When I first dipped my toes into the world of welding aluminum, I quickly realized it’s a different beast than steel. The challenges of heat management, oxidation, and choosing the right filler material can be a real head-scratcher. That’s why I’ve spent time sifting through various options to find the best welding aluminum solutions out there. Whether you’re a seasoned pro looking for new gear or a beginner trying to tackle your first aluminum project, this guide will walk you through seven reliable products that can make your aluminum welding experience smoother and more successful.

Contents

- 50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

- YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

- ARCCAPTAIN Silicon Aluminum Welding Wire ER4043 .035″ Mig…

- Aluminum Brazing Rods, Aluminum Welding Rods, Welding…

- AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V…

- YESWELDER Silicon Aluminum Welding Wire, ER4043 .030-Inch…

- Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons…

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Aluminum: Your Questions Answered

- Q1: What makes welding aluminum different from welding steel?

- Q2: Can I weld aluminum with a regular MIG welder?

- Q3: What’s the difference between ER4043 and ER5356 aluminum welding wire?

- Q4: Are flux-cored aluminum rods effective for structural applications?

- Q5: What kind of shielding gas do I need for welding aluminum?

- Q6: How important is surface preparation when welding aluminum?

- Q7: What’s the best way for a beginner to start welding aluminum?

50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

These flux-cored aluminum rods are a fantastic option for those who want simplicity without sacrificing quality. What really stands out is the no-solder-powder-needed design, meaning you don’t have to fuss with extra materials. They’re super easy to use, making them a go-to for quick repairs or beginners venturing into aluminum projects. Made from durable aluminum, they offer a great welding effect with a low melting point, ensuring a strong, corrosion-resistant bond on various aluminum types.

- Key features that stand out:

- NO SOLDER POWDER NEEDED: Flux cored design eliminates the need for external solder powder.

- HIGH QUALITY MATERIAL: Made from nontoxic, odorless, and durable aluminum.

- PERFECT WELDING EFFECT: Low melting point, great weldability, and corrosion resistance.

- WIDELY USE: Suitable for aluminum, aluminum alloy, aluminum-magnesium alloy, and other white metals.

- Pros:

- Extremely easy to use, especially for beginners.

- No need for additional flux, simplifying the process.

- Good for a variety of aluminum materials and repair tasks.

- Produces strong, corrosion-resistant welds.

- Cons: Not suitable for high-stress or critical structural welds requiring maximum strength.

- Best for: Quick repairs, DIY projects, and beginners looking for a straightforward aluminum welding solution.

- Expert Opinion: These rods are excellent for accessibility. They lower the barrier to entry for aluminum brazing, making small repairs and hobby work much more approachable without complex equipment.

YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

For those stepping into TIG welding or needing a reliable filler for general purpose aluminum applications, the YESWELDER ER4043 TIG rods are a solid choice. Referred to as “AlSi5” due to its 5% silicon content, this filler metal is one of the most widely used for aluminum thanks to its improved fluidity and resistance to weld cracking. It produces brighter welds and is compatible with a range of common aluminum grades, making it versatile for both new fabrications and repair work requiring thermal treatment.

- Key features that stand out:

- ER4043: Contains 5% silicon for improved fluidity and crack resistance.

- EXCELLENCE: Produces brighter welds and is less sensitive to cracking.

- MULTIPLE USAGE: Ideal for base metals requiring thermal treatment, weld forge, and casting materials.

- APPLICATION: Suitable for grades like 3003, 5052, 6061, 6063, and various casting alloys.

- Pros:

- Excellent fluidity, making it easier to achieve good bead aesthetics.

- Good resistance to hot cracking, leading to stronger welds.

- Highly versatile for many aluminum alloys and applications.

- Produces clean, bright welds.

- Cons: The 5% silicon can cause a grey appearance after anodizing.

- Best for: General-purpose TIG welding of aluminum, especially 6xxx series alloys and castings, where good fluidity and crack resistance are important.

- Expert Opinion: ER4043 is the workhorse of aluminum TIG fillers. YESWELDER delivers a consistent product that experienced welders trust for its reliable performance and ease of use with 100% Argon shielding gas.

ARCCAPTAIN Silicon Aluminum Welding Wire ER4043 .035″ Mig…

If you’re into MIG welding aluminum, the ARCCAPTAIN ER4043 wire is engineered to give you a smooth welding experience with excellent arc stability. This 5% silicon aluminum filler metal is specifically tailored for the MIG process, ensuring easy control and a great weld bead appearance. Its versatility means you can use it on a variety of common aluminum grades, making it a great addition to any workshop dealing with aluminum fabrication.

- Key features that stand out:

- Smooth Welding Experience: Ensures stable arc characteristics and excellent weld bead appearance.

- ER4043 Aluminum Welding Wire: Contains 5% silicon (AlSi5) for MIG welding.

- Versatile Application: Suitable for grades like 3003, 5052, 6061, 6063, and casting alloys.

- Melting Range and Density: Melts from 1065 °F to 1170 °F, density of 0.097 lbs/in³.

- Pros:

- Promotes a very smooth and stable arc, which is crucial for MIG aluminum.

- Produces aesthetically pleasing weld beads.

- Wide compatibility with common aluminum alloys.

- Good choice for general fabrication and repair.

- Cons: Like other ER4043, it will be gray when anodized, which might not suit all aesthetic needs.

- Best for: MIG welding aluminum sheets, extrusions, and general fabrication where ease of use and good appearance are key.

- Expert Opinion: For clean MIG aluminum welds, arc stability is paramount. ARCCAPTAIN’s ER4043 wire provides that stability, making it easier to achieve quality results without constant adjustments, especially with a spool gun.

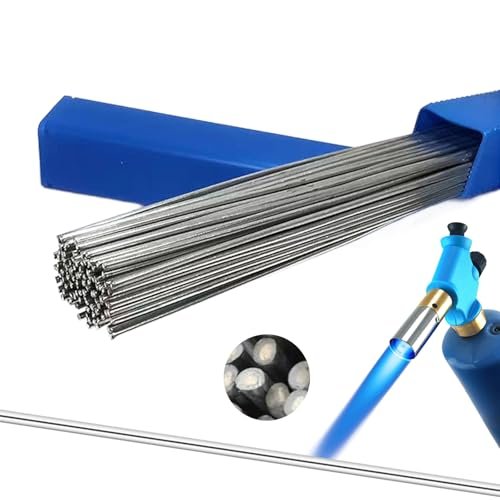

Aluminum Brazing Rods, Aluminum Welding Rods, Welding…

These aluminum brazing rods are all about efficiency and ease of use, much like the first flux-cored option, but with an emphasis on multipurpose functionality. They boast a flux-cored design that means you don’t need additional solder powder, streamlining your welding process significantly. With a low melting point and great weldability, they promise a perfect welding effect for various aluminum and white metal projects, catering to both professional welders and enthusiastic DIYers.

- Key features that stand out:

- Efficient No Solder Powder: Flux-cored rods eliminate the need for extra solder powder.

- Perfect Welding Effect: Low melting point, good weldability, corrosion resistance, high thermal and electrical conductivity.

- Suitable for Various Materials: Works with aluminum, aluminum alloy, aluminum-magnesium alloy, and other white metals.

- High-Quality Material: Made from premium nontoxic, odorless, durable aluminum.

- Pros:

- Extremely convenient for quick, efficient welding without external flux.

- Delivers strong, durable, and corrosion-resistant welds.

- Versatile for a wide range of aluminum and white metal projects.

- User-friendly for both pros and DIY enthusiasts.

- Cons: May require thorough surface preparation for optimal adhesion and strength.

- Best for: Repairing aluminum components, general brazing tasks, and DIY projects where simplicity and effectiveness are desired.

- Expert Opinion: These brazing rods are a great solution for those needing to join aluminum without investing in complex welding equipment. Their flux-cored nature is a huge time-saver and delivers respectable strength for non-critical applications.

AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V…

Now, for those looking for a complete machine, the AZZUNO Aluminum MIG Welder is a multiprocess powerhouse designed with versatility in mind. It handles Gasless MIG, Gas MAG, Aluminum MIG, Stick, and Lift TIG, making it incredibly adaptable. Its ability to achieve smooth aluminum MIG welding without needing a Teflon liner or spool gun (though a spool gun is recommended for optimal results with some setups) is a significant advantage. With dual voltage and synergic mode, it’s a fantastic option for various applications and material thicknesses, offering robust performance for anyone serious about welding aluminum.

- Key features that stand out:

- MULTIPROCESS ALUMINUM WELDER: Offers Gasless MIG, Gas MAG, Aluminum MIG, Stick, and Lift TIG modes.

- VARIETY WELDING WIRE OPTIONS: Supports 1-2 lb spools, .030″-.040″ flux core, solid, and aluminum wire.

- STREAMLINED ALUMINUM WELDING: Designed for hassle-free aluminum MIG without needing a Teflon liner initially.

- VERSATILE MIG WELDING OPTIONS: Features SYN, 2T, and 4T modes for optimized and flexible control.

- Pros:

- Highly versatile with multiple welding processes.

- Dual voltage (110V/220V) for flexibility in power sources.

- Synergic mode simplifies settings for beginners and speeds up setup for pros.

- Specific design considerations for easier aluminum MIG welding.

- Cons: While it streamlines aluminum MIG, a dedicated spool gun is still recommended for best results with softer aluminum wires.

- Best for: Welders who need a versatile, all-in-one machine capable of handling various materials and welding processes, with a strong emphasis on efficient aluminum MIG welding.

- Expert Opinion: The AZZUNO 155Amp is an impressive entry-level multi-process machine that makes aluminum MIG welding more accessible. Its synergic control takes much of the guesswork out, which is a huge benefit when learning the nuances of aluminum.

YESWELDER Silicon Aluminum Welding Wire, ER4043 .030-Inch…

This YESWELDER Silicon Aluminum Welding Wire is a premium ER4043 filler metal specifically for MIG welding. What makes it stand out is its excellent performance and enhanced fluidity due to the 5% silicon content. It ensures superb wetting action, improves crack resistance, and produces smooth, clean welds with minimal spatter. Packaged on a robust ABS plastic spool, this wire is built to perform reliably in a variety of applications, from auto repair to DIY projects, consistently delivering professional results.

- Key features that stand out:

- ER4043 WELDING WIRE: Premium 5% silicon aluminum filler for MIG welding.

- EXCELLENT PERFORMANCE: Enhanced fluidity, improved crack resistance, good corrosion resistance, minimal spatter.

- VERSATILE APPLICATIONS: Suitable for metal fabrication, auto repair, equipment maintenance, and DIY projects.

- MATERIAL COMPATIBILITY: Welds 3003, 3004, 5052, 6061, 6063, and casting alloys.

- Pros:

- Provides excellent arc stability and fluidity for superior weld quality.

- High crack resistance ensures durable, long-lasting bonds.

- Versatile for a wide range of aluminum alloys and project types.

- Robust spool design prevents issues during use.

- Cons: Requires a proper MIG setup with shielding gas and potentially a spool gun for optimal feeding.

- Best for: Professional and serious hobbyist MIG welders looking for high-quality ER4043 wire that ensures excellent performance and reliability for diverse aluminum projects.

- Expert Opinion: This YESWELDER wire consistently delivers. The added silicon truly makes a difference in weld puddle control and overall bead appearance for MIG aluminum, making it a favorite for those aiming for professional finishes.

Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons…

Every welder knows practice makes perfect, and this Therwen Welding Kit provides an ideal tool for beginners to master aluminum welding. You get three aluminum welding coupons in different styles, offering a comprehensive array of shapes to practice various techniques. Constructed from quality aluminum, these coupons can withstand significant heat, providing a realistic and durable practice surface. Their user-friendly design allows you to hold, bend, and weld them easily, helping you improve your skills and reduce errors without needing extra tools.

- Key features that stand out:

- Complete Set for Practice: 3 welding coupons (2 square, 1 triangular) for diverse practice.

- Aluminum Structure: Made from quality, durable aluminum that withstands welding heat.

- Ideal Tool for Beginners: Provides a structured way to learn, train, and practice aluminum welding skills.

- Convenient and User Friendly Design: Simplified design for easy holding, bending, and welding.

- Pros:

- Excellent for beginners to develop aluminum welding skills.

- Durable aluminum construction provides realistic practice.

- Different shapes encourage varied technique practice.

- Can also be used as decorative items after practice.

- Cons: Not a consumable product for actual projects, strictly for practice.

- Best for: Novice welders or anyone looking to hone their aluminum welding techniques and reduce material waste on real projects.

- Expert Opinion: You can’t learn to weld without burning metal. These aluminum coupons are an invaluable asset for beginners, allowing them to gain confidence and muscle memory on aluminum before tackling functional pieces.

Helpful Comparison Short Insights

When choosing the best welding aluminum solution, your project type and experience level are key. For ultimate simplicity and quick repairs, the flux-cored rods (50 Pieces Flux Core Aluminum Rods and Aluminum Brazing Rods) are hard to beat, as they require minimal equipment and no external flux. However, for professional-grade strength and aesthetics, you’ll want dedicated TIG or MIG filler metals like the YESWELDER ER4043 TIG Rods or the ARCCAPTAIN/YESWELDER ER4043 MIG Wires. These require specialized equipment but deliver superior, crack-resistant welds.

If you’re ready to invest in a machine that can do it all, the AZZUNO Aluminum MIG Welder offers incredible versatility, especially for those looking to get into MIG aluminum welding without needing a separate spool gun right away. Finally, don’t overlook the importance of practice – the Therwen Welding Kit is essential for anyone serious about developing their aluminum welding prowess, regardless of the method you choose. Remember, while rods are great for convenience, wires offer better control and faster deposition for larger projects.

Final Verdict

Navigating the world of aluminum welding can feel daunting, but with the right tools, it becomes an incredibly rewarding skill. For sheer ease of use and accessibility, especially for small repairs or DIYers, the flux-cored aluminum rods are standout performers, offering a surprisingly strong bond without complicated setups. If you’re a TIG or MIG enthusiast focused on precision and strength, the YESWELDER and ARCCAPTAIN ER4043 wires and rods are your best bet, providing the reliability and quality professionals demand. And for the ambitious welder seeking a multi-process machine that genuinely streamlines aluminum MIG, the AZZUNO 155Amp Welder offers exceptional value and capability. No matter your skill level or project needs, there’s a fantastic option here to help you achieve your best welding aluminum results.

Best Welding Aluminum: Your Questions Answered

Q1: What makes welding aluminum different from welding steel?

A1: Welding aluminum is trickier due to several factors. Aluminum has a much lower melting point and a higher thermal conductivity than steel, meaning heat dissipates quickly, requiring more amperage. It also forms a stubborn oxide layer that must be cleaned off, and it doesn’t change color significantly before melting, making it harder to judge temperature. Also, aluminum is prone to “hot cracking” if the right filler metal isn’t used.

Q2: Can I weld aluminum with a regular MIG welder?

A2: While some standard MIG welders can be adapted, it’s generally best to use a MIG welder specifically designed for aluminum or one with an aluminum spool gun. Aluminum wire is soft and can “bird-nest” in a long MIG gun liner. A spool gun feeds the wire directly, minimizing feeding issues. You’ll also need 100% Argon shielding gas and ER4043 or ER5356 aluminum filler wire.

Q3: What’s the difference between ER4043 and ER5356 aluminum welding wire?

A3: ER4043 contains 5% silicon, which improves fluidity and reduces cracking, making it excellent for general-purpose applications and joining 6xxx series alloys. However, it can appear gray after anodizing. ER5356 contains 5% magnesium, offering higher tensile strength and better ductility, making it ideal for marine environments or projects requiring color matching after anodizing, but it’s more prone to cracking.

Q4: Are flux-cored aluminum rods effective for structural applications?

A4: Flux-cored aluminum rods are generally recommended for small repairs, hobby projects, and non-structural applications. While they can create a strong bond, they typically don’t offer the same level of strength, ductility, or fatigue resistance as TIG or MIG welds using appropriate filler metals and shielding gas. For critical structural components, TIG or MIG welding is preferred.

Q5: What kind of shielding gas do I need for welding aluminum?

A5: For TIG and MIG welding aluminum, 100% pure Argon is the most common and generally recommended shielding gas. Argon provides excellent arc stability and good cleaning action. For thicker aluminum, some welders use an Argon/Helium mix (e.g., 75% Argon/25% Helium) to increase heat input and improve penetration.

Q6: How important is surface preparation when welding aluminum?

A6: Surface preparation is extremely important when welding aluminum. The oxide layer on aluminum has a much higher melting point than the base metal and can contaminate the weld. You should always clean the aluminum surface thoroughly with a stainless steel brush (dedicated to aluminum only), acetone or a degreaser, and then weld within a few hours to prevent re-oxidation.

Q7: What’s the best way for a beginner to start welding aluminum?

A7: Beginners often find success starting with flux-cored aluminum rods for simple brazing tasks due to their ease of use. For actual welding, practicing with aluminum coupons (like the Therwen kit) using a multi-process welder (like the AZZUNO) with a spool gun and ER4043 wire on thicker material (e.g., 1/8″ or 3mm) is a good approach. Start with good cleaning practices, appropriate settings, and consistent travel speed.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.