When I started diving deep into maximizing the legendary 5.9L 12-valve Cummins engine, I quickly realized that simply bolting on the best aftermarket turbo for 12 valve cummins is only half the battle. This engine’s power potential is huge, but hitting those high horsepower and torque numbers requires reliable supporting components—especially around the P7100 injection pump and the critical oil and air management systems. We’ve compiled a guide to the essential parts you need to ensure your 12V performs reliably under the pressures of performance tuning.

Contents

- Tiny Force Throttle Body Accelerator Cable Compatible with 1994-1998 Dodge Ram 2500 3500 Cummins 12 Valve Turbo Diesel

- JEENDA Oil Filler Tube Kits 3921644 4962608 Compatible with Cummins 6BT 5.9L 1989-1998 Dodge 12 Valve

- GLOCRORET 12V Fuel Shut Off Solenoid Valve 3935649 fit for Cummins 5.9L 8.3L Engines 4B 6B 6C Diesel Engine, Replace SA-4764-12

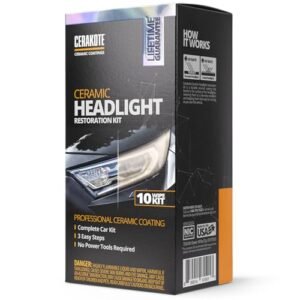

- Turbo Oil Feed Line & Connector Kit 3913824 for 1989-1998 Dodge Ram 5.9L 12V Cummins Diesel Engine – Direct Fit Replacement Turbocharger Oil Line Assembly

- IMIFAFTAbT P7100 AFC Housing Air Aneroid Fits For Cummins 12V Valve Diesel Turbo 5.9L 6BT 1994-1998 Dodge

- KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

- Machined Milled Rocker Arm Pedestal Assembly Kit 5.9L 12V Dodge Cummins for Head Studs – Xotic Performance™ CP200

- Helpful Comparison Short Insights

- Final Verdict: Building a Reliable Platform for Power

- Common Questions About Best Aftermarket Turbo for 12 Valve Cummins

- Why are supporting components so important when installing a best aftermarket turbo for 12 valve cummins?

- Do I really need to use head studs when upgrading my turbo?

- What is the role of the P7100 AFC Housing?

- How do I prevent valve float on my 12V Cummins after adding a performance turbo?

- Is the turbo oil feed line failure common on older 12V engines?

- If I install a best aftermarket turbo for 12 valve cummins, will I need to upgrade my fuel shut-off solenoid?

Tiny Force Throttle Body Accelerator Cable Compatible with 1994-1998 Dodge Ram 2500 3500 Cummins 12 Valve Turbo Diesel

If you’re running a 1994-1998 12V, your throttle cable is crucial for translating your foot movement into fuel delivery, directly impacting how quickly your turbo spools. Over time, the original cable can stretch or fray, leading to sluggish response or inconsistent RPM control. This replacement ensures crisp, immediate linkage, which is absolutely vital when trying to maintain specific boost levels or fine-tune your P7100 pump adjustments. Proper fueling control means quicker, more predictable boost.

Key features that stand out:

– Compatible models: Specifically designed for 1994-1998 12V Dodge Ram 2500/3500 with the 5.9L Cummins Turbo Diesel.

– Cross Reference Part Numbers: Provides reliable fitment based on OEM specifications (0489 7406 AA).

– High Quality: Constructed from durable materials designed to withstand the harsh conditions under the hood.

Pros:

– Restores factory-like throttle responsiveness.

– Direct replacement makes installation straightforward (though professional help is recommended).

– Cost-effective solution for a common wear item.

Cons:

– Installation can be fiddly, requiring careful adjustment for optimal performance.

Best for:

Restoring immediate throttle response and ensuring precise fueling control after a P7100 pump adjustment.

Expert Opinion: A cheap, high-quality throttle cable is non-negotiable for a performance 12V. If you’re chasing high boost and big power, inconsistent fueling from a worn cable compromises both driveability and safety.

JEENDA Oil Filler Tube Kits 3921644 4962608 Compatible with Cummins 6BT 5.9L 1989-1998 Dodge 12 Valve

Oil management is a foundation of engine health, especially in turbocharged environments where oil temperatures can skyrocket. This JEENDA Oil Filler Tube Kit ensures a proper seal and reliable access point for lubrication. A cracked or poorly sealed oil filler tube can lead to vacuum leaks or, worse, oil leaks that spray onto hot turbo housings or exhaust components. Maintaining the integrity of the crankcase ventilation system is critical for turbo longevity.

Key features that stand out:

– Replace Part Number: Direct replacement for 3921644 and 4962608.

– Compatibility: Fits a wide range of 12V 6BT 5.9L engines from 1989 through 1998.

– Aftermarket Quality: A brand-new aftermarket item designed for reliable performance.

Pros:

– Essential for preventing oil leaks and maintaining a clean engine bay.

– Easy replacement process.

– Compatible across all years of the classic 12V design.

Cons:

– While high quality, it is a basic maintenance part and doesn’t directly enhance horsepower.

Best for:

Standard maintenance and ensuring engine compartment cleanliness, especially useful when performing other major engine work.

Expert Opinion: Don’t overlook the simple things. A well-sealed engine compartment and robust oil delivery system are foundational. If you’re building a reliable platform for the best aftermarket turbo for 12 valve cummins, this is a must-check item.

GLOCRORET 12V Fuel Shut Off Solenoid Valve 3935649 fit for Cummins 5.9L 8.3L Engines 4B 6B 6C Diesel Engine, Replace SA-4764-12

The fuel shut-off solenoid is perhaps the most important electrical component controlling the P7100 pump. If this fails, your truck either won’t start or won’t shut off, leading to a dangerous run-on situation. Reliability is key here. This solenoid operates at 12V and is designed to handle the critical function of fuel delivery control to the injection pump. Choosing a high-quality solenoid prevents unexpected roadside failures.

Key features that stand out:

– Part Number: Cross-references major OEM and aftermarket part numbers (3935649, SA-4765-12).

– Specification: Features the standard 3-inch mounting bolt spacing and 3-pin connector common on P7100 applications.

– High Durability: Made from robust materials designed to handle the constant cycling required.

Pros:

– Essential reliability component for P7100-equipped trucks.

– Provides consistent function for starting and stopping the engine.

– Wide compatibility with various Cummins B and C series engines.

Cons:

– If installed incorrectly, wiring issues can quickly lead to solenoid burnout.

Best for:

Ensuring reliable engine start and stop functionality, especially after rebuilding or tuning the injection pump system.

Expert Opinion: The P7100 solenoid is notorious for failure on aging trucks. When you invest time and money into the best aftermarket turbo for 12 valve cummins, a reliable shut-off solenoid is cheap insurance against catastrophic failure or simply getting stranded.

Turbo Oil Feed Line & Connector Kit 3913824 for 1989-1998 Dodge Ram 5.9L 12V Cummins Diesel Engine – Direct Fit Replacement Turbocharger Oil Line Assembly

This is arguably the most essential component directly related to the turbocharger itself. The oil feed line delivers clean, pressurized oil directly to the turbo’s bearings. Failure here means instant, catastrophic turbo failure due to lack of lubrication. The original lines often become brittle or clog over decades of high heat exposure. This direct-fit replacement ensures consistent, high-pressure oil delivery, which is non-negotiable when running high boost.

Key features that stand out:

– Part Number: Replaces original part number 3913824 exactly.

– Reliable Construction: Manufactured with corrosion-resistant materials to withstand extreme diesel engine heat and pressure.

– Leak-Free Operation: Tested to ensure proper fit and consistent flow, crucial for turbo lifespan.

Pros:

– Absolutely critical for the life of both stock and aftermarket turbochargers.

– Durable construction handles high temperatures reliably.

– Direct-fit design simplifies the replacement process.

Cons:

– Requires careful routing during installation to avoid chafing or bending.

Best for:

Anyone installing a new or upgraded turbocharger, or performing standard maintenance on an existing high-mileage 12V engine.

Expert Opinion: Never reuse an old oil feed line when installing the best aftermarket turbo for 12 valve cummins. The risks associated with clogging or rupture far outweigh the cost of a high-quality replacement kit like this one. Clean oil to the turbo is life.

IMIFAFTAbT P7100 AFC Housing Air Aneroid Fits For Cummins 12V Valve Diesel Turbo 5.9L 6BT 1994-1998 Dodge

For the 1994-1998 12V engines equipped with the P7100 pump, the AFC (Air Fuel Control) housing is where the magic happens. This component uses boost pressure from the turbo to govern how much fuel the pump delivers. By swapping or tuning this housing, you control smoke output and low-end driveability. When you upgrade to a larger best aftermarket turbo for 12 valve cummins, tuning the AFC housing is essential for quick spooling and managing power delivery off the line.

Key features that stand out:

– Part Name: AFC Housing Air Aneroid P7100, directly controls the fueling curve based on boost.

– Application: Specifically for 1994-1998 Cummins 12V 5.9L 6BT engines.

– Tuning Potential: Provides a robust platform for customizing fueling characteristics.

Pros:

– Allows for precise tuning of fuel delivery relative to turbo boost.

– Crucial for reducing excessive black smoke when running high performance tunes.

– Directly impacts throttle response and mid-range torque.

Cons:

– Tuning this component requires specialized knowledge and attention to detail.

Best for:

Performance enthusiasts who have upgraded their turbo and need to fine-tune the P7100 pump to match the new airflow characteristics.

Expert Opinion: You can have the best aftermarket turbo for 12 valve cummins on the market, but if the AFC housing isn’t adjusted to match the airflow, you’ll either smoke excessively or run out of fuel too quickly. This component is the bridge between air and diesel.

KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

If you plan on running your 12V Cummins hard—especially with a performance turbo that increases boost and allows for higher RPMs—you must upgrade your valve springs. The stock springs are prone to ‘valve float’ at high RPMs under heavy boost. This specialized Valve Spring Compressor Tool is indispensable for safely installing upgraded valve springs or performing maintenance without removing the cylinder head.

Key features that stand out:

– Function: Works directly on the Cummins 6bt 5.9L 12 Valve Engine for valve spring maintenance.

– Material: Made of high-quality, robust, and corrosion-resistant metal for long service life.

– Fits: Comprehensive fitment for 1988-1998 12-Valve trucks.

Pros:

– Saves significant time and hassle by allowing in-place spring replacement.

– Necessary tool for performance builds requiring stronger springs.

– Robust construction ensures safe operation.

Cons:

– It’s a specialized tool only useful for valve train work on the 12V.

Best for:

DIY mechanics and shops planning to install heavy-duty valve springs to prevent valve float when running high boost with a best aftermarket turbo for 12 valve cummins.

Expert Opinion: Any performance build aiming for 40+ PSI of boost or sustained high RPM use must address valve float. This tool makes the valve spring swap much safer and faster, making performance upgrades feasible in your home garage.

Machined Milled Rocker Arm Pedestal Assembly Kit 5.9L 12V Dodge Cummins for Head Studs – Xotic Performance™ CP200

When you install the best aftermarket turbo for 12 valve cummins and start pushing the engine over 40-50 PSI of boost, cylinder pressure skyrockets. To prevent the cylinder head from lifting off the block—a common failure point—head studs are essential. These CP200 Machined Milled Rocker Arm Pedestals are required because the larger diameter of head studs interferes with the stock pedestals. This kit pre-machines the clearances needed for head stud installation, saving crucial time and ensuring precision.

Key features that stand out:

– Head Stud Ready: Specifically milled to allow proper clearance for aftermarket head studs (sold separately).

– Fits: Designed for 1989-1998 Dodge Cummins 5.9L Diesel 12V models.

– Time Saver: Purchasing them pre-milled saves the installer the hassle and cost of machine shop work.

Pros:

– Absolutely necessary for high boost applications (40+ PSI).

– Provides a stable, durable platform for the rocker arm assembly.

– Rigorous quality inspections ensure premium fitment.

Cons:

– This is an expense required solely for head stud installation, not an independent performance part.

Best for:

Extreme performance builds where high boost levels necessitate the use of heavy-duty head studs for engine reliability.

Expert Opinion: If your power goal includes high boost, you need head studs. If you need head studs, you need these pedestals. This kit eliminates the guesswork and wait time associated with machining the stock parts, providing a reliable platform for serious power.

Helpful Comparison Short Insights

While all these components are crucial for maintaining and upgrading the 12V Cummins, they serve distinct purposes.

For pure performance tuning and response, the IMIFAFTAbT P7100 AFC Housing and the Tiny Force Throttle Body Cable are your priority. The AFC Housing allows you to manage the engine’s power output relative to the boost being generated by your best aftermarket turbo for 12 valve cummins, while the cable ensures immediate translation of throttle input.

If reliability and protection are your main concern, especially when pushing higher boost, focus on the Turbo Oil Feed Line & Connector Kit and the GLOCRORET Fuel Shut Off Solenoid. A failed oil line instantly kills a turbo, and a failed solenoid guarantees frustration. The JEENDA Oil Filler Tube Kit supports overall engine longevity by ensuring a clean, sealed environment.

For extreme power durability, the Machined Milled Rocker Arm Pedestal Assembly Kit and the KSJED Valve Spring Compressor are mandatory investments. The pedestals enable head studs, providing the clamping force needed to prevent head lift at high boost, while the compressor tool allows you to install the necessary stiffer valve springs to avoid costly engine damage from valve float. Don’t skimp on these structural components if you plan to maximize power.

Final Verdict: Building a Reliable Platform for Power

Finding the absolute best aftermarket turbo for 12 valve cummins is exhilarating, but the foundation you build beneath it determines whether that upgrade lasts 50 miles or 50,000 miles.

If you are performing standard maintenance and light tuning, prioritize the Turbo Oil Feed Line, the Fuel Shut Off Solenoid, and the Throttle Cable. These three items prevent common failures and restore crisp driveability.

If you are building a high-horsepower truck (400+ HP), your investment must pivot to durability components. The Machined Milled Rocker Arm Pedestals (to enable head studs), the Valve Spring Compressor Tool (to enable stiffer springs), and the AFC Housing are now non-negotiable. These components directly support the increased stresses imposed by the best aftermarket turbo for 12 valve cummins and ensure the engine itself can handle the immense cylinder pressure.

By addressing these supporting systems, you ensure that whatever performance turbo you choose has the reliable foundation it needs to truly shine.

Common Questions About Best Aftermarket Turbo for 12 Valve Cummins

Why are supporting components so important when installing a best aftermarket turbo for 12 valve cummins?

The 12-valve Cummins is robust, but pushing high boost pressures (anything over 30 PSI) dramatically increases stress on fuel systems, cylinder clamping force, and oil delivery systems. Essential supporting components, like the oil feed line, reinforced rocker arm pedestals, and tuneable AFC housing, ensure the engine can reliably manage the increased heat and pressure generated by a performance turbocharger. Ignoring these parts often leads to early turbo failure or internal engine damage.

Do I really need to use head studs when upgrading my turbo?

For stock or moderate power levels (under 350 HP), high-quality stock bolts may suffice. However, if you are installing a large best aftermarket turbo for 12 valve cummins with the goal of exceeding 40 PSI of boost, head studs are highly recommended. High cylinder pressures can cause the head to lift off the block, leading to coolant leaks, blown head gaskets, and eventually, total engine failure. The machined rocker arm pedestals are needed to physically clear the larger head studs.

What is the role of the P7100 AFC Housing?

The AFC (Air Fuel Control) housing on 1994–1998 12V Cummins trucks controls the fuel rack travel inside the P7100 injection pump based on available boost pressure. Essentially, it determines how much fuel is delivered before the turbo has fully spooled. Tuning the AFC housing—often by swapping components—is key to managing black smoke during acceleration and ensuring the engine doesn’t over-fuel before the best aftermarket turbo for 12 valve cummins is producing adequate air.

How do I prevent valve float on my 12V Cummins after adding a performance turbo?

Valve float occurs when the stock valve springs can’t close the valves quickly enough against high cylinder pressure and inertia at elevated RPMs (typically over 3,000 RPMs). When running a best aftermarket turbo for 12 valve cummins, preventing valve float requires installing stiffer, heavy-duty valve springs. The specialized valve spring compressor tool reviewed in this article is necessary to safely install these new springs without removing the cylinder head.

Is the turbo oil feed line failure common on older 12V engines?

Yes, turbo oil feed line failure is a relatively common and very serious issue on aging 12V engines. These lines are subjected to immense heat cycles over decades, causing the material to become brittle or internal carbon buildup to occur. A failure can lead to catastrophic oil loss and immediate starvation of the turbocharger bearings, which is why replacing this line with a high-quality unit is essential when installing any best aftermarket turbo for 12 valve cummins.

If I install a best aftermarket turbo for 12 valve cummins, will I need to upgrade my fuel shut-off solenoid?

While the performance turbo doesn’t directly interact with the solenoid, high-performance tuning often exposes weak links in the existing electrical and fuel systems. Given that the fuel shut-off solenoid is a known failure point on P7100 systems, it is highly advisable to replace it with a reliable unit during any major performance overhaul to ensure consistent engine starting and stopping functionality.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.