When I first dipped my toes into the world of MIG welding, I quickly realized that having the right guidance makes all the difference. It’s not just about turning on the machine; it’s about understanding the best MIG welding techniques, mastering electrode stick-out, wire feed speed, and getting that perfect bead. Over the years, I’ve seen countless resources, and to truly hone your MIG welding skills, a good foundation is essential. This guide will walk you through some of the top books and resources available to help you master MIG welding, whether you’re just starting or looking to refine your craft.

Contents

- MIG WELDING FOR BEGINNERS: MIG WELDING BASIC SKILLS AND…

- Farm and Workshop Welding, Third Revised Edition:…

- Learn to Weld: Beginning MIG Welding and Metal Fabrication…

- Welder’s Handbook: A Complete Guide to MIG, TIG, Arc &…

- Welding Complete, 2nd Edition: Techniques, Project Plans &…

- Basic Welding Techniques: Arc, Oxyacetylene, Tig and Mig

- All About Steel – Welding Practice for TIG and MIG…

- Comparison Insights for Best MIG Welding Techniques Resources

- Final Verdict

- Best MIG Welding Techniques: Comprehensive FAQ

- Q1: What are the fundamental “best MIG welding techniques” for beginners?

- Q2: How important is gas shielding in MIG welding, and what are common types?

- Q3: What common problems do beginners face with MIG welding, and how can they be fixed?

- Q4: Can I learn “best MIG welding techniques” purely from a book, or do I need hands-on training?

- Q5: What’s the difference between “pushing” and “pulling” techniques in MIG welding?

- Q6: How do I choose the right wire feed speed and voltage for “best MIG welding techniques”?

- Q7: Are there specific “best MIG welding techniques” for different types of metal, like aluminum or stainless steel?

MIG WELDING FOR BEGINNERS: MIG WELDING BASIC SKILLS AND…

This book is a fantastic starting point for anyone new to the craft, laying a solid foundation for MIG welding basic skills. It breaks down complex processes into easy-to-understand steps, making it ideal for self-learners. You’ll find it focuses on getting you comfortable with your equipment and achieving your first consistent welds, setting you up for future success in MIG welding projects.

- Key features that stand out:

- Fundamental Concepts: Clearly explains welding safety, equipment setup, and basic techniques.

- Step-by-Step Instructions: Guides you through practice exercises for consistent bead laying.

- Troubleshooting Tips: Helps diagnose common welding issues and how to fix them.

- Pros:

- Extremely beginner-friendly and easy to follow.

- Covers essential safety and setup procedures thoroughly.

- Great for building initial confidence.

- Cons: Limited in advanced techniques or specific project plans.

- Best for: Absolute beginners seeking a clear, introductory guide.

- Expert Opinion: This book excels at demystifying MIG welding for newcomers. Its straightforward approach ensures that even those with no prior experience can start practicing effectively and safely.

Farm and Workshop Welding, Third Revised Edition:…

For those working in a practical, hands-on environment like a farm or a personal workshop, this revised edition offers invaluable insights. It doesn’t just teach you to weld; it teaches you to weld for practical repairs, fabrication, and maintenance tasks common in such settings. This resource emphasizes practical MIG welding applications and problem-solving, making it more than just a technique guide.

- Key features that stand out:

- Practical Project Focus: Tailored for common farm and workshop repairs and fabrications.

- Material-Specific Guidance: Offers advice on welding different types of metals often found in these environments.

- Tool and Equipment Selection: Helps you choose the right gear for your workshop needs.

- Pros:

- Highly practical and immediately applicable to real-world tasks.

- Covers a broader range of welding scenarios beyond just MIG.

- Provides cost-effective solutions for repairs.

- Cons: Might be too specific if you’re not working in a farm/workshop setting.

- Best for: Farmers, hobbyists, and workshop owners needing functional welding skills.

- Expert Opinion: This guide is a treasure trove for anyone needing to get practical work done. Its focus on real-world applications and specific material handling makes it indispensable for maintenance and fabrication tasks.

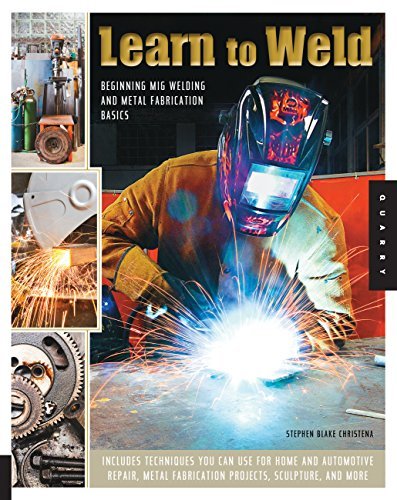

Learn to Weld: Beginning MIG Welding and Metal Fabrication…

This comprehensive guide is perfect for aspiring fabricators who want to go beyond just laying beads. It bridges the gap between basic MIG welding and actual metal fabrication, showing you how to conceptualize and execute projects. It’s a great choice for those who want to understand the entire process from design to finish, making it a powerful tool for developing advanced MIG welding techniques through practical projects.

- Key features that stand out:

- Project-Based Learning: Includes detailed instructions for various metal fabrication projects.

- Design and Layout Principles: Teaches you how to plan and prepare your workpieces.

- Tool and Safety Information: Comprehensive overview of necessary tools and safe shop practices.

- Pros:

- Excellent for learning metal fabrication in conjunction with welding.

- Projects help solidify theoretical knowledge into practical skills.

- Clear, illustrative diagrams and photos.

- Cons: May assume some very basic welding familiarity before diving into projects.

- Best for: Enthusiasts eager to undertake full metal fabrication projects using MIG welding.

- Expert Opinion: This book is a standout for those who learn by doing. The inclusion of fabrication techniques alongside welding makes it a holistic resource for creating functional and aesthetic metalwork.

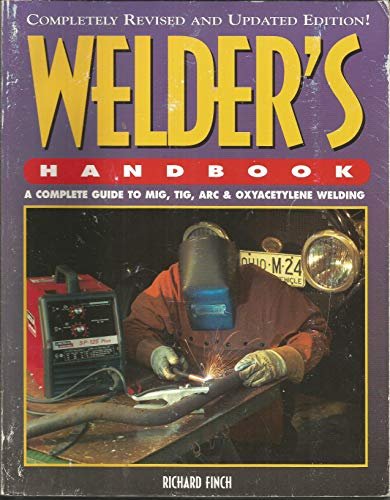

Welder’s Handbook: A Complete Guide to MIG, TIG, Arc &…

Richard Finch’s “Welder’s Handbook” is a perennial favorite, and this completely revised and updated edition ensures its relevance. While it covers multiple welding processes, its sections on MIG welding are thorough, making it a reliable resource for anyone looking for comprehensive knowledge. This paperback offers a deep dive into the theory and application, suitable for both serious hobbyists and those looking for professional development in MIG welding principles.

- Key features that stand out:

- Multi-Process Coverage: Comprehensive guide covering MIG, TIG, Arc, and Oxyacetylene welding.

- Theoretical and Practical Balance: Explains the science behind welding alongside practical application.

- Troubleshooting and Maintenance: Detailed sections on identifying and solving common welding problems and maintaining equipment.

- Pros:

- An excellent all-in-one reference for various welding methods.

- Highly detailed and authoritative content.

- Valuable for understanding the nuances of different processes.

- Cons: Its breadth means MIG-specific content isn’t as singularly focused as other books.

- Best for: Welders who want a broad, authoritative reference covering multiple welding processes.

- Expert Opinion: This handbook is a must-have for any serious welder’s library. Its updated content keeps it current, offering deep insights across various welding disciplines, not just MIG, which is incredibly valuable for a diverse skillset.

Welding Complete, 2nd Edition: Techniques, Project Plans &…

“Welding Complete, 2nd Edition” is a fantastic resource that truly lives up to its name, offering a blend of techniques and practical project plans. This book excels in guiding you from understanding MIG welding setup to executing actual projects, solidifying your skills with each weld. It’s particularly good at showing how different techniques contribute to a finished product, enhancing your overall MIG welding proficiency.

- Key features that stand out:

- Extensive Project Plans: Offers numerous projects to practice and apply learned techniques.

- Visual Learning: Rich with photographs and illustrations to demonstrate techniques.

- Material Selection and Preparation: Guidance on choosing and preparing various metals.

- Pros:

- Provides a well-rounded approach with both theory and application.

- Projects are well-documented and encouraging for skill development.

- Suitable for various skill levels looking to expand their welding repertoire.

- Cons: Some content might be introductory if you’re already an experienced welder.

- Best for: Welders looking for a comprehensive guide with practical projects to hone their skills.

- Expert Opinion: I’ve found this book particularly helpful for intermediate welders. The combination of technique explanations and engaging projects means you’re constantly learning and applying new skills.

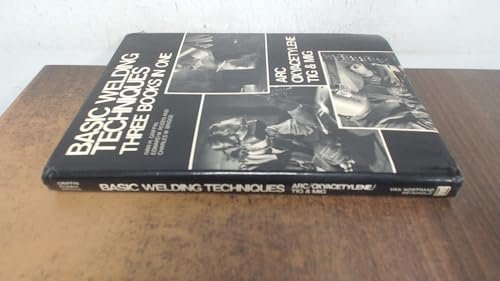

Basic Welding Techniques: Arc, Oxyacetylene, Tig and Mig

As its title suggests, “Basic Welding Techniques” provides a clear and concise overview of several welding methods, with a solid section dedicated to MIG welding. It’s designed to give you a foundational understanding without overwhelming you with overly technical jargon. This makes it an excellent choice for those who appreciate a straightforward approach to learning MIG welding basics and other essential methods.

- Key features that stand out:

- Clear Explanations: Simplifies complex welding concepts for easy understanding.

- Multi-Process Introduction: Covers Arc, Oxyacetylene, TIG, and MIG welding fundamentals.

- Safety Guidelines: Emphasizes crucial safety practices for each welding type.

- Pros:

- Great for getting a general overview of multiple welding processes.

- Uses plain language, making it accessible to all.

- Focuses on the core principles required for safe and effective welding.

- Cons: Less depth on advanced MIG techniques compared to specialized MIG books.

- Best for: Beginners who want a quick, comprehensive introduction to a range of welding techniques including MIG.

- Expert Opinion: This resource is fantastic for someone trying to decide which welding process they want to focus on, or for getting a quick grounding in several. Its MIG section is well-articulated for foundational understanding.

All About Steel – Welding Practice for TIG and MIG…

This unique resource stands out by offering a highly practical, project-based approach, focusing specifically on steel applications for TIG and MIG welding. Instead of just theory, it provides a tangible welding practice project: creating a small-scale steel sculpture with a geometric knotted design. This approach is incredibly effective for anyone who learns by doing and wants to develop precise and strong welds through hands-on work.

- Key features that stand out:

- Hands-on Project: Features a specific project (steel sculpture) to practice welding.

- Design Focus: Emphasizes creating interlocking knots with steel wire and rod.

- Technique Application: Directly applies MIG (or TIG) techniques to a real fabrication task.

- Integrated Safety: Highlights the importance of protective gear during the project.

- Pros:

- Excellent for developing practical precision welding skills.

- The project format makes learning engaging and rewarding.

- Directly applies theoretical knowledge to a tangible outcome.

- Cons: It’s more of a project guide than a general technique book.

- Best for: Welders looking for a specific, engaging project to refine their MIG (and TIG) welding skills on steel.

- Expert Opinion: This is a creative and highly effective way to refine your welding skills. Working on a project like this steel sculpture forces you to think about joint design, heat management, and precision, all critical for mastering MIG welding.

Comparison Insights for Best MIG Welding Techniques Resources

When looking for the best MIG welding techniques resources, consider your current skill level and learning style. For absolute beginners, “MIG WELDING FOR BEGINNERS” offers the clearest path to initial success, while “Basic Welding Techniques” provides a broader, yet still foundational, introduction to multiple processes including MIG.

If your aim is practical application in a workshop or farm, “Farm and Workshop Welding” is an unrivaled resource, focusing on real-world repairs and fabrication. For those who want to learn by building projects, “Learn to Weld” and “Welding Complete, 2nd Edition” both offer extensive plans to solidify your skills. “All About Steel” takes this project-based learning to a very specific and artistic level, perfect for refining precision MIG welding.

Finally, if you need a comprehensive reference that spans beyond just MIG, Richard Finch’s “Welder’s Handbook” is a robust choice, ensuring you have a go-to guide for various welding methods and advanced concepts. Each resource offers a unique approach to mastering MIG welding skills, so choose the one that best aligns with your goals.

Final Verdict

Navigating the world of MIG welding can seem daunting at first, but with the right guidance, it becomes an incredibly rewarding skill. After exploring these top resources, it’s clear that the “best” choice really depends on your individual needs.

For those taking their very first steps, “MIG WELDING FOR BEGINNERS” is an excellent starting block, providing straightforward, confidence-building instruction. If you’re a hands-on learner eager to tackle projects, “Learn to Weld” or “Welding Complete, 2nd Edition” will serve you incredibly well, offering a blend of technique and practical application that truly cements your knowledge.

However, if I had to pick one all-around resource that offers both depth and breadth for serious learning and long-term reference, Richard Finch’s “Welder’s Handbook” stands out. Its comprehensive coverage across multiple welding types, combined with its detailed explanations, makes it an invaluable asset for anyone committed to mastering welding, including the nuances of best MIG welding techniques. It’s the kind of book you’ll revisit repeatedly as your skills grow.

Ultimately, investing in any of these resources will set you on the path to becoming a more skilled and confident welder. Happy welding!

Best MIG Welding Techniques: Comprehensive FAQ

Q1: What are the fundamental “best MIG welding techniques” for beginners?

A1: For beginners, the best MIG welding techniques involve mastering consistent wire feed speed, maintaining proper electrode stick-out (typically 3/8 to 1/2 inch), and using the correct travel angle (pushing the puddle for thin materials, pulling for thicker). Focus on a smooth, consistent motion to create an even bead. Practice is key to developing muscle memory for these core skills.

Q2: How important is gas shielding in MIG welding, and what are common types?

A2: Gas shielding is critically important in MIG welding to protect the molten weld pool from atmospheric contamination (oxygen, nitrogen). Without it, your welds will be porous and weak. Common shielding gases for MIG include 100% CO2 (for deeper penetration, but more spatter), 75% Argon/25% CO2 (a common mix for general-purpose welding, offering good penetration and cleaner welds), and sometimes Argon/Oxygen mixes for stainless steel. Selecting the right gas is crucial for optimal MIG welding results.

Q3: What common problems do beginners face with MIG welding, and how can they be fixed?

A3: Beginners often encounter issues like porosity (holes in the weld due to gas contamination or too fast travel), lack of penetration (weld sits on top, usually from too low power or too fast travel), and excessive spatter (tiny metal droplets, often from incorrect voltage/wire speed or too much CO2). To fix these, ensure proper gas flow, adjust voltage and wire speed to match your material thickness, maintain correct stick-out, and clean your base metal thoroughly before welding. Learning MIG welding troubleshooting is essential for improvement.

Q4: Can I learn “best MIG welding techniques” purely from a book, or do I need hands-on training?

A4: While books and guides (like those reviewed) provide invaluable theoretical knowledge, safety protocols, and technique explanations, hands-on training is absolutely essential for mastering MIG welding. Welding is a tactile skill that requires practice to develop fine motor control, hand-eye coordination, and the ability to “read the puddle.” The best approach is to combine learning from comprehensive resources with consistent practical application in a safe environment.

Q5: What’s the difference between “pushing” and “pulling” techniques in MIG welding?

A5: The “pushing” technique (forehand) involves pointing the torch in the direction of travel, ahead of the weld puddle. This generally results in shallower penetration and a wider, flatter bead, making it suitable for thin materials and achieving cleaner welds with less spatter. The “pulling” technique (backhand) involves dragging the torch, pointing it back at the weld puddle. This provides deeper penetration and a narrower, convex bead, often preferred for thicker materials or when a stronger, more penetrating weld is desired. Both are vital MIG welding travel techniques.

Q6: How do I choose the right wire feed speed and voltage for “best MIG welding techniques”?

A6: Choosing the correct wire feed speed (WFS) and voltage is critical and they work in tandem. WFS controls the amperage and the rate at which the wire melts, while voltage controls the arc length and width. A good starting point is to use the settings recommended by your welding machine manufacturer or a welding chart for your specific material thickness and wire diameter. You then fine-tune by listening to the arc sound (a steady sizzle like frying bacon is ideal) and observing the weld puddle and bead appearance. Too high voltage or WFS can lead to burn-through, while too low can result in lack of fusion.

Q7: Are there specific “best MIG welding techniques” for different types of metal, like aluminum or stainless steel?

A7: Yes, specific techniques are needed. For MIG welding aluminum, you typically use 100% Argon shielding gas, a spool gun (to prevent wire tangles), and a “push” technique with faster travel speeds due to aluminum’s high thermal conductivity. For MIG welding stainless steel, an Argon/CO2 blend (or Argon/Oxygen for some) is common, and you often use a slightly slower travel speed and lower heat input to prevent distortion and carbide precipitation, which can reduce corrosion resistance. Understanding these material-specific MIG welding practices is key to success.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.