As someone who’s spent countless hours in the shop tackling various fabrication projects, I know firsthand the demands of welding thick materials. When you’re looking to weld 1/2 inch steel, you’re stepping into serious territory where your equipment truly matters. It’s not just about having a MIG welder; it’s about having the right MIG welder with enough power, duty cycle, and the right consumables to lay down strong, reliable beads on heavy-duty applications. This guide will walk you through some top contenders and essential gear to conquer those thick metal projects.

Contents

- Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon…

- ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6…

- YESWELDER 8″ MIG Welding Pliers, Anti-Rust and Durable…

- TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless…

- TOOLIOM MIG/TIG/CUT/Stick Welder 5 in 1 Multiprocess…

- Eastwood 250 Amp MIG Welder Machine for Steel & Aluminum…

- MIG200 Welding Machine 3 in 1 Flux MIG/Lift TIG/MMA…

- Eastwood MP250i Elite Multi-Process Welder | MIG – TIG -…

- Eastwood 180 Amp MIG Welder Machine Dual Voltage 110V…

- Eastwood 140 Amp 120V MIG Welder Machine for Sheet Metal…

- Helpful Comparison Short Insights

- Final Verdict

- Best MIG Welder For 1/2 Inch Steel: Your Questions Answered

- Q1: What amperage do I need to weld 1/2 inch steel with a MIG welder?

- Q2: Can I weld 1/2 inch steel with a 120V MIG welder?

- Q3: What wire size and type are best for welding 1/2 inch steel?

- Q4: How many passes are typically required for 1/2 inch steel with MIG?

- Q5: What is duty cycle, and why is it important for welding thick steel?

- Q6: Do I need shielding gas for MIG welding 1/2 inch steel?

Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon…

When you’re dealing with substantial steel, the quality of your wire is paramount. This Blue Demon ER70S6 MIG wire is a solid choice for general shop work, even when you encounter less-than-perfect fit-up. It’s engineered to deliver exceptionally strong, porosity-free welds, which is critical for structural integrity on 1/2 inch steel projects. While .030 might require multiple passes for very thick material, its quality ensures those passes build up reliably.

Key features that stand out:

– Engineered for porosity-free, X-ray quality welds

– Highest tensile strength among plain carbon steel wires

– Versatile for general shop and salvage applications

– Requires shielding gas (CO2 and/or CO2 mix)

Pros:

– Delivers high-quality, strong welds

– Excellent for general fabrication and less-than-ideal conditions

– Provides reliable performance for multi-pass welding on thick steel

Cons:

– As a .030 wire, it might require more passes for full penetration on 1/2 inch steel compared to thicker wires.

Best for: Fabricators and DIY enthusiasts looking for high-strength, reliable wire for general shop use and multi-pass welding on heavy gauge steel.

Expert Opinion: This wire is a workhorse for achieving robust welds. While a thicker wire might be considered for single-pass 1/2 inch work, the ER70S6’s strength and quality make it an excellent choice for consistent multi-pass applications.

ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6…

ARCCAPTAIN’s ER70S-6 .030″ MIG wire offers consistent, high-quality performance for a range of welding tasks. Its TÜV certification speaks to its rigorous testing and reliability. For welding 1/2 inch steel, this wire’s smooth feeding, stable arc, and optimal penetration are crucial for building up strong, clean weld beads, especially when employing multi-pass techniques. The balanced deoxidizers also help in keeping the weld pool clean.

Key features that stand out:

– TÜV Tested and Approved for consistent quality

– Smooth feeding and stable arc characteristics

– Excellent wetting for proper molten metal flow

– Minimizes spatter for a cleaner weld appearance

Pros:

– Ensures high-quality welds with minimal impurities

– User-friendly with excellent arc stability and feedability

– Produces a smooth, visually appealing weld bead

Cons:

– The .030″ diameter means it’s best suited for multi-pass applications on 1/2 inch steel.

Best for: Welders seeking certified, high-performance wire for consistent results and ease of use on various projects, including multi-pass heavy steel welding.

Expert Opinion: The smooth feedability and minimal spatter of this ARCCAPTAIN wire are significant advantages, especially when you’re laying down multiple passes on thick material like 1/2 inch steel where consistency is key.

YESWELDER 8″ MIG Welding Pliers, Anti-Rust and Durable…

While not a welder itself, a good pair of MIG welding pliers is an indispensable tool for working with 1/2 inch steel and any other MIG project. These YESWELDER pliers are designed for multi-functionality, from wire cutting and tip removal to spatter cleaning and hammering. When you’re working with heavy steel, proper setup and maintenance are crucial, and these pliers make those tasks significantly easier and more efficient. Their durable construction ensures they can withstand the rigors of a busy workshop.

Key features that stand out:

– Multi-functional for wire cutting, tip/nozzle work, spatter cleaning, and more

– Serrated jaws provide a powerful grip on hot metal

– Constructed from premium high-carbon steel with HRC60 hardness

– Ergonomic, spring-loaded design for comfort and ease of use

Pros:

– All-in-one tool reduces the need for multiple instruments

– Extremely durable and rust-resistant for longevity

– Comfortable to use, reducing hand fatigue during long jobs

Cons:

– It’s a tool, not a welder, so it doesn’t directly contribute to the weld but is essential for prep and maintenance.

Best for: Every MIG welder, from professional fabricators working on heavy steel to DIY enthusiasts, needing a reliable, versatile tool for setup and maintenance.

Expert Opinion: Don’t underestimate the value of quality welding pliers. When you’re managing heavy materials and hot parts, having a robust, multi-functional tool like this can save significant time and frustration.

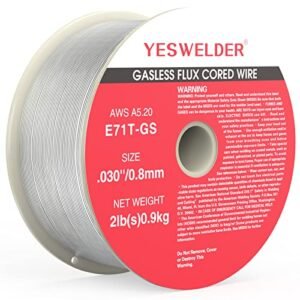

TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless…

This TOOLIOM flux-cored wire is a special entry here because it’s stainless steel. While the primary article focus is on carbon steel, understanding that flux-cored wire exists for various materials and conditions is important. Flux-cored wire shines when welding dirty, rusty, or painted materials, and it’s excellent for outdoor or high-altitude work because it’s self-shielded, eliminating the need for external gas. For 1/2 inch stainless steel or situations where you need to weld carbon steel with contaminants and don’t have gas, this type of wire can be a lifesaver, though this specific product is for stainless.

Key features that stand out:

– Flux core stabilizes the arc and provides self-shielding

– Produces less spatter and high-quality welds

– Ideal for rusty, dirty, or painted materials

– All-positions capability for versatile welding

Pros:

– No shielding gas required, making it highly portable and suitable for outdoor use

– Excellent for challenging environments and less-than-clean base materials

– Versatile for welding in all positions (though this is stainless flux-core, a specialized application)

Cons:

– This specific wire is for stainless steel, so it’s not suitable for general carbon steel projects on 1/2 inch material.

Best for: Welders needing to join stainless steel in challenging conditions (dirty material, outdoors) without shielding gas, or for understanding the benefits of flux-cored for heavy steel in certain scenarios.

Expert Opinion: Flux-cored wire is incredibly useful for specific applications, especially where portability and welding contaminated surfaces are priorities. While this specific one is stainless, knowing its benefits can guide choices for carbon steel flux-core when gas isn’t an option for thick material.

TOOLIOM MIG/TIG/CUT/Stick Welder 5 in 1 Multiprocess…

The TOOLIOM 5-in-1 multiprocess welder is a powerhouse for any serious fabricator. With 200A MIG capability, it’s definitely in the running for welding 1/2 inch steel, likely requiring multi-pass techniques to achieve full penetration. Its versatility to also TIG, Stick, and even Plasma Cut (up to 1/2″ severance cut) means you have a comprehensive solution for various heavy-duty projects. The large LCD panel and synergistic settings make it user-friendly for both beginners and seasoned pros.

Key features that stand out:

– 5-in-1 Multi-functionality: MIG, TIG, CUT, Stick

– 200A MIG Welder for substantial power

– 50A Plasma Cutter with 1/2″ severance cut capacity

– MIG synergistic and manual settings for precise control

– Aluminum welding capability with optional spool gun

Pros:

– Extremely versatile, covering multiple welding and cutting needs

– Sufficient MIG amperage (200A) for multi-pass 1/2 inch steel

– User-friendly with clear LCD and synergistic settings

Cons:

– Welding aluminum requires an additional spool gun, increasing the overall cost.

Best for: Workshops and individuals needing a single, highly versatile machine that can handle various welding processes and cutting tasks, including heavy steel fabrication.

Expert Opinion: A 200A MIG output is perfectly capable of welding 1/2 inch steel, assuming proper technique and multiple passes. The added cutting and other welding functions make this an exceptional value for a comprehensive workshop.

Eastwood 250 Amp MIG Welder Machine for Steel & Aluminum…

Now we’re talking serious power for 1/2 inch steel! The Eastwood 250 Amp MIG Welder is specifically designed for thick materials, explicitly stating its capability to weld “up to ½-inch steel plates.” With an infinitely adjustable 50-250 amp range and advanced IGBT inverter technology, this machine provides the control and power needed for heavy-duty fabrication. Its dual voltage compatibility (120v/240v) adds to its flexibility, making it a strong contender for your shop.

Key features that stand out:

– 250 Amp output, explicitly rated for ½-inch steel plates

– Dual voltage (120v/240v) for versatile power options

– Latest IGBT Inverter Technology for efficiency and control

– Infinitely adjustable amperage (50-250 amps)

Pros:

– Ample power for single or multi-pass welding on 1/2 inch steel

– Highly portable for a machine of its capability

– Excellent control over amperage for precise welding

Cons:

– At 46 lbs, it’s portable but still a substantial machine to move around.

Best for: Professional fabricators and serious DIYers who frequently weld heavy gauge steel, including 1/2 inch plates, and need robust power with precise control.

Expert Opinion: For consistent, high-quality welds on 1/2 inch steel, 250 amps gives you significant headroom. This machine’s ability to run on both 120V and 240V makes it incredibly adaptable for different workshop setups.

MIG200 Welding Machine 3 in 1 Flux MIG/Lift TIG/MMA…

The MIG200 is another fantastic multi-process machine, offering Flux MIG, Lift TIG, and MMA welding. With a 200A output, it’s well-equipped to handle 1/2 inch steel, typically through multiple passes, delivering superior bead formation and minimal spatter. Its full digital control system ensures a stable arc and precise welding, which is essential when working on critical heavy-duty joints. The durable construction promises longevity, making it a reliable tool for your shop.

Key features that stand out:

– Full digital control system for precise arc stability

– Powerful 200A output for Flux MIG, Lift TIG, and MMA

– Minimal spatter and superior bead formation

– Durable, high-quality construction for extended use

– User-friendly interface with unified adjustment mode

Pros:

– Offers three versatile welding processes in one unit

– Digital control enhances weld quality and consistency on thick materials

– Easy to use for both experienced welders and beginners

Cons:

– You might need to check your circuit breaker rating (25A or above recommended) to utilize its full power.

Best for: Welders who need a versatile, powerful, and easy-to-use multi-process machine for various applications, including welding 1/2 inch steel with MIG or Stick.

Expert Opinion: The digital control system on this 200A machine is a huge advantage for dialing in perfect settings for thick steel. For 1/2 inch, it’s a very capable machine, especially when using a multi-pass technique.

Eastwood MP250i Elite Multi-Process Welder | MIG – TIG -…

The Eastwood MP250i Elite is explicitly marketed as a multi-process welder capable of “MIG Welds thin steel metal or up to 1/2 inch steel plate.” This 250 amp machine delivers the raw power required for such demanding tasks. Like its MIG-only counterpart, it features IGBT Inverter technology and dual voltage (120V/240V) operation. What sets it apart is the inclusion of TIG and Stick welding capabilities, making it an incredibly flexible solution for a wide array of fabrication and repair projects on heavy metals.

Key features that stand out:

– 250 Amp multi-process (MIG, TIG, Stick) output

– Explicitly welds up to 1/2 inch steel plate (MIG)

– Dual voltage (120V/240V) for maximum versatility

– IGBT Inverter-based power supply for stable performance

– Welds aluminum with optional spool gun

Pros:

– High amperage (250A) perfectly suited for 1/2 inch steel

– Provides comprehensive multi-process capabilities for diverse projects

– Flexible dual voltage operation and compatibility with both 8″ and 12″ wire spools

Cons:

– TIG welding capabilities might be limited for very fine work compared to dedicated TIG machines.

Best for: Professional fabricators and serious hobbyists who need a single machine that can confidently handle 1/2 inch steel with MIG and also perform TIG and Stick welding on various materials.

Expert Opinion: This is arguably one of the best choices if your main goal is 1/2 inch MIG welding but you also want the flexibility of TIG and Stick. The 250 amps ensures you have plenty of power to get the job done right.

Eastwood 180 Amp MIG Welder Machine Dual Voltage 110V…

The Eastwood 180 Amp MIG Welder is a robust and portable option. While it’s an excellent machine for many tasks, it’s important to note its listed capacity for mild and stainless steel is “24 gauge to 5/16″ (3/16″ on 120V)”. For 1/2 inch steel, this machine would require significant multi-pass welding and might struggle to achieve full penetration. However, it’s a solid choice for heavy-duty projects up to 5/16 inch, and its dual voltage and IGBT inverter technology provide great performance and versatility within that range. It even includes a spool gun for aluminum up to 1/4 inch.

Key features that stand out:

– Portable and lightweight (under 26 Lb)

– Dual voltage (120V/240V) with 30-180 amp range

– Welds up to 5/16″ steel, includes spool gun for aluminum

– Metal drive motor and 2T/4T modes for comfort

Pros:

– Highly portable and easy to move around the workshop

– Good power for substantial projects up to 5/16″ steel

– Includes a spool gun for out-of-the-box aluminum welding

Cons:

– It’s not ideally suited for single-pass welding on 1/2 inch steel, requiring multiple passes or limiting its effectiveness on this thickness.

Best for: Welders needing a powerful, portable MIG machine for substantial projects up to 5/16 inch steel, and who also need to weld aluminum. It can tackle 1/2 inch with multiple passes but might be stretched.

Expert Opinion: While a 180 amp machine can indeed weld 1/2 inch steel using a multi-pass approach, it’s not its optimal sweet spot. It’s a fantastic, versatile welder for a wide range of other heavy-duty tasks just shy of 1/2 inch.

Eastwood 140 Amp 120V MIG Welder Machine for Sheet Metal…

The Eastwood 140 Amp 120V MIG Welder is an excellent entry-level or enthusiast machine, particularly suited for sheet metal and lighter fabrication. It’s lightweight and operates on standard 120V power, making it incredibly accessible. However, its maximum capacity for mild and stainless steel is listed as 3/16″. Therefore, this machine is NOT recommended for welding 1/2 inch steel as it lacks the necessary amperage for effective penetration, even with multiple passes. It’s fantastic for learning, DIY projects, and fabricating thinner materials, but for 1/2 inch, you’ll need something more powerful.

Key features that stand out:

– Lightweight (under 25 Lbs) and 120V operation for maximum portability

– 30-140 amp welding range with IGBT Inverter Technology

– Designed for 24 gauge to 3/16″ mild and stainless steel

– 2T/4T modes and uses common Tweco-style consumables

Pros:

– Extremely portable and easy to use on standard household power

– Great for beginners and hobbyists for sheet metal and light fabrication

– Can also perform Flux-Core welding without gas

Cons:

– Insufficient power (140 amps) for reliably welding 1/2 inch steel, even with multiple passes.

Best for: Beginners, hobbyists, and those working on automotive sheet metal or light fabrication projects up to 3/16″ steel. Not suitable for 1/2 inch steel.

Expert Opinion: While a fantastic starter machine or for lighter work, a 140 amp 120V unit simply doesn’t have the juice needed for 1/2 inch thick steel. Always match your welder’s capacity to your material thickness for safety and quality.

Helpful Comparison Short Insights

When looking for the best MIG welder for 1/2 inch steel, power output is king. The Eastwood 250 Amp MIG Welder and the Eastwood MP250i Elite Multi-Process Welder both explicitly state their capability for 1/2 inch steel, offering 250 amps of robust power. These are your top contenders if 1/2 inch steel is your primary target.

The TOOLIOM 5 in 1 Multiprocess Welder and the MIG200 Welding Machine are excellent choices for versatility, both providing 200 amps. While slightly less powerful than the 250 amp machines, 200 amps is still highly capable for 1/2 inch steel, especially with a solid multi-pass technique. They offer the added benefit of TIG, Stick, and sometimes plasma cutting, making them incredibly useful all-around shop machines.

It’s crucial to distinguish between machines that can handle 1/2 inch steel and those that are better suited for lighter gauges. The Eastwood 180 Amp MIG Welder is a great, portable machine, but its 5/16 inch rating suggests it’ll be stretched for 1/2 inch, requiring many passes. The Eastwood 140 Amp 120V MIG Welder is clearly designed for sheet metal up to 3/16 inch and is not suitable for 1/2 inch steel. It’s important to check the amperage and material thickness specifications carefully.

Don’t forget the consumables and accessories! High-quality MIG wire like the Blue Demon ER70S6 or ARCCAPTAIN ER70S-6 (even in .030″) is essential for strong welds, often used in multiple passes for thick steel. For challenging environments or material, specific wires like the TOOLIOM Gasless Flux-Cored (Stainless) offer unique benefits (though this one is stainless, not general carbon steel). And a robust tool like the YESWELDER MIG Welding Pliers is invaluable for prep and maintenance.

Final Verdict

Choosing the best MIG welder for 1/2 inch steel boils down to your specific needs for power, versatility, and budget.

For uncompromising power and explicit 1/2 inch steel capability, the Eastwood 250 Amp MIG Welder stands out as a dedicated workhorse. If you need that same raw power but also desire the flexibility of TIG and Stick welding in one unit, the Eastwood MP250i Elite Multi-Process Welder is a top-tier choice that won’t leave you wanting for more.

If you’re looking for a highly versatile machine that still capably handles 1/2 inch steel (with multi-pass techniques) and offers additional processes like plasma cutting or TIG/Stick, the TOOLIOM 5 in 1 Multiprocess Welder and the MIG200 Welding Machine are excellent, feature-rich options that deliver significant value.

Remember, a powerful machine is only as good as its consumables. Investing in high-quality MIG wire like the Blue Demon or ARCCAPTAIN ER70S-6, and essential tools like the YESWELDER MIG Welding Pliers, will ensure you get the best performance out of your chosen welder when tackling demanding 1/2 inch steel projects. Always prioritize safety and read your machine’s manual carefully.

Best MIG Welder For 1/2 Inch Steel: Your Questions Answered

Q1: What amperage do I need to weld 1/2 inch steel with a MIG welder?

A: To effectively weld 1/2 inch steel, you’ll generally need a MIG welder capable of at least 200-250 amps. While 180 amps might technically work with many passes and preheating, 200+ amps provides better penetration and a more efficient welding process. Machines around 250 amps are ideal for achieving quality welds on 1/2 inch steel, potentially even in fewer passes.

Q2: Can I weld 1/2 inch steel with a 120V MIG welder?

A: Most 120V MIG welders max out around 140-180 amps and typically have duty cycles that are too low for continuous welding on 1/2 inch steel. While some may claim to weld up to 1/2 inch, this usually requires extensive multi-pass techniques, significant preheating, and may not achieve full structural integrity. For reliable, strong welds on 1/2 inch steel, a 240V machine with higher amperage (200A+) is strongly recommended.

Q3: What wire size and type are best for welding 1/2 inch steel?

A: For 1/2 inch steel, a .035″ or .045″ solid MIG wire (ER70S-6) is generally preferred. Thicker wire allows for higher amperage and deposition rates, leading to better penetration. Flux-cored wire (FCAW-S or FCAW-G) in similar diameters can also be very effective, especially for thicker materials, outdoor use, or less clean surfaces, as it often provides deeper penetration than solid wire.

Q4: How many passes are typically required for 1/2 inch steel with MIG?

A: Welding 1/2 inch steel often requires multiple passes. A single pass might achieve sufficient penetration for thinner materials, but for 1/2 inch, you’ll likely need to lay down several beads to build up the weld and ensure full fusion. The exact number of passes depends on your welder’s amperage, wire type/size, joint design, and desired weld strength. Machines with 250 amps can sometimes achieve substantial penetration in fewer passes than 200 amp units.

Q5: What is duty cycle, and why is it important for welding thick steel?

A: Duty cycle is the percentage of a 10-minute period a welder can operate at its maximum rated output before needing to cool down. For example, a 60% duty cycle at 200 amps means it can weld for 6 minutes continuously at 200 amps, then needs 4 minutes to cool. When welding thick steel like 1/2 inch, you’ll be running at higher amperages for longer durations. A higher duty cycle (e.g., 40-60% at max amperage) is crucial to avoid frequent stops, making your work more efficient and preventing machine overheating.

Q6: Do I need shielding gas for MIG welding 1/2 inch steel?

A: Yes, for Gas Metal Arc Welding (GMAW or “MIG”), shielding gas is essential to protect the molten weld pool from atmospheric contamination. For welding carbon steel, a mix of 75% Argon / 25% CO2 (C25) is a common and versatile choice, offering a good balance of arc stability and penetration. Pure CO2 can also be used for deeper penetration on thicker steel but tends to produce more spatter. Alternatively, flux-cored wire can be used without external shielding gas, which is often chosen for its deeper penetration and suitability in outdoor or windy conditions.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.