As someone who’s spent countless hours under the hood, I know firsthand that choosing the right stick welding rods can make all the difference between a frustrating mess and a clean, strong weld. It’s not just about getting the job done; it’s about doing it right, efficiently, and with confidence. That’s why I’ve put these best stick welding rods through their paces, pulling together this guide to help you pick the perfect welding electrodes for your next project, whether you’re a seasoned pro or just starting out.

Contents

- YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon…

- YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

- YESWELDER E6013 3/32” 2LB Welding Rod Carbon Steel Stick…

- YESWELDER E7018 3/32″(2.5lb)+1/8″(2.5lb) Welding Rod Carbon…

- Saker E6013 Welding Rod 3/32” 1-Pound Carbon Steel Stick…

- Sunstac E6013 Welding Rod 1/8″ 5LB Carbon Steel Stick…

- Helpful Comparison Short Insights

- Final Verdict

- Best Stick Welding Rods FAQ

- What’s the main difference between E7018 and E6013 welding rods?

- Can I use E7018 welding rods with an AC welder?

- What kind of metal are E6013 welding rods best for?

- How do I properly store low-hydrogen welding rods like E7018?

- What amperage should I use for 3/32″ and 1/8″ stick welding rods?

- Are larger diameter welding rods always better for thicker materials?

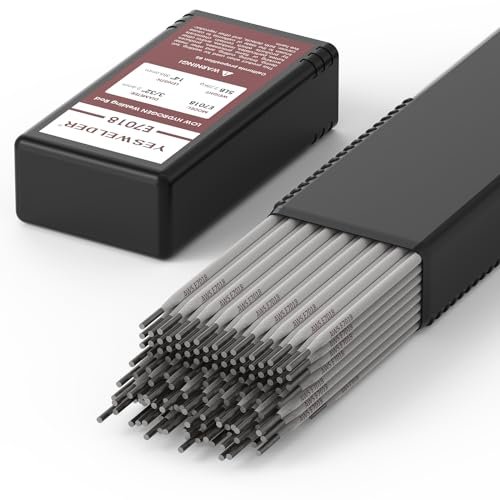

YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon…

This 3/32″ YESWELDER E7018 rod is a fantastic option for those needing high-quality welds on a variety of steel types. It’s a low-hydrogen electrode, which means it reduces the risk of hydrogen-induced cracking, making your welds super reliable and strong. I found its steady arc and low spatter really contribute to a cleaner work environment and less post-weld cleanup, which is always a win in my book.

Key features that stand out:

– MODEL: E7018 is a low-hydrogen iron powder type electrode that produces high quality x-ray welds.

– FEATURES: All position welding, recommended for welding medium grade carbon steels where no preheat is used, and on cold rolled steels normally exhibiting excessive porosity when welded with conventional electrodes.

– PERFORMANCE: Steady arc, low spatter, excellent re-striking ability and high deposition efficiency.

– APPLICATION: Low-alloy structurals, low, medium and high carbon steels, offshore rigs and power plants, steel structures, tack welds for tubular wire applications.

– SPECIFICATION: Diameter: 3/32”; Length: 14”; Weight: 5LB. Recommended Amperages: 70A-100A.

Pros:

– Produces high-quality, X-ray worthy welds.

– Low hydrogen content reduces cracking risk.

– Operates well in all positions on AC or DC reverse polarity.

– Excellent re-striking ability for consistent work.

Cons:

– May require careful storage to maintain low-hydrogen properties.

Best for: Critical structural welding, medium to high carbon steels, and applications where weld integrity is paramount.

Expert Opinion: This rod’s consistent performance and low hydrogen formulation make it a solid choice for professional-grade work, offering reliability that’s hard to beat.

YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

If you’re tackling thicker materials or jobs requiring more fill, the 1/8″ YESWELDER E7018 steps up to the plate. Like its smaller sibling, it’s a low-hydrogen, iron powder electrode designed for high-quality, X-ray standard welds. The larger diameter means it’s capable of higher deposition rates, saving you time on bigger projects, all while maintaining that stable arc and minimal spatter we love.

Key features that stand out:

– MODEL: E7018 is a low-hydrogen iron powder type electrode that produces high quality x-ray welds.

– FEATURES: All position welding, recommended for welding medium grade carbon steels where no preheat is used, and on cold rolled steels normally exhibiting excessive porosity when welded with conventional electrodes.

– PERFORMANCE: Steady arc, low spatter, excellent re-striking ability and high deposition efficiency.

– APPLICATION: Low-alloy structurals, low, medium and high carbon steels, offshore rigs and power plants, steel structures, tack welds for tubular wire applications.

– SPECIFICATION: Diameter: 1/8”; Length: 14”; Weight: 5LB. Recommended Amperages: 115A-165A.

Pros:

– Ideal for heavier material and higher deposition.

– Maintains excellent weld quality with low hydrogen.

– Works effectively in all welding positions.

– Good for applications needing strong, crack-resistant welds.

Cons:

– Not suitable for very thin materials due to its larger diameter.

Best for: Heavy fabrication, thick sections of low to high carbon steels, and industrial applications requiring strong, reliable welds.

Expert Opinion: The 1/8″ E7018 is a workhorse for substantial projects, delivering the strength and quality expected from a low-hydrogen rod with increased productivity.

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

The ARCCAPTAIN E7018 rod, specifically the 3/32″ diameter, is another strong contender in the low-hydrogen category. It boasts outstanding X-ray values and high tensile strength, making it a great choice for critical applications where weld integrity is crucial. I found it to have a very smooth and stable arc, which translated into less frustration and better-looking beads, even in trickier positions.

Key features that stand out:

– Welding Rod Model: E7018 is an iron powder electrode with low hydrogen content, delivering high-quality x-ray welds. It is suitable for welding in any position using AC or DC reverse polarity.

– Advantages: Outstanding X-ray values, high tensile strength, and good resistance to cracking allow for use in a variety of welding positions.

– Performance: E7018 welding rods have high melting efficiency, a smooth and stable arc, and less spatter. The low hydrogen content and few defects ensure high-quality welds.

– Widely Used: E7018 stick welding rods are ideal for low, medium, and high carbon steels, and structural components.

Pros:

– Delivers excellent X-ray quality and crack resistance.

– Smooth, stable arc with high melting efficiency.

– Low spatter and low hydrogen content for superior welds.

– Suitable for a wide range of structural and pipeline applications.

Cons:

– Requires proper storage to maintain its low-hydrogen properties.

Best for: High-pressure pipelines, ship hulls, structural components, and applications demanding superior weld strength and quality.

Expert Opinion: ARCCAPTAIN’s E7018 offers competitive performance with a focus on weld integrity, making it a reliable choice for demanding structural and industrial projects.

YESWELDER E6013 3/32” 2LB Welding Rod Carbon Steel Stick…

For general purpose welding, especially on thinner materials or where fit-up isn’t perfect, the YESWELDER E6013 3/32″ is a fantastic, user-friendly option. It’s a mild-steel rod known for its easy arc start and excellent slag removal, often virtually self-cleaning in vertical-down fillets. This rod is incredibly versatile and works well even on low-voltage AC machines, making it a staple for many home workshops.

Key features that stand out:

– MODEL: E6013 is a mild-steel general purpose rod. It operates on AC or DC welding current and works well on low voltage AC machines.

– FEATURES: All position welding, general purpose rod for shallow penetration or in poor fitted conditions.

– PERFORMANCE: Low spatter and excellent slag removal, virtually self cleaning in vertical down fillets.

– USAGE: Use for all types of mild steel. Great for light gauge metal, sheet metal and duct work.

– SPECIFICATION: Diameter: 3/32”; Length: 14”; Weight: 2LB. Recommended Amperages: 45A-90A.

Pros:

– Very forgiving and easy to use, even for beginners.

– Excellent for shallow penetration on sheet metal and light gauge.

– Works on both AC and DC, including low-voltage AC machines.

– Minimal cleanup thanks to easy slag removal.

Cons:

– Not suitable for critical structural welds where high strength is paramount.

Best for: Beginners, light gauge metal fabrication, sheet metal work, general repairs, and hobby projects.

Expert Opinion: The E6013 is a welder’s friend for everyday tasks; its forgiving nature and easy operation make it perfect for learning and tackling less critical repairs.

YESWELDER E7018 3/32″(2.5lb)+1/8″(2.5lb) Welding Rod Carbon…

This mixed pack from YESWELDER is pure genius for welders who tackle a variety of projects. You get both the 3/32″ and 1/8″ E7018 rods, offering versatility for different material thicknesses without having to buy two separate packs. Both diameters retain the E7018’s low-hydrogen properties, delivering high-quality, X-ray capable welds with a steady arc and minimal spatter across the board.

Key features that stand out:

– MODEL: E7018 is a low-hydrogen iron powder type electrode that produces high quality x-ray welds.

– FEATURES: All position welding, recommended for welding medium grade carbon steels where no preheat is used, and on cold rolled steels normally exhibiting excessive porosity when welded with conventional electrodes.

– PERFORMANCE: Steady arc, low spatter, excellent re-striking ability and high deposition efficiency.

– APPLICATION: Low-alloy structurals, low, medium and high carbon steels, offshore rigs and power plants, steel structures, tack welds for tubular wire applications.

– SPECIFICATION: Diameter: 3/32″(2.5LB)+1/8″(2.5LB); Length: 14″; Weight: 5LB. Recommended Amperages: 115A-165A (for the 1/8″), 70A-100A (for the 3/32″).

Pros:

– Offers versatility with two common E7018 diameters.

– High-quality, low-hydrogen welds for critical applications.

– Excellent for various carbon steels and structural components.

– Economical way to get both sizes for different jobs.

Cons:

– The mixed pack might not be ideal if you only consistently use one diameter.

Best for: Welders who frequently work with varying material thicknesses, from medium to heavy, and require the strength of E7018 welds.

Expert Opinion: This combination pack is incredibly practical, providing the right tool for the job whether you’re working on thinner plate with the 3/32″ or heavier sections with the 1/8″, all with the consistent quality of E7018.

Saker E6013 Welding Rod 3/32” 1-Pound Carbon Steel Stick…

The Saker E6013 3/32″ rod is another excellent choice for general purpose welding, especially for those smaller projects or beginners. Its easy arc start and smooth, consistent welds make it incredibly user-friendly. I appreciate its versatility, working well on both AC and DC, even with basic low-voltage machines. The smaller 1-pound pack is also great for hobbyists who don’t need a bulk supply.

Key features that stand out:

– Versatile Welding Rod: E6013 welding rod 3/32” is a versatile low-carbon steel electrode that works with both AC and DC welding currents.

– All-Position Welding: Designed for all-position welding, these welding rods are perfect for a variety of welding positions, including flat and vertical.

– Easy to Use: The E6013 welding rods are known for their easy arc start and minimal spatter. The flux coating ensures excellent slag removal.

– Ideal for Low Carbon Steel: These welding electrodes are specifically designed for use on low-carbon steel, making them perfect for light metal fabrication, sheet metal work, and pipe welding.

– Specifications: Diameter: 3/32″ (2.5mm),Weight: 1 lb (0.45 kg).

Pros:

– Extremely easy to strike an arc and maintain a bead.

– Very forgiving for new welders and poor fit-up.

– Excellent slag removal, often self-cleaning.

– Small pack size is convenient for hobbyists and small projects.

Cons:

– Not designed for high-stress structural applications.

Best for: Beginners, small repairs, light fabrication, hobby projects, and anyone needing a reliable, easy-to-use general-purpose rod.

Expert Opinion: Saker’s E6013 shines for its ease of use and versatility, particularly beneficial for those just starting out or needing a forgiving rod for non-critical applications.

Sunstac E6013 Welding Rod 1/8″ 5LB Carbon Steel Stick…

Rounding out our E6013 selections, the Sunstac E6013 1/8″ provides the same user-friendly performance with increased deposition for slightly thicker mild steel. Its titanium oxide coating contributes to a stable arc and minimal spatter, which means less time cleaning up and more time welding. This rod is incredibly flexible for various positions, making it suitable even for complex structures where maneuverability is key.

Key features that stand out:

– PRODUCT DETAILS: Style: E6013; Diameter: 1/8″; Length: 14″; Weight: 5 lb.

– TITANIUM OXIDE COATING: Titanium oxide coating formula contains a large amount of titanium oxides (such as TiO₂), belongs to acidic electrodes, has a stable arc and less spatter to improve the performance of the weld seam.

– ARC STABILITY: This 6013 welding rod is easy to re-arc, the arc burns smoothly, and the molten pool control is flexible, making it suitable for thin plate welding and fine operations.

– ALL POSITION WELDING: This 6013 welding stick can be welded in all positions such as horizontal, vertical, horizontal and upward, and is especially suitable for complex structures and narrow spaces.

– FINE WELDING: This welding rod is commonly used for welding steel plates and thin plates, especially suitable for cover welding and scenarios that require high surface quality.

Pros:

– Stable arc and smooth molten pool control.

– Low spatter and good for cover welding.

– Works well in all positions, including challenging spaces.

– Ideal for thin plates and scenarios requiring high surface quality.

Cons:

– Not the primary choice for heavy-duty, high-strength applications.

Best for: General fabrication, thin plate welding, cover passes, and situations where a smooth, aesthetically pleasing bead is desired on mild steel.

Expert Opinion: The Sunstac E6013 1/8″ is a solid all-rounder for mild steel, particularly valuable for achieving nice-looking welds on thinner materials or for versatile positional work.

Helpful Comparison Short Insights

When looking at the best stick welding rods, you’ll quickly notice a split between E7018 and E6013 types. The E7018 rods (like the YESWELDER and ARCCAPTAIN options) are your go-to for high-strength, low-hydrogen welds, ideal for critical applications like structural work, pressure vessels, and heavy fabrication where weld integrity is paramount. They usually require a bit more skill and careful storage.

On the other hand, the E6013 rods (from YESWELDER, Saker, and Sunstac) are known for being user-friendly, with an easy arc start and excellent for general purpose welding. They’re perfect for beginners, light gauge metal, and projects where good appearance and ease of use are more important than extreme strength. They’re much more forgiving with arc length and machine settings.

Within the E7018 category, the 3/32″ diameter is best for thinner materials and less amperage, offering more control, while the 1/8″ diameter excels on thicker sections due to its higher deposition rate and greater penetration, requiring more amperage. The YESWELDER mixed pack offers the best of both worlds for E7018 users. For E6013, similar principles apply, with 3/32″ being great for sheet metal and 1/8″ for slightly heavier mild steel or faster fill.

Final Verdict

Choosing the best stick welding rods really boils down to your specific project needs and your skill level.

If you’re after maximum strength and integrity for structural or critical applications, the YESWELDER E7018 3/32″ or ARCCAPTAIN E7018 3/32″ are stellar choices. For heavier jobs with the same high standards, the YESWELDER E7018 1/8″ will serve you well. And if you need that versatility, the YESWELDER E7018 3/32″+1/8″ combo pack is an absolute winner.

However, if you’re a beginner, working on light gauge metals, or tackling general repairs where ease of use and a good-looking bead are priorities, the YESWELDER E6013 3/32″ or Saker E6013 3/32″ are incredibly forgiving and effective. For slightly thicker mild steel with the same ease of use, the Sunstac E6013 1/8″ is a reliable option.

Ultimately, understanding the differences between low-hydrogen E7018 and general-purpose E6013 electrodes is key to making the right choice for your next stick welding adventure.

Best Stick Welding Rods FAQ

What’s the main difference between E7018 and E6013 welding rods?

The primary difference lies in their properties and applications. E7018 rods are low-hydrogen electrodes designed for high-strength, critical welds, offering excellent ductility and resistance to cracking, typically used on medium to high carbon steels and structural applications. E6013 rods are general-purpose electrodes known for their ease of use, smooth arc, and good appearance on mild steel, ideal for light fabrication and non-critical repairs, especially for beginners.

Can I use E7018 welding rods with an AC welder?

Yes, E7018 rods can be used with both AC and DC welding current. However, they generally perform best on DC reverse polarity (DCEP) for optimal arc stability and penetration. Always check your specific rod’s instructions for recommended current type and amperage settings.

What kind of metal are E6013 welding rods best for?

E6013 welding rods are specifically designed for welding mild steel and low carbon steels. They are excellent for light gauge metal, sheet metal work, and applications where fit-up might be poor, providing good bead appearance and easy slag removal.

How do I properly store low-hydrogen welding rods like E7018?

To maintain their low-hydrogen properties, E7018 welding electrodes must be stored in a dry, heated environment, ideally in a rod oven at temperatures around 250-300°F (120-150°C). Exposure to moisture can introduce hydrogen into the flux, compromising weld quality and increasing the risk of cracking.

What amperage should I use for 3/32″ and 1/8″ stick welding rods?

Amperage settings vary based on the specific rod type, material thickness, and welding position. For 3/32″ E6013 rods, a common range is 45-90A. For 3/32″ E7018 rods, it’s usually 70-100A. For 1/8″ E6013 rods, you might use 90-130A, and for 1/8″ E7018 rods, 115-165A is typical. Always consult the manufacturer’s recommendations on the rod packaging.

Are larger diameter welding rods always better for thicker materials?

Generally, yes. Larger diameter welding rods deliver more filler metal (higher deposition rate) and typically provide deeper penetration, making them more efficient and effective for joining thicker sections of metal. However, they also require higher amperage and can be less controllable on thinner materials where too much heat can cause burn-through.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.