When I first started modifying my 12-valve Cummins, I quickly realized that the factory cluster offered almost zero vital information—you absolutely need to know your EGT (Exhaust Gas Temperature), boost, and fuel pressure if you plan on running these engines hard. After installing and testing countless setups, I put together this comprehensive guide covering the best gauges for 12 valve cummins, including full kits, essential adapters, and critical maintenance tools that ensure long-term engine health and maximum power output.

Contents

- GlowShift Diesel Gauge Package Compatible with Dodge Ram Cummins First Gen 1986-1993 – Black 7 Color 60 PSI Boost, 1500 F Pyrometer EGT & 30 PSI Fuel Pressure Gauges – Black Triple Pillar Pod

- Lang Tools 3079 Master Feeler Gauge Set for Heavy-Duty Truck Valve Adjustment, One Size

- GlowShift Fuel Pressure Snubber Valve Sensor Adapter Compatible with 12-Valve & 24V 5.9L 6.7L Dodge Ram 2500 3500 Cummins Diesel – 1/8-27 NPT Threads – Installs to Fuel Filter Housing

- GlowShift Water Coolant Temperature Sensor T-Fitting Adapter Compatible with Dodge Ram 12-Valve Cummins 1994-1998 – 1/8-27 NPT Sensor Port – Includes Hose Clamps

- GlowShift Fuel Pressure Banjo Bolt Sensor Thread Adapter Compatible with P7100 12-Valve Dodge Ram 2500 3500 Cummins Diesel 1994-1998 – Installs to Fuel Filter Housing – Includes Crush Washers

- Fuel Injection Pump Overflow Valve – Check Valve Compatible with 1994-1998 Dodge Ram Cummins 6BT 6B P7100 Pump 12-Valve 5.9L 2500 3500 OFV010 OFV020 4761307 4883838AA

- Camoo 3163530 Engine Brake Adjustment Tools 7MM for Cummins ISX Engine Jake Brake Feeler Gauge (7MM – 3163530)

- GlowShift Fuel Pressure Big Line Kit Compatible with Dodge Ram 2500 3500 12-Valve P-Pump Cummins 1994-1998 – Upgrades Fuel Line Size – Includes Rubber Hose, T-Fitting Adapter & Fittings

- KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

- maXpeedingrods Billet Aluminum Tappet Cover for 5.9L 12V 24V Cummins Diesel, for Dodge Ram 1500 2500 3500 Dual Port 1989-2002 VE44 P7100 Pumps

- Comparison and Practical Insights

- Final Verdict: Our Top Recommendation for Critical Monitoring

- Common Questions About best gauges for 12 valve cummins

- How accurate do my EGT and boost gauges need to be for a modified 12V?

- Where is the best location to install the EGT probe on a 12V Cummins?

- What fuel pressure should I maintain on my P7100 12-valve engine?

- Can I use mechanical gauges instead of electronic ones for boost and fuel pressure?

- What essential maintenance gauge is needed besides the dashboard instruments?

- Are gauge pillar pods or dash mounts better for 12-valve visibility?

GlowShift Diesel Gauge Package Compatible with Dodge Ram Cummins First Gen 1986-1993 – Black 7 Color 60 PSI Boost, 1500 F Pyrometer EGT & 30 PSI Fuel Pressure Gauges – Black Triple Pillar Pod

This GlowShift kit is a fantastic, all-in-one monitoring solution specifically designed for the older 1st Gen Cummins truck. If you’re looking for a quick and professional way to monitor the three most critical parameters (boost, EGT, and fuel pressure) without hunting down individual parts, this package delivers. The included pillar pod provides a factory-style mounting location, keeping your gauges easily visible while maintaining a clean interior aesthetic. This kit significantly simplifies the installation process for vital diesel engine monitoring.

Key features that stand out:

– Comprehensive Kit: Includes Boost, EGT (Pyrometer), and Fuel Pressure gauges.

– Color Customization: Features 7 solid color modes, allowing you to match your dash lighting or pick a custom look.

– Included Adapters: Comes with the necessary Banjo Bolt/Snubber Valve adapter for fuel pressure, simplifying the install on the sensitive P7100 fuel system.

Pros:

– Complete package minimizes sourcing issues.

– Integrated pillar pod for clean installation.

– 7-color display offers great visibility in various lighting conditions.

– Necessary diesel-specific sensors are included.

Cons:

– Wiring harness management requires patience during installation.

Best for: 1st Generation Cummins owners (1986-1993) seeking a turn-key monitoring solution.

Expert Opinion: This kit is highly valued for its completeness. The inclusion of the fuel pressure snubber/banjo combo is critical for stabilizing readings on the 12v engine, making it one of the most reliable best gauges for 12 valve cummins setups right out of the box.

Lang Tools 3079 Master Feeler Gauge Set for Heavy-Duty Truck Valve Adjustment, One Size

While not a dashboard gauge, a feeler gauge set is arguably one of the most important “gauges” a 12-valve owner can possess. These engines require routine valve adjustments, and precise clearance settings are crucial for optimal performance, efficiency, and longevity. This Lang Tools set is specifically tailored for heavy-duty truck applications, offering the exact range needed for intake and exhaust valve adjustments on the Cummins engine. Regular use of a quality feeler gauge prevents costly engine damage.

Key features that stand out:

– Application Specific: Range of .008″ to .030″ covers Cummins heavy-duty applications.

– Color-Coded Handles: Light blue for intake, red for exhaust, simplifying the critical adjustment process.

– Made in the USA: Assures high quality and precision manufacturing.

Pros:

– Designed specifically for heavy-duty truck valve adjustments.

– Durable construction expected of professional shop tools.

– Easy identification through color coding.

Cons:

– Primarily useful only for internal engine maintenance, not daily monitoring.

Best for: Serious 12-valve maintenance enthusiasts and professional diesel technicians.

Expert Opinion: You can buy the best gauges for 12 valve cummins for monitoring, but if the valves aren’t adjusted correctly using a tool like this, performance will suffer. This set is rugged and offers the precise measurements required for 12V maintenance schedules.

GlowShift Fuel Pressure Snubber Valve Sensor Adapter Compatible with 12-Valve & 24V 5.9L 6.7L Dodge Ram 2500 3500 Cummins Diesel – 1/8-27 NPT Threads – Installs to Fuel Filter Housing

Monitoring fuel pressure is paramount for protecting your 12-valve’s injection pump, especially the P7100. However, the fuel system is prone to extreme pressure pulsations, particularly during startup and hard acceleration, which can quickly destroy standard fuel pressure sensors. This GlowShift Snubber Valve acts as a buffer, regulating and normalizing these pressure spikes, ensuring your pressure gauge sensor gets stable, accurate readings, and significantly extending the life of the sensor itself. This small component is essential for long-term fuel pressure gauge accuracy.

Key features that stand out:

– Stabilizes Readings: Eliminates fuel pressure spikes and pulsations.

– Sensor Protection: Protects sensitive electronic pressure sensors from damage.

– Wide Compatibility: Works across 12-valve, 24-valve, and 6.7L Cummins engines.

Pros:

– Crucial for accurate and sustained fuel pressure monitoring.

– Affordable insurance against sensor failure.

– Easy installation at the fuel filter housing.

Cons:

– Must be used in conjunction with a separate pressure sensor and gauge.

Best for: Anyone installing an electronic fuel pressure gauge on a Cummins engine.

Expert Opinion: Never skip the snubber valve on a P7100 truck. Without it, even the best gauges for 12 valve cummins systems will eventually fail or provide jumpy readings. This is a non-negotiable part of a proper fuel pressure setup.

GlowShift Water Coolant Temperature Sensor T-Fitting Adapter Compatible with Dodge Ram 12-Valve Cummins 1994-1998 – 1/8-27 NPT Sensor Port – Includes Hose Clamps

Monitoring engine coolant temperature accurately requires placing the sensor directly in the coolant flow, typically by tapping into a hose. This T-Fitting Adapter is designed specifically for the 1994-1998 12-valve Cummins, allowing you to install a temperature sensor into the thermostat bypass hose. This method provides direct, real-time temperature readings, which is much more reliable than relying on the factory sensor location. The inclusion of sturdy hose clamps ensures a leak-free installation.

Key features that stand out:

– Accurate Placement: Installs directly into the coolant line (thermostat bypass hose).

– Leak-Free Design: Includes two hose clamps for secure mounting.

– NPT Port: Standard 1/8-27 NPT thread for most aftermarket sensors.

Pros:

– Provides extremely accurate temperature data.

– Simple inline installation.

– Specifically sized for the 2nd Gen 12V coolant hoses.

Cons:

– Requires cutting a coolant hose for installation.

Best for: Adding an aftermarket coolant temperature gauge for performance monitoring or towing applications.

Expert Opinion: This T-fitting removes the guesswork from sensor placement. For those upgrading from the basic factory idiot light, pairing this adapter with a quality temperature gauge offers true peace of mind, especially when hauling heavy loads.

GlowShift Fuel Pressure Banjo Bolt Sensor Thread Adapter Compatible with P7100 12-Valve Dodge Ram 2500 3500 Cummins Diesel 1994-1998 – Installs to Fuel Filter Housing – Includes Crush Washers

For owners of the 1994-1998 P7100 12-valve, tapping into the fuel system for gauge readings can be complicated. This specialized Banjo Bolt Adapter replaces the factory banjo bolt on the fuel filter housing, offering a clean 1/8-27 NPT port for installing your fuel pressure sensor. This method is preferred by many mechanics as it provides an accurate reading point without requiring major modifications to the fuel lines. The kit includes the crucial crush washers needed for a leak-free seal.

Key features that stand out:

– Direct Replacement: Replaces the existing factory banjo bolt.

– Clean Tap Point: Provides a secure 1/8-27 NPT port for sensor installation.

– Leak Prevention: Comes with two crush washers tailored for the P7100 system.

Pros:

– Very clean and secure way to tap the fuel pressure system.

– Designed specifically for the P7100 pump on 12V models.

– Instructions are straightforward.

Cons:

– Requires careful torque specification during installation to prevent leaks.

Best for: Owners installing a fuel pressure gauge who prefer using a Banjo Bolt location on the P7100 injection pump.

Expert Opinion: This adapter is essential if you don’t use a full kit that provides a similar solution. When selecting best gauges for 12 valve cummins monitoring, the method of sensor installation matters as much as the gauge quality, and this banjo bolt method is highly reliable.

Fuel Injection Pump Overflow Valve – Check Valve Compatible with 1994-1998 Dodge Ram Cummins 6BT 6B P7100 Pump 12-Valve 5.9L 2500 3500 OFV010 OFV020 4761307 4883838AA

The overflow valve, while not a monitoring gauge, directly influences the reading displayed on your fuel pressure gauge. If this valve fails or wears out, it allows fuel pressure to drop below critical levels, which can starve the P7100 pump, leading to poor performance and damage—and your fuel pressure gauge will accurately reflect this failure. Replacing a weak overflow valve with a quality direct-replacement unit restores proper fuel pressure regulation, ensuring that the readings on your dashboard gauges are within the safe operating range. This is a preventative maintenance component that ensures accurate fuel pressure readings.

Key features that stand out:

– Restores Fuel Pressure: Critical for maintaining the required base pressure for the P7100 pump.

– Direct Replacement: Matches multiple OEM and cross-reference part numbers.

– Complete Kit: Includes necessary washers for installation.

Pros:

– Essential for P7100 pump longevity.

– Relatively inexpensive maintenance item.

– Directly impacts the reliability of fuel pressure monitoring.

Cons:

– Often overlooked until pressure drops significantly.

Best for: P7100 12V owners experiencing low fuel pressure readings despite having a functional fuel pressure gauge.

Expert Opinion: If your fuel pressure gauge shows a decline, check this component immediately. A functioning overflow valve is crucial for verifying that your best gauges for 12 valve cummins are reflecting healthy system operation, not just a system struggling due to worn parts.

Camoo 3163530 Engine Brake Adjustment Tools 7MM for Cummins ISX Engine Jake Brake Feeler Gauge (7MM – 3163530)

This specialized feeler gauge tool is designed for precise adjustment of the engine brake (Jake Brake) on the Cummins ISX engine. While the ISX is distinct from the 12-valve 5.9L, this item highlights the range of precise measuring tools necessary within the Cummins heavy-duty lineup. It features an angled design, which is a major advantage for accessing tight spots and ensuring accurate clearance between the slave piston and the exhaust valve adjusting screw. Accurate engine brake adjustment is critical for safety and system longevity.

Key features that stand out:

– Angled Design: Allows for easier and more accurate insertion in restricted spaces.

– Precision Ground: Ensures highly accurate 7.0MM measurement (+/- .0005 inch tolerance).

– Prevents Catastrophic Failure: Crucial for maintaining engine noise levels and optimum performance.

Pros:

– Extremely high precision and durability.

– Unique angled shape enhances usability.

– A must-have for ISX engine maintenance.

Cons:

– Highly specialized tool; limited use for standard 5.9L 12V owners (unless they also service ISX engines).

Best for: Professional mechanics or fleet operators maintaining Cummins ISX engines requiring engine brake adjustment.

Expert Opinion: This type of specialized feeler gauge showcases that “gauges” go beyond dashboard meters. For specific heavy-duty applications, precise adjustment tools like the 7mm shim are required to keep complex systems running smoothly.

GlowShift Fuel Pressure Big Line Kit Compatible with Dodge Ram 2500 3500 12-Valve P-Pump Cummins 1994-1998 – Upgrades Fuel Line Size – Includes Rubber Hose, T-Fitting Adapter & Fittings

The factory fuel lines on the 12-valve can be restrictive, especially when performance modifications increase fuel demand. This “Big Line” kit upgrades the fuel line diameter to 3/8″, significantly improving fuel flow and stabilizing fuel pressure delivery to the injection pump. It also includes a barbed T-Fitting with an NPT port, which can be used to install your fuel pressure sensor. By ensuring less restrictive flow, this kit improves the performance and accuracy of your fuel pressure monitoring.

Key features that stand out:

– Increased Flow: Upgrades line size to 3/8″ inner diameter.

– Integrated Tap Point: Includes a T-fitting adapter with a 1/8-27 NPT port for a sensor.

– Complete Hardware: Comes with the necessary hose clamps and AN adapters.

Pros:

– Reduces potential fuel starvation issues.

– Provides a convenient, high-quality pressure sensing location.

– Increases overall fuel system reliability under load.

Cons:

– Requires more extensive modification than a simple banjo bolt adapter.

Best for: Modified 1994-1998 12V P-Pump owners who need high fuel delivery and accurate pressure readings.

Expert Opinion: If you’ve upgraded the injectors or turbo on your P-pump, increasing fuel flow is necessary. This big line kit not only supports performance but also provides a sturdy tap location, ensuring the best gauges for 12 valve cummins pressure monitoring get the most stable possible signal.

KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

Maintaining the top end of the 12-valve often requires replacing valve springs, seals, or keepers. This specialized Valve Spring Compressor tool is designed specifically for the 5.9L 12-valve engine, allowing technicians or home mechanics to easily and safely compress the springs without removing the cylinder head. While this isn’t a gauge, it’s a crucial maintenance tool that often goes hand-in-hand with valve adjustments (where feeler gauges are used) and general engine upkeep required by owners who actively monitor their engine’s health. Proper valve maintenance is essential for performance indicated by boost and EGT gauges.

Key features that stand out:

– Application Specific: Designed only for the 5.9L 12-valve engine (1988-1998).

– Non-Head Removal: Allows maintenance to be performed without pulling the cylinder head.

– Durable Construction: Made from high-quality, corrosion-resistant metal.

Pros:

– Saves significant labor time and complexity during valve work.

– Ensures safe removal and installation of valve components.

– Essential for high-performance spring upgrades.

Cons:

– Very specific function; only useful for valve train service.

Best for: 12V owners upgrading valve springs or performing high-mileage cylinder head maintenance.

Expert Opinion: Tools like this compressor and the feeler gauges (Lang Tools, Camoo) are the unsung heroes of 12V ownership. You need the best gauges for 12 valve cummins monitoring systems, but you also need the right tools to maintain the engine components they monitor.

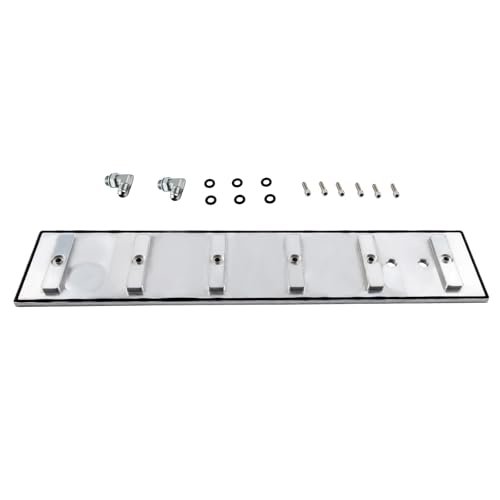

maXpeedingrods Billet Aluminum Tappet Cover for 5.9L 12V 24V Cummins Diesel, for Dodge Ram 1500 2500 3500 Dual Port 1989-2002 VE44 P7100 Pumps

The factory steel tappet cover is prone to corrosion and leaks. This maXpeedingrods replacement is made from billet aluminum, providing a much stronger, leak-resistant cover for the side of your block. It’s a dual-port design, offering versatility for either 12V or 24V applications. While primarily an aesthetic and protection upgrade, a sealed and healthy engine block contributes directly to consistent performance metrics reflected by your gauges (like ensuring no crankcase pressure issues affect engine health). The billet construction offers superior durability over the OEM part.

Key features that stand out:

– Billet Aluminum: Highly durable and corrosion-resistant construction.

– Dual Port: Versatile fitment for both 12V (VE44, P7100) and 24V (VP44) setups.

– Complete Kit: Includes stainless steel mounting bolts, fittings, and O-rings.

Pros:

– Addresses common oil leak issues associated with the factory cover.

– Significantly improves engine bay aesthetics.

– Easy installation with all necessary hardware provided.

Cons:

– Requires minor grinding for VP44 pump fitment (though unnecessary for P7100).

Best for: Owners looking for an aesthetic upgrade and permanent solution to factory tappet cover leaks.

Expert Opinion: While it doesn’t house gauges, this billet cover is a worthy upgrade for any engine you invest heavily in monitoring. Ensuring the engine is sealed and robust is the foundation upon which accurate gauge readings rely.

Comparison and Practical Insights

When looking for the best gauges for 12 valve cummins, you quickly realize the necessary components fall into two categories: Monitoring Hardware (dashboard gauges and sensors) and Maintenance Gauges/Tools (feeler gauges and specialized service tools).

- Monitoring Kits vs. Components: If you own a 1st Gen 12V, the GlowShift Diesel Gauge Package (Product 1) is a strong choice as it provides the critical triad (EGT, Boost, Fuel Pressure) and the necessary adapters. For 2nd Gen P7100 owners, you may prefer combining individual components like the GlowShift Snubber Valve (Product 3) and the Banjo Bolt Adapter (Product 5) with high-quality gauges of your choosing to build a custom system.

- Fuel Pressure Focus: Monitoring fuel pressure is arguably the most important task on a P7100 12V. You must include the Snubber Valve (Product 3) to protect the sensor and ensure readings are stable. Furthermore, if your pressure is consistently low, swapping out the Overflow Valve (Product 6) should be a priority before assuming your pressure gauge is faulty.

- Maintenance Essentials: Never overlook the need for internal measurement. The 12-valve requires precise valve adjustments. The Lang Tools Master Feeler Gauge Set (Product 2) is indispensable for ensuring the correct lash clearance, directly impacting engine efficiency that your boost and EGT gauges reflect.

Digital vs. Analog: Most of the modern best gauges for 12 valve cummins setups (like the GlowShift kits) are digital or electronic analog. Electronic sensors are generally more accurate than mechanical versions, particularly for EGT and boost, and they allow for safer routing of wires into the cab, rather than running high-pressure lines.

Final Verdict: Our Top Recommendation for Critical Monitoring

Choosing the absolute best gauges for 12 valve cummins setup depends entirely on your needs (stock vs. performance) and your truck generation.

For Maximum Protection and Simplicity on any 12V (especially 2nd Gen P-Pump models), we recommend a hybrid approach:

- Fuel System Protection: You absolutely must pair a quality electronic fuel pressure gauge with the GlowShift Fuel Pressure Snubber Valve Sensor Adapter (Product 3). This is the foundation of protecting your injection pump.

- Exhaust Monitoring: Invest in a high-quality EGT gauge (pyrometer) setup. EGT is the primary metric for saving your turbo and pistons during heavy towing or hard acceleration.

- Engine Health Maintenance: Own the Lang Tools 3079 Master Feeler Gauge Set (Product 2). Monitoring is vital, but routine maintenance using specialized measurement tools is the only way to guarantee the longevity that Cummins owners crave.

Common Questions About best gauges for 12 valve cummins

How accurate do my EGT and boost gauges need to be for a modified 12V?

For modified 12-valve Cummins engines, precision is paramount, especially for EGT (Pyrometer). An accurate EGT reading (within 50°F of true temperature) is necessary because exceeding 1250°F for sustained periods can melt pistons and warp the turbocharger. Boost gauges should be rated to handle pressures up to 60 PSI, which is common in highly modified 12V applications. Investing in quality electronic sensors over cheaper mechanical options provides the necessary stability and accuracy.

Where is the best location to install the EGT probe on a 12V Cummins?

The best gauges for 12 valve cummins monitoring will require sensor placement pre-turbocharger, ideally in the exhaust manifold. This placement provides the highest and most accurate real-time exhaust gas temperature reading, allowing you to react quickly to unsafe temperature spikes. Post-turbo readings are generally 200–300°F lower and do not provide sufficient warning time to prevent engine damage.

What fuel pressure should I maintain on my P7100 12-valve engine?

A healthy P7100 pump requires fuel pressure to be maintained, ideally, between 25 and 35 PSI at cruising speed. If your fuel pressure gauge shows readings consistently dropping below 20 PSI under load, you are risking pump failure due to lubrication starvation. This usually indicates a failing lift pump, weak overflow valve (like Product 6), or a fuel restriction.

Can I use mechanical gauges instead of electronic ones for boost and fuel pressure?

Yes, you can use mechanical gauges, but most owners prefer electronic best gauges for 12 valve cummins setups for safety and convenience. Mechanical boost gauges require running a boost reference line into the cabin, and mechanical fuel pressure gauges require routing a pressurized fuel line into the cab, which is a major fire hazard. Electronic gauges use sensors installed safely in the engine bay (often requiring a snubber valve for fuel pressure) and route only electrical wiring into the truck interior.

What essential maintenance gauge is needed besides the dashboard instruments?

The most essential maintenance “gauge” for a 12-valve Cummins is a high-quality feeler gauge set (like Product 2). Because the 12V uses mechanical tappets, the intake and exhaust valves must be adjusted every 15,000 miles (or as per your maintenance schedule). Failure to use accurate feeler gauges for these adjustments leads to poor performance, excessive engine noise, and potential valve train damage.

Are gauge pillar pods or dash mounts better for 12-valve visibility?

Pillar pods, such as those included with the GlowShift Gauge Package (Product 1), are generally preferred because they place the critical monitoring information directly in the driver’s peripheral view, minimizing the time your eyes are off the road. Dash mounts can be distracting or obstruct airflow, depending on placement.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.