I remember the first time I saw oil weeping down the side of my engine block—a telltale sign that the valve cover gasket had finally given up. Replacing that gasket isn’t just a simple fix; choosing the right material is crucial for long-term reliability and preventing another costly leak down the road. After years of turning wrenches, I’ve tested countless brands and compositions to figure out what truly makes the best valve cover gasket material. This guide breaks down the top choices, comparing durable sheet materials with high-quality pre-formed kits, ensuring your next repair lasts.

Contents

- FEL-PRO 3157 Gasket Making Material

- Exactly Rubber – Neoprene Sheet, 60A Durometer Rubber Mat, Gasket Material with -30 to 195°F Temperature Resistance, Oil and Gasoline-Resistant Rubber Sheet, Made in The USA, 1/16 x 9″ x 12″

- FEL-PRO VS 21566 C Valve Cover Gasket Set

- FEL-PRO VS 50504 R-1 Engine Valve Cover Gasket Set for Chevrolet Silverado 1500

- FEL-PRO VS 50088 R Engine Valve Cover Gasket Set for Chevrolet K1500

- TICFROG Watch Gasket O Ring Rubber Seal Watch Back Cover for Watch Repair, 1mm Cross-Section Diameter Metric Sealing Gasket for Automotive Machine Plumbing, Pack of 10 with Watch Cleaning Cloth (35mm)

- FEL-PRO VS 50358 R Valve Cover Gasket Set

- Comparison Insights: Finding the Best Valve Cover Gasket Material

- Final Verdict: Which Gasket Material Should You Choose?

- Frequently Asked Questions About Best Valve Cover Gasket Material

- What is the difference between cork-rubber and pure silicone valve cover gaskets?

- How often should I replace my valve cover gasket?

- Are there different valve cover gasket materials for aluminum versus cast iron heads?

- Can I reuse an old valve cover gasket?

- Do I need to use RTV silicone sealant with a new valve cover gasket?

- What are the signs of a properly installed valve cover gasket?

FEL-PRO 3157 Gasket Making Material

Sometimes, you need a custom fit for an older or specialty application, and that’s where gasket sheet material comes in handy. The FEL-PRO 3157 is a reliable rubber-fiber sheet designed for customization. It’s thick enough to provide excellent conformity when cut, making it a great choice for tricky timing covers or differential carriers, though it handles valve covers well too. Its rubber-fiber composite is specifically formulated to resist common automotive fluids like oil and gasoline, giving you confidence in the seal’s longevity.

Key features that stand out:

– COMPATIBILITY: Fits various custom applications using a 1/32″ sheet size.

– Rubber-Fiber Composition: Excellent resistance to oil, gasoline, and coolant exposure.

– Versatile Use: Recommended for timing covers, axle housing, and differential gaskets.

Pros:

– Ideal for custom cutting and unique applications

– Strong resistance to chemical deterioration

– Highly dependable material composition

Cons:

– Requires manual cutting and fitting, which adds labor time.

Best for: Custom, vintage, or specialty engine applications requiring unique dimensions.

Expert Opinion: This is a classic choice for mechanics who prefer to cut their own gaskets. While pre-formed kits are easier, this rubber-fiber material offers superior chemical resistance when you need to fabricate a unique valve cover gasket or seal for an older engine where kits are unavailable.

Exactly Rubber – Neoprene Sheet, 60A Durometer Rubber Mat, Gasket Material with -30 to 195°F Temperature Resistance, Oil and Gasoline-Resistant Rubber Sheet, Made in The USA, 1/16 x 9″ x 12″

Neoprene is highly valued in the gasket world for its toughness and excellent temperature stability across a wide range. This Exactly Rubber neoprene sheet provides professional-grade material that can handle both cold starts and warm running temperatures, ranging from -30°F up to 195°F. Its 60A durometer gives it a firm yet highly pliable surface, making it effective for creating leak-free seals, especially in environments exposed to oil and gasoline splatter.

Key features that stand out:

– Professional Neoprene: Solid rubber construction with a smooth, non-adhesive surface.

– Excellent Durability: 200% elongation capacity ensures stretch and strength under pressure.

– Oil and Gasoline Resistance: Synthetic rubber resists chemical deterioration, crucial for engine use.

Pros:

– Exceptional resistance to ozone and harsh weather conditions

– Ideal pliability for sealing imperfect surfaces

– Made in the USA quality manufacturing

Cons:

– The maximum temperature rating is lower than some silicone options.

Best for: General-purpose engine applications requiring robust oil and weather resistance.

Expert Opinion: When looking at sheet material compositions, Neoprene is a fantastic material if the engine bay temperature isn’t excessively high. Its resistance to petroleum products makes it a solid contender for creating the best valve cover gasket material when you need sheet stock.

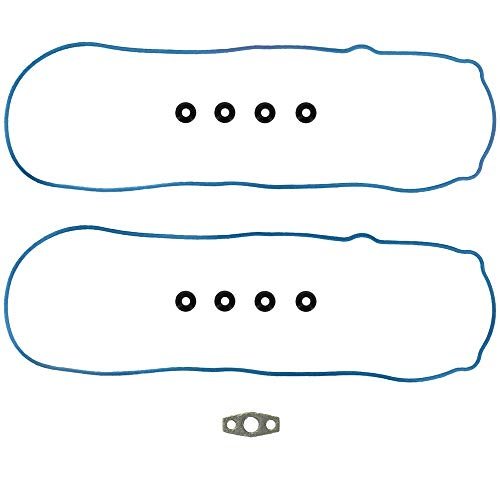

FEL-PRO VS 21566 C Valve Cover Gasket Set

When dealing with older engine designs or high-mileage blocks, the sealing surfaces are often far from perfect. The FEL-PRO VS 21566 C set is engineered specifically to address these “imperfect sealing surfaces.” Featuring a proprietary cork-rubber formulation, this gasket is highly conformable. This flexibility allows the gasket to compress unevenly and still maintain a superior seal, preventing leaks where rigid materials might fail.

Key features that stand out:

– Designed for Imperfect Surfaces: Specifically engineered for the repair environment.

– Proprietary Cork-Rubber: Highly conformable material formulation.

– Complete Kit: Includes all necessary parts for a full, secure repair.

Pros:

– Excellent choice for engines with slightly warped valve covers or uneven heads

– Highly conformable, ensuring a superior seal

– Reliable, real-world tested performance

Cons:

– Cork-rubber can harden and become brittle over many heat cycles if torqued incorrectly.

Best for: High-mileage or older engines known for minor imperfections or warpage in sealing surfaces.

Expert Opinion: For most common domestic and import applications, the cork-rubber combination is a time-tested winner. This specific kit from Fel-Pro provides confidence because it’s engineered to compensate for the reality of worn engines rather than assuming a brand-new, perfect surface.

FEL-PRO VS 50504 R-1 Engine Valve Cover Gasket Set for Chevrolet Silverado 1500

This particular Fel-Pro set focuses on specific compatibility, catering to a range of popular GM, Buick, and Cadillac models, including the ubiquitous Chevrolet Silverado 1500. Like other quality Fel-Pro kits, the VS 50504 R-1 utilizes the proprietary cork-rubber formulation. This ensures the material is superiorly conformable, which is essential for V8 engines where heat variance can cause subtle differences in cover alignment over time.

Key features that stand out:

– Specific Compatibility: Designed for common, high-volume GM vehicles (check fitment).

– Engineered to Perform: Uses the proprietary cork-rubber blend for durability.

– Superior Seal: Highly conformable to manage subtle sealing surface imperfections.

Pros:

– Precision fit for designated models, simplifying installation

– Reliable sealing on V8 engines exposed to high operational heat

– Trusted brand reputation in high-volume aftermarket parts

Cons:

– Only useful if your specific vehicle is listed in the extensive compatibility notes.

Best for: Owners of compatible GM trucks and SUVs seeking an OEM-grade replacement set.

Expert Opinion: If your vehicle is on the fitment list, choosing a specific kit like this is generally the best valve cover gasket material option because the dimensions are guaranteed to be spot-on. The cork-rubber excels at accommodating the heat expansion common in truck engines.

FEL-PRO VS 50088 R Engine Valve Cover Gasket Set for Chevrolet K1500

The FEL-PRO VS 50088 R set is another excellent cork-rubber option but stands out due to its broad and often older vehicle compatibility list, fitting classic models like the Chevrolet K1500 and even specific vintage Excalibur and Hummer models. This cork-rubber formulation is extremely beneficial for older vehicles because it has been engineered specifically for the repair environment. It maintains a strong seal even if decades of use have slightly altered the dimensions of the cover or head mating surface.

Key features that stand out:

– Wide Vintage Compatibility: Suitable for numerous older/classic vehicle applications.

– Repair Environment Design: Built to seal imperfect or worn surfaces effectively.

– Proprietary Cork-Rubber: Delivers superior conformity and oil resistance.

Pros:

– Excellent solution for hard-to-find gaskets on older vehicles

– Highly trusted material composition for engine sealing

– Included every part needed for the repair

Cons:

– Requires careful attention to torque specifications during installation to avoid over-compression.

Best for: Classic vehicle restoration projects and older trucks/SUVs where original sealing surface condition is questionable.

Expert Opinion: When dealing with older cast-iron components, you need a gasket that yields easily but doesn’t immediately deteriorate. The cork-rubber composite in this set strikes that balance perfectly, offering the flexibility needed to seal minor pitting or warping.

TICFROG Watch Gasket O Ring Rubber Seal Watch Back Cover for Watch Repair, 1mm Cross-Section Diameter Metric Sealing Gasket for Automotive Machine Plumbing, Pack of 10 with Watch Cleaning Cloth (35mm)

While the TICFROG O-Ring set is primarily designed for small applications like watch repair and general plumbing, the material itself—Nitrile Butadiene Rubber (NBR)—is highly relevant to automotive sealing. NBR offers great oil and heat resistance (up to 212°F or 100°C) and excellent wear resistance. While these specific small O-rings won’t function as a full valve cover gasket, understanding the material is key. Nitrile is often used for smaller auxiliary seals, spark plug tube gaskets, and fittings within the valve cover assembly where oil contact is constant.

Key features that stand out:

– Nitrile Butadiene Rubber (NBR): Great oil and heat resistance.

– Hardness: 70A Durometer provides good resistance to penetration.

– Application Relevance: Used in automotive machines, valves, and plumbing, demonstrating NBR’s utility.

Pros:

– Nitrile offers exceptional resistance to petroleum products

– Good temperature range for general engine sealing applications

– Versatile material used broadly across automotive systems

Cons:

– These specific O-rings are too small for primary valve cover sealing applications.

Best for: Understanding the quality of Nitrile (NBR) rubber for auxiliary engine sealing components.

Expert Opinion: Nitrile rubber is a fantastic sealing material, particularly because of its oil resistance. When you are looking for the overall best valve cover gasket material, ensure any included spark plug tube seals or bolt grommets are made from a high-quality oil-resistant rubber like NBR or Viton.

FEL-PRO VS 50358 R Valve Cover Gasket Set

The FEL-PRO VS 50358 R offers a high-quality, dependable kit designed for a range of vehicles requiring a robust seal. Utilizing the proven proprietary cork-rubber formulation, this kit excels at handling real-world engine conditions. Like its counterparts, it is tested on-vehicle and validated to ensure optimal performance, particularly when dealing with the high-heat, high-vibration environment of an engine compartment. It guarantees superior conformability, ensuring that every time you replace the valve cover, the seal is leak-free and long-lasting.

Key features that stand out:

– Superior Conformability: Ensures a tight seal even on uneven surfaces.

– Every Part Included: Comprehensive set for a full and professional repair.

– Real-World Tested: Validated for optimal performance on the road.

Pros:

– Highly versatile kit for various vehicle makes and models

– Extremely reliable long-term sealing performance

– Reduces the risk of leaks associated with imperfect installation surfaces

Cons:

– If your valve cover is severely warped, even this conformable material may struggle without proper machining.

Best for: General mechanics and DIYers seeking a highly reliable, proven kit for modern and older vehicles.

Expert Opinion: If you are unsure which specific kit to buy, a high-quality, comprehensive set like the VS 50358 R that utilizes cork-rubber is a safe bet. This blend is arguably the best valve cover gasket material when balancing conformity, cost, and durability for standard automotive repairs.

Comparison Insights: Finding the Best Valve Cover Gasket Material

When deciding on the best valve cover gasket material, you’re primarily choosing between composition (material type) and format (sheet vs. pre-formed kit).

If you prioritize ease of installation and guaranteed fit, a pre-formed kit like the Fel-Pro VS series (VS 21566 C, VS 50504 R-1, etc.) is the way to go. These kits are often cork-rubber composite, which provides the superior ability to seal against imperfect surfaces—a huge benefit in older engines.

For classic or custom applications where you must fabricate your own shape, sheet material is necessary. Materials like the Rubber-Fiber composite (FEL-PRO 3157) or Neoprene (Exactly Rubber) offer fantastic oil and gasoline resistance. Neoprene is especially tough and resistant to ozone, making it suitable for exposed engine components.

Keep in mind that while silicone is often considered the top-tier material for heat resistance, the cork-rubber blend provides better compression recovery and is often more forgiving if your valve cover bolts don’t apply pressure perfectly evenly. High-quality Nitrile rubber (NBR), though seen here in O-rings, confirms its excellent properties for oil exposure in smaller components within the valve cover assembly.

Final Verdict: Which Gasket Material Should You Choose?

Selecting the best valve cover gasket material truly depends on your vehicle and maintenance philosophy.

If you own a standard vehicle (e.g., Chevy Silverado) and seek maximum reliability against imperfect sealing surfaces: Go with the FEL-PRO VS 50504 R-1 Engine Valve Cover Gasket Set or similar specialized cork-rubber kit. The conformability ensures a leak-free outcome even if the mating surfaces aren’t pristine.

If you need custom fabrication for a classic or unique engine: The FEL-PRO 3157 Gasket Making Material (Rubber-Fiber) is your strongest choice. Its high chemical resistance and ease of cutting make it ideal for non-standard repairs.

For the best balance of conformity and durability in a generic kit form: The FEL-PRO VS 50358 R Valve Cover Gasket Set is a time-tested, dependable option that handles the demands of daily driving exceptionally well.

Frequently Asked Questions About Best Valve Cover Gasket Material

What is the difference between cork-rubber and pure silicone valve cover gaskets?

Pure silicone gaskets generally offer the highest temperature resistance and longevity. However, silicone can sometimes require near-perfect sealing surfaces and specific torque application. Cork-rubber composites, found in many Fel-Pro sets, are more pliable and conformable. They are much better at filling minor gaps and sealing slightly uneven or warped valve covers, making them a more forgiving and often equally durable choice for the average mechanic.

How often should I replace my valve cover gasket?

Valve cover gaskets don’t have a specific maintenance interval; they should be replaced when they show signs of failure. Common indicators include visible oil leaks along the mating seam, a burning oil smell (as oil drips onto the hot exhaust manifold), or oil residue collecting on the engine block. In modern cars, they are often replaced during major engine maintenance, such as spark plug replacement, as the cover must be removed anyway.

Are there different valve cover gasket materials for aluminum versus cast iron heads?

While the material composition itself (like cork-rubber or silicone) doesn’t change based on the head material, the properties you need might. Aluminum heads expand and contract more rapidly with temperature changes than cast iron. Therefore, materials that offer excellent compression set and recoverability—like high-quality rubber or specialized cork-rubber—are often considered the best valve cover gasket material for aluminum heads to accommodate thermal cycling.

Can I reuse an old valve cover gasket?

It is strongly not recommended to reuse an old valve cover gasket, especially if it is made of cork or a rigid rubber composite. Once these materials are compressed and exposed to heat cycles, they lose their elasticity and ability to conform to the surface. Reinstalling an old gasket almost always leads to an immediate or rapid leak. The minor cost savings aren’t worth the risk of a failure.

Do I need to use RTV silicone sealant with a new valve cover gasket?

In most cases, no, RTV sealant is not needed if you are using a quality pre-formed gasket kit (like the Fel-Pro VS series). These gaskets are designed to seal dry. RTV is typically only required at specific joints or corners, such as where the timing cover or cam bearing cap meets the cylinder head, creating a complex intersection of materials. Check your manufacturer or gasket instructions before applying RTV.

What are the signs of a properly installed valve cover gasket?

A properly installed gasket should be completely dry with no visible weeping or seepage of oil around the valve cover perimeter immediately after installation and subsequent driving cycles. The most critical factor for proper installation is applying the correct bolt torque specification in the sequence recommended by the vehicle manufacturer. Overtightening will crush and prematurely destroy even the best valve cover gasket material.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.