When I first started out in MIG welding, I remember the frustration of inconsistent welds – too much spatter, poor penetration, or just a generally ugly bead. It took me a while to realize that beyond my technique and machine settings, the shielding gas was a huge factor. Choosing the best gas for MIG welding isn’t just about grabbing any cylinder; it’s about matching the right blend to your metal and project for cleaner, stronger, and more stable welds. This guide dives into some of the top options and essential accessories to help you achieve professional-quality results every time.

Contents

- PrimeWeld 75% Argon 25% CO2 Bottle 125CF | DOT 3AA

- 80 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

- Generic, 60 cuft 75 Argon 25 CO2 Welding Gas Cylinder Tank

- 40 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

- 125 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

- New 60 cu ft Steel Argon Gas Cylinder with CGA580

- PrimeWeld 100% Argon Gas Welding Tank Full 125CF | DOT

- RX WELD Argon Regulator Flowmeter Gas Gauge for Mig Tig

- 80 cu/ft 100% Argon Cylinder Tank Welding Gas CGA 580

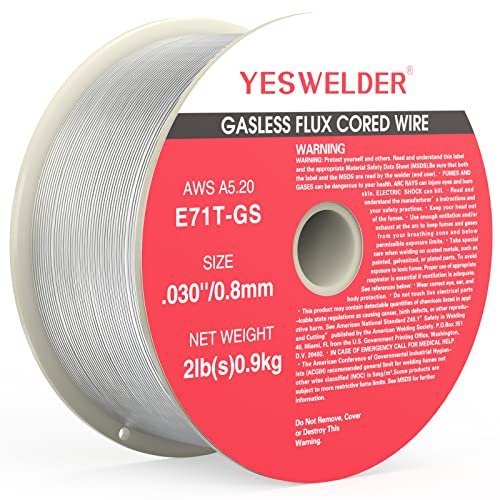

- YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon

- Gas for Mig Welding: Comparison Insights

- Final Verdict

- Best Gas for Mig Welding: Your Top Questions Answered

- Q1: What is the best gas for MIG welding mild steel?

- Q2: Can I use 100% Argon for MIG welding steel?

- Q3: When should I use 100% Argon for MIG welding?

- Q4: Is it better to buy or rent a MIG welding gas cylinder?

- Q5: Can I MIG weld without any shielding gas?

- Q6: What’s the difference between different cylinder sizes (e.g., 40 cu/ft vs. 125 cu/ft)?

- Q7: What is the role of an Argon regulator in MIG welding?

PrimeWeld 75% Argon 25% CO2 Bottle 125CF | DOT 3AA

This PrimeWeld tank is a fantastic choice for anyone serious about their MIG welding, offering the highly versatile 75% Argon and 25% CO2 blend. It’s designed to be delivered right to your door, which is a huge convenience, especially if you’re tired of high rental fees or inconvenient trips to the welding supply shop. This blend is often called C25 and is considered the gold standard for welding mild steel and even some nonferrous metals, providing excellent arc stability and controlled spatter.

Key features that stand out:

– Welding Gas to Your Door: Industrial grade gas cylinder delivered, avoiding costly rental fees.

– DOT 3AA Certified: Arrives full, fully certified, and 10-year date stamped for easy refills.

– Best Gas for MIG: Optimized blend for mild steel and nonferrous metals, ensuring arc stability and reduced spatter.

– No Costly Fees: Low ownership cost compared to traditional leasing agreements.

Pros:

– Convenience of direct delivery

– Avoids ongoing rental fees

– Excellent all-purpose blend for MIG welding

– Certified and ready to use

Cons:

– Might be a larger initial investment than renting a smaller tank.

Best for: Welders who frequently work with mild steel and want the convenience of owning their cylinder without recurring rental costs.

Expert Opinion: The 75% Argon / 25% CO2 mixture is undeniably the most popular and effective shielding gas for general-purpose MIG welding on carbon steel. Its balance provides deep penetration from the CO2 and a smooth arc from the Argon, making it incredibly versatile for various thicknesses.

80 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

For those needing a solid, mid-sized option for their MIG welding projects, this 80 cu/ft cylinder with the classic 75% Argon and 25% CO2 blend is a great pick. It comes full and ready to tackle mild steel, offering reliable performance. The tank is built to meet industry standards, ensuring it’s safe and widely accepted for refills at most welding supply stores.

Key features that stand out:

– Certified Cylinder: Comes with a 10-year hydrotest date stamped and meets DOT/ISO regulations.

– Ready to Use: Arrives full and is guaranteed to be within two years of its stamped date.

– Standard MIG Blend: Contains the popular 75% Argon 25% CO2 mixture for effective steel welding.

Pros:

– Reliable and industry-standard gas blend

– Convenient size for hobbyists and smaller shops

– Certified for safety and refills

Cons:

– Shipping is restricted to the Continental US.

Best for: Hobbyist welders or small workshops needing a dependable supply of C25 gas for mild steel without needing the largest tank available.

Expert Opinion: An 80 cu/ft tank is a practical size for many home and small shop users. It offers a good balance between capacity and portability, meaning fewer trips for refills while still being manageable to transport if needed.

Generic, 60 cuft 75 Argon 25 CO2 Welding Gas Cylinder Tank

This 60 cu/ft cylinder offers another excellent choice for the popular 75% Argon and 25% CO2 MIG blend. It’s a slightly more compact option than the 80 cu/ft, making it ideal for those with less storage space or who only weld occasionally. Like its larger counterparts, it arrives filled and ready for use, adhering to important ISO regulations for quality and safety.

Key features that stand out:

– ISO Certified: Tank meets ISO9809-1 USA standards and comes with a 10-year hydrotest date.

– Compact Size: 60 cu/ft capacity, perfect for hobbyists or light-duty applications.

– Comes Full: Cylinder arrives pre-filled with the versatile 75% Argon 25% CO2 mixture.

Pros:

– Ideal for portability and smaller spaces

– Comes ready to weld with popular gas blend

– ISO certified for quality assurance

Cons:

– Only ships within the Continental US, limiting availability.

Best for: Beginners, hobbyists, or mobile welders who need a compact, ready-to-use cylinder for mild steel fabrication.

Expert Opinion: Smaller cylinders like this 60 cu/ft option are fantastic for starting out or for those with limited welding projects. While the gas won’t last as long as a 125 cu/ft tank, the convenience and lower initial cost can be very appealing.

40 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

This 40 cu/ft cylinder provides the same reliable 75% Argon and 25% CO2 shielding gas in an even more compact form factor. It’s perfect for very light welding tasks, occasional use, or situations where extreme portability is key. Despite its smaller size, it still meets important DOT and ISO standards and comes hydrotested, ensuring safety and compatibility for refills.

Key features that stand out:

– Highly Portable: Small 40 cu/ft size is easy to transport and store.

– Certified Quality: Meets DOT and/or ISO regulations with a 10-year hydrotest date.

– Ready-to-Weld: Arrives filled with the versatile 75% Argon 25% CO2 blend.

Pros:

– Extremely portable and easy to manage

– Great for small, intermittent projects

– Industry-certified for peace of mind

Cons:

– The smaller capacity means more frequent refills for regular use.

Best for: Very light-duty welders, those needing maximum portability, or for specialized small projects where larger tanks are impractical.

Expert Opinion: A 40 cu/ft tank is truly for the most occasional user or for very specific, small-scale jobs. It’s a convenient entry point for owning your gas cylinder, but you’ll find yourself refilling it often if you do any significant amount of welding.

125 cu/ft 75% Argon 25% CO2 Welding Gas Cylinder Tank

If you’re looking for a substantial supply of the highly effective 75% Argon and 25% CO2 blend, this 125 cu/ft cylinder is a robust choice. It offers the same generous capacity as the PrimeWeld option but from a generic source, making it a strong contender for those who prefer to own their large-capacity tanks. It arrives full and certified to high standards, ready to support extensive MIG welding projects on mild steel.

Key features that stand out:

– Large Capacity: Generous 125 cu/ft supply reduces refill frequency.

– Industry Compliant: Meets DOT and/or ISO regulations and comes with a 10-year hydrotest stamp.

– Full & Ready: Delivered filled with the common 75% Argon 25% CO2 mixture.

Pros:

– Excellent capacity for continuous welding

– Industry-standard certification

– Comes full and ready for immediate use

Cons:

– Its size can make it less portable and require more storage space.

Best for: Dedicated hobbyists or small fabrication shops with ongoing mild steel MIG welding projects, looking to minimize refill trips.

Expert Opinion: A 125 cu/ft cylinder is a workhorse for many welders. It provides enough gas for numerous projects without constant worrying about running out, making it an economical choice in the long run if you weld frequently.

New 60 cu ft Steel Argon Gas Cylinder with CGA580

Unlike the other tanks that arrive pre-filled, this 60 cu/ft cylinder is an empty tank, ready for you to fill with the specific gas you need. It comes DOT approved and features a durable, thick-walled steel construction, ensuring it can withstand demanding work environments. The installed CGA580 valve is standard for inert gases like Argon, making it a perfect vessel for 100% Argon for TIG welding or MIG welding aluminum, or even a custom Argon/CO2 mix if filled locally.

Key features that stand out:

– DOT Approved: Certified for safe use and refilling.

– Quality Construction: Thick-walled steel tank designed for durability.

– CGA580 Valve: Pre-installed valve suitable for Argon and other inert gases.

– 60 cu ft Capacity: A good medium size for various applications.

Pros:

– Own your tank, avoiding rental fees

– High-quality, durable construction

– Versatile for filling with different gases (Argon, Ar/CO2)

Cons:

– It arrives empty, requiring an additional trip for filling before use.

Best for: Welders who prefer to own their cylinders and need a durable tank to be filled with 100% Argon for TIG or aluminum MIG, or their preferred Ar/CO2 blend for steel MIG.

Expert Opinion: Purchasing an empty cylinder offers great long-term value as you avoid all rental fees. This 60 cu/ft tank is a good choice for those who want to commit to owning their gas supply, just be sure to factor in the cost and logistics of its first fill.

PrimeWeld 100% Argon Gas Welding Tank Full 125CF | DOT

While primarily known as the best gas for TIG welding, 100% Argon also plays a crucial role in MIG welding, especially when working with aluminum. This PrimeWeld 125CF tank arrives full and ready to go, just like its 75/25 CO2 counterpart, offering the same convenience of direct delivery and no rental fees. Pure Argon ensures a very stable arc and excellent puddle control, crucial for quality welds on reactive metals.

Key features that stand out:

– Direct Delivery: Industrial grade 100% Argon gas cylinder delivered to your door.

– DOT 3AA Certified: Arrives full, fully certified, and 10-year date stamped.

– Best Gas for TIG & Aluminum MIG: Provides an inert environment and stable arc for precise welding.

– No Costly Fees: Low ownership cost eliminates high leasing fees.

Pros:

– Ideal for TIG welding and MIG welding aluminum

– Convenience of direct delivery

– Avoids ongoing rental fees

– Certified and ready to use

Cons:

– Not suitable for general-purpose mild steel MIG welding.

Best for: Welders focusing on TIG applications, or those performing MIG welding on aluminum or other reactive metals.

Expert Opinion: Pure Argon is essential for any welding application where contamination is a concern, such as TIG welding or MIG welding aluminum. Its inert nature prevents oxidation and ensures a clean, stable arc. Using 100% Argon on steel with MIG, however, will result in an undesirable, ropey bead and inadequate penetration.

RX WELD Argon Regulator Flowmeter Gas Gauge for Mig Tig

While not a gas itself, a high-quality regulator and flowmeter like the RX WELD unit are absolutely essential for using any shielding gas effectively in MIG or TIG welding. This device connects to your CGA-580 tanks (Argon, Helium, CO2) and precisely controls the gas flow, ensuring optimal weld quality and preventing gas waste. Its robust brass construction means it’s built to last in tough workshop conditions.

Key features that stand out:

– CGA-580 Compatibility: Easily attaches to standard Argon, Helium, and CO2 tanks.

– Accurate Flow Control: Adjustable from 10 to 60 cfh for precise gas metering.

– Durable Construction: Made from high-quality brass to withstand harsh environments.

– Complete Kit: Includes regulator, 6.6ft hose, hose clamp, and mounting nut.

Pros:

– Essential for precise gas flow in MIG/TIG welding

– Compatible with common shielding gas tanks

– Durable and well-made components

– Comes with useful accessories

Cons:

– Requires careful handling to avoid damage to gauges.

Best for: Any welder using shielding gas for MIG or TIG, needing accurate and reliable control over gas flow for optimal weld quality.

Expert Opinion: A good regulator is as crucial as the gas itself. Without proper flow control, you’ll either waste gas or suffer from poor shielding, leading to porosity and contamination. This type of flowmeter, with its ball indicator, provides excellent visual confirmation of your gas flow rate.

80 cu/ft 100% Argon Cylinder Tank Welding Gas CGA 580

This 80 cu/ft 100% Argon cylinder provides a ready-to-use supply of pure Argon for specific MIG and TIG welding needs. It’s a versatile option for those who frequently weld aluminum with MIG or perform TIG welding, offering a mid-range capacity that balances frequent use with manageable size. The tank meets all necessary DOT and ISO regulations, ensuring safe and reliable operation.

Key features that stand out:

– Pure Argon Supply: 100% Argon gas for aluminum MIG and TIG welding.

– Mid-Size Capacity: 80 cu/ft is a good balance for regular, but not constant, use.

– Certified & Stamped: Meets DOT/ISO regulations with a 10-year hydrotest date.

– Comes Full: Ready for immediate use upon arrival.

Pros:

– Ideal for aluminum MIG and TIG welding

– Good capacity for diverse projects

– Industry-standard certification for safety

Cons:

– Less effective for general mild steel MIG welding.

Best for: Welders who primarily focus on aluminum MIG welding or TIG welding projects, looking for a reliable and certified source of pure Argon.

Expert Opinion: Having a dedicated 100% Argon tank is a must for certain applications. An 80 cu/ft size is a practical choice for workshops that perform a moderate amount of TIG or aluminum MIG welding.

YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon

Sometimes, the best gas for MIG welding is no gas at all! This YESWELDER Flux Core Gasless MIG Wire is an excellent solution for welders who need portability or work in outdoor, windy conditions where shielding gas would be blown away. This self-shielding wire creates its own protective atmosphere as it burns, eliminating the need for an external gas cylinder. It’s especially useful for welding mild carbon steel and delivers good performance with low spatter and easy slag removal.

Key features that stand out:

– E71T-GS Flux Core Wire: Self-shielding design eliminates the need for external gas.

– Excellent Performance: Produces low spatter, easy slag removal, and porosity-free deposits.

– Versatile Applications: Ideal for outdoor windy conditions and all-position welding.

– Robust Spool: Supplied on a durable ABS plastic spool for reliable feeding.

Pros:

– No shielding gas required, enhancing portability

– Excellent for outdoor or windy environments

– Good performance on mild carbon steel

– Durable spool design

Cons:

– Produces more slag and spatter than gas-shielded MIG and can create more fumes.

Best for: Welders needing to work outdoors, in windy conditions, or those prioritizing portability and gasless operation for mild steel projects.

Expert Opinion: Flux-cored wire like this is a game-changer for gasless MIG welding, particularly for field work or situations where managing a gas cylinder isn’t feasible. While it generally requires a bit more cleanup than gas-shielded MIG, its ability to weld through light rust and paint with deep penetration is a significant advantage.

Gas for Mig Welding: Comparison Insights

When choosing the best gas for MIG welding, it really boils down to your specific needs. For general mild steel fabrication, the 75% Argon / 25% CO2 blend is the undisputed champion. You’ll find options from PrimeWeld and other generics in various sizes like 125 cu/ft, 80 cu/ft, 60 cu/ft, and 40 cu/ft, catering to everything from heavy-duty work to small hobby projects. The 125 cu/ft tanks offer the best value for frequent welders, reducing the hassle of constant refills, while the smaller tanks are excellent for portability or occasional use.

If you’re delving into MIG welding aluminum or doing any TIG welding, then 100% Argon is non-negotiable. PrimeWeld and other brands offer full 100% Argon tanks in sizes like 125 cu/ft and 80 cu/ft. Remember, you cannot effectively MIG weld steel with 100% Argon; it’ll result in a poor, ropey bead.

Don’t forget the accessories! A reliable Argon regulator and flowmeter is crucial for optimizing your gas use, ensuring consistent welds and preventing waste, regardless of the gas type you choose. And for those times when gas just isn’t an option, or you need maximum portability, flux-cored wire like the YESWELDER offering is an ingenious alternative, eliminating the need for any shielding gas at all.

Finally, consider ownership versus rental. Brands like PrimeWeld emphasize owning your tank to avoid costly long-term rental fees, which can be a significant saving for regular welders. However, if you opt for an empty cylinder, factor in the trip to your local gas supplier for the initial fill.

Final Verdict

Deciding on the best gas for MIG welding isn’t a one-size-fits-all answer; it’s a strategic choice based on your specific welding tasks, materials, and workflow.

For the vast majority of MIG welders working with mild steel, a 75% Argon / 25% CO2 (C25) blend is your go-to. If you weld frequently and value convenience, the PrimeWeld 75% Argon 25% CO2 Bottle 125CF stands out for its direct delivery and ownership model, making it a strong contender for the overall best. For lighter use or portability, the 80 cu/ft or 60 cu/ft generic C25 tanks are excellent, cost-effective alternatives.

If your projects involve aluminum MIG welding or any TIG welding, then 100% Argon is essential. The PrimeWeld 100% Argon Gas Welding Tank Full 125CF offers the same great ownership benefits for these specialized applications.

And remember, whether you’re using C25 or 100% Argon, a good RX WELD Argon Regulator Flowmeter is an indispensable tool to ensure precise gas delivery and optimal weld quality. For situations where gas isn’t practical, the YESWELDER Flux Core Gasless MIG Wire provides a powerful, portable solution.

Ultimately, assess your primary material, the frequency of your welding, and your budget for the initial cylinder purchase versus long-term rental fees. Making an informed choice here will significantly improve your welding results and overall experience.

Best Gas for Mig Welding: Your Top Questions Answered

Q1: What is the best gas for MIG welding mild steel?

A1: For mild steel, the best gas for MIG welding is overwhelmingly a blend of 75% Argon and 25% Carbon Dioxide (CO2), often referred to as C25. This mixture provides excellent arc stability, good penetration, and manageable spatter, making it versatile for various thicknesses and applications.

Q2: Can I use 100% Argon for MIG welding steel?

A2: While 100% Argon is used for MIG welding aluminum, it’s generally not recommended for MIG welding steel. Using pure Argon on steel will result in a very narrow, ropey bead with poor penetration and an unstable arc, leading to weak and aesthetically unpleasing welds. The CO2 component in a C25 mix is crucial for proper penetration and arc characteristics on steel.

Q3: When should I use 100% Argon for MIG welding?

A3: 100% Argon is the best gas for MIG welding aluminum, stainless steel (though often with a small percentage of Helium or CO2 for stainless), and other non-ferrous, reactive metals. It provides a clean, inert shielding environment necessary for these materials and is also the standard for TIG welding across all materials.

Q4: Is it better to buy or rent a MIG welding gas cylinder?

A4: This depends on how frequently you weld and your budget. Owning a gas cylinder like those from PrimeWeld typically has a higher upfront cost but eliminates ongoing rental fees, which can save you money in the long run if you weld regularly. Renting might be better for very occasional welders, but rental fees can add up quickly over time. Owning also gives you more flexibility on where you refill.

Q5: Can I MIG weld without any shielding gas?

A5: Yes, you can MIG weld without shielding gas by using flux-cored wire (FCAW-S), such as the YESWELDER Flux Core Gasless MIG Wire reviewed above. This wire contains a flux within its core that creates a gas shield as it burns, eliminating the need for an external gas cylinder. It’s excellent for outdoor or windy conditions and for portability but generally produces more spatter and slag than gas-shielded MIG.

Q6: What’s the difference between different cylinder sizes (e.g., 40 cu/ft vs. 125 cu/ft)?

A6: The cubic foot (cu/ft) measurement refers to the volume of gas the cylinder holds. Larger cylinders like 125 cu/ft hold significantly more gas, meaning fewer trips for refills, making them ideal for frequent welders or larger projects. Smaller cylinders like 40 cu/ft or 60 cu/ft are more portable and have a lower initial cost, making them suitable for hobbyists, occasional use, or mobile welding applications. The best gas for MIG welding choice often comes down to balancing capacity with portability and budget.

Q7: What is the role of an Argon regulator in MIG welding?

A7: An Argon regulator, like the RX WELD unit, is a critical component that attaches to your gas cylinder. It reduces the high pressure of the gas in the tank to a usable working pressure for your welding machine. More importantly, it features a flowmeter that precisely controls the rate at which shielding gas flows out to your MIG gun (measured in Cubic Feet per Hour, or CFH). Proper gas flow is essential for ensuring your weld puddle is adequately shielded from atmospheric contamination, preventing porosity and ensuring a clean, strong weld.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.