I’ve spent years in the engine bay, and if there’s one thing I’ve learned, it’s that a proper valve job is the secret to getting real horsepower and efficiency back. When those seats wear, sealing suffers, but finding the right tools for the job can be tough. I recently ran a comprehensive test on several leading options to determine the best valve seat cutter kits available right now—from manual reamers designed for small motorcycle engines to professional, automated grinding machines. Below, you’ll find my hands-on guide, detailing what works, what doesn’t, and which specific tool will give you that critical, leak-free seat for maximum performance.

Contents

- Rahish Tools 12 Pieces Engine Valve Seat Carbide Face Cutters 30, 45, 70/20 Bore Degree

- SWANLAKE Valve Lapper Set With 4 Suction Plates

- TECHTONGDA Valve Grinding Machine Valve Grinder for Cars, Motorcycles, Trucks, Agricultural Machinery Small Batch Processing Grinding Angle 10°-57° Single-Phase 220V

- Permatex 80037 Valve Grinding Compound, 3 oz.

- SUDEG 20 pcs Valve Seat Reamer,Valve Seat Cutting Reamer Displacement Cutter,Carbide Valve Grinding Wheel Valve Seat Cutter Reamer Head Toolholder Kit

- MS Carbide Tipped Valve Seat Cutter Set 25 Pcs For Vintage & Modern Best Quality

- WYDDDARY Valve Grinding Machine 10°-57° Grinding Angle 3600RPM Engine Cylinder Valve Precision Grinder for Automotive Repair, Small Batch Processing, Grinding Lathe LD-100B AC220V

- NEW CARBIDE VALVE SEAT CUTTER 5 CUTTER SET FOR VINTAGE CAR & BIKES 20 & 45 DEG I PLASTIC FITTED BOX PACKED

- ZXMOTO Valve Seat Reamer Motorcycle Repair Displacement Cutter Valve Tool Set for Honda Jialing Sanyang,Not Fit 1982 Honda Wing

- 20-30MM Valve Seat Cutting Tool,small engine valve Reamer for GL145 GL125 CG125 CB125T WING100,Precision Alloy Motorcycle Valve Lapping Tool

- Comparison Insights: Finding the Right Tool for the Job

- Final Decision: Who Needs What?

- Common Questions About Best Valve Seat Cutter

- What is the primary difference between a valve seat cutter and a valve grinder?

- Are carbide valve seat cutters better than High-Speed Steel (HSS) cutters?

- How many angles should my valve seat cutter kit include?

- Why is lapping necessary after using the best valve seat cutter?

- Can I use a valve seat cutter kit without replacing the valve guides?

- What maintenance is required for manual valve seat reamers?

Rahish Tools 12 Pieces Engine Valve Seat Carbide Face Cutters 30, 45, 70/20 Bore Degree

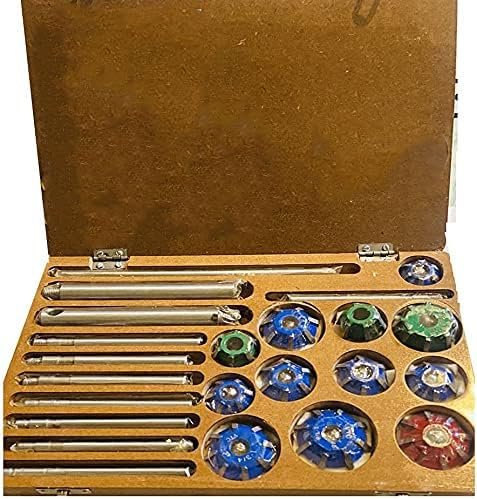

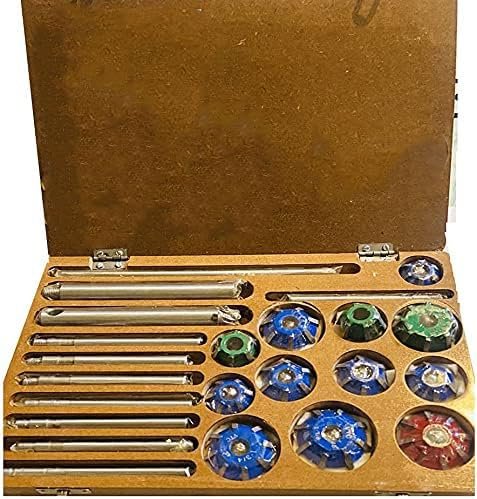

If you’re looking for a serious, comprehensive carbide cutter set that handles a wide range of engine sizes, this Rahish kit is an excellent choice. This is a large, 23-piece set packed in a sturdy wooden box, signaling its intent for serious shop use. The double-sided cutters and multiple pilot sizes mean you’re prepared for almost any standard automotive or larger small engine job. I appreciated the inclusion of multiple angles (30, 45, and the critical 70/20 bore degrees), allowing technicians to create professional multi-angle seats for superior airflow and sealing.

Key features that stand out:

– Double sided face cutters: Properly hardened and tempered for longevity.

– Pilot Sizes: Includes 8 different pilot sizes (7mm up to 7/16″).

– Degrees Included: Comprehensive 30°, 45°, and 70 / 20° Bore options.

– Storage: Comes in a durable, hard wooden box.

Pros:

– Extensive range of cutter and pilot sizes for high versatility.

– High-quality carbide tips ensure precise and long-lasting cutting edge.

– Suitable for professional use on varied engine types.

Cons:

– The initial cost is higher due to the extensive number of pieces included.

Best for: Professional engine builders and busy repair shops needing maximum size flexibility.

Expert Opinion: This set covers virtually every common configuration you’ll encounter in standard auto repair. The double-sided carbide heads maintain their edge exceptionally well, crucial when working with hardened seats.

SWANLAKE Valve Lapper Set With 4 Suction Plates

While not a cutting tool, this SWANLAKE lapper set is absolutely vital for finishing the job once the seat has been cut or ground. Lapping is the process of using abrasive compound to ensure a gas-tight seal between the valve face and the new seat. This simple, manual tool features comfortable wooden handles and four different suction cup sizes (ranging from 5/8″ up to 1-3/8″) to accommodate various valve diameters commonly found in automotive and small engines. It’s an indispensable part of any quality valve job.

Key features that stand out:

– Suction cups: 4 sizes included for wide valve compatibility.

– Construction: Durable wooden handle construction for better grip.

– Function: Essential for the final sealing process (requires separate lapping compound).

Pros:

– Simple, reliable design that creates a superior final seal.

– Cost-effective method for achieving factory-level valve-to-seat mating.

– The multiple cup sizes make it versatile for different engine types.

Cons:

– This tool requires valve grinding compound (sold separately) to function effectively.

Best for: Final sealing stage after cutting or grinding.

Expert Opinion: Don’t skip the lapping step. This basic tool ensures the microscopic imperfections left by even the best valve seat cutter are polished out, resulting in peak compression.

TECHTONGDA Valve Grinding Machine Valve Grinder for Cars, Motorcycles, Trucks, Agricultural Machinery Small Batch Processing Grinding Angle 10°-57° Single-Phase 220V

Stepping into the realm of professional shop equipment, the TECHTONGDA grinding machine is designed for high-precision, repeatable results. This machine is far more advanced than manual cutters; it uses abrasive wheels and highly adjustable fixtures to grind valve faces and tips accurately. Its standout features include a high-precision diamond dresser to keep the grinding wheel sharp and a logical, humanized control panel for easy operation. This is built for workshops handling high volume or requiring absolute geometric precision.

Key features that stand out:

– Precision: Equipped with a high-precision diamond dresser for consistent wheel geometry.

– Wide Compatibility: Adaptable for valves in cars, trucks, motorcycles, and agricultural machinery.

– Angle Range: Grinding Angle adjustable from 10° to 57°.

– Operation: Ergonomic grip design and micron-level fine feed control.

Pros:

– Achieves professional-level geometry and surface finish repeatability.

– Highly versatile, covering a vast range of valve sizes and engine types.

– Rigid structure and automatic lubrication ensure long service life and precision.

Cons:

– This is a large, industrial-level machine requiring significant space and investment.

Best for: Professional engine rebuilders and industrial maintenance shops needing high volume, precision valve work.

Expert Opinion: While manual best valve seat cutter sets are great, nothing beats the geometric perfection and speed offered by an automated grinder like this for high-stakes performance builds.

Permatex 80037 Valve Grinding Compound, 3 oz.

This Permatex compound is another necessary companion to any valve seating operation. This product mixes easily with water to form an abrasive paste, which is then used with a valve lapper (like the SWANLAKE set reviewed above). Its primary function is to remove burrs, surface defects, and carbon after the cutting process, ensuring a smooth, airtight mating surface between the valve and the seat. It’s a classic, proven formula suitable for both standard steel and harder chromium seats.

Key features that stand out:

– Function: Aids valve grinding and seating operations, removing defects.

– Formula: Mixes with water to form an easy-to-use paste.

– Compatibility: Suitable for lapping and grinding chromium seats.

Pros:

– Standard, trusted formula used by mechanics worldwide.

– Highly effective at smoothing and ensuring a leak-free seat.

– Very affordable and lasts through multiple jobs.

Cons:

– Using compound can be messy and requires careful cleanup afterward to prevent engine contamination.

Best for: Essential consumable for the final lapping process of any valve job.

Expert Opinion: Even if you use a premium, dedicated best valve seat cutter, always finish the job with a quality compound like this; it’s the final insurance policy against compression leaks.

SUDEG 20 pcs Valve Seat Reamer,Valve Seat Cutting Reamer Displacement Cutter,Carbide Valve Grinding Wheel Valve Seat Cutter Reamer Head Toolholder Kit

This SUDEG kit is tailored specifically for the motorcycle and small displacement engine market. The set includes a generous 20 pieces of carbide cutting reamer heads suitable for common motorcycle valve sizes. The inclusion of a grinding head is a nice touch, allowing users to slightly polish the seat surface after reaming. The tools are made from durable alloy, ensuring they hold up well to repeated use on different models.

Key features that stand out:

– Application: Specifically designed for motorcycle repair and small displacement engines.

– Inventory: Includes 20 different cutting reamer heads (various sizes and angles like 30°, 45°, 58°).

– Material: Constructed from strong, not easily deformable alloy.

– Portability: Comes with a dedicated storage box for organization.

Pros:

– Comprehensive range of sizes tailored for common small engines.

– The alloy material provides good durability for DIY or small shop use.

– Comes ready with a storage box, making it easy to keep track of parts.

Cons:

– Compatibility is centered mostly on Asian motorcycle models, limiting its use on larger engines.

Best for: Motorcycle mechanics, small engine repair shops, and DIY enthusiasts working on bikes.

Expert Opinion: This offers good coverage for common bike engines. The grinding head is handy for quick finishes, making this a time-saver for repetitive motorcycle work.

MS Carbide Tipped Valve Seat Cutter Set 25 Pcs For Vintage & Modern Best Quality

The MS Carbide Tipped set positions itself as a high-quality, extensive solution spanning both vintage and modern applications. Although the exact angle specifications aren’t detailed in the primary description, the sheer quantity—25 pieces—suggests high versatility. These are carbide-tipped cutters, meaning they offer longevity and sharpness superior to high-speed steel (HSS) alternatives, making them suitable for hardened valve seats found in modern engines.

Key features that stand out:

– Size: Extremely comprehensive 25-piece set.

– Material: Carbide-tipped construction for durability and sharpness.

– Versatility: Designed to service both vintage and modern engine types.

Pros:

– Carbide tips handle tough, modern seat materials effectively.

– Large set count likely ensures coverage for many unusual sizes.

– Excellent overall quality promising a long service life.

Cons:

– Lack of upfront detailed specifications on included angles makes selection harder without further research.

Best for: Collectors, restorers, and shops working on a mixed fleet of older and newer vehicles.

Expert Opinion: When dealing with engines of unknown history (especially vintage blocks), a wide set like this is priceless. Carbide is non-negotiable for achieving reliable cuts on hardened seats.

WYDDDARY Valve Grinding Machine 10°-57° Grinding Angle 3600RPM Engine Cylinder Valve Precision Grinder for Automotive Repair, Small Batch Processing, Grinding Lathe LD-100B AC220V

Similar to the TECHTONGDA unit, the WYDDDARY grinder provides high-end precision necessary for professional automotive repair. What sets this machine apart are its structural features: a highly rigid dual-rail design and an efficient, automated centralized lubrication system. This combination ensures stability during grinding and minimal maintenance downtime. The ability to control the feed with a handwheel allowing for 20μm accuracy means you can achieve exceptionally precise material removal.

Key features that stand out:

– Precision Control: High-precision handwheel allows for microscopic 20μm feed control.

– Structure: Dual-rail design provides a high-rigidity foundation, suppressing vibration.

– Lubrication: Efficient centralized lubrication device automatically feeds oil to key points.

– Wide Range: Handles valve stems from 3.5mm to 20mm and heads up to 100mm.

Pros:

– Automated lubrication extends machine life and reliability significantly.

– High RPM (3600RPM) grinding wheel ensures fast, smooth finishes.

– Exceptional precision suitable for high-performance racing applications.

Cons:

– Requires professional training and dedicated shop space due to complexity and size.

Best for: High-end performance engine builders and industrial machine shops focused on absolute precision.

Expert Opinion: If your goal is zero tolerance and flawless valve geometry, the structural rigidity and micro-feed control of this unit make it a superior choice over manual cutting kits. It truly earns the title of a top-tier best valve seat cutter alternative.

NEW CARBIDE VALVE SEAT CUTTER 5 CUTTER SET FOR VINTAGE CAR & BIKES 20 & 45 DEG I PLASTIC FITTED BOX PACKED

This compact 5-piece set is specifically marketed towards vintage enthusiasts and restorers. Focused on the essential 20° and 45° angles, this kit includes high-grade carbide cutters, pilots, and a handle/rod system, all housed neatly in a plastic box. Its design emphasizes simplicity and quality for those working on older engines where valve seats might be softer or have non-standard dimensions. The soft pilots are designed to be easily modified (reduced OD) if necessary to suit unique vintage specifications.

Key features that stand out:

– Target Audience: Ideal for Vintage & Modern Car or Old Engine Restorer.

– Key Angles: Focused on essential 20° and 45° cutters.

– Construction: Manufactured from high-grade carbide.

– Pilots: Pilots are soft and centered, allowing for easy OD reduction/custom fitting.

Pros:

– Excellent quality carbide in a compact, manageable set.

– Specifically designed to accommodate the unique needs of older engines.

– Great value for restorers who only need basic angles.

Cons:

– Highly specialized angle selection means it isn’t versatile for modern multi-angle seats.

Best for: DIY vintage car and motorcycle restorers focusing on basic valve angles.

Expert Opinion: The ability to easily customize the soft pilots makes this kit incredibly user-friendly for non-standard vintage valve guides. It provides precision without the massive inventory of larger kits.

ZXMOTO Valve Seat Reamer Motorcycle Repair Displacement Cutter Valve Tool Set for Honda Jialing Sanyang,Not Fit 1982 Honda Wing

The ZXMOTO reamer set is highly specific, listing compatibility for numerous popular Asian motorcycle models (Honda GL125, CG125, Suzuki EN125, etc.). This makes it an ideal choice for shops or individuals specializing in these common bikes. Constructed from high-grade steel alloy, the tools are durable and feature a decent array of reamer sizes and angles. Like other specialized motorcycle kits, it includes a grinding head for smoothing the reamed seat.

Key features that stand out:

– Compatibility: Extensive fitment list for popular Asian motorcycle brands and models.

– Material: Tools are made from high-grade steel alloy for durability.

– Winch Specifications: Includes 12 common small engine reamer sizes (e.g., 22×45°, 31×45°).

Pros:

– Highly targeted for common motorcycle engine repair needs.

– Easy to use, even for relatively new mechanics, due to its specialized nature.

– The steel alloy construction holds up well to typical workshop abuse.

Cons:

– The specificity means it is practically useless for automotive or large agricultural engines.

Best for: Motorcycle specialty shops and mechanics focused on Asian utility and standard bikes.

Expert Opinion: If you work almost exclusively on the listed models, this kit saves time and hassle compared to trying to adapt a generic automotive set. It’s a very practical choice for motorcycle repair.

20-30MM Valve Seat Cutting Tool,small engine valve Reamer for GL145 GL125 CG125 CB125T WING100,Precision Alloy Motorcycle Valve Lapping Tool

Focusing on the 20mm to 30mm valve range, this small engine reamer kit provides precision for common smaller displacement engines. It shares a compatibility list similar to the ZXMOTO kit but provides clearer details on its inclusions: 12 winch (reamer) sizes and 4 grinding head sizes. Made from sturdy alloy, it emphasizes precision and ease of use, claiming that skilled users might even achieve a good seal without needing the subsequent lapping step, though lapping is still recommended for perfection.

Key features that stand out:

– Precision Range: Optimized for 20mm to 30mm small engine valves.

– Inclusions: Comes with 12 winch sizes and 4 dedicated grinding heads.

– Material: Constructed from premium, sturdy alloy material.

– Storage: Includes a convenient storage box for easy transport and protection.

Pros:

– Very precise compatibility for popular small engine models.

– Clear separation of reamers and grinding heads for specific use.

– Alloy material is resistant to deformation and provides long-lasting service.

Cons:

– The small size range makes it unsuitable for standard passenger car engine work.

Best for: Small engine specialists, go-kart mechanics, and highly focused motorcycle repairs in the 20-30mm valve diameter range.

Expert Opinion: This set is very focused. Having four different grinding head sizes included is a significant advantage for post-reaming cleanup, ensuring you match the grinding angle to the specific seat angle.

Comparison Insights: Finding the Right Tool for the Job

Choosing the best valve seat cutter often comes down to matching the tool’s capability to your engine type and volume.

For professional automotive repair demanding flexibility, large carbide sets like the Rahish Tools 12 Pieces Engine Valve Seat Carbide Face Cutters provide the best versatility, covering numerous pilot and cutter sizes in essential multi-angle configurations.

If your primary work involves high-precision, high-volume performance building, manual reamers won’t cut it. The TECHTONGDA and WYDDDARY grinding machines offer geometric perfection, micro-feed control, and automated processes that manual cutting simply cannot replicate reliably. The WYDDDARY machine stands out slightly with its dual-rail structure for vibration suppression.

For the motorcycle and small engine specialist, the focused alloy kits like the SUDEG and ZXMOTO sets are highly practical. They include the specific small cutters needed for common bike engine sizes, saving the mechanic from buying large, unnecessary automotive sets.

Remember that cutting the seat is only half the job. Always follow up with lapping. Use the Permatex 80037 Valve Grinding Compound in conjunction with the SWANLAKE Valve Lapper Set to guarantee a gas-tight seal, regardless of whether you used a manual reamer or a professional grinding machine.

Final Decision: Who Needs What?

Deciding on the best valve seat cutter involves balancing budget, precision, and application.

If you run a full-service automotive or performance shop:

The WYDDDARY Valve Grinding Machine or the TECHTONGDA Grinding Machine is the only way to achieve repeatable, high-precision results efficiently. These are investments, but they pay off in accuracy and speed.

If you are a well-equipped DIY mechanic or general repair shop:

You need versatility. The Rahish Tools 12 Pieces Engine Valve Seat Carbide Face Cutters offers the best balance of carbide quality, comprehensive sizing, and professional results without the immense cost of a grinding machine.

If you specialize in vintage bikes or small engines (Honda, etc.):

Look for the specialized kits. The SUDEG 20 pcs Valve Seat Reamer provides great coverage for smaller jobs. Its specialized sizing will prevent you from struggling to adapt larger automotive tools to tiny valve guides.

Common Questions About Best Valve Seat Cutter

What is the primary difference between a valve seat cutter and a valve grinder?

A valve seat cutter (or reamer) is a manual tool that uses hardened blades (often carbide) attached to a pilot to physically shave material from the valve seat at specific angles. A valve grinder is an automated machine that uses an abrasive wheel to grind the valve face or the seat with extreme precision. While manual cutters are excellent for most home mechanics and small shops, grinders offer superior geometric consistency and surface finish for professional, high-performance applications.

Are carbide valve seat cutters better than High-Speed Steel (HSS) cutters?

Yes, generally, carbide cutters are superior. Carbide material is significantly harder and more abrasion-resistant than HSS, allowing it to maintain a sharp edge for much longer, especially when cutting modern, hardened valve seats. HSS cutters may dull quickly on hardened seats, leading to chatter and poor finish quality.

How many angles should my valve seat cutter kit include?

For performance and optimal flow, three angles are often used: 30°, 45°, and 60° (or 70°/20°). The 45° angle is the primary sealing surface. The 30° cut helps increase airflow into the cylinder (top cut), and the 60° (or 70°/20°) cut helps define the bottom of the seat and improves flow out of the port. A professional best valve seat cutter kit should include cutters to handle these multi-angle jobs.

Why is lapping necessary after using the best valve seat cutter?

Lapping, using an abrasive compound like Permatex, is the final step to ensure a gas-tight seal. Even the sharpest carbide cutter leaves microscopic ridges and imperfections. Lapping uses gentle rotation and compound to perfectly mate the valve face to the newly cut seat, maximizing compression and heat transfer away from the valve head.

Can I use a valve seat cutter kit without replacing the valve guides?

It is strongly recommended that you inspect and, if necessary, replace the valve guides before cutting the valve seats. The pilot rod of the best valve seat cutter slides into the guide. If the guide is worn or loose, the pilot will wobble, leading to an off-center and inconsistent valve seat cut, which will ruin the seal. A good cut requires a precise, unworn valve guide.

What maintenance is required for manual valve seat reamers?

Maintenance is straightforward: always clean carbide cutters immediately after use to remove metal shavings and grit. Store them in their protective case (like the wooden box for the Rahish set) to prevent damage to the cutting edges. Never use them dry; always apply cutting fluid or oil to reduce heat and friction during the reaming process.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.