As someone who’s spent countless hours in the workshop, I know the difference a reliable welding machine can make. When it comes to everyday repairs, DIY projects, or even light industrial tasks, a single phase welding machine is often the practical choice. It’s about finding that sweet spot of power, portability, and ease of use. In this guide, I’ll walk you through five top-rated single phase welders I’ve either used or thoroughly researched, offering hands-on insights to help you pick the best single phase welding machine that truly fits your needs, whether you’re a hobbyist or a professional looking for a dependable workhorse.

Contents

- Hoteche Portable Spot Welder Single Phase Spot Welding…

- Triumph 1.5kW 4 in 1 Integrated Fiber Laser Welding…

- Stark USA Portable Spot Welder 1/8″ Electric Single Phase…

- Triumph 1500W 4 in 1 Integrated Fiber Laser Welding…

- 110Volt/60Hz Spot Welder Welding Hand Machine Portable…

- Helpful Comparison Short Insights

- Final Verdict

- Best Single Phase Welding Machine: Your Questions Answered

- What does “single phase” mean for a welding machine?

- Are single phase welding machines powerful enough for thick materials?

- What’s the main difference between a spot welder and a laser welder?

- What should I look for in a portable single phase welding machine?

- How important is duty cycle for a single phase welder?

- Can beginners use these single phase welding machines?

- What maintenance is required for a single phase laser welder?

Hoteche Portable Spot Welder Single Phase Spot Welding…

If you’re looking for a dependable spot welder for quick and clean joins, the Hoteche Portable Spot Welder is a standout. It brings high-powered performance to your workbench, making light work of various materials for both DIY enthusiasts and more demanding professional tasks. With its compact and portable design, complete with an American plug for 110-120V input, you can easily move it around your workspace or take it on the go without sacrificing capability. This machine truly delivers efficient spot welding capacity, capable of handling material thicknesses up to 1.2mm + 1.2mm.

Key features that stand out:

– High-Powered Performance: Features an 8KW input capacity for excellent spot welds.

– Efficient Spot Welding Capacity: Capable of welding 1.2mm + 1.2mm thick materials, ideal for sheet metal and auto repair.

– Compact and Portable Design: Equipped with an American plug (110-120V) for easy use anywhere.

– Consistent Performance: Offers a 50% duty cycle, ensuring efficient, prolonged operation without overheating.

– Versatile and Reliable: Suitable for light industrial tasks, home use, metal fabrication, and electronics repair.

Pros:

– Provides strong, clean spot welds quickly.

– Highly portable and easy to set up with standard outlets.

– Good duty cycle for sustained use in its class.

– Versatile for a range of small to medium projects.

Cons:

– Primarily designed for spot welding, not an all-purpose welder.

Best for: DIY projects, automotive repair, sheet metal work, and light industrial applications requiring precise and fast spot welds.

Expert Opinion: This unit is a solid choice for those needing dedicated spot welding capabilities. Its portability and decent power make it surprisingly capable for its compact footprint, especially for sheet metal and automotive work.

Triumph 1.5kW 4 in 1 Integrated Fiber Laser Welding…

The Triumph 1.5kW Fiber Laser Welder is truly a game-changer if you’re stepping into the world of advanced metal fabrication. This isn’t just a welder; it’s a 4-in-1 powerhouse that can weld, clean rust, clean welding seams, and even perform simple cuts! Its incredibly compact and portable design means you can easily carry it around your shop or to different job sites. With a light and flexible welding gun and an auto wire feeder, it makes complex welds feel effortless, reducing fatigue during long working hours.

Key features that stand out:

– 4-in-1 Integrated Functionality: Offers welding, rust cleaning, welding seam cleaning, and simple cutting.

– Compact and Portable Design: Small footprint (25”H x 13″W x 25″L) for maximum mobility.

– Flexible Welding Gun & Auto Wire Feeder: Designed for comfort and precision, even during extended use.

– Wide Material Compatibility: Welds steel, stainless steel, copper, aluminum, gold, silver, and other metals.

– USA Stock & Quick Shipping: Available for fast delivery within 2-5 days in the USA.

– Long-Life Laser Source & Warranty: Boasts a 100,000-hour laser source life and a two-year warranty with strong after-sales support.

Pros:

– Exceptional versatility with its 4-in-1 capabilities.

– High precision and clean welds with minimal post-processing.

– Significantly reduces user fatigue due to ergonomic design.

– No consumables needed, lowering operational costs.

– Excellent for complex and irregular welding processes.

Cons:

– Represents a significant upfront investment compared to traditional welders.

Best for: Professionals in metal fabrication, cabinet making, kitchen manufacturing, and specialized industries requiring high precision, speed, and multi-functional metal processing.

Expert Opinion: This machine represents the cutting edge of welding technology for single-phase power. Its integrated laser capabilities redefine efficiency, making it ideal for high-end fabrication and repetitive, precise work where speed and clean finishes are paramount.

Stark USA Portable Spot Welder 1/8″ Electric Single Phase…

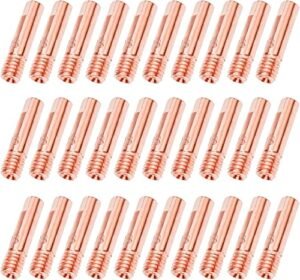

The Stark USA Portable Spot Welder is a robust and incredibly easy-to-use solution for a wide array of spot welding needs. Whether you’re in metal manufacturing, automotive making, or electronics assembly, its wide applications make it a versatile tool. This machine delivers high power output with a 1.5KVA rated input capacity and a maximum output current of 5500A, ensuring swift and efficient welding for both light and heavy-duty tasks. You’ll appreciate the durable copper welding tips, crafted for long-lasting performance and perfect welds on various material thicknesses.

Key features that stand out:

– Wide Applications: Ideal for metal manufacturing, automotive, electronics assembly, and general metal fabrication.

– High Power Output: Rated input capacity of 1.5KVA and a maximum output current of 5500A for efficient welds.

– Durable Copper Welding Tips: Constructed from high-quality copper for longevity and consistent perfect welds.

– Easy-To-Use Design: Simple lever operation suitable for both novices and seasoned professionals.

– Lightweight & Compact: Portable design with an attached handle for easy transport between job sites.

Pros:

– Very straightforward and intuitive operation, great for beginners.

– Delivers strong and quick spot welds on various materials.

– Robust construction with durable welding tips for extended life.

– Compact and easily transportable.

Cons:

– Its functionality is limited to spot welding only.

Best for: Small workshops, automotive enthusiasts, DIYers, and professionals seeking a powerful, durable, and user-friendly spot welder for repetitive tasks.

Expert Opinion: For sheer ease of use and consistent spot welds, the Stark USA stands out. Its durable construction and strong output make it a reliable tool for quickly joining thin to moderate gauge materials without a steep learning curve.

Triumph 1500W 4 in 1 Integrated Fiber Laser Welding…

Building on the excellence of the Triumph laser welder line, this 1500W 4-in-1 Integrated Fiber Laser Welding machine steps up the power for even more demanding tasks. Like its counterpart, it boasts 4-in-1 functionality—welding, rust cleaning, seam cleaning, and cutting—but with an increased wattage that significantly expands its material thickness capabilities. It retains the same compact and portable design (25”H x 13″W x 25″L) and the flexible welding gun for fatigue-free operation. This unit is particularly noteworthy for its detailed specifications on maximum welding thickness, allowing you to confidently tackle thicker stainless steel, iron, carbon steel, brass, and aluminum.

Key features that stand out:

– Higher Power (1500W): Enhanced capability for welding thicker materials; e.g., 4mm Stainless Steel, 3mm Aluminum.

– 4-in-1 Integrated Functionality: Combines welding, rust cleaning, seam cleaning, and cutting into one machine.

– Compact and Portable Design: Maintains a small footprint for easy transport and on-site work.

– Flexible Welding Gun & Auto Wire Feeder: Ensures ergonomic use and consistent, precise welds.

– Wide Material Compatibility & Thickness Range: Excellent for various metals and complex industrial processes.

– Long-Life Laser Source & Warranty: Backed by a 100,000-hour laser source life and a two-year warranty with comprehensive support.

Pros:

– Can weld significantly thicker materials compared to lower wattage models.

– Retains the exceptional versatility of 4-in-1 laser processing.

– Provides incredibly clean, precise welds with minimal distortion.

– Low operating cost due to no consumables and long laser life.

– Strong customer support and training resources for all skill levels.

Cons:

– Requires a substantial investment and a learning curve for new users.

Best for: Industrial fabrication, specialized workshops, and professionals who need high power and multi-functional capabilities for precise welding on a wider range of material thicknesses.

Expert Opinion: This 1500W model is a serious contender for businesses looking to upgrade their welding capabilities. The increased power output combined with the 4-in-1 features and exceptional support package makes it a very attractive, long-term investment for high-precision, heavy-duty applications.

110Volt/60Hz Spot Welder Welding Hand Machine Portable…

For those seeking an entry-level or highly portable solution for basic spot welding tasks, this 110Volt/60Hz Spot Welder is a straightforward and effective option. It’s designed to be a single phase, portable unit, making it incredibly easy to use right out of the box with standard household power. The electronic control simplifies the welding process, allowing you to achieve quick, strong spot welds with minimal effort. A key benefit of this machine is its ability to weld uncoated stock, expanding its utility for various small projects and repairs.

Key features that stand out:

– Single Phase: Operates on standard 110V/60Hz household power.

– Portable: Lightweight and compact for easy transport and storage.

– Electronic Control: Simplifies the welding process for consistent results.

– Welds Uncoated Stock: Capable of welding materials without pre-treatment.

– Quick Strong Spot Welds: Designed for efficiency in making robust point welds.

Pros:

– Extremely portable and convenient for small spaces.

– Very easy to operate, even for beginners.

– Cost-effective solution for basic spot welding needs.

– Effectively creates quick, strong welds on appropriate materials.

Cons:

– Limited in power and versatility compared to higher-end models.

Best for: Hobbyists, DIYers, and individuals needing a very basic, budget-friendly, and highly portable spot welder for occasional, light-duty sheet metal work or small repairs.

Expert Opinion: This unit embodies simplicity and portability for basic spot welding. While it lacks the advanced features of other machines, its electronic control and ability to make quick, strong welds on uncoated material make it a practical, no-frills option for light-duty tasks.

Helpful Comparison Short Insights

When comparing these single phase welding machine options, it’s clear we have two distinct categories: dedicated spot welders and advanced laser welders.

For traditional spot welding, the Hoteche Portable Spot Welder stands out for its strong 8KW performance and impressive 50% duty cycle, making it great for sustained use in auto body or sheet metal work. The Stark USA Portable Spot Welder offers similar power but shines with its exceptionally durable copper tips and user-friendly operation, a fantastic choice for both pros and novices. For the most budget-friendly entry into spot welding, the 110Volt/60Hz Spot Welder is your no-frills, highly portable option, perfect for quick, occasional tasks on uncoated stock.

Shifting to the cutting edge, both Triumph Laser Welders offer transformative 4-in-1 functionality (weld, clean, cut) that significantly boosts productivity and precision. While the Triumph 1.5kW model provides excellent versatility and speed for many applications, the Triumph 1500W version is the clear winner for handling thicker materials with greater ease and efficiency, making it the powerhouse for demanding industrial jobs. Both Triumph models benefit from USA stock and quick shipping, along with a long-life laser source and minimal consumables, offering long-term value.

Final Verdict

Choosing the best single phase welding machine truly boils down to your specific needs, skill level, and budget.

If your projects mostly involve quick, strong spot welds on thinner materials, the Hoteche Portable Spot Welder or the Stark USA Portable Spot Welder are both excellent, reliable choices that prioritize portability and ease of use. For the most budget-conscious entry into spot welding, or for extremely light, occasional tasks, the 110Volt/60Hz Spot Welder is a viable, no-frills option.

However, if you’re ready to invest in cutting-edge technology for unparalleled precision, versatility, and efficiency across a wide range of metals and tasks – including cleaning and cutting – then either of the Triumph Laser Welders (1.5kW or 1500W) will be a transformative addition to your workshop. The Triumph 1500W is particularly impressive for its detailed specifications on handling thicker materials, making it the powerhouse for demanding laser welding jobs.

Ultimately, consider what tasks you’ll tackle most often, your skill level, and your budget to find your ideal single phase welding companion.

Best Single Phase Welding Machine: Your Questions Answered

What does “single phase” mean for a welding machine?

A single phase welding machine operates on a standard household electrical supply, typically 110V or 220V in North America. This makes them highly accessible for home workshops, garages, and smaller commercial settings without requiring specialized industrial power connections. They’re generally more portable and simpler to use for a wide range of common welding tasks compared to three-phase machines.

Are single phase welding machines powerful enough for thick materials?

It depends on the specific machine and technology. While traditional single phase welders are excellent for light to medium-duty applications and thinner materials, modern single phase laser welders (like the Triumph models reviewed) can handle surprisingly thick materials, with the 1500W model welding stainless steel up to 4mm. For heavy industrial fabrication with very thick metals, three-phase machines are usually preferred.

What’s the main difference between a spot welder and a laser welder?

A spot welder creates a weld at a single point by applying pressure and electrical current, typically used for joining sheet metal. A laser welding machine, on the other hand, uses a focused laser beam to melt and fuse materials, offering much higher precision, speed, and cleaner welds. Laser welders can also perform continuous seams, cleaning, and cutting, making them far more versatile.

What should I look for in a portable single phase welding machine?

When choosing a portable single phase welding machine, consider its weight and dimensions, the input voltage (110V for standard outlets, 220V for more power), duty cycle for continuous operation, output amperage (for material thickness), and ease of use. Features like an attached handle, compact design, and simple controls are also beneficial for on-the-go projects.

How important is duty cycle for a single phase welder?

The duty cycle is crucial as it indicates how long a welder can operate continuously within a 10-minute period before needing to cool down. For instance, a 50% duty cycle at 100A means you can weld for 5 minutes at 100A and then need 5 minutes of rest. For longer projects or professional use, a higher duty cycle is vital to prevent overheating and maintain productivity.

Can beginners use these single phase welding machines?

Absolutely! Many single phase welding machines, especially spot welders like the Stark USA or the basic 110V unit, are designed with user-friendliness in mind, making them suitable for beginners. Laser welders, while more advanced, often come with intuitive controls and extensive training materials, allowing beginners to master them relatively quickly with practice. Always prioritize safety and read the manual thoroughly.

What maintenance is required for a single phase laser welder?

One of the significant advantages of fiber laser welding machines is their low maintenance. They typically have a very long laser source lifespan (e.g., 100,000 hours) and often require no consumables beyond occasional cleaning of optics. Unlike traditional welders that need shielding gas or replacement electrodes, laser welders are largely “set and forget” once properly installed and calibrated.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.