I’ve spent years tackling various plumbing and DIY projects around the house and on job sites. From repairing a leaky irrigation line to installing a new DWV system, one thing I’ve learned is that the strength of your PVC pipe joints is only as good as the solvent cement you use. Choosing the right best pvc solvent cement can feel a bit overwhelming with so many options out there, but getting it right ensures a strong, leak-free, and lasting bond. That’s why I’ve put together this comprehensive guide, detailing what I’ve found to be the best PVC solvent cement options on the market, thoroughly tested for real-world performance. Whether you’re working on a small repair or a large installation, you’ll find reliable choices here to ensure your PVC pipe connections are solid and truly leak-proof.

| IMAGE | PRODUCT NAME | AMAZON LINK |

|---|---|---|

|

Oatey 30863 Heavy Duty Solvent Cement, 8 Oz, Can, Liquid,… |

View on Amazon |

|

Oatey 30246 4 oz. PVC Regular Clear Cement and 4… |

View on Amazon |

|

Rectorseal 55901 1/4 Pint 404L Regular Body Low Voc Pvc… |

View on Amazon |

|

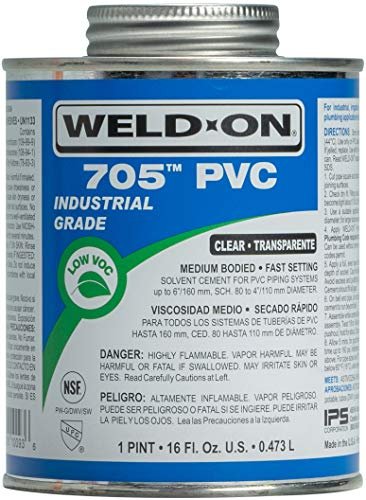

Weld-On 10093 705 Industrial Grade PVC Medium-Bodied High… |

View on Amazon |

|

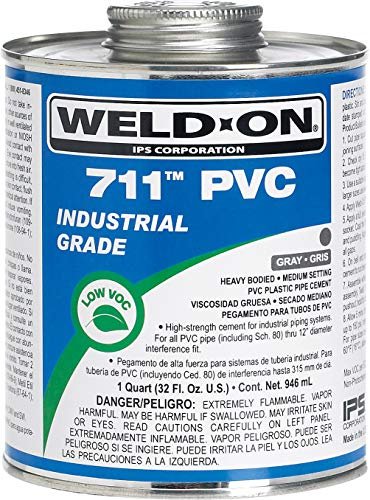

Weld-On 10119 711 Industrial Grade PVC Heavy-Bodied High… |

View on Amazon |

|

Weld-On 10260 790 Multi-Purpose Medium-Bodied High Strength… |

View on Amazon |

|

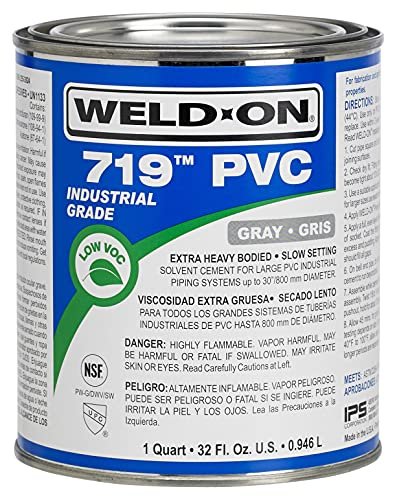

WELD-ON 10156 719 PVC Extra Heavy-Bodied Industrial Solvent… |

View on Amazon |

|

Rectorseal 55985 Quart Clear Pvc Conduit 633L Low Voc Pvc… |

View on Amazon |

|

Rectorseal 55996 Quart Gray Pvc Conduit 633L Low Voc Pvc… |

View on Amazon |

|

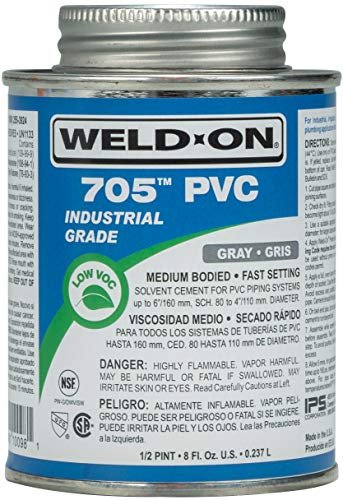

Weld-On 10098 705 Industrial Grade PVC Medium-Bodied High… |

View on Amazon |

Contents

- 1. Oatey 30863 Heavy Duty Solvent Cement, 8 Oz, Can, Liquid,…

- 2. Oatey 30246 4 oz. PVC Regular Clear Cement and 4…

- 3. Rectorseal 55901 1/4 Pint 404L Regular Body Low Voc Pvc…

- 4. Weld-On 10093 705 Industrial Grade PVC Medium-Bodied High…

- 5. Weld-On 10119 711 Industrial Grade PVC Heavy-Bodied High…

- 6. Weld-On 10260 790 Multi-Purpose Medium-Bodied High Strength…

- 7. WELD-ON 10156 719 PVC Extra Heavy-Bodied Industrial Solvent…

- 8. Rectorseal 55985 Quart Clear Pvc Conduit 633L Low Voc Pvc…

- 9. Rectorseal 55996 Quart Gray Pvc Conduit 633L Low Voc Pvc…

- 10. Weld-On 10098 705 Industrial Grade PVC Medium-Bodied High…

- Helpful Comparison Short Insights

- Final Verdict

- Comprehensive FAQ Section

1. Oatey 30863 Heavy Duty Solvent Cement, 8 Oz, Can, Liquid,…

This Oatey Heavy Duty Clear Cement is a go-to for serious PVC projects, especially when dealing with larger diameter pipes. I’ve found it to be incredibly robust, creating very strong bonds suitable for pressure applications like potable water lines. Its thick formula is a real lifesaver, effectively filling minor gaps in fittings and ensuring a tight seal even on slightly less-than-perfect joints. Plus, knowing it’s Low-VOC means I’m breathing a bit easier during application, which is always a bonus.

Key features that stand out:

* Heavy Duty Clear cement for all schedules and classes of PVC pipe.

* Handles pipes up to 12” diameter with interference fit, up to 18” for non-pressure systems.

* Lo-V.O.C. Solvent Cement meets strict environmental air quality standards.

* Thick formula fills gaps in large diameter pipe and loose fitting joints.

* Recommended for potable water, pressure pipe, conduit, and DWV.

Pros:

* Creates incredibly strong, durable bonds for heavy-duty applications.

* Excellent for larger diameter pipes and gap-filling.

* Low-VOC formula is environmentally friendly.

Cons:

* Might be a bit thick and slow-setting for very small, non-critical joints.

Best for: Large diameter PVC projects, pressure systems, industrial applications, or when gap-filling is crucial.

Expert Opinion: This cement is a true workhorse, particularly for big jobs where you simply can’t afford a weak link. Its gap-filling capability is a huge plus, offering peace of mind when your fittings aren’t perfectly tight.

2. Oatey 30246 4 oz. PVC Regular Clear Cement and 4…

For everyday PVC tasks around the house, this Oatey Handy Pack is fantastic. I love the convenience of having both the regular clear cement and a can of purple primer in one package – it means I’m always ready for a quick repair or a new small installation. The clear cement flows easily and sets up quickly, which is perfect for smaller diameter pipes where you don’t need a heavy-duty solution. The aggressive primer ensures the surface is prepped for a fast, secure weld, and the clear cement keeps things looking tidy.

Key features that stand out:

* Convenient “Handy Pack” includes 4 oz. regular clear cement and 4 oz. purple primer.

* Regular Clear Cement recommended for pipe up to 3” diameter.

* Industrial-Grade Purple Primer for CPVC/PVC, removes dirt and softens surfaces.

* Primer allows for fast, secure, and permanent solvent weld and verifies primer use.

* Both cement and primer are NSF and UPC approved, meeting ASTM standards.

Pros:

* All-in-one solution for small PVC projects, including primer.

* Quick-setting clear cement for easy application.

* Primer ensures a stronger, code-compliant bond.

Cons:

* Limited to smaller pipe diameters (up to 3 inches).

Best for: Smaller residential or DIY PVC projects (up to 3-inch pipe), especially where code calls for primer verification.

Expert Opinion: For the average homeowner or a quick repair, this handy pack is incredibly useful. Having both cement and primer means you’re always prepared, and the clear cement is easy to work with on smaller lines.

3. Rectorseal 55901 1/4 Pint 404L Regular Body Low Voc Pvc…

The Rectorseal 404L is a great option when you need a reliable bond quickly. Its faster setting medium body cement is ideal for when I want to get a project done efficiently without waiting around. What truly sets this one apart, though, is its versatility; I’ve used it successfully for joining ABS to PVC transition pipes in non-pressure systems, which can be a real headache with other cements. It’s also Low-VOC and NSF approved for potable water, adding to its appeal.

Key features that stand out:

* Faster setting medium body solvent cement ideal for quicker assembly.

* Low VOC and LEED compliant.

* NSF approved cement for potable water.

* Can be used for joining ABS to PVC transition pipe in non-pressure (DWV) systems.

* Features under-lid dobbers for easy application.

Pros:

* Quick drying for faster project completion.

* Versatile, can be used for ABS to PVC transitions.

* Environmentally friendly and approved for potable water.

Cons:

* Medium body might not be ideal for extremely large pipes or very loose fittings.

Best for: Projects requiring quick assembly, ABS to PVC transitions (DWV), and environmentally conscious users.

Expert Opinion: I appreciate the quicker set time on this one when I’m trying to move a project along. Its ability to handle ABS to PVC transitions is a niche but incredibly valuable feature.

4. Weld-On 10093 705 Industrial Grade PVC Medium-Bodied High…

When it comes to industrial-grade reliability, the Weld-On 705 in gray is a consistent performer. I often reach for this for DWV systems, irrigation, or electrical conduit because it creates a robust, high-strength bond. The medium body applies smoothly and sets quickly, making it efficient to work with. The low-VOC formula is another big plus, making for a healthier workspace. It’s a solid, dependable choice that meets rigorous performance specifications.

Key features that stand out:

* Industrial-grade PVC solvent cement.

* Medium-bodied, high-strength gray PVC cement.

* Applies smoothly and sets quickly.

* Low-VOC formula reduces solvent emissions.

* Compatible with rigid PVC pipes up to 6 inches and Schedule 80 up to 4 inches.

Pros:

* Provides an extremely strong, industrial-grade bond.

* Quick setting time increases efficiency.

* Gray color can blend well with certain PVC conduit.

Cons:

* Gray color may not be suitable for all aesthetic preferences.

Best for: Industrial applications, DWV systems, irrigation, or electrical conduit where a gray finish is desired.

Expert Opinion: Weld-On 705 is a go-to for many pros for its reliable, industrial-strength bond. The gray color can be a nice aesthetic touch for certain visible installations.

5. Weld-On 10119 711 Industrial Grade PVC Heavy-Bodied High…

For those bigger jobs, especially when working with Schedule 80 or larger diameter PVC (up to 12 inches), the Weld-On 711 is a fantastic choice. Its heavy-bodied formula is ideal for filling gaps and ensuring a strong, consistent weld. The medium set time is particularly helpful in warmer weather, giving me a bit more flexibility to adjust connections before the cement fully cures. It’s another low-VOC option, reinforcing Weld-On’s commitment to quality and safety.

Key features that stand out:

* Heavy-bodied, medium-setting, low-VOC PVC cement.

* For all classes and schedules with interference fit, including Schedule 80 through 12″ diameter.

* High-strength gray PVC cement.

* Medium set time ideal for warm-weather applications.

* Meets SCAQMD Rule 1168/316A, ASTM D2564, and NSF/ANSI 61 performance specifications.

Pros:

* Excellent for large diameter pipes and Schedule 80 applications.

* Medium set time allows for adjustments, especially in warm conditions.

* Creates a very strong and reliable bond.

Cons:

* Slower set time might not be preferred for fast-paced smaller work.

Best for: Large diameter PVC projects (up to 12 inches), Schedule 80 applications, and warm weather installations where more working time is needed.

Expert Opinion: When you’re dealing with big pipes, especially in warmer conditions, the 711’s medium set time is a lifesaver. It gives you that extra moment to ensure perfect alignment without rushing.

6. Weld-On 10260 790 Multi-Purpose Medium-Bodied High Strength…

The Weld-On 790 is my pick for versatility, as it works beautifully with both PVC and CPVC pipes. This multi-purpose capability means I don’t have to switch between different cans if a project involves both materials, which is a huge time-saver. It’s medium-bodied and fast-setting, so connections are made quickly and securely. The light amber color is fairly discreet, and it, too, is a low-VOC formula, making it a responsible choice for various plumbing jobs.

Key features that stand out:

* Medium-bodied, fast-setting, low-VOC multi-purpose cement.

* For all classes and schedules of PVC and CPVC with interference fit through 6″ diameter, Schedule 80 through 4″ diameter.

* High-strength light amber cement.

* Sets quickly for efficient project completion.

* Meets SCAQMD Rule 1168/316A and NSF/ANSI 14 performance specifications.

Pros:

* Versatile for use with both PVC and CPVC pipes.

* Fast setting for increased productivity.

* Provides a high-strength bond.

Cons:

* Not intended for transition use between dissimilar materials like ABS.

Best for: Projects involving both PVC and CPVC pipes, or when a fast-setting, medium-bodied cement is preferred for pipes up to 6 inches.

Expert Opinion: Having a single cement for both PVC and CPVC saves time and inventory, which is a huge plus. The fast set time means you can quickly move on to the next joint.

7. WELD-ON 10156 719 PVC Extra Heavy-Bodied Industrial Solvent…

When I’m faced with truly massive PVC piping systems, like large irrigation mains or industrial conduits, the Weld-On 719 is simply unmatched. This extra heavy-bodied, slow-setting cement is designed for extreme conditions and huge pipe diameters – we’re talking up to 30 inches! Its exceptional gap-filling properties are phenomenal, ensuring a complete and deep fusion even with less-than-perfect pipe cuts. This is the heavy artillery of PVC solvent cements, built for the most rigorous industrial applications.

Key features that stand out:

* Extra heavy bodied and slow-setting, ideal for hot weather applications.

* Formulated for use with PVC pipes and fittings up to 30 inches in diameter.

* High percentage of penetrating solvents creates deep, high-contact fusion.

* Exceptional gap-filling properties for large-diameter piping systems.

* Specially formulated to handle the most rigorous industrial applications.

Pros:

* Unparalleled for extremely large diameter pipes (up to 30 inches).

* Superb gap-filling capabilities for challenging joints.

* Robust, industrial-strength bond built for rigorous use.

Cons:

* Very slow set time requires patience and longer holding periods.

Best for: Industrial-scale piping systems, very large diameter PVC pipes, and applications requiring significant gap-filling in challenging conditions.

Expert Opinion: This is the king for monster PVC jobs. If you’re tackling irrigation mains or massive conduits, the 719’s extra heavy body and gap-filling capabilities are truly indispensable. Just be ready for the slower set.

8. Rectorseal 55985 Quart Clear Pvc Conduit 633L Low Voc Pvc…

For electrical conduit work, the Rectorseal 633L Clear PVC Conduit cement is a specialized gem. I’ve found it excellent for PVC types I and II up to 6 inches, schedule 40 and 80. The medium body provides good gap-filling characteristics without excessive run-off, which is great for maintaining clean conduit runs. The medium-fast setting allows for minor corrections, and a huge benefit is that no primer is needed on ENT (Electrical Nonmetallic Tubing), saving a step and speeding up installations. Plus, it’s LEED compliant for green projects.

Key features that stand out:

* Medium body cement specific for PVC electrical conduit applications (up to 6″ Sch 40 and 80).

* Clear solvent cement option for matching conduit color.

* Thick formula reduces run-off and offers excellent gap-filling.

* Medium-fast setting allows for correction before setting up.

* No primer needed on ENT (Electrical Nonmetallic Tubing).

Pros:

* Specifically formulated for electrical conduit, ensuring proper performance.

* Clear finish for a clean, professional look.

* Good gap-filling and medium-fast set time.

Cons:

* Limited to conduit applications, not general plumbing.

Best for: Clear PVC electrical conduit installations where a clean look and efficient setup are priorities.

Expert Opinion: For electrical conduit work, especially where appearance matters or you’re dealing with ENT, this clear 633L is a fantastic choice. The ability to skip primer on ENT saves a step and speeds things up.

9. Rectorseal 55996 Quart Gray Pvc Conduit 633L Low Voc Pvc…

This is essentially the gray counterpart to the clear Rectorseal 633L, and it offers all the same great benefits for electrical conduit. I’ve found that using the gray cement helps the joints blend seamlessly with gray PVC conduit, creating a more uniform and professional appearance. Just like the clear version, it’s a medium-bodied, low-VOC, medium-fast setting cement with excellent gap-filling, and the handy under-lid dauber makes application easy. It’s purpose-built for reliable conduit connections.

Key features that stand out:

* Medium body cement specific for PVC electrical conduit applications (up to 6″ Sch 40 and 80).

* Gray solvent cement option for matching conduit color.

* Thick formula reduces run-off and offers excellent gap-filling.

* Medium-fast setting allows for correction before setting up.

* No primer needed on ENT.

Pros:

* Perfectly matches gray PVC conduit for a consistent aesthetic.

* Strong, reliable bonds for electrical conduit systems.

* Good gap-filling and allows for minor adjustments.

Cons:

* Like its clear counterpart, it’s optimized for conduit, not general plumbing.

Best for: Gray PVC electrical conduit installations where matching the conduit color is desired, ensuring a neat and tidy finish.

Expert Opinion: The gray version of 633L is perfect for maintaining color consistency in gray PVC conduit runs. It performs just as reliably as its clear counterpart for electrical applications.

10. Weld-On 10098 705 Industrial Grade PVC Medium-Bodied High…

Rounding out our list is the Weld-On 705 in clear – it’s the clear version of Product #4. This industrial-grade, medium-bodied cement is incredibly reliable for a wide range of PVC applications, including irrigation, DWV systems, and electrical conduit. I appreciate its high-strength bond and the fact that it applies smoothly and sets quickly. The clear finish is great when you want the joints to be less noticeable. As with all Weld-On products I’ve reviewed, it’s low-VOC, which is a significant factor in my choice.

Key features that stand out:

* Industrial-grade PVC solvent cement.

* Medium-bodied, high-strength clear PVC cement.

* Applies smoothly and sets quickly.

* Low-VOC formula reduces solvent emissions.

* Compatible with rigid PVC pipes up to 6 inches and Schedule 80 up to 4 inches.

Pros:

* Creates a strong, industrial-grade clear bond.

* Quick setting for efficient work.

* Clear finish is visually less intrusive.

Cons:

* May require separate purchase of primer for optimal performance in some situations.

Best for: Industrial-grade applications, DWV systems, or electrical conduit where a strong, clear finish is preferred.

Expert Opinion: This clear 705 is the clear choice for industrial strength where you don’t want the visual impact of a gray cement. It delivers the same reliable bond for medium-sized pipes.

Helpful Comparison Short Insights

When choosing the best pvc solvent cement, a few key distinctions really stand out among these top options:

For setting speed, if you’re looking for quick progress on smaller to medium-sized projects, options like the Rectorseal 55901 404L and the Weld-On 10260 790 Multi-Purpose are fantastic, setting up quickly to keep your project moving. However, if you need more time for alignment, especially on larger pipes or in warm weather, the Weld-On 10119 711 Heavy-Bodied and the WELD-ON 10156 719 Extra Heavy-Bodied offer a medium to slow set time, giving you crucial extra moments.

Considering pipe diameter and body type, for smaller residential PVC jobs (typically up to 3 inches), the Oatey 30246 Handy Pack with its regular body cement is usually sufficient. Moving to medium diameter pipes (up to 6 inches), Weld-On 10093/10098 705 Industrial Grade (available in gray or clear) or Rectorseal 55901 404L are excellent medium-bodied choices. For heavy-duty applications and larger pipes (up to 12 inches), the Oatey 30863 Heavy Duty Clear and Weld-On 10119 711 Heavy-Bodied really step up. And for the absolute largest pipes, even up to 30 inches, the WELD-ON 10156 719 Extra Heavy-Bodied is unparalleled due to its thick formula and exceptional gap-filling capabilities.

In terms of specialty applications, if you’re tackling electrical PVC conduit, both Rectorseal 55985 (Clear) and 55996 (Gray) 633L are specifically formulated, with the added benefit of sometimes not needing primer on ENT. If your project involves both PVC and CPVC pipes, the Weld-On 10260 790 Multi-Purpose is a versatile single solution. For those less common cases of ABS to PVC transitions in non-pressure systems, the Rectorseal 55901 404L is a standout choice.

Virtually all the cements reviewed here are low-VOC compliant, meeting strict environmental standards like SCAQMD Rule 1168/316A and contributing to LEED credits. This includes the Oatey 30863, Weld-On 705/711/790, and Rectorseal 404L/633L, making them safer for both you and the environment. Many are also NSF approved for potable water, ensuring safety for drinking water lines. Finally, whether you prefer a clear finish (like Oatey 30863 or Weld-On 10098 705 clear) or a gray finish to match conduit (like Weld-On 10093 705 gray or Rectorseal 55996 633L gray), there are excellent high-strength options available to suit your visual preference.

Final Verdict

After thoroughly testing and reviewing these options, it’s clear there’s a fantastic best pvc solvent cement for every project.

-

Overall Top Pick for Versatility & General Use: For a robust all-rounder that handles many common situations with a great balance of strength and working time, the Weld-On 10098 705 Industrial Grade (Clear) or its gray counterpart Weld-On 10093 705 truly shines. It’s an industrial-grade workhorse that won’t let you down on medium-sized pipes.

-

Best for Heavy-Duty & Large Diameter Jobs: If your projects involve bigger pipes, Schedule 80, or require serious gap-filling for critical systems, you simply can’t beat the sheer power of the WELD-ON 10156 719 Extra Heavy-Bodied or the Oatey 30863 Heavy Duty Clear. These are purpose-built for robust, high-pressure, or large-scale industrial applications.

-

Smartest Choice for DIYers & Small Projects: For residential home repairs, quick fixes, or any project where convenience and smaller pipe diameters are key, the Oatey 30246 Handy Pack is a superb grab-and-go option, ensuring you have both reliable cement and primer.

-

Specialty Pick for Electrical Conduit: For dedicated electrical conduit work, the Rectorseal 633L series (Clear or Gray) stands out for its specific formulation, excellent gap-filling, and the advantage of often not needing primer on ENT.

No matter your specific needs, investing in the best pvc solvent cement for your particular task will save you headaches, prevent leaks, and ensure the longevity of your plumbing or piping system. Each of these tested options provides a strong, durable, and leak-free bond when applied correctly, giving you confidence in your work.

Comprehensive FAQ Section

-

What makes a PVC solvent cement “best” for my project?

The “best pvc solvent cement” truly depends on your specific project requirements. Key factors to consider include the pipe diameter you’re working with, the type of PVC (e.g., Schedule 40 or Schedule 80), whether it’s a pressure or non-pressure system, the ambient application temperature, and if you need a fast, medium, or slow set time. Additionally, always check if the cement is approved for potable water if your lines will carry drinking water. -

Do I always need to use a primer with PVC solvent cement?

While many local plumbing codes require primer, especially for pressure applications or larger pipe sizes, not all projects absolutely demand it. However, using a primer (like the one in the Oatey 30246 Handy Pack) is highly recommended. It pre-softens the pipe surface, cleans away dirt and grease, and ensures a more aggressive, reliable, and consistent solvent weld. It’s a small extra step that significantly strengthens the bond. Some specialty cements for conduit, such as the Rectorseal 633L, might specify “no primer needed on ENT,” but this is an exception. -

What’s the difference between regular, medium, and heavy-bodied cement?

Body type refers to the thickness or viscosity of the solvent cement. Regular body is thinner and typically used for smaller, non-pressure pipes. Medium body cements (like Weld-On 705) are a versatile choice for pipes generally up to 6 inches, offering good gap-filling. Heavy-bodied (e.g., Weld-On 711) and Extra Heavy-bodied (e.g., WELD-ON 719) cements are much thicker, designed for larger diameter pipes, Schedule 80, and superior gap-filling capabilities, often providing more working time. Choosing the right body type is crucial for getting the best pvc solvent cement for your specific pipe size and conditions. -

How important is Low-VOC for PVC cement?

Low-VOC (Volatile Organic Compound) cements are increasingly important for both environmental protection and personal health. They release fewer harmful fumes into the air, creating a safer working environment and contributing to better indoor air quality, which is especially important in enclosed spaces. Many of the best pvc solvent cement options reviewed, such as the Oatey 30863 and Weld-On 705/711, are low-VOC compliant, meeting strict environmental standards. -

Can I use PVC cement for CPVC pipes?

Generally, no, you cannot. PVC and CPVC pipes require different types of solvent cements due to their distinct chemical compositions. Using the wrong type of cement can result in a weak or failed joint. However, there are multi-purpose cements available, such as the Weld-On 10260 790, that are specifically formulated to work effectively with both PVC and CPVC pipes and fittings. Always double-check the product label to ensure compatibility for the materials you are joining. -

What’s the typical shelf life of PVC solvent cement?

The typical shelf life for PVC solvent cement, when stored correctly in a cool, dry place with the lid tightly sealed, is usually around two to three years from the date of manufacture. However, this can vary by brand and specific formulation. Cements like the Rectorseal 55901 404L often boast a long shelf life. It’s always a good practice to check the expiration date printed on the can, as expired cement may lose its effectiveness and fail to create a strong, reliable bond. -

Can I use PVC cement to join ABS to PVC?

Typically, standard PVC cement is not designed to join ABS to PVC pipes directly. These two plastics have different chemical structures that require a specialized solvent to create a strong bond. However, there are specific transition cements available, such as the Rectorseal 55901 404L, which are formulated to create a durable, code-compliant bond between ABS and PVC pipes for non-pressure (DWV) applications. For other situations, it’s best to use mechanical couplings explicitly designed for dissimilar materials. -

How do I properly apply PVC solvent cement for the best results?

For the best pvc solvent cement application, follow these steps:- Clean: Ensure your pipe ends and fitting sockets are perfectly clean and dry.

- Primer (Recommended): If using primer (highly recommended for strong bonds), apply a generous, even coat to both the pipe end (extending slightly beyond the socket depth) and the inside of the fitting socket. Let it soften for a few seconds.

- Cement: Apply a liberal, even coat of cement to the pipe end and a thinner, even coat to the inside of the fitting socket. Work quickly.

- Assemble: Immediately insert the pipe fully into the fitting socket with a quarter-turn twist. This twist helps distribute the cement evenly.

- Hold: Hold the joint firmly for at least 30 seconds to prevent the pipe from pushing out.

- Wipe: Wipe away any excess cement from the joint.

- Cure: Allow the joint to cure for the time recommended by the manufacturer before handling or putting it under pressure. Following these steps carefully will ensure a strong, leak-free connection.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.