Having spent countless hours in my workshop, I’ve learned that the secret to a rock-solid J-B Weld repair often comes down to one crucial factor: temperature. It’s not just about mixing the parts correctly; understanding the best temperature for J-B Weld to cure can significantly impact the strength and longevity of your bond. I’ve personally experimented with various J-B Weld products under different conditions, from quick fixes to heavy-duty automotive repairs, and I’m here to share what I’ve discovered about optimizing cure times and achieving maximum durability. Let’s dive into some top J-B Weld formulations and how their curing properties can benefit your next project.

Contents

- J-B Weld High Heat Epoxy Syringe, Dark Grey

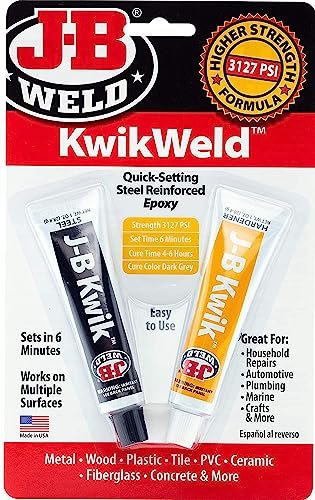

- J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy

- J-B Weld WaterWeld, 1 Hour Cure, Epoxy Putty Stick

- J-B Weld SteelStik, 1 Hour Cure, Steel Reinforced Epoxy

- J-B Weld 8297 HighHeat 500 Degree Epoxy Putty Stick

- J-B Weld Original Steel Reinforced Epoxy Syringe, High

- J-B Weld 37901 ExtremeHeat High Temperature Resistant

- Helpful Comparison Short Insights

- Final Verdict

- Best Temperature For JB Weld To Cure: FAQ Section

- Q1: What is the ideal temperature for J-B Weld to cure?

- Q2: Can cold temperatures affect J-B Weld’s curing process?

- Q3: Does heat help J-B Weld cure faster?

- Q4: What happens if J-B Weld gets too hot during curing?

- Q5: Can I use a heat gun or blow dryer to speed up J-B Weld curing?

- Q6: What is the maximum temperature J-B Weld can withstand after it’s fully cured?

- Q7: How does moisture affect the ideal temperature for J-B Weld to cure?

J-B Weld High Heat Epoxy Syringe, Dark Grey

This J-B Weld High Heat epoxy is a real workhorse for those repairs destined for hot environments. It’s a two-part system designed to withstand extreme temperatures, making it incredibly versatile. I’ve found it creates a permanent, heat-resistant bond that’s also surprisingly strong against chemicals and fuel, which is crucial for automotive or industrial applications where things tend to get messy and hot. The great thing is that while it cures perfectly well at room temperature, you can really speed things up with a bit of warmth.

Key features that stand out:

– High Heat Resistance: Handles up to 550°F continuously.

– Accelerated Cure with Heat: Sets in 1 hour at room temp, but can cure in 1 hour at 250°F.

– Impressive Strength: Boasts a 4730 PSI tensile strength.

– Chemical and Fuel Resistant: Provides a durable bond against harsh substances.

Pros:

– Excellent for applications needing high heat tolerance.

– Cure time can be significantly reduced with controlled heat.

– Very strong and resistant to various chemicals.

Cons:

– Requires a heat source for its fastest cure, which isn’t always convenient.

Best for: Exhaust systems, engine components, fireboxes, or any repair exposed to consistent high temperatures.

Expert Opinion: This product excels where conventional epoxies fail due to heat. Its ability to accelerate curing with warmth provides a significant advantage for urgent repairs in high-temperature settings, truly achieving its advertised heat resistance.

J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy

When you need a quick fix that doesn’t compromise on strength, J-B Weld KwikWeld is often my go-to. It’s like a fast-setting version of the original, offering reliable, lasting repairs on a multitude of surfaces. I’ve used it on everything from a cracked plastic bumper to a loose metal bracket, and its steel-reinforced formula gives me confidence in its hold. The quick set time means less waiting around, which is always a bonus when you’re in a hurry, though it still needs a few hours to reach its full strength.

Key features that stand out:

– Fast Setting: Takes only 6 minutes to set after mixing.

– Steel Reinforced: Provides enhanced durability and strength.

– Versatile Application: Works on metal, plastic, wood, ceramic, and more.

– Moderate Temperature Resistance: Withstands up to 230°F (110°C) when cured.

Pros:

– Extremely fast set time is great for urgent repairs.

– Strong and durable, capable of being sanded, drilled, or molded.

– Waterproof and resistant to petroleum, chemicals, and acids.

Cons:

– Its temperature resistance is lower compared to high-heat specific J-B Weld products.

Best for: General household repairs, automotive quick fixes, marine applications, and crafts where speed is essential.

Expert Opinion: KwikWeld perfectly balances speed with robust strength, making it ideal for everyday repairs where a rapid bond is crucial before full cure. The 6-minute set time is a standout feature for practical, immediate applications.

J-B Weld WaterWeld, 1 Hour Cure, Epoxy Putty Stick

This J-B Weld WaterWeld putty stick is a lifesaver for plumbing emergencies or boat repairs. The fact that it can cure under water is its standout feature, allowing for repairs in challenging wet conditions where other epoxies simply wouldn’t work. I’ve used it to seal a leaky pipe and patch a small hole in a water tank, and its off-white color makes for a decent finish. It’s a hand-mixable putty, so no messy tubes or syringes, which is convenient when you’re working in a tight spot.

Key features that stand out:

– Cures Under Water: Ideal for wet or submerged repairs.

– Potable Water Safe: NSF certified, safe for drinking water contact.

– Quick Cure Time: Sets in 25 minutes and cures in 1 hour.

– Good Temperature Tolerance: Withstands up to 300°F continuous, 350°F intermittent.

Pros:

– Unbeatable for marine and plumbing repairs, even underwater.

– Convenient hand-mixable stick format.

– NSF certified for potable water contact.

Cons:

– The initial kneading can be a bit messy on your hands.

Best for: Leaky pipes, fuel tanks, boat repairs, pool and spa fixes, and potable water tanks.

Expert Opinion: WaterWeld is an indispensable tool for anyone facing a leak in a wet environment. Its rapid 1-hour cure, even underwater, combined with its NSF certification, makes it uniquely suited for critical plumbing and marine applications.

J-B Weld SteelStik, 1 Hour Cure, Steel Reinforced Epoxy

For metal-on-metal repairs, J-B Weld SteelStik is my preferred choice. This hand-mixable epoxy putty stick is steel-reinforced and non-rusting, offering a powerful bond that feels incredibly robust. I’ve used it to rebuild stripped threads and repair metal machinery, and it’s impressively strong. The ability to mold, shape, sand, drill, and tap it after curing makes it incredibly versatile for structural repairs where precision matters. Its quick set and cure times are also a huge advantage for getting projects done efficiently.

Key features that stand out:

– Steel Reinforced: Extremely durable and non-rusting for metal repairs.

– Rapid Cure: Sets in 5 minutes and cures in 1 hour.

– High Tensile Strength: Boasts a 4000 PSI strength.

– Moldable and Machinable: Can be shaped, sanded, drilled, and tapped after curing.

Pros:

– Excellent for rebuilding or repairing anything made of metal.

– Very strong and resistant to chemicals and high temperatures.

– Quick set and cure times for efficient work.

Cons:

– Like other putty sticks, it requires hand mixing which can be a little sticky.

Best for: Repairing metal equipment, automotive components, stripped threads, and industrial maintenance.

Expert Opinion: SteelStik delivers exceptional performance for metal repairs, combining the convenience of a putty stick with the strength of steel. Its fast 1-hour cure and machinability make it a true powerhouse for both emergency fixes and lasting structural repairs.

J-B Weld 8297 HighHeat 500 Degree Epoxy Putty Stick

This is another high-temperature specialist from J-B Weld, but in a convenient putty stick form. J-B Weld HighHeat 500 Degree is specifically designed for repairs that will endure extreme heat in automotive and industrial settings, like exhaust manifolds or engine blocks. I’ve found it to be incredibly robust, holding strong where regular epoxies would simply fail. It’s significantly stronger at higher temperatures compared to conventional putties, giving me peace of mind for critical repairs.

Key features that stand out:

– Extreme Heat Resistance: Withstands continuous heat up to 450°F and intermittent heat up to 500°F.

– 3x Stronger at High Temps: Maintains superior strength even under heat.

– Machinable: Can be tapped and drilled after curing.

– Fast Setting: Sets in 1 hour and cures in 8 hours.

Pros:

– Specifically formulated for very high-temperature applications.

– Maintains impressive strength even when hot.

– Convenient putty stick format for targeted application.

Cons:

– The 8-hour cure time is longer than some other J-B Weld products.

Best for: Exhaust system repairs, engine blocks, mufflers, duct work, and other high-temperature industrial equipment.

Expert Opinion: This HighHeat putty stick is a top-tier solution for demanding repairs in extremely hot environments. Its superior strength retention at elevated temperatures sets it apart, ensuring long-lasting bonds in critical applications like exhaust systems.

J-B Weld Original Steel Reinforced Epoxy Syringe, High

The J-B Weld Original is truly the classic for a reason. It’s a two-part epoxy that delivers an incredibly strong, permanent bond for a wide range of materials. I’ve relied on it for heavy-duty repairs where maximum strength is non-negotiable, and it consistently performs. While it takes longer to fully cure than its “Kwik” counterparts, that extended cure time often translates to a more robust bond, allowing for deeper chemical reactions and a stronger final product.

Key features that stand out:

– The Original Cold-Weld: Provides strong, lasting repairs to metal and multiple surfaces.

– High Tensile Strength: Boasts an impressive 5020 PSI.

– High Temperature Tolerance: Withstands temperatures up to 550°F when fully cured.

– Versatile: Can be shaped, tapped, filed, sanded, and drilled after curing.

Pros:

– Delivers one of the strongest bonds available from J-B Weld.

– Excellent temperature resistance once fully cured.

– Versatile for a wide range of repairs, from household to automotive.

Cons:

– Requires a longer full cure time (15 hours) compared to faster-setting options.

Best for: Heavy-duty repairs where maximum strength and durability are paramount, and you have ample time for a full cure.

Expert Opinion: The Original J-B Weld is a benchmark for robust, permanent repairs. Its extended cure time, while requiring patience, ultimately yields a bond with superior strength and exceptional heat resistance, making it an enduring favorite for demanding projects.

J-B Weld 37901 ExtremeHeat High Temperature Resistant

When heat is truly extreme, J-B Weld ExtremeHeat is the answer. This product is specifically formulated for repairs to iron, steel, and metal that will be exposed to incredibly high temperatures – up to 1000°F (537°C)! I wouldn’t trust anything else for repairs on a furnace, fireplace, or even some parts of an exhaust that get exceptionally hot. It’s non-flammable and contains no solvents, which adds a layer of safety for high-temperature applications. Once cured, it’s strong enough to be drilled, machined, or sanded, providing a professional finish.

Key features that stand out:

– Extreme High-Temperature Resistance: Withstands up to 1000°F / 537°C.

– Non-Flammable: Safe for use in high-heat environments.

– No Solvents or VOCs: Environmentally friendly and safer to use.

– Machinable: Can be drilled, machined, or sanded once fully cured.

Pros:

– Unparalleled heat resistance for the most extreme temperature applications.

– Creates a permanent bond stronger than steel.

– Safe to use with no flammable solvents.

Cons:

– It’s a very specialized product, so its application might be limited for general use.

Best for: Exhaust manifolds, pipe connections, mufflers, catalytic converters, outdoor grills, fireboxes, and furnaces.

Expert Opinion: For the absolute hottest repairs, ExtremeHeat is unmatched. Its ability to withstand temperatures up to 1000°F makes it a critical tool for industrial, automotive, and home applications where extreme thermal conditions are present.

Helpful Comparison Short Insights

When choosing the right J-B Weld, the best temperature for J-B Weld to cure really depends on the specific product and its intended use. For general repairs where you need speed, KwikWeld is fantastic with its 6-minute set, but keep in mind its temperature tolerance is moderate. If you’re dealing with anything metal, SteelStik offers a powerful, machinable 1-hour cure. For wet environments, WaterWeld is the undeniable champion, curing under water in just 1 hour.

For repairs that will face continuous heat, the J-B Weld High Heat Epoxy Syringe is excellent, handling up to 550°F and even accelerating its cure with heat. The J-B Weld Original is a classic for a reason, offering the highest tensile strength and a impressive 550°F heat resistance after its longer 15-hour cure. If you need a high-heat putty, the J-B Weld 8297 HighHeat 500 Degree Epoxy Putty Stick is a great option, particularly strong at elevated temperatures. Finally, for the truly extreme thermal challenges, J-B Weld ExtremeHeat stands alone, offering an incredible 1000°F resistance for repairs in the hottest environments.

Each J-B Weld product is engineered for specific conditions, so always check the label for the recommended operating temperatures and J-B Weld cure time.

Final Verdict

Making the right choice for your J-B Weld project hinges entirely on your specific needs. There isn’t a single “best” option that covers every scenario, but rather a spectrum of specialized formulations designed for distinct challenges.

If speed and versatility for general household and automotive fixes are your priority, the KwikWeld is tough to beat. For those tricky underwater or plumbing repairs, WaterWeld is an absolute necessity. When you’re working with metal components that need rebuilding or reinforcement, SteelStik is an outstanding choice due to its strength and machinability.

However, if your repair is going to face significant heat, that’s where the high-temperature products truly shine. For sustained heat up to 550°F, the Original J-B Weld offers unmatched tensile strength with a patient cure, or the J-B Weld High Heat Epoxy Syringe provides a faster cure when heat is applied. If you need a high-heat putty stick, the HighHeat 500 Degree Epoxy Putty Stick is a solid performer. And for the most extreme temperatures, pushing beyond 500°F and up to 1000°F, J-B Weld ExtremeHeat is your only real contender.

Ultimately, by understanding the best temperature for J-B Weld to cure for each specific formula and aligning it with your project’s demands, you’ll achieve a bond that’s not just strong, but truly lasts.

Best Temperature For JB Weld To Cure: FAQ Section

Q1: What is the ideal temperature for J-B Weld to cure?

A1: Most J-B Weld products are designed to cure at room temperature, typically between 60°F and 75°F (15°C – 24°C). However, some formulations, like J-B Weld High Heat, can have their cure times significantly accelerated by applying controlled heat, such as 250°F for one hour. Always check the specific product’s instructions for its recommended curing temperature range.

Q2: Can cold temperatures affect J-B Weld’s curing process?

A2: Yes, cold temperatures can significantly slow down the J-B Weld cure time, potentially preventing a full cure or weakening the final bond. If working in cold conditions, it’s best to warm both the J-B Weld components and the repair surface to at least room temperature before mixing and applying. Curing in a warmer environment will help ensure optimal strength.

Q3: Does heat help J-B Weld cure faster?

A3: For certain J-B Weld products, yes, controlled heat can drastically accelerate the cure time. For instance, the J-B Weld High Heat epoxy syringe can cure in just 1 hour at 250°F, compared to 24 hours at room temperature. Always refer to the product’s packaging, as not all J-B Weld varieties benefit from or tolerate accelerated heat curing.

Q4: What happens if J-B Weld gets too hot during curing?

A4: Applying excessive or uncontrolled heat during the curing process can actually be detrimental. Too much heat can cause the epoxy to cure too quickly, leading to a brittle bond, bubbling, or improper cross-linking of the polymers, which will result in a weaker repair. Stick to the temperatures recommended by the manufacturer.

Q5: Can I use a heat gun or blow dryer to speed up J-B Weld curing?

A5: While some heat can accelerate curing for specific J-B Weld products, using a heat gun or blow dryer needs caution. It’s very easy to apply too much heat unevenly, which can compromise the bond. If you choose to use one, maintain a safe distance and keep the heat moving to avoid scorching the epoxy or exceeding its recommended curing temperature. Using a controlled oven for specific products (like High Heat) is often safer and more effective.

Q6: What is the maximum temperature J-B Weld can withstand after it’s fully cured?

A6: The maximum temperature J-B Weld can withstand varies greatly by product. For example, the J-B Weld Original and High Heat Epoxy Syringe can tolerate up to 550°F, while J-B Weld ExtremeHeat is designed for environments up to 1000°F. KwikWeld, on the other hand, is suitable up to 230°F. Always verify the heat resistance on the specific J-B Weld product you are using for its fully cured state.

Q7: How does moisture affect the ideal temperature for J-B Weld to cure?

A7: While temperature is crucial, moisture can also impact curing. Most J-B Weld products prefer a dry environment for optimal curing. However, specialized products like WaterWeld are formulated to cure even underwater, making them exceptions. For general epoxies, ensure the surface is dry and free of moisture before application and during the curing process, irrespective of the temperature.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.