down to accommodate your best compound turbo setup for 12 valve, this is more than sufficient.

Valve Grinding Lapping Compound Kit Fine and Coarse Grade Bundle with Capners Creations Valve Grinding Compound Tool Guide and One Pair of Black Gloves

This comprehensive bundle is an excellent choice for the hands-on DIY enthusiast who needs flexibility. The kit includes both fine and coarse grades of lapping compound, allowing you to start with the aggressive coarse grit to remove heavier pitting and then finish with the fine grade for a mirror-smooth seal. The inclusion of a helpful tool guide and a pair of gloves adds significant value, making it a truly complete package for achieving superior valve restoration.

Key features that stand out:

– Superior Valve Restoration: Includes both Fine and Coarse Grade compounds for multi-stage lapping.

– Precision Grinding Tool Guide: Ensures accurate and professional-grade grinding results.

– Protective Gloves Included: Enhances safety and user convenience during the messy process.

– Versatile & Durable Materials: Suitable for various valve types and sizes.

Pros:

– Two grades of compound provide flexibility for different levels of damage.

– The included guide is very useful for first-time lappers.

– Complete kit eliminates the need to buy accessories separately.

Cons:

– The provided guide is helpful but doesn’t replace hands-on experience.

Best for: Home mechanics tackling their first full 12 Valve engine rebuild who need a versatile compound kit and educational guidance.

Expert Opinion: Having both coarse and fine compounds is non-negotiable for serious engine prep. You need the coarse grit to quickly cut through hard carbon deposits and pitting, and the fine grade to achieve the critical air-tight finish required for a tight seal under high boost from a best compound turbo setup for 12 valve.

Valve Lapping Tool Kit, valve lapping tool and compound kit with 5 Suction Plates 1000rpm to 1250rpm Working Speed valve grinding Compound Valve Lap Tool Attachment Kit for Motorc

This kit appears to be functionally very similar to the LZVXTYM unit, focusing on speed and efficiency through drill operation. It includes the motorized valve grinding attachment and the five suction cup adapters, designed to fit and seat valves correctly. Its primary goal is ensuring that the valve fits securely into the valve guide, eliminating subsurface damage—a key aspect of longevity when installing high-performance upgrades.

Key features that stand out:

– Main Function: Designed to properly fit and seat valves, eliminating subsurface damage for a secure fit.

– Working Speed: Optimized working speed between 1000rpm and 1250rpm Maximum.

– Automatic Direction Change: Allows for easy valve insertion and even wear.

– Package Include: Includes the motorized attachment and five suction cup adapters.

Pros:

– Great time saver compared to traditional manual methods.

– Suitable for a wide variety of valve sizes commonly found in vehicle maintenance.

– Provides consistent results necessary for high-performance builds.

Cons:

– It requires the purchase of lapping compound separately.

Best for: Mechanics focused on high-volume engine work where time saved during the lapping process is crucial.

Expert Opinion: The inclusion of the automatic direction change, mirroring the functionality of premium tools, makes this an effective choice for prepping the cylinder head before installing the boost-heavy best compound turbo setup for 12 valve.

Permatex 80036 Valve Grinding Compound, 1.5 oz.

This is the smaller counterpart to the 3-ounce Permatex container reviewed earlier. The 1.5 oz. tube contains the same trusted, abrasive compound designed to assist valve grinding and seating operations. Just like its larger sibling, it mixes readily with water to create an easy-to-manage paste. This size is ideal for those who only need a small amount for a specific project or don’t want a large container sitting around the shop for years. It still efficiently removes common debris like carbon and gum.

Key features that stand out:

– Aids Valve Seating: Essential for ensuring a precise seal between the valve and seat.

– Mixes with water: Forms an easy-to-use, water-soluble paste.

– Removes Debris: Effectively clears burrs, surface defects, and corrosion.

Pros:

– Small, easily stored size perfect for single-use jobs.

– The established quality and reliability of the Permatex brand.

– Quick and easy cleanup with water.

Cons:

– Limited quantity means it’s not economical for large, heavily pitted jobs.

Best for: Single-cylinder maintenance, emergency repairs, or detailed checks on a few valves prior to assembly.

Expert Opinion: If you’ve had your 12 Valve head professionally cut and simply need to perform a final lapping check to ensure the seat is perfect before installation, this smaller tube gives you exactly what you need without waste.

Comparison Short Insights

When evaluating the tools and compounds required for proper 12 Valve engine preparation, it’s important to understand the different approaches.

If you are dealing with heavy pitting or significant imperfections, you absolutely need a compound kit that includes both coarse and fine grades, such as the Capners Creations bundle. Starting with a coarse grit maximizes material removal and saves immense time, whereas a single, medium-grade compound might struggle.

For efficiency and reducing physical strain, the motorized lapping tools (like the LZVXTYM or the Valve Lapping Tool Kit) are a clear winner. They maintain a consistent, automated rotation speed and direction change, which is difficult to replicate manually, ensuring a highly accurate seal necessary for a best compound turbo setup for 12 valve. However, remember these motorized kits often do not include the compound itself, requiring a separate purchase.

Conversely, manual lapping tools paired with a quality compound like Permatex 80037 offer the highest degree of tactile feedback. If you are an experienced mechanic and prefer feeling the resistance of the valve against the seat, a manual approach is often favored for its precision in the final stages.

Finally, the weyleity Valve Spring Compressor is a separate but necessary investment. No amount of compound or lapping time matters if you cannot safely and efficiently handle the valve springs during assembly and tear-down.

Final Verdict

Building a high-performance 12 Valve engine capable of handling a best compound turbo setup for 12 valve requires reliable tools. Your choice should depend on the scale of your project:

For the Comprehensive Engine Builder: The best overall combination for someone tackling a full 12 Valve head rebuild is the Valve Grinding Lapping Compound Kit Fine and Coarse Grade Bundle combined with the LZVXTYM Valve Lapping Tool Kit. This pairing gives you the necessary dual-grade abrasives for tackling any job and the efficiency of the motorized attachment. Don’t forget the weyleity Automotive Valve Spring Compressor Tool—it’s non-negotiable for safe spring management.

For Quick Tune-Ups and Reliability: If you simply need a proven, reliable compound for final seating checks or minor adjustments, the Permatex 80037 Valve Grinding Compound, 3 oz. offers the best value and performance in a single-grade product. It’s the staple of virtually every serious mechanic’s toolbox.

For Budget and Convenience: The J-B Weld Valve Grinding Compound is an excellent choice for minor spot work due to its pleasant, odorless, water-based formulation and compact size, making it a reliable option for small jobs without the mess.

Common Questions About best compound turbo setup for 12 valve Preparation Tools

Why is valve lapping important when installing a best compound turbo setup for 12 valve?

When you install a compound turbo setup, you dramatically increase the cylinder pressures inside the engine. If the valves do not seal perfectly against the valve seats, you will lose compression and power, leading to wasted boost and potentially burnt valves over time. Valve lapping, using compounds like Permatex, ensures a tight, concentric seal, maximizing combustion efficiency and protecting the engine under high-boost conditions.

Can I skip lapping if my valves are new or my seats are freshly cut?

While freshly cut seats and new valves are usually close to perfect, skipping the lapping process is risky. Lapping uses a fine abrasive to marry the two surfaces, confirming that the contact pattern is uniform across the entire face of the valve. This final seating check is crucial to verify the integrity of the seal before the engine is subjected to high power demands from the best compound turbo setup for 12 valve.

What’s the difference between coarse and fine lapping compound grades?

Coarse grade compounds are more aggressive and are used first to quickly remove material, fix heavy pitting, or eliminate severe carbon deposits. Fine grade compounds are used second (or exclusively on light jobs) to provide the final polish and achieve the gas-tight, mirror-smooth finish necessary for peak sealing integrity. Using both ensures maximum reliability.

Are motorized valve lapping tools better than manual tools?

Motorized tools, like the attachments reviewed, offer significant speed and consistency, making them ideal for mechanics doing high volumes of work. They reduce user fatigue and ensure the correct rotational speed (around 1000–1250rpm). However, manual tools offer greater tactile feedback, which many experienced builders prefer for the precise, final seating adjustment.

What kind of maintenance does a 12 valve Cummins need before a high boost compound turbo setup?

Beyond impeccable valve seating preparation (using the compounds and tools reviewed), a 12 Valve Cummins being prepped for high boost often requires fire-ringing or O-ringing the cylinder head, upgrading the valve springs and retainers (requiring a tool like the weyleity compressor), and potentially installing upgraded head studs to handle the intense pressures generated by a powerful best compound turbo setup for 12 valve.

Do I need a special valve spring compressor for diesel engines?

Diesel engines, especially high-performance units like the 12 Valve Cummins, often have much stiffer valve springs than typical gasoline engines. A heavy-duty C-clamp or specialized lever-style compressor is generally required to safely and effectively compress these stiff springs without bending the tool or causing damage. Tools like the weyleity kit are designed with this higher durability in mind.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.