I remember this one time my trusty old garden cart had a cracked plastic wheel well, and I thought it was destined for the scrap heap. Then, a friend recommended J-B Weld, and honestly, I was skeptical. Could an adhesive really fix something that seemed so broken? After diving into their extensive line, from heavy-duty epoxies to specialized plastic bonders, I discovered that choosing the best strongest JB Weld adhesive for the job makes all the difference for a durable bond. That experience taught me that with the right product, you can tackle almost any repair, making things stronger than ever. In this guide, we’ll explore the top 10 J-B Weld adhesives to help you make informed choices for all your projects.

Contents

- J-B Weld 50139 Plastic Bonder Body Panel Adhesive and Gap…

- J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy…

- J-B Weld 33120H SuperWeld Glue – Clear Super Glue -…

- J-B Weld 8281 Professional Size Steel Reinforced Epoxy -…

- J-B Weld 50133 Plastic Bonder Structural Adhesive Syringe -…

- J-B Weld Original Steel Reinforced Epoxy Syringe, High…

- J-B Weld SuperWeld Extreme Superglue – 15g

- J-B Weld Light-Activated Superglue, Clear, 5g, 2-Pack

- J-B Weld ClearWeld 5 Minute Epoxy, Clear, Syringe, 2…

- J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength,…

- Helpful Comparison Short Insights

- Final Verdict

- Your Questions Answered: Best Strongest JB Weld Adhesive FAQs

- What makes J-B Weld adhesives so strong and reliable?

- Which J-B Weld product is best for metal repairs, especially for high heat?

- Can J-B Weld be used on plastic, and which one is recommended?

- How long does J-B Weld typically take to fully cure?

- Is J-B Weld waterproof and heat resistant after it cures?

- What’s the difference between J-B Weld’s epoxy and super glue products, and when should I use each for the strongest bond?

- What is the ideal surface preparation for using J-B Weld for optimal adhesion?

J-B Weld 50139 Plastic Bonder Body Panel Adhesive and Gap…

When you’re dealing with plastic repairs that need to hold up, this Plastic Bonder is a lifesaver. It’s a fast-acting, two-part urethane adhesive system designed to create strong, lasting repairs on a variety of plastics and composites. What truly stands out is its ability to not just bond, but also fill gaps, curing to a hard, permanent black bond that you can sand and paint. It’s definitely earned its reputation for tackling tough plastic challenges, making it a reliable choice for automotive body panels or everyday plastic items.

Key features that stand out:

– Quick-Set, 2-Part Urethane Adhesive: Offers rapid setting and strong adhesion.

– Versatile Plastic Compatibility: Works on thermoset, carbon fiber composites, thermoplastics, and more.

– High Tensile Strength: Boasts a robust 3770 PSI for durable repairs.

– Great Gap Filler: Ideal for filling gaps and irregularities, curing to a black finish.

Pros:

– Sets quickly in 15 minutes, allowing for fast project turnaround.

– Creates a very strong and permanent bond on various plastic types.

– Can be sanded after 30 minutes, simplifying finishing work.

– Dries black, which is great for many common plastic parts.

Cons:

– The dark color might not be suitable for all applications where a clear bond is needed.

Best for: Repairing plastic body panels, filling gaps in plastic, and bonding various plastic composites where a black finish is acceptable.

Expert Opinion: This is my go-to for cracked plastic bumpers or trim pieces. The 3770 PSI strength is impressive for a plastic bonder, and the ability to sand it means you can achieve a really clean, seamless repair. Just make sure the surface is clean for optimal adhesion.

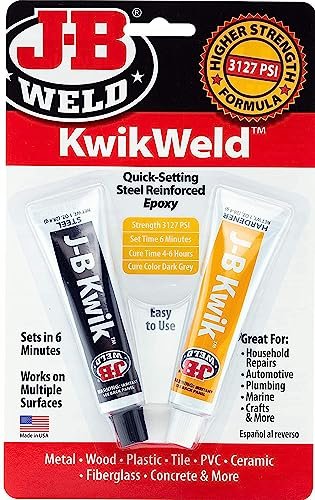

J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy…

J-B Weld KwikWeld is the rapid-fire solution when you need a strong, permanent bond without the long wait. As a fast-setting, steel-reinforced epoxy, it’s a versatile powerhouse for everything from household fixes to automotive and marine repairs. You get the legendary J-B Weld strength in a much shorter timeframe, making it perfect for urgent projects. Once cured, it’s not only incredibly strong but also waterproof and resistant to various chemicals, making it exceptionally dependable.

Key features that stand out:

– Fast-Setting Cold Weld Epoxy: Sets in just 6 minutes.

– Steel Reinforced: Provides exceptional strength and durability.

– High Temperature Resistance: Withstands up to 230°F (110°C) when cured.

– Waterproof and Chemical Resistant: Ensures lasting repairs in harsh conditions.

Pros:

– Rapid set time of 6 minutes is excellent for quick repairs.

– Steel reinforcement provides superior strength and longevity.

– Versatile across many surfaces including metal, wood, plastic, and concrete.

– Can be tapped, filled, sanded, molded, and drilled once fully cured.

Cons:

– The 4-6 hour cure time, while faster than original J-B Weld, still requires some patience.

Best for: Quick, strong repairs on metal, wood, concrete, and ceramic, especially when you need a fast initial set for assembly.

Expert Opinion: KwikWeld is a fantastic all-rounder for emergency repairs. Its steel reinforcement gives you peace of mind that the bond will be robust, and the shorter set time means you can move on with your day quicker. I often recommend it for minor engine block cracks or exhaust system patch-ups.

J-B Weld 33120H SuperWeld Glue – Clear Super Glue -…

For those instant bonds that need to be clear and strong, J-B Weld’s SuperWeld Glue is your go-to. This isn’t just any super glue; it’s a specially formulated cyanoacrylate adhesive designed for a super strong, instant bond in seconds. It’s incredibly handy for smaller, intricate repairs where precision is key, and its clear finish makes it almost invisible. From delicate china to rubber and even rearview mirrors, it’s a versatile addition to any DIY toolkit.

Key features that stand out:

– Super Strong Cyanoacrylate Formula: Delivers an instant, powerful bond.

– Precision Applicator: Allows for pinpoint application on small areas.

– Clear Drying: Ideal for discreet repairs on a variety of materials.

– Multi-Surface Compatibility: Bonds china, glass, rubber, plastic, metal, and more.

Pros:

– Achieves an instant bond in seconds for rapid fixes.

– Clear finish ensures repairs are virtually unnoticeable.

– Easy-to-use applicator makes precise application simple.

– Works effectively on a wide range of household materials.

Cons:

– Best for smaller surface areas and not ideal for large structural repairs.

Best for: Instant, clear repairs on small items like china, glass, auto accessories, and various plastics where discretion is important.

Expert Opinion: While not an epoxy, this SuperWeld glue earns its spot because sometimes you just need an instant bond. Its clarity and precision tip are invaluable for those tiny, fiddly repairs that often frustrate us. Just be careful; it lives up to its “super glue” name!

J-B Weld 8281 Professional Size Steel Reinforced Epoxy -…

This is the legendary J-B Weld Original in a professional-sized package, and it truly embodies the concept of a “cold weld.” Designed as an alternative to torch welding, this two-part epoxy system delivers a bond that’s quite literally stronger than steel. If you need maximum strength and durability for serious projects, this is it. It can withstand extreme temperatures, is waterproof, and resistant to chemicals, making it the benchmark for heavy-duty repairs across automotive, marine, and industrial applications.

Key features that stand out:

– Original Cold Weld Formula: Creates a bond stronger than steel.

– Professional 5 oz. Tubes: Ample supply for larger or multiple projects.

– Extreme Temperature Resistance: Tolerates up to 550°F (287°C) when fully cured.

– Very High Tensile Strength: Boasts an impressive 5020 PSI.

Pros:

– Unrivaled strength, often exceeding the material it’s bonding.

– Exceptional heat and chemical resistance for industrial-grade repairs.

– Can be machined, sanded, drilled, and painted after curing.

– Large size offers great value for extensive or multiple applications.

Cons:

– Requires a longer set time (4-6 hours) and full cure time (15-24 hours).

Best for: Heavy-duty, permanent repairs on metal, engine blocks, exhaust systems, and critical applications where maximum strength and durability are paramount.

Expert Opinion: When someone asks for the strongest J-B Weld, this is often what they’re thinking of. The 5020 PSI tensile strength is simply phenomenal. It might take longer to cure, but the result is a repair you can trust for the long haul, even in extreme conditions. This is what you grab for major structural fixes.

J-B Weld 50133 Plastic Bonder Structural Adhesive Syringe -…

Similar to its black counterpart, this Plastic Bonder comes in a convenient syringe for easy 1:1 mixing and features a tan cure color. It’s a quick-setting, multi-purpose urethane adhesive system specifically formulated for plastics, offering a robust and lasting bond. The syringe design is a thoughtful touch, preventing drying out and leaks, which means you can use it for multiple small repairs over time. It’s excellent for filling dents, repairing bumpers, and general plastic restoration, blending well with lighter-colored plastics.

Key features that stand out:

– Tan Curing Color: Ideal for matching lighter plastic surfaces.

– Convenient Syringe Dispenser: Ensures easy 1:1 mixing and multiple uses.

– Structural Adhesive & Gap Filler: Provides strong bonds and fills imperfections.

– Good Tensile Strength: Delivers a respectable 3770 PSI.

Pros:

– Tan color blends well with many plastics, offering a less noticeable repair.

– Syringe applicator simplifies use and reduces waste.

– Strong bond and gap-filling capabilities for diverse plastic repairs.

– Sets in 15 minutes, allowing for quicker progress.

Cons:

– The 30-hour full cure time is on the longer side for a plastic bonder.

Best for: Repairing plastic surfaces, filling dents in plastic, bumper repairs, and general restoration of light-colored plastic items.

Expert Opinion: The tan color option is a huge plus for those aesthetic plastic repairs where black would stand out too much. Structurally, it performs identically to its black sibling, offering excellent strength. The syringe design makes it super user-friendly and helps prolong its shelf life, which is always a bonus.

J-B Weld Original Steel Reinforced Epoxy Syringe, High…

This is the classic J-B Weld Original formula, but in an easy-to-use syringe format. You get the same legendary cold-weld, steel-reinforced strength and high-temperature resistance, but with the convenience of a precise, re-sealable syringe. It’s perfect for those who love the strength and durability of the original formula but prefer a cleaner, more controlled application for smaller projects or intricate repairs. Once cured, it’s incredibly versatile – you can machine it, sand it, drill it, just like metal.

Key features that stand out:

– Original Cold-Weld Formula in Syringe: Combines classic strength with modern convenience.

– High Tensile Strength: Offers 5020 PSI for an incredibly strong bond.

– Extreme Heat Resistance: Withstands up to 550°F (287°C) when fully cured.

– Dark Grey Curing Color: A standard, professional finish for metal repairs.

Pros:

– Syringe ensures easy 1:1 mixing ratio and reduces mess.

– Provides the maximum strength and durability of the original J-B Weld.

– Ideal for precision applications where controlled dispensing is crucial.

– Excellent for household, automotive, marine, and craft repairs.

Cons:

– Still requires a significant cure time (15 hours for full cure).

Best for: Strong, permanent repairs on metal and multiple surfaces, especially when precise application is needed for smaller or intricate fixes.

Expert Opinion: For anyone who values the strength of the Original J-B Weld but finds the tubes a bit cumbersome for smaller, more precise jobs, this syringe version is a fantastic alternative. It delivers the same 5020 PSI strength, so you’re not compromising on durability. It’s a must-have for detailed metal repairs or creating small, durable prototypes.

J-B Weld SuperWeld Extreme Superglue – 15g

J-B Weld SuperWeld Extreme takes super glue to another level, offering a strong, flexible, and impact-resistant bond. Unlike traditional super glues that can be brittle, this formula maintains flexibility, making it perfect for materials that experience movement or impact. Its no-drip, precision tip makes application easy on both vertical and horizontal surfaces. From leather to rubber, plastics to metal, this versatile adhesive is engineered to handle a wider range of challenging materials that typically struggle with rigid super glues.

Key features that stand out:

– Flexible and Impact Resistant Bond: Ideal for materials that flex or face impact.

– Precision Tip, No-Drip Formula: Ensures clean, controlled application.

– Versatile Material Compatibility: Works well on plastics, leather, rubber, glass, metal.

– Good Tensile Strength: Resists up to 3,000 PSI.

Pros:

– Provides a flexible bond, preventing cracking on dynamic surfaces.

– High impact resistance adds durability to repairs.

– Fast set time of 30 seconds for quick assembly.

– Precision applicator allows for accurate, mess-free work.

Cons:

– Full cure takes 24 hours, which is longer than some instant glues.

Best for: Bonding flexible materials like rubber and leather, as well as plastics and metals where impact resistance and some give in the bond are needed.

Expert Opinion: The flexibility of SuperWeld Extreme is its defining feature. Most super glues are rigid and crack under stress, but this one holds up beautifully. I’ve used it successfully on shoe repairs and even flexible plastic trim pieces. The 3,000 PSI strength combined with that flexibility is a real winner.

J-B Weld Light-Activated Superglue, Clear, 5g, 2-Pack

Talk about innovation! J-B Weld Light-Activated Superglue cures almost instantly when exposed to the included light. This means you have ample time to perfectly position your pieces before hitting them with the light for a rapid, firm bond in just 10 seconds. It also doubles as a traditional super glue, setting in a minute and fully curing in 24 hours without the light. With its clear finish and precision tip, it’s ideal for intricate, clear, and perfectly aligned repairs where every second counts.

Key features that stand out:

– Light-Activated Instant Cure: Cures in 10 seconds with the included light.

– Dual Curing Method: Also cures naturally (1 min set, 24 hr cure) without light.

– Precision Tip Applicator: Ensures no mess and accurate placement.

– Clear Finish: Provides invisible repairs on glass, clear plastics, and more.

Pros:

– Unprecedented control over cure time, allowing perfect positioning.

– Incredibly fast cure with light exposure for instant results.

– Versatile with both light-activated and natural curing options.

– Clear bond ensures discreet repairs.

Cons:

– Requires the included light for instant curing, which might be less convenient than standard super glues for some.

Best for: Precision repairs on clear materials, delicate assemblies, or any project where perfect alignment and instant setting are crucial.

Expert Opinion: This light-activated super glue is a game-changer for intricate work. The ability to precisely position parts and then “flash cure” them in seconds is incredibly useful. I’ve used it for jewelry repair and small electronic components where accuracy is paramount. The 2800 PSI strength is solid for an instant adhesive.

J-B Weld ClearWeld 5 Minute Epoxy, Clear, Syringe, 2…

When you need the strength of an epoxy but want a crystal-clear finish and a rapid set, J-B Weld ClearWeld is an excellent choice. This two-part epoxy comes in a convenient syringe, making the 1:1 mixing ratio simple and mess-free. It sets in just 5 minutes and cures to a strong, transparent bond in an hour. Its versatility spans metal, most plastics, ceramic, glass, and wood, making it a reliable solution for repairs where visibility of the adhesive is a concern.

Key features that stand out:

– Clear Curing Epoxy: Provides a transparent, virtually invisible bond.

– Fast 5-Minute Set Time: Allows for quick assembly and progress.

– Convenient Syringe Dispenser: Easy 1:1 mixing and re-sealable for multiple uses.

– Strong Tensile Strength: Achieves 3900 PSI when fully cured.

Pros:

– Fast set time is ideal for projects needing quick handling.

– Clear finish is perfect for aesthetic repairs on glass or clear materials.

– Syringe design simplifies application and minimizes waste.

– Strong enough for a wide range of materials including metal and ceramics.

Cons:

– Not suitable for all types of plastics, particularly some hard-to-bond varieties.

Best for: Fast, strong, and clear bonding on glass, ceramics, and various metals and plastics where a transparent repair is desired.

Expert Opinion: ClearWeld is my preferred choice for anything where the adhesive needs to be invisible, like glass repairs or clear plastic accents. The 5-minute set time is very practical, and at 3900 PSI, you’re getting serious strength for a clear epoxy. Always do a small test patch on plastics to ensure compatibility, though.

J-B Weld 6 Minute Set Epoxy KwikWeld, High Strength,…

This is another iteration of the popular KwikWeld, presented in a user-friendly syringe. It offers the same fast-setting (6-minute) cold-weld capabilities and steel-reinforced strength as its tube counterpart. The syringe design is a game-changer for precise dispensing and ensuring an accurate 1:1 mix ratio without the fuss. It cures to a dark grey, durable bond that’s resistant to water and chemicals, making it ideal for everything from automotive touch-ups to quick household fixes on a multitude of surfaces.

Key features that stand out:

– Fast-Setting 6-Minute Epoxy: Ideal for quick repairs and assembly.

– Syringe Dispenser: Ensures easy and accurate 1:1 mixing.

– Steel Reinforced Strength: Provides robust and durable bonds.

– Multi-Surface Compatibility: Works on metal, plastic, wood, concrete, and fiberglass.

Pros:

– Very fast setting allows for quick project completion.

– Syringe offers easy, mess-free application and multiple uses.

– Strong tensile strength (3127 PSI) for reliable repairs.

– Versatile for a wide range of materials and applications.

Cons:

– The dark grey color might not be suitable for light-colored materials where aesthetics are critical.

Best for: Rapid, high-strength repairs on metal, wood, plastic, and concrete, particularly when precision and easy mixing are priorities.

Expert Opinion: The KwikWeld syringe is incredibly practical. It gives you all the benefits of the original KwikWeld – the 6-minute set time and solid 3127 PSI strength – but in a much more controlled package. I find myself reaching for this one often for small, urgent repairs around the house or garage where I don’t want to deal with measuring from tubes.

Helpful Comparison Short Insights

When looking for the best strongest JB Weld adhesive, understanding their nuances is key. For ultimate structural integrity, especially on metal, the J-B Weld 8281 Professional Size Steel Reinforced Epoxy (Original) and the J-B Weld Original Steel Reinforced Epoxy Syringe lead the pack with an incredible 5020 PSI tensile strength and superior temperature resistance. These are your go-to for engine blocks or industrial repairs where a “stronger than steel” bond is required, albeit with a longer cure time.

If speed is your priority without sacrificing too much strength, the J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy and its syringe counterpart, the J-B Weld 6 Minute Set Epoxy KwikWeld, are excellent. They set in 6 minutes and offer a robust 3127 PSI, making them perfect for quick, reliable fixes on various materials.

For plastic-specific repairs, both the J-B Weld 50139 Plastic Bonder (Black) and the J-B Weld 50133 Plastic Bonder (Tan) offer 3770 PSI strength and are fantastic gap fillers. Choose based on the desired final color.

When you need an invisible bond, the J-B Weld ClearWeld 5 Minute Epoxy is superior with its clear finish and 3900 PSI, ideal for glass or transparent materials. For instant, discreet, small-scale fixes, J-B Weld 33120H SuperWeld Glue delivers an instant, clear bond.

Finally, for flexible or impact-prone materials, the J-B Weld SuperWeld Extreme Superglue stands out with its flexible bond and 3000 PSI strength, offering durability where rigid glues might fail. And for unparalleled control over setting time, the J-B Weld Light-Activated Superglue is revolutionary, allowing perfect positioning before an instant light-cured bond.

Final Verdict

Choosing the absolute best strongest JB Weld adhesive isn’t about finding a single king, but rather the perfect match for your specific challenge. If you’re tackling heavy-duty metal repairs that demand uncompromising strength and can afford a longer cure time, the J-B Weld Original Professional Size Steel Reinforced Epoxy (or its syringe version for precision) is the undisputed champion with its 5020 PSI. It creates a bond that truly lives up to the “stronger than steel” claim.

For those situations where time is of the essence but you still need a formidable bond across multiple surfaces, the J-B Weld KwikWeld (either the original version or the convenient syringe) offers an excellent balance of speed and strength at around 3127 PSI. It’s the go-to for most general-purpose, urgent repairs.

When it comes to plastics, the J-B Weld Plastic Bonder series, whether in black or tan, provides specialized, high-strength adhesion (3770 PSI) that’s hard to beat, especially for gap filling. And for delicate, clear repairs where precision and aesthetics matter, the J-B Weld ClearWeld epoxy or the innovative Light-Activated Superglue will be your best allies. For those small, instant, everyday fixes, a trusty SuperWeld will always save the day.

Ultimately, J-B Weld offers an adhesive for nearly every scenario. By considering the material, required strength, set time, and desired finish, you can confidently select the perfect product to achieve a reliable, long-lasting repair that truly stands the test of time.

Your Questions Answered: Best Strongest JB Weld Adhesive FAQs

What makes J-B Weld adhesives so strong and reliable?

J-B Weld’s renowned strength comes primarily from its two-part epoxy systems, which create a chemical reaction upon mixing. Many of these are steel-reinforced, incorporating pulverized steel particles that contribute to their incredible tensile strength and durability. This “cold weld” process results in a bond that is often stronger than the base material itself, capable of withstanding extreme temperatures, water, and various chemicals.

Which J-B Weld product is best for metal repairs, especially for high heat?

For the best strongest JB Weld adhesive for metal repairs, especially those exposed to high heat (up to 550°F or 287°C), the J-B Weld 8281 Professional Size Steel Reinforced Epoxy (The Original) or the J-B Weld Original Steel Reinforced Epoxy Syringe are your top choices. They boast a superior 5020 PSI tensile strength and are designed as an alternative to torch welding, making them ideal for engine blocks, exhaust systems, and other critical automotive or industrial applications.

Can J-B Weld be used on plastic, and which one is recommended?

Yes, J-B Weld offers specific adhesives designed for plastics. The J-B Weld 50139 Plastic Bonder Body Panel Adhesive (Black) and the J-B Weld 50133 Plastic Bonder Structural Adhesive (Tan) are highly recommended. These urethane adhesives are excellent for bonding various thermoplastics, thermosets, and carbon fiber composites, offering a strong 3770 PSI bond and gap-filling capabilities. For general plastic repairs, some epoxies like KwikWeld or ClearWeld also work, but always check compatibility with the specific plastic type.

How long does J-B Weld typically take to fully cure?

The curing process varies significantly among J-B Weld products. Fast-setting epoxies like KwikWeld typically set in 6 minutes and achieve a full cure in 4-6 hours. The Original J-B Weld, designed for maximum strength, sets in 4-6 hours but requires 15-24 hours for a full, maximum strength cure. Super glues, like SuperWeld, bond instantly but might take up to 24 hours for a full, robust cure, while light-activated versions can cure instantly with the light. Always refer to the product instructions for specific cure times.

Is J-B Weld waterproof and heat resistant after it cures?

Many J-B Weld epoxy products, especially the steel-reinforced ones like J-B Weld Original and KwikWeld, are designed to be fully waterproof and highly resistant to petroleum, chemicals, and acids once completely cured. Their temperature resistance also varies, with the Original J-B Weld withstanding up to 550°F (287°C), making them suitable for demanding environments. Always check the specific product’s features for its resistance ratings.

What’s the difference between J-B Weld’s epoxy and super glue products, and when should I use each for the strongest bond?

J-B Weld’s epoxy adhesives (like Original, KwikWeld, ClearWeld) are two-part systems that chemically react to form incredibly strong, rigid, and durable bonds, often with high tensile strength and temperature resistance. They are ideal for structural, heavy-duty, or long-lasting durable bond repairs on metal, wood, concrete, and many plastics.

Super glue products (like SuperWeld, SuperWeld Extreme, Light-Activated Superglue) are single-component cyanoacrylate adhesives that provide an instant bond in seconds. They are best for smaller, non-structural, fast fixes on a wide range of materials where an immediate, clear, or flexible bond is needed. While strong, their bond isn’t typically as structurally robust or heat-resistant as their epoxy counterparts.

What is the ideal surface preparation for using J-B Weld for optimal adhesion?

For the best strongest JB Weld adhesive results and optimal adhesion, proper surface preparation is crucial. Always ensure the surfaces are clean, dry, and free from dirt, oil, grease, paint, or loose debris. Roughening smooth surfaces with sandpaper or a wire brush creates a better mechanical bond. Some plastics might require specific cleaning agents. Following these steps significantly enhances the durability and strength of the J-B Weld bond.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.