I’ve been there – staring at a small, disheartening drip under my vehicle, knowing it was my gas tank. It’s a frustrating moment that often makes you think of costly repairs. But thankfully, a good JB Weld for gas tank repair can often save the day, and your wallet. Over the years, I’ve had my share of hands-on experience with different formulas, testing which ones truly hold up against the harsh realities of fuel, heat, and vibration. This guide will walk you through five reliable options, highlighting their strengths, so you can confidently pick the right solution for your leaky fuel tank.

Contents

- J-B Weld 8217 TankWeld Gas Tank Repair – 1 oz.,Dark…

- J-B Weld 2110 Metal Fuel Tank Repair Kit, Gray

- J-B Weld 8281 Professional Size Steel Reinforced Epoxy -…

- J-B Weld WaterWeld, 1 Hour Cure, Epoxy Putty Stick -…

- J-B Weld 8237 PlasticWeld Plastic Repair Epoxy Putty – 2…

- Helpful Comparison Insights

- Final Verdict

- Frequently Asked Questions About Best JB Weld For Gas Tank

- How do I prepare my gas tank surface before applying JB Weld?

- Is JB Weld a permanent fix for a gas tank leak?

- Can JB Weld be used on both metal and plastic gas tanks?

- How long does JB Weld take to cure on a gas tank?

- What if my gas tank leak is too large for JB Weld?

- Are there any safety precautions I should take when using JB Weld on a fuel tank?

J-B Weld 8217 TankWeld Gas Tank Repair – 1 oz.,Dark…

When you’ve got a metal gas tank leak and need a quick fix, this TankWeld putty is often my go-to. It’s incredibly user-friendly since it’s a hand-mixable epoxy putty that literally forms to the shape you need. I’ve used it on small pinholes and even slightly larger cracks on steel tanks, and it sets surprisingly fast, getting you back on the road without a lengthy waiting period. Its dark, steel-reinforced formula means it blends in well and creates a robust, non-rusting bond that can even be machined once fully cured.

Key features that stand out:

– Hand-mixable, steel-reinforced epoxy putty

– Great for gas tanks, radiators, and all metals

– Sets in 5 minutes, fully cures in 1 hour

– Tensile strength of 900 PSI

– Withstands temperatures up to 300ºF

Pros:

– Super fast setting and curing time, ideal for urgent repairs.

– Easy to use and mold by hand, no special tools needed.

– Provides a strong, permanent bond on metal surfaces.

– Can be drilled, tapped, and painted after curing.

Cons:

– Its quick set time means you have to work fast.

Best for: Rapid, on-the-spot metal gas tank repairs where time is critical.

Expert Opinion: This specific TankWeld is fantastic for its immediacy. It’s what you grab when you’ve got a minor metal tank issue and don’t want to wait around. Just make sure the surface is clean and dry for the best adhesion.

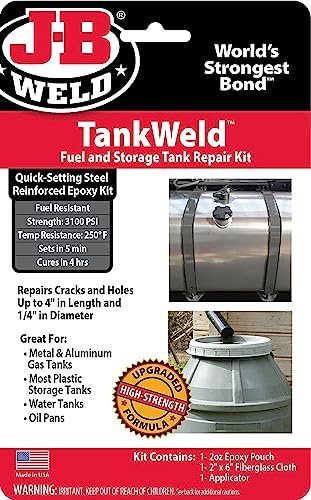

J-B Weld 2110 Metal Fuel Tank Repair Kit, Gray

If you’re facing a leak that feels a bit more substantial than a tiny pinhole, or you just want the peace of mind of a comprehensive solution, the J-B Weld Metal Fuel Tank Repair Kit is an excellent choice. This kit really takes the guesswork out of the repair process, providing everything you need from start to finish. I appreciate that it includes fiberglass cloth and sandpaper, which are crucial for preparing the surface and reinforcing larger repairs. Plus, the fact that you don’t have to remove the gas tank is a huge time and labor saver!

Key features that stand out:

– Complete kit for professional quality repairs

– No gas tank removal required

– Fixes holes up to 3/8″ diam. or cracks up to 4″ long

– Includes epoxy putty, fiberglass cloth, sandpaper, and applicator

– Versatile for gas tanks, metal tanks, and oil pan repairs

Pros:

– All-inclusive kit for tackling various leak sizes.

– Eliminates the need for tank removal, simplifying the job.

– Provides strong, permanent repairs on metal fuel tanks.

– Easy-to-follow instructions guide you through the process.

Cons:

– Requires a bit more prep and application time compared to a simple putty stick.

Best for: Repairing larger holes or cracks in metal gas tanks, or for those who prefer a complete, guided repair solution.

Expert Opinion: This kit is designed for durability and ease of use for more significant metal tank damage. The inclusion of fiberglass cloth is key here; it adds a layer of structural integrity that simple putty alone might not provide for larger breaches.

J-B Weld 8281 Professional Size Steel Reinforced Epoxy -…

The original J-B Weld formula is truly a legendary product, and this professional size offers more of that tried-and-true power. While it takes longer to cure than some of the specialized tank formulas, its unmatched tensile strength of 5020 PSI and incredible temperature resistance make it an absolute workhorse. I’ve used this on countless projects, and its ability to bond to almost any surface, including metal, plastic, and even fiberglass, makes it incredibly versatile. For a really robust, long-term repair on a metal gas tank, where patience isn’t an issue, this is a top contender.

Key features that stand out:

– Original cold weld two-part epoxy system

– Professional 5 oz tubes

– Tensile strength of 5020 PSI, stronger than steel

– Withstands temperatures up to 550°F (continuous)

– Waterproof and resistant to petroleum, chemical, and acid

– Bonds to Metal, Plastic & PVC, Wood, Concrete, Ceramic & Tile, Fiberglass

Pros:

– Extremely strong and durable, creating a bond stronger than steel.

– Highly resistant to extreme temperatures, chemicals, and acids.

– Versatile, works on a wide array of surfaces, not just metal.

– Large tubes offer more material for bigger or multiple jobs.

Cons:

– Has a longer set and cure time, requiring patience.

Best for: The strongest, most permanent repairs on metal gas tanks, especially when extreme durability and chemical resistance are paramount, and you have ample cure time.

Expert Opinion: The “Original” is a classic for a reason. While it’s slower, its bond strength and resistance to virtually everything make it ideal for a really tough, permanent repair. Just make sure you can secure the area for the full cure time without disturbance.

J-B Weld WaterWeld, 1 Hour Cure, Epoxy Putty Stick -…

Don’t let the name “WaterWeld” fool you; this epoxy putty stick is surprisingly versatile and can be an excellent option for fuel tanks, especially if you have a damp or even slightly weeping leak. The standout feature here is its ability to cure underwater, which translates to excellent performance in less-than-ideal, fuel-present environments (though I always recommend draining and cleaning a tank as much as possible for any repair!). It forms a strong, off-white bond that’s also safe for potable water, hinting at its impressive chemical resistance.

Key features that stand out:

– Hand-mixable two-part epoxy putty stick

– Cures under water

– Ideal for plumbing, fuel tanks, and potable water tanks

– Sets in 25 minutes, cures in 1 hour

– Lap shear strength of 1300 PSI

– Chemical resistant against petroleum and hydraulic fluids

Pros:

– Can be applied and cures effectively in damp or wet conditions.

– Good for emergency repairs where complete drying isn’t feasible.

– Strong bond with good chemical resistance to fuels.

– Relatively quick set and cure times.

Cons:

– Not specifically formulated only for fuel tanks, so ensure compatibility.

Best for: Gas tank repairs where the area might be damp, or for quick fixes needing good fuel resistance and a faster cure than the Original J-B Weld.

Expert Opinion: WaterWeld’s ability to cure in damp conditions is a huge advantage for tricky fuel tank leaks where it’s hard to get the area perfectly dry. Its resistance to petroleum makes it a viable, albeit less specialized, choice for gas tanks.

J-B Weld 8237 PlasticWeld Plastic Repair Epoxy Putty – 2…

Modern vehicles often use plastic gas tanks, and that’s where the J-B Weld PlasticWeld truly shines. Unlike metal tanks, plastic requires a specialized adhesive that can properly bond to its unique composition. This hand-mixable epoxy putty stick is specifically formulated for rigid and semi-flexible plastics, including ABS, PVC, and CPVC, which are common materials for fuel tanks and other automotive parts. It provides a durable, non-shrinking repair that can be molded, shaped, and even painted.

Key features that stand out:

– Hand-mixable two-part epoxy putty stick

– Formulated to repair and rebuild various plastic compounds and surfaces

– Ideal for ABS, PVC & CPVC pipes and plastics, auto bumpers, plastic water tanks

– Sets in 25 minutes, cures in 3 hours

– Lap shear strength of 600 PSI

– Does not shrink, can be molded, shaped, sanded, drilled, and cut

Pros:

– Specifically designed for bonding to and repairing plastics, including those used in gas tanks.

– Offers a strong, durable, and non-shrinking bond on plastic surfaces.

– Versatile for various plastic automotive and household repairs.

– Easy to mold and shape for custom applications.

Cons:

– Lower tensile strength compared to the metal-specific J-B Welds.

Best for: Repairing plastic gas tanks and other plastic automotive components where standard metal epoxies won’t properly bond.

Expert Opinion: For anyone dealing with a plastic fuel tank, this is your dedicated solution. Using a metal-focused epoxy on plastic often leads to a failed repair, so having a product specifically engineered for plastic is critical for a lasting fix.

Helpful Comparison Insights

When choosing the best JB Weld for gas tank repair, consider your tank’s material and how quickly you need the fix. For metal gas tanks, the J-B Weld 8217 TankWeld is your quickest option, setting in just 5 minutes, while the J-B Weld 2110 Metal Fuel Tank Repair Kit provides a more comprehensive solution for larger metal leaks. If you need the absolute strongest bond on metal and have time for a full cure, the J-B Weld 8281 Professional Size Original Epoxy is an outstanding choice.

If you’re dealing with a plastic gas tank, the J-B Weld 8237 PlasticWeld is the only product specifically formulated for that material, offering a strong, tailored bond. The J-B Weld WaterWeld, while not exclusively for gas tanks, offers versatility if you’re working in damp conditions or need decent fuel resistance with a faster cure than the Original, making it a viable alternative for either metal or some plastic applications if surface prep is challenging. Always match the product to your tank’s material for the most reliable outcome.

Final Verdict

Choosing the right JB Weld for gas tank repair boils down to the material of your tank and the urgency of the repair.

Our Top Pick for Metal Gas Tanks (General Use):

For most small to medium leaks on metal gas tanks, the J-B Weld 8217 TankWeld stands out for its rapid set time and reliable, steel-reinforced bond. It’s perfect for getting you out of a bind quickly.

Best for Comprehensive Metal Tank Repair:

If you have a more significant leak on a metal tank or prefer an all-in-one package, the J-B Weld 2110 Metal Fuel Tank Repair Kit is an excellent choice. It provides everything you need for a robust repair without having to remove the tank.

Best for Plastic Gas Tanks:

Without a doubt, for plastic gas tanks, the J-B Weld 8237 PlasticWeld is your specialist. It’s engineered to bond effectively with the various plastic compounds found in modern fuel tanks, ensuring a durable and lasting repair.

Remember, while these products offer impressive temporary and often long-term solutions, they are repairs. Always consider professional inspection or replacement for critical structural damage.

Frequently Asked Questions About Best JB Weld For Gas Tank

How do I prepare my gas tank surface before applying JB Weld?

Surface preparation is crucial for a lasting repair. First, ensure the tank is as empty as possible and allow any residual fuel to evaporate. Clean the area thoroughly with a degreaser or brake cleaner to remove all grease, oil, and dirt. Then, roughen the surface around the leak with sandpaper (often included in kits like the 2110). This creates a better anchor for the epoxy to bond to. Finally, wipe away any dust with a clean cloth.

Is JB Weld a permanent fix for a gas tank leak?

While J-B Weld products create an incredibly strong and durable bond, especially those formulated for fuel tanks, they are considered a high-quality repair rather than a complete tank replacement. Many users report long-term, permanent repairs with J-B Weld. However, factors like the size and location of the leak, proper surface preparation, and exposure to extreme conditions can influence its longevity. For peace of mind, always monitor the repaired area.

Can JB Weld be used on both metal and plastic gas tanks?

No, not all J-B Weld products are suitable for both materials. You must use the correct product for your tank’s material. The J-B Weld 8217 TankWeld and 2110 Metal Fuel Tank Repair Kit are specifically for metal tanks. For plastic gas tanks, you’ll need a specialized formula like the J-B Weld 8237 PlasticWeld, which is designed to bond to various plastic compounds. Using the wrong type of epoxy can lead to a failed repair.

How long does JB Weld take to cure on a gas tank?

Cure times vary significantly by product. The J-B Weld 8217 TankWeld sets in 5 minutes and fully cures in 1 hour. The J-B Weld WaterWeld sets in 25 minutes and cures in 1 hour. The J-B Weld 8237 PlasticWeld sets in 25 minutes and cures in 3 hours. The original J-B Weld 8281 Professional Size takes the longest, setting in 4-6 hours and fully curing in 15-24 hours. Always allow the full cure time before refilling your tank and exposing the repair to fuel pressure.

What if my gas tank leak is too large for JB Weld?

J-B Weld products are generally effective for small holes (up to 3/8″ diameter) and cracks (up to 4″ long), especially with a reinforcement like fiberglass cloth found in the 2110 Metal Fuel Tank Repair Kit. However, if the leak is very large, involves a seam, or the tank itself is heavily rusted or corroded in multiple spots, JB Weld may not be an adequate solution. In such cases, it’s best to consult a professional mechanic for welding, tank replacement, or a more extensive automotive repair.

Are there any safety precautions I should take when using JB Weld on a fuel tank?

Absolutely. Safety is paramount when working with fuel. Always ensure you are in a well-ventilated area to disperse any fuel fumes. Have a fire extinguisher readily available. Wear appropriate personal protective equipment, including gloves and safety glasses, to avoid skin and eye contact with the epoxy. Avoid open flames, sparks, or any ignition sources near the work area. Never attempt to repair a tank that is full of gasoline; drain it as much as possible and allow it to air out before beginning any repair work.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.