Having spent countless hours in my garage, tackling everything from rust repair to full panel replacements, I know how crucial the right tool is for welding car panels. You need precision, control, and a machine that won’t blow through thin sheet metal like a laser. Finding the best MIG welder for car panels isn’t just about power; it’s about finesse and reliability. I’ve put together this guide to help you navigate the options, focusing on welders that truly excel at auto body welding without leaving you with a mountain of grinding work. Let’s dive into some top contenders that make welding thin gauge metal a much smoother process.

Contents

- Tobewan MIG 3IN1 Welder Machine MIG/LIFT TIG/MMA Welding…

- BILT HARD 135A 3-in-1 IGBT Inverter Welder, 110V Flux…

- MIG200 Welding Machine 3 in 1 Flux MIG/Lift TIG/MMA…

- AWT MIG Welding Machine,160A 5 in 1 Plasma Cutter Welder…

- SereneLife Inverter MIG Welding Machine – Dual Voltage…

- Comparison Insights

- Final Verdict

- Best MIG Welder For Car Panels: FAQ

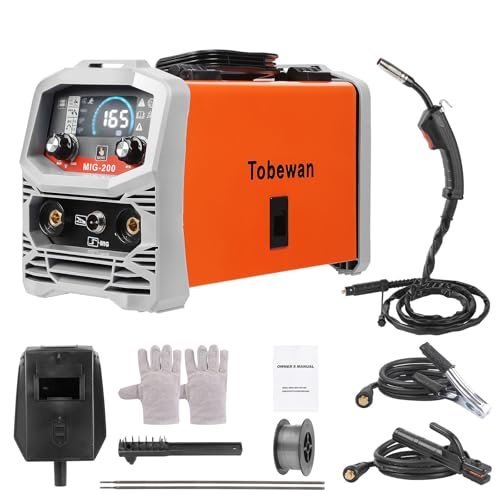

Tobewan MIG 3IN1 Welder Machine MIG/LIFT TIG/MMA Welding…

This compact Tobewan 3-in-1 welder is a versatile powerhouse, perfect for those needing flexibility without sacrificing performance on car panel repairs. Its digital control panel allows for precise adjustments of voltage, current, and wire speed, crucial for preventing burn-through on thin metals. Weighing just 7.7lb, it’s incredibly portable, making it easy to move around your vehicle or workshop, and its IGBT inverter technology ensures a stable arc and minimal spatter for cleaner welds.

Key features that stand out:

– Multi-functional 3 in 1 (Flux MIG/Lift TIG/MMA): Offers great versatility for various materials and tasks.

– Intelligent Regulation & Efficient Output: Precise digital control over welding parameters and IGBT inverter technology for stable performance.

– Extremely Portable: Weighs only 7.7lb with a compact design and handle.

– User-friendly Experience: Clearly marked parameters and one-click adjustment for ease of use.

– Safety Protection: Built-in overvoltage/overcurrent/overload/overheating safety functions.

Pros:

– Incredibly lightweight and portable for easy maneuverability around vehicles.

– Precise digital controls are excellent for delicate car panel welding.

– Multi-process capability adds value for other workshop tasks.

– User-friendly interface, great for beginners and DIYers.

Cons:

– Only 110V, which might limit some heavier-duty applications beyond thin car panels.

Best for: Hobbyists, DIYers, and small car panel repair jobs where portability and precision on thin metals are key.

Expert Opinion: This Tobewan unit shines for its exceptional portability and precise digital controls. For anyone primarily focused on delicate auto body work, its ability to finely tune settings is a significant advantage, helping to prevent common issues like burn-through on thinner metals.

BILT HARD 135A 3-in-1 IGBT Inverter Welder, 110V Flux…

The BILT HARD 135A is a robust choice for auto body enthusiasts, offering a 3-in-1 multi-process design that excels in Flux Core MIG for quick fixes on car panels. What truly sets it apart is the synergic control system, which automatically adjusts voltage and wire feed speed, simplifying the process for cleaner, more consistent welds on various thicknesses. With its LED digital display and comprehensive accessory package, it’s practically ready to use right out of the box, making it great for beginners.

Key features that stand out:

– 3-in-1 Multi-Process Welder (Flux Core MIG, Lift TIG, Stick): Versatile for different welding needs.

– LED Digital Display: Real-time tracking of voltage/current/wire speed with intuitive controls.

– Synergic Control System: Automatically adjusts parameters, making it user-friendly for beginners and consistent for experienced welders.

– Safety Protection: Auto shutdown with error codes for enhanced safety.

– Ready to Weld Package: Comes with a helmet, wire, tips, and other accessories.

Pros:

– Synergic control is fantastic for simplifying parameter setup, especially for welding car panels.

– Comprehensive accessories mean you can start welding immediately.

– Supports 2T/4T/Spot trigger modes, useful for varied auto body tasks.

– Strong focus on safety with auto-shutdown features.

Cons:

– TIG torch isn’t included, requiring a separate purchase for that mode.

Best for: Beginners and DIYers seeking an easy-to-use, feature-rich MIG welder for car panel repairs and general fabrication, especially those who appreciate a “ready-to-weld” package.

Expert Opinion: The synergic control on the BILT HARD 135A is a standout feature for car panel welding. It takes a lot of the guesswork out of setting up for thin metal, allowing users to focus more on technique and less on dialing in parameters, which is a huge benefit for achieving clean, consistent results.

MIG200 Welding Machine 3 in 1 Flux MIG/Lift TIG/MMA…

The MIG200 welding machine delivers powerful welding functionality with a focus on superior bead formation and minimal spatter, making it an excellent candidate for meticulous car panel work. Its full digital control system ensures a stable arc and precise adjustments, crucial for handling thin materials without burn-through. Designed for both durability and user-friendliness, this machine promises extended usage while maintaining high performance, whether in a professional shop or for DIY projects.

Key features that stand out:

– Advanced Control System: Full digital control for precise welding, stable arc, and enhanced performance.

– Powerful Welding Functionality: Minimal spatter and superior bead formation, great for clean welds on auto body panels.

– Durable Construction: Crafted from high-quality materials for longevity.

– User-Friendly Operation: Intuitive interface with unified adjustment mode.

– Versatile Applications: Supports Flux MIG, Lift TIG, and MMA welding processes.

Pros:

– Excellent spatter control and bead formation are ideal for aesthetic car panel repairs.

– Digital control system provides great precision for thin materials.

– Durable build ensures long-term reliability in the workshop.

– Unified adjustment mode simplifies operation for various skill levels.

Cons:

– Requires a 25A or above circuit breaker, which might not be standard in all home garages.

Best for: Experienced DIYers and small professional shops prioritizing precise control, clean welds, and durability for consistent car body repairs.

Expert Opinion: This MIG200 unit’s focus on minimal spatter and superior bead formation makes it highly appealing for auto body work where aesthetics are paramount. The digital control system empowers users to achieve very precise results, which is essential when dealing with the fine details of car panels.

AWT MIG Welding Machine,160A 5 in 1 Plasma Cutter Welder…

For the serious fabricator or auto restorer looking for an all-in-one solution, the AWT 5-in-1 machine is a compelling choice. Beyond its MIG synergic control for easy setup and precise welds on car panels, it integrates HF TIG for non-contact arc ignition on delicate materials and a powerful 40A plasma cutter for efficient sheet metal removal. Its dual 110/220V voltage capability adds immense flexibility, making it a true workhorse for comprehensive auto body and fabrication tasks.

Key features that stand out:

– 5-in-1 Multifunction (Flux MIG, Gas MIG, HF TIG, Plasma Cutting, Stick): Unrivaled versatility for welding and cutting.

– MIG Synergic Control: Automatically adjusts current and wire feed speed for effortless and precise MIG welding on auto panels.

– HF TIG Welding: Non-contact arc ignition for high-precision welding, reducing contamination risks.

– Plasma Cutting: Powerful 40A output with dual voltage for clean cuts up to 9mm on various metals.

– Dual Voltage (110/220V): Increased flexibility for different power sources and applications.

Pros:

– The ultimate multi-tool for auto body work, combining welding and cutting in one unit.

– Synergic MIG control simplifies setup for thin car panels.

– HF TIG is excellent for high-precision welds on delicate materials.

– Plasma cutting function is invaluable for rust removal and panel fabrication.

Cons:

– The increased complexity and number of functions might be overkill for someone only needing basic MIG welding.

Best for: Professional auto restorers, serious hobbyists, and workshops needing a comprehensive, versatile machine for all stages of car panel fabrication and repair, from cutting out old metal to welding in new.

Expert Opinion: The AWT 5-in-1 is a game-changer for comprehensive auto body work. Having MIG synergic control for precise panel welding, HF TIG for fine work, and plasma cutting for efficient material removal all in one unit is incredibly efficient. It’s an investment that pays off quickly for anyone tackling full restorations or custom fabrication.

SereneLife Inverter MIG Welding Machine – Dual Voltage…

The SereneLife Inverter MIG Welder is an accessible and reliable option for tackling car panels, especially for those new to welding or looking for a straightforward machine. Its dual voltage 110V/220V capability offers flexibility for different power sources, and the full bridge circuit design provides professional-level stability, ensuring consistent output for smooth welds. With adjustable wire feed speed and a clear focus on ease of use, it’s designed to help beginners achieve excellent results on up to 0.08” plate steel, which covers most automotive sheet metal.

Key features that stand out:

– 130 AMP MIG Style Welder: Easier for beginners compared to TIG or Stick.

– Gas or Flux Core: Supports both types of MIG welding, offering flexibility.

– Full Bridge Circuit: Provides professional-level stability and a 60% duty cycle.

– Dual Voltage (110V/220V): Adapts to different power outlets, supporting welding up to 0.08” plate steel.

– Adjustable Speed Wire Feed: Allows for precise dialing in of weld parameters.

Pros:

– Dual voltage capability offers great versatility for home garages or workshops.

– Full bridge circuit design ensures stable and professional-level performance for car panels.

– Very straightforward and user-friendly, ideal for those learning to weld.

– Good duty cycle for sustained welding on automotive projects.

Cons:

– Less advanced digital controls compared to some other models, relying more on manual adjustment.

Best for: Beginners and home DIYers who want a reliable, easy-to-use MIG welder with dual voltage capability for general car panel repair and light fabrication.

Expert Opinion: The SereneLife unit is a solid choice for its simplicity and dual voltage flexibility. Its full bridge circuit ensures good stability, which is crucial for beginners trying to lay down consistent beads on thin car panels. It’s a no-frills workhorse that gets the job done effectively for common automotive thickness.

Comparison Insights

When looking for the best MIG welder for car panels, certain features really stand out. For ultimate portability and precision, the Tobewan MIG 3IN1 is a clear winner, weighing in at a mere 7.7lb with excellent digital control for thin metals. If ease of use and synergic control are your top priorities, especially as a beginner, the BILT HARD 135A is hard to beat, automatically setting parameters for you. For those who value superior bead formation and minimal spatter for aesthetic car repairs, the MIG200’s advanced digital control system delivers outstanding results. The AWT MIG Welding Machine stands out as the most versatile option, offering 5-in-1 functionality including plasma cutting for full auto body restorations. Finally, the SereneLife Inverter MIG provides a great balance of dual voltage flexibility and stable performance in a user-friendly package, ideal for general DIY car panel work.

Final Verdict

Choosing the best MIG welder for car panels truly depends on your specific needs, skill level, and budget.

If you’re a beginner or a DIY enthusiast primarily focused on precise, clean car panel repairs and appreciate synergic control to make things easy, the BILT HARD 135A is an exceptional choice. Its ready-to-weld package and intuitive operation get you started quickly.

For the hobbyist or small workshop needing extreme portability and fine-tuned control for delicate thin metal work, the Tobewan MIG 3IN1 offers unmatched lightness and precise digital adjustments.

However, if you’re undertaking comprehensive auto body restoration or serious fabrication and need an all-in-one powerhouse that can weld, cut, and handle various processes with both gas and flux core, the AWT MIG Welding Machine (5-in-1) is arguably the most capable and versatile option on this list, despite being a larger investment. It truly streamlines complex projects.

Ultimately, any of these welders will serve you well for car panels, but considering your project scope and personal experience will guide you to your perfect match.

Best MIG Welder For Car Panels: FAQ

Q1: What wire size should I use for welding car panels?

A1: For thin car panels (typically 18-22 gauge), 0.023″ (0.6mm) or 0.024″ (0.6mm) welding wire is generally recommended. This smaller diameter wire allows for finer control and reduces the risk of burning through thin sheet metal. Some welders might also effectively use 0.030″ (0.8mm) wire with appropriate settings, but smaller is usually better for auto body work.

Q2: Should I use flux core or solid wire with gas for car panels?

A2: For the cleanest welds with minimal spatter on car panels, solid wire with a shielding gas (typically 75% Argon/25% CO2, known as C25) is highly recommended. Flux core wire is more convenient as it doesn’t require gas, but it produces more spatter and a less aesthetically pleasing weld, requiring more cleanup. For professional-looking auto body work, gas MIG is preferred.

Q3: What voltage is best for welding thin gauge metal on cars?

A3: Most MIG welders suitable for car panels operate on 110V (standard household current). This is generally sufficient for welding thin gauge automotive sheet metal up to 1/8 inch thick. While 220V machines offer more power and duty cycle for thicker materials, 110V is perfectly adequate and often more convenient for auto body welding on thinner panels. Dual voltage welders offer the best of both worlds.

Q4: How important is synergic control for a beginner welding car panels?

A4: Synergic control is incredibly beneficial for beginners when welding car panels. It automatically adjusts the voltage and wire feed speed based on your amperage selection, taking a lot of the guesswork out of setting up the machine. This helps beginners achieve more consistent and cleaner welds on thin metal, reducing frustration and improving results significantly.

Q5: What’s a good duty cycle for welding car panels?

A5: For car panel repair, a duty cycle of 30-40% at maximum amperage is usually sufficient for home and hobbyist use. This means the machine can weld for 3-4 minutes out of every 10-minute cycle before needing to cool down. Since car panel work often involves short bursts of welding (tack welds, short stitch welds), a higher duty cycle isn’t always critical but is a nice bonus if you’re doing longer continuous welds.

Q6: Can I use a multi-process welder for auto body work?

A6: Yes, absolutely! Multi-process welders (like the 3-in-1 or 5-in-1 options reviewed) are very versatile. While MIG is typically preferred for car panel welding due to its speed and ease, having TIG for more precise, high-quality welds or Stick for heavier fabrication can be extremely useful in an auto body shop or even a home garage. A plasma cutting function, as seen in the AWT, is also invaluable for efficiently removing rusted panels.

Q7: How do I prevent burn-through when welding thin car panels?

A7: Preventing burn-through on thin car panels requires a combination of factors:

– Proper settings: Use lower amperage and voltage.

– Smaller wire: 0.023″ or 0.024″ wire is ideal.

– Technique: Use a series of tack welds or short stitch welds rather than long continuous beads. Allow the metal to cool between tacks.

– Shielding gas: Use 75/25 Argon/CO2 for better arc control and less heat input than flux core.

– Copper backing: Sometimes, a copper block behind the weld can help dissipate heat and prevent burn-through.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.