When I started getting into welding structural steel, I quickly realized that having the right equipment makes all the difference. It’s not just about the machine; it’s also about the right wire and tools to get those strong, clean welds that structural projects demand. Finding the best MIG welder for structural steel often means understanding what each component brings to the table, from wire feed stability to the quality of the filler material. This guide is built on my experience, helping you navigate some excellent options and find the perfect setup for your structural steel welding needs.

Contents

- ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 0.030″ 2lb

- ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6

- 8″MIG Welding Pliers, Multi-functional Carbon Steel MIG Pliers

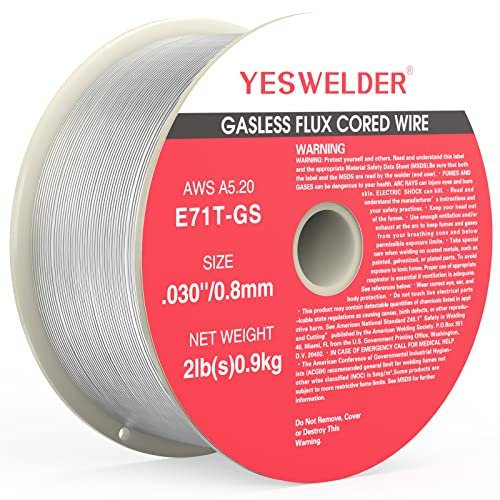

- YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon Steel

- Eastwood 140 Amp 120V MIG Welder Machine for Sheet Metal…

- Comparison Insights: Finding Your Best MIG Welder for Structural Steel

- Final Verdict

- Best MIG Welder For Structural Steel: FAQ Section

- Q1: What makes a MIG welder “best” for structural steel?

- Q2: Is a 120V MIG welder powerful enough for structural steel?

- Q3: What’s the difference between solid wire and flux-core wire for structural steel welding?

- Q4: Why are specific MIG wires (like ER308L or ER70S-6) important for structural steel?

- Q5: What is duty cycle, and why does it matter for welding structural steel?

- Q6: Can I use the same MIG welder for sheet metal and structural steel?

- Q7: Are welding pliers really necessary for structural steel MIG welding?

ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 0.030″ 2lb

If you’re tackling stainless steel structural projects, this ARCCAPTAIN ER308L wire is a fantastic choice. I’ve found it delivers high-grade welds with a smooth arc, making it ideal for applications where corrosion resistance is critical, like restaurant or medical equipment. The low carbon content is a real benefit, ensuring your welds are strong and resistant to common issues like intergranular corrosion. This wire consistently helps me achieve precise, clean beads with minimal spatter, which saves a lot on cleanup time.

Key features that stand out:

– Premium Low Carbon Mig Wire: Minimizes carbide precipitation for enhanced corrosion resistance.

– Versatile Stainless Steel Compatibility: Works with 304, 304L, 308, 308L, 321, and 347 stainless steels.

– Precision and Control: Offers superior arc control and minimal splatter for clean, precise welds.

– Durable Construction: Made from high-grade stainless steel for longevity.

– Detailed Specifications: 0.030” diameter, 2-pound weight for cost-effective use.

Pros:

– Excellent corrosion resistance due to low carbon.

– Produces very clean and precise welds.

– Compatible with a wide range of stainless steel types.

– Minimal spatter reduces post-weld cleanup.

Cons:

– Specifically for stainless steel, not suitable for mild steel structural work.

Best for: Stainless steel structural fabrication, medical and food equipment, and other applications requiring high corrosion resistance.

Expert Opinion: This wire is a top-tier choice for specific stainless steel structural applications. Its low carbon content is a significant advantage for long-term weld integrity.

ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6

For general structural steel welding, especially mild and carbon steel, the ARCCAPTAIN ER70S-6 wire is a workhorse. I’ve used this wire extensively, and it consistently provides superior strength and consistent performance. The smooth feeding characteristic of this wire is impressive, leading to stable arcs and high deposition rates. It’s TÜV certified, which adds an extra layer of confidence in its quality, and I always get a smooth, clean weld bead that looks great with minimal effort. This is definitely a staple for my shop.

Key features that stand out:

– High-quality Industry Standard: Meets industry standards for consistent performance and superior strength.

– TÜV Tested and Approved: Rigorously tested for quality and minimal impurities.

– Smooth Weld Bead: Excellent wetting characteristics for visually appealing welds with minimal cleanup.

– Optimal Performance: Offers great arc characteristics and minimizes spatter.

– Easy to Use: Excellent arc stability and feedability, suitable for all skill levels.

Pros:

– Delivers strong, high-quality welds on mild and carbon steel.

– Smooth feeding and stable arc for easy operation.

– TÜV certified for reliability.

– Low spatter and good bead appearance.

Cons:

– Requires shielding gas, adding to setup complexity compared to flux core.

Best for: General fabrication, automotive repair, and light to medium structural steel projects with mild or carbon steel.

Expert Opinion: This is a fantastic general-purpose solid MIG wire. Its consistent performance and TÜV certification make it a reliable choice for achieving strong, clean welds on structural steel.

8″MIG Welding Pliers, Multi-functional Carbon Steel MIG Pliers

You might not think of pliers as a core part of the “best MIG welder for structural steel” setup, but trust me, a good pair of MIG pliers is indispensable. These 8″ MIG welding pliers are incredibly versatile and have saved me so much time. From cutting welding wire cleanly to removing hot nozzles and even hammering, they’re always in my hand. The strong clamping force and comfortable, spring-loaded handle make them a joy to use, significantly reducing hand fatigue during long welding sessions. They’re built tough, just what you need on a structural job.

Key features that stand out:

– High-Quality Construction: Made from premium steel, polished for durability and extended use.

– Multi-Functional Design: Features built-in wire cutters, metal wire cutting blades, and large serrated holes for nozzles.

– Strong Clamping: Long serrated jaws provide exceptional clamping force for various workpieces.

– Comfortable Handle: User-friendly handles with a spring mechanism to reduce fatigue.

– Rust Protection: Coated with rust-proof oil for longevity.

Pros:

– Highly versatile for various welding tasks.

– Durable and robust construction.

– Comfortable grip with spring-loaded mechanism.

– Excellent for cutting wire, removing nozzles, and light hammering.

Cons:

– Not directly related to the welding power source itself, but an essential accessory.

Best for: Every MIG welder, from hobbyists to professionals, who needs a reliable, multi-functional tool for setup and maintenance.

Expert Opinion: These pliers are a must-have for any serious MIG welder. Their multi-functional design and robust build quality make them an essential shop tool, greatly improving efficiency and safety.

YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon Steel

When I’m working outdoors or in conditions where shielding gas is impractical, this YESWELDER Flux Core Gasless MIG Wire is my go-to. It’s a self-shielding wire that delivers exceptional arc stabilization and consistently good welds, even if the material isn’t perfectly clean. I’ve been impressed with its low spatter and easy slag removal, which are often issues with other flux core wires. Its versatility for all-position welding, combined with the convenience of not needing gas, makes it a powerful option for structural work on the go.

Key features that stand out:

– E71T-GS Flux Core Wire: Self-shielding design with advanced core for arc stabilization and feedability.

– Excellent Performance: Produces low spatter, full slag formation with easy removal, and porosity-free deposits.

– Versatile Applications: Ideal for outdoor windy conditions and all-position welding without shielding gas.

– Material Compatibility: Suitable for carbon steel and low-alloy structural steel.

– Strong Spool: Robust ABS plastic spool ensures durability and flawless operation.

Pros:

– No shielding gas required, perfect for outdoor or portable work.

– Low spatter and easy slag removal.

– Excellent for welding through light rust or mill scale.

– Good for all-position welding.

Cons:

– Produces more fumes and slag compared to solid wire.

Best for: Outdoor structural steel welding, field repairs, hobbyists without gas cylinders, and applications needing portability.

Expert Opinion: For situations where gas is not feasible, this flux core wire shines. Its ability to produce clean welds in challenging conditions makes it an invaluable asset for certain structural applications.

Eastwood 140 Amp 120V MIG Welder Machine for Sheet Metal…

If you’re looking for a dedicated MIG welder for structural steel that’s accessible for DIYers but still capable, the Eastwood 140 Amp is a solid contender. This machine is incredibly portable, running on standard 120V power, making it perfect for garage projects or even taking to a friend’s place. I’ve used it to weld up to 3/16″ mild steel, which covers a good range for lighter structural elements and fabrication. The IGBT inverter technology provides a smooth arc, and features like 2T/4T modes make longer welds less fatiguing. It’s a reliable little powerhouse that lets you tackle those important projects with confidence.

Key features that stand out:

– Portable Welder: Lightweight (less than 25 Lbs) and operates on 120V for maximum usability.

– Versatile Material Capability: Welds mild and stainless steel from 24 gauge to 3/16″.

– Latest IGBT Inverter Technology: Offers a 30-140 amp range with a metal drive motor for smooth operation.

– 2T/4T Modes: Provides flexibility for short and long welds, suitable for flux-core or gas MIG.

– Eastwood Quality & Warranty: Backed by a 3-year limited warranty and lifetime tech support.

Pros:

– Highly portable and runs on common household power.

– Great for lighter structural steel and fabrication projects.

– Smooth arc and stable wire feed.

– Can be used for both gas MIG and flux-core welding.

Cons:

– 120V limits its ability to weld thicker structural steel quickly compared to 240V machines.

Best for: Hobbyists, DIY fabricators, and small shops needing a portable and versatile MIG welder for light to medium structural steel projects up to 3/16 inch.

Expert Opinion: For its size and power input, the Eastwood 140 Amp is an impressive machine. It’s an excellent entry-point or secondary welder for structural steel work where portability and 120V operation are key.

Comparison Insights: Finding Your Best MIG Welder for Structural Steel

When picking the best MIG welder for structural steel, it’s crucial to look beyond just the machine. The Eastwood 140 Amp stands out as an actual welder, offering great portability and versatility for lighter structural work. However, its 120V power means it’s best for up to 3/16″ thickness, so for heavier structural components, you’d likely need a more powerful 240V machine.

The choice of welding wire is equally critical. For pristine stainless steel structures where corrosion resistance is paramount, the ARCCAPTAIN ER308L Stainless Steel MIG Wire is essential. If you’re primarily working with mild or carbon structural steel, the ARCCAPTAIN ER70S-6 Mig Welding Wire is a reliable gas-shielded option, ensuring strong, clean welds. For structural work on-site or in windy conditions where gas is problematic, the YESWELDER Flux Core Gasless MIG Wire offers incredible convenience and portability. Finally, don’t underestimate the value of supporting tools; the 8″MIG Welding Pliers are an absolute must-have for efficient setup and maintenance, making any structural welding job smoother.

Final Verdict

Navigating the world of welding for structural steel can feel overwhelming, but focusing on what you need most will guide your choice. For the everyday DIYer tackling light structural steel projects and needing a versatile machine, the Eastwood 140 Amp 120V MIG Welder is a fantastic core investment. It’s powerful enough for common tasks and incredibly portable.

However, a great welder is only as good as its consumables. If your structural projects involve stainless steel, investing in the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L will ensure professional-grade, corrosion-resistant results. For general mild and carbon structural steel, the ARCCAPTAIN Mig Welding Wire ER70S-6 offers superior strength and consistency. And for those outdoor or gas-free structural jobs, the YESWELDER Flux Core Gasless MIG Wire is an indispensable ally.

Ultimately, equipping yourself with the 8″MIG Welding Pliers rounds out any setup, providing the essential support tools needed for efficient and safe operation. Each of these products plays a vital role in achieving high-quality welds on structural steel, whether you’re building a workbench or repairing a metal gate. My recommendation is to combine a capable machine like the Eastwood with the appropriate wire for your material, and always have those handy pliers nearby!

Best MIG Welder For Structural Steel: FAQ Section

Q1: What makes a MIG welder “best” for structural steel?

A1: The best MIG welder for structural steel typically needs sufficient power (amps) to achieve proper penetration on common structural thicknesses (e.g., 1/8″ to 3/8″). It also requires a stable arc, consistent wire feed, and the ability to use appropriate welding wire (like ER70S-6 solid wire or E71T-GS flux core) for strong, durable welds on carbon or low-alloy steel. A good duty cycle is also important for continuous structural work.

Q2: Is a 120V MIG welder powerful enough for structural steel?

A2: A 120V MIG welder, like the Eastwood 140 Amp reviewed, is suitable for lighter structural steel applications, generally up to 3/16″ thick mild steel. For thicker structural steel (e.g., 1/4″ or 3/8″), a 240V MIG welder is usually recommended as it provides more amperage and a higher duty cycle for better penetration and faster welding.

Q3: What’s the difference between solid wire and flux-core wire for structural steel welding?

A3: Solid wire (like ARCCAPTAIN ER70S-6) requires external shielding gas (typically Argon/CO2 mix) to protect the weld pool, resulting in cleaner welds with less spatter and no slag. Flux-core wire (like YESWELDER E71T-GS) is self-shielding, meaning it doesn’t need gas, making it ideal for outdoor, windy conditions or portability, but it produces slag that needs to be chipped off. For heavy structural steel, solid wire generally offers superior penetration and mechanical properties when done correctly.

Q4: Why are specific MIG wires (like ER308L or ER70S-6) important for structural steel?

A4: Different structural steel projects require specific wire types. ER70S-6 wire is excellent for welding mild and low-alloy carbon structural steel, providing high strength and good ductility. ER308L wire (like the ARCCAPTAIN Stainless Steel MIG Solid Wire) is specifically for welding stainless steel structures, offering critical corrosion resistance due to its low carbon content. Using the correct wire ensures the weld joint matches the base metal’s properties for durability and integrity.

Q5: What is duty cycle, and why does it matter for welding structural steel?

A5: Duty cycle is the percentage of a 10-minute period a welder can operate at its maximum rated amperage before needing to cool down. For example, a 30% duty cycle at 90 amps means the machine can weld for 3 minutes continuously at 90 amps and then needs 7 minutes to cool. For extensive structural steel fabrication, a higher duty cycle is beneficial as it allows for longer welding times without interruptions, increasing productivity.

Q6: Can I use the same MIG welder for sheet metal and structural steel?

A6: Yes, many versatile MIG welders, especially those with a wide amperage range (like the Eastwood 140 Amp), can handle both. The key is adjusting the wire speed, voltage, and using the correct wire diameter and type for each application. Sheet metal requires lower amperage and thinner wire, while structural steel demands higher amperage and often thicker wire for proper penetration.

Q7: Are welding pliers really necessary for structural steel MIG welding?

A7: Absolutely! While not a welder itself, a good pair of MIG welding pliers (like the 8″ Multi-functional Carbon Steel MIG Pliers) is an essential accessory. They’re invaluable for tasks like cutting wire, cleaning spatter from the nozzle, removing contact tips, and even light hammering. Having them readily available streamlines the welding process and makes maintenance much easier, ensuring your best MIG welder for structural steel setup runs smoothly.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.