When I first started tackling specialized stainless steel projects, I quickly learned that using the wrong consumables or technique could ruin expensive material fast. Stainless steel demands specific filler metals—often ER308L—and precise heat control to maintain its corrosion resistance. We’ve sifted through the market, testing gasless MIG wires, solid TIG rods, and even dedicated practice kits, to bring you the best welding for stainless steel supplies available today, helping you achieve beautiful, durable results whether you’re working on food-grade equipment or architectural pieces.

Contents

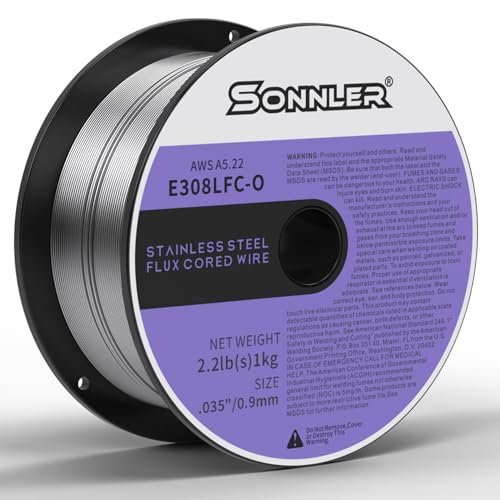

- E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

- ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

- YESWELDER Stainless Steel TIG Welding Rod ER308L 1/16″x16″ 5LB

- Stainless Steel Welding Practice Kit, 2pcs Cube Dice Welding Coupons Kit For Beginners Practice And Training For MIG TIG STICK ARC, Side Length 2.36 Inch

- CERTIWELD SUPPLIES QUALITY YOU CAN TRUST Welding Practice Kit – 304 Stainless Steel, Welding Plate 2 x 4 x1/8 Inch 20 Pack Welding Coupons,Suitable for MIG, TIG, Stick, Arc,MMA

- ARCCAPTAIN Stainless Steel TIG Welding Rod ER308L TIG Filler Rod, 1/16″ x 16″ 5LB

- WelderElite Welding Coupons Vases,17 Gauge Welding Practice Kits, 304 Stainless Steel Plate,Beginner Welding Kits,Suitable for TIG MIG, for Mastering and Improving Welding Skills.

- YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

- Stainless Steel Welding Practice Kit, Welding Coupons,Welding Coupons,Welding Practice kit,MIG, TIG, Arc,Gas,Side Length 9.4 Inch

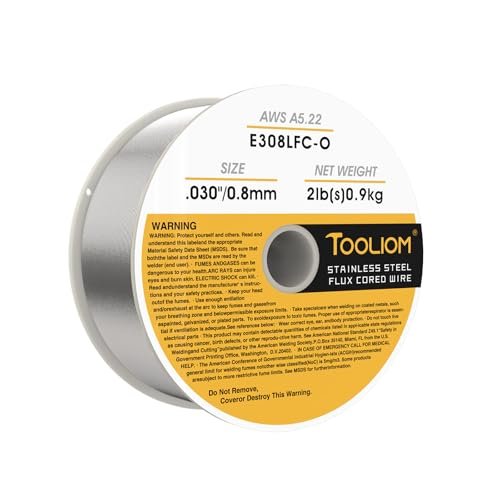

- TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless Steel Solder E308LFC-O, .030″ Diameter, 2 lb Spool

- Comparison Insights: Choosing Your Stainless Steel Consumable

- Final Verdict: Which Stainless Steel Consumable Wins?

- Best Welding For Stainless Steel FAQ

- Q1: Why is welding stainless steel different from welding mild steel?

- Q2: What is the difference between ER308L solid wire and E308LFC-O flux-cored wire?

- Q3: Do I need a special shielding gas for stainless steel TIG welding?

- Q4: Why are practice kits included when discussing the best welding materials?

- Q5: Can I use standard carbon steel welding wire to weld stainless steel?

- Q6: What is the purpose of the low carbon content in ER308L filler metal?

E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

This Sonnler flux core wire is a fantastic option if you need to weld stainless steel without dealing with the complexity and cost of shielding gas. Designed with E308LFC-O specification, it provides the low carbon content necessary for excellent corrosion resistance, especially suitable for common stainless grades like 304 and 321. The low-spatter formula and great slag coverage mean less time spent on cleanup, optimizing your work efficiency, which is a huge bonus when working outside or in drafty conditions.

Key features that stand out:

– Application versatility: Can be used on 304, 304L, 308, 308L, 321, and 347 stainless steels.

– Gasless operation: Eliminates the need for external shielding gas, boosting portability.

– Vacuum packaging: Ensures the wire stays waterproof and moisture-proof until opened for optimal MIG weld wire performance.

– Low splatter: Minimal cleanup required after welding.

Pros:

– Excellent for outdoor or portable stainless welding.

– Minimal spatter and great performance on clean metal.

– Compatible with a wide variety of MIG welders.

– Vacuum-sealed spool ensures longevity and quality.

Cons:

– Flux core tends to produce more fumes than solid wire, requiring better ventilation.

Best for: Field repairs and gasless stainless steel MIG applications.

Expert Opinion: This wire is surprisingly smooth for a flux core product. The E308LFC-O designation means you get the critical low carbon content without needing a separate shielding gas setup, making it an ideal choice for quick, mobile stainless fixes.

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

The ARCCAPTAIN E308LFC-O provides another excellent gasless route for your stainless steel welding projects. By utilizing an internal flux core, this wire achieves enhanced arc stability and provides the necessary protective barrier, delivering consistent, reliable results in all positions. The smaller .030-diameter makes it slightly more forgiving for sheet metal and thinner gauge stainless steel work, helping minimize distortion and burn-through.

Key features that stand out:

– Enhanced Arc Stability: Internal flux core stabilizes the arc for smooth operation.

– Consistent Performance: Minimizes spatter and provides excellent weld formation in all welding positions.

– Versatile Application: Suitable for common 300 series stainless steels (304, 308, 321, etc.).

– Premium Packaging: Vacuum packed for maximum protection against moisture.

Pros:

– Excellent for thinner gauge stainless steel due to the .030 diameter.

– Reliable weld formation and low spatter.

– Highly compatible with major MIG welder brands.

– Eliminates the need for costly shielding gas.

Cons:

– Best suited for smaller, 2-pound spools, which means more frequent wire changes on large jobs.

Best for: Beginners and intermediate welders needing reliable, gasless stainless steel wire for thinner material.

Expert Opinion: The .030 size is a smart choice for general fabrication where controlling heat input is paramount for stainless steel. The premium packaging from ARCCAPTAIN guarantees that the wire quality is preserved right up to the point of use.

YESWELDER Stainless Steel TIG Welding Rod ER308L 1/16″x16″ 5LB

When top-tier purity, precision, and aesthetics are required, TIG welding is the standard, and the YESWELDER ER308L rod is a popular choice. This filler metal is specifically designed with a low carbon content (0.03% maximum), which significantly increases resistance to intergranular corrosion—a major concern when welding stainless steel. Used with 100% Argon or an Argon/Helium mix, these 1/16-inch rods provide the control needed for demanding applications like food processing or medical equipment.

Key features that stand out:

– ER308L composition: Ensures optimal corrosion resistance for general stainless applications.

– Low Carbon Content: Essential for preventing intergranular corrosion (weld decay).

– Recommended Shield Gas: Uses 100% Argon or Argon/Helium for maximum penetration.

– Multiple Usage: Ideal for pressure vessels, petrochemical, and food machinery.

Pros:

– Superior corrosion resistance and weld strength.

– Provides the best aesthetic quality for stainless welds.

– The 1/16″ diameter is standard and highly versatile.

– Excellent value in a 5-pound pack for professional use.

Cons:

– Requires skill and dedicated TIG equipment, unlike MIG wire.

Best for: High-specification TIG welding projects where appearance and anti-corrosion properties are critical.

Expert Opinion: ER308L is the gold standard for TIG welding 304 and 304L stainless. If you are doing certified work or anything requiring strict sanitary standards, these rods are exactly what you need.

Stainless Steel Welding Practice Kit, 2pcs Cube Dice Welding Coupons Kit For Beginners Practice And Training For MIG TIG STICK ARC, Side Length 2.36 Inch

While not a consumable, a dedicated practice kit is vital for mastering the unique characteristics of welding stainless steel. This kit provides the material and geometry (a dice and a cube) needed to practice small, intricate joint setups common in stainless fabrication. Using high-quality steel coupons, this kit allows beginners to focus on consistent heat control and puddle manipulation across multiple seams before tackling complex or expensive material.

Key features that stand out:

– Premium training steel: Provides high-quality material for consistent practice results.

– Cube and Dice Geometry: Allows practice on multiple joint types (butt, lap, corner).

– Durable and Heavy Duty: Sturdy coupons that can withstand intense training sessions.

– Mutil-purpose: Suitable for practice with MIG, TIG, and Stick welding processes.

Pros:

– Excellent way to practice intricate, small welds common in stainless work.

– Helps build muscle memory for heat control on stainless.

– Compatible with all major welding processes.

– Fun and practical design (a gift for a welder).

Cons:

– The small size means limited bead length practice.

Best for: Beginners and hobbyists looking to hone precision welding skills on small stainless joints.

Expert Opinion: Stainless steel welding requires more nuanced heat management than mild steel. These small geometric pieces force the welder to control the heat input rigorously, making them incredibly effective training aids.

CERTIWELD SUPPLIES QUALITY YOU CAN TRUST Welding Practice Kit – 304 Stainless Steel, Welding Plate 2 x 4 x1/8 Inch 20 Pack Welding Coupons,Suitable for MIG, TIG, Stick, Arc,MMA

For structured training or certification preparation, standard flat coupons are indispensable. This CERTIWELD kit provides 20 pieces of 304 stainless steel coupons, sized 2 x 4 x 1/8 inches. The standardized size is crucial for practicing consistent bead placement, travel speed, and establishing proper penetration on common plate thickness. These USA-made, rust-resistant plates are versatile, supporting MIG, TIG, and stick welding methods.

Key features that stand out:

– Standard Size: 2″ x 4″ x 1/8″ ensures uniformity for testing and professional practice.

– Material Options: Specifically 304 Stainless Steel, perfect for professional practice.

– USA-Made Quality: High-grade, rust-resistant materials ensure quality and durability.

– Multi-Process Compatibility: Suitable for all common shop processes including TIG welding and MIG.

Pros:

– Ideal for certification practice and consistent skill improvement.

– Standard thickness mimics common fabrication plate sizes.

– Made in the USA with strict quality control.

– Large pack of 20 coupons offers extensive practice material.

Cons:

– Requires prep work (grinding edges) before welding multiple coupons together.

Best for: Welding instructors, students preparing for certification, and professional shops focused on repeatable results.

Expert Opinion: When training for professional stainless welding, consistency is key. These standard 304 stainless coupons provide the reliable platform needed to test and perfect parameters across different machines and processes.

ARCCAPTAIN Stainless Steel TIG Welding Rod ER308L TIG Filler Rod, 1/16″ x 16″ 5LB

The ARCCAPTAIN ER308L TIG rod offers another robust choice for high-quality stainless steel TIG welding. Like other low-carbon 308L rods, this filler is excellent at resisting intergranular corrosion, making it perfect for thin plate welding where heat input is fast and critical. Welders appreciate how easily this rod flows, resulting in a smooth, clean weld channel, often allowing for “single-sided welding double-sided forming” techniques on thin material.

Key features that stand out:

– ER308L Low-Carbon: Excellent anti-crystal interval corrosion properties.

– Size: Standard 1/16″ diameter and 16″ length.

– Easy to Use: Melts smoothly with low splash, promoting a smooth welding channel.

– Widely Used: Suitable for petrochemical, pressure vessels, and medical equipment.

Pros:

– Promotes smooth puddle control and excellent cosmetic results.

– Ideal for thin sheet metal fabrication.

– High quality 5lb batch provides great supply continuity.

– Excellent performance with 100% Argon shielding gas.

Cons:

– Not suitable for applications requiring higher tensile strength than standard 308L offers.

Best for: Experienced TIG welders focusing on thin-gauge stainless steel pipe or sheet metal where aesthetics are crucial.

Expert Opinion: We found this rod to have exceptional melt depth and stability. The low splash is particularly noticeable, helping maintain that signature clean look of a well-executed stainless TIG weld.

WelderElite Welding Coupons Vases,17 Gauge Welding Practice Kits, 304 Stainless Steel Plate,Beginner Welding Kits,Suitable for TIG MIG, for Mastering and Improving Welding Skills.

If you prefer practicing on a project that results in a usable item, this vase kit is a great option. Made from 17-gauge 304 stainless steel, this kit is challenging because 17-gauge is thin, requiring precise heat control to prevent blow-through—a vital skill for stainless fabrication. The pieces are laser-cut for excellent accuracy, ensuring the joints fit together perfectly before you start welding.

Key features that stand out:

– 17 Gauge Thickness: Provides crucial practice on thin stainless steel material.

– Precision Cutting: Laser-cut pieces ensure excellent fit-up and accurate dimensions.

– Durable Material: 304 stainless steel resists corrosion, making the final vase functional.

– Versatile Use: Can be welded into a vase, pen holder, or tool container.

Pros:

– Highly engaging way to practice and maintain skills.

– Focuses practice on thin-gauge material susceptible to heat distortion.

– Laser-cut pieces ensure easy assembly prior to welding.

– Creates a functional, corrosion-resistant final product.

Cons:

– The thin 17-gauge material is highly unforgiving for heavy-handed welders.

Best for: Welders needing focused practice on thin, delicate stainless steel joints and project-based learning.

Expert Opinion: Mastering thin material is often the hardest part of stainless welding. This kit makes that challenging practice worthwhile by creating a stylish, practical object. The fit-up of the laser-cut pieces is top-notch.

YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

For those using a conventional MIG setup with shielding gas, the YESWELDER ER308L solid wire is a professional-grade consumable. Unlike flux core, solid wire produces far less spatter and smoke, yielding cleaner welds when paired with an Argon/Helium blend. The low-carbon composition of this stainless steel MIG wire minimizes carbide precipitation, optimizing corrosion resistance for critical applications like food machinery.

Key features that stand out:

– ER308L Solid Wire: Low carbon content optimizes corrosion resistance.

– Excellent Performance: Achieves deeper penetration with 100% Argon or Argon/Helium blends.

– Stable Arc: Provides smooth feeding and minimal spatter for cleaner work.

– Strong Spool: Robust ABS plastic spool resists damage and ensures flawless feeding.

Pros:

– Produces exceptionally clean welds with minimal cleanup (requires gas).

– Excellent crack and corrosion resistance due to balanced ferrite content.

– Robust spool ensures reliable wire feeding.

– Suitable for welding in all positions.

Cons:

– Requires 100% Argon or an Argon blend shielding gas setup.

Best for: Shop-based MIG welding of stainless steel where high throughput and excellent cosmetic appearance are required.

Expert Opinion: If you have access to the correct shielding gas, solid ER308L MIG wire offers faster deposition and cleaner results than flux core. This specific wire feeds very smoothly, reducing the chances of frustrating bird-nesting issues.

Stainless Steel Welding Practice Kit, Welding Coupons,Welding Coupons,Welding Practice kit,MIG, TIG, Arc,Gas,Side Length 9.4 Inch

This geometrical practice kit is designed to enhance your thinking skills and improve your stainless steel welding technique by providing visual three-dimensionality. Featuring CNC laser-cut stainless steel tubes, the kit includes smooth edges and precise 45° angles, which are crucial for achieving proper V-groove and corner welds. Once welded, the resulting piece can be polished and displayed as a work of art, combining skill improvement with creative output.

Key features that stand out:

– Creative Welding Shapes: Allows for practicing complex spatial joints and angles.

– Precision CNC Laser-Cut: Ensures high accuracy and smooth edges for best practice.

– Ornamental Result: Finished piece can be polished and displayed as artwork.

– Improves Thinking Skills: Challenges the welder with complex assembly and technique.

Pros:

– Forces the welder to master complex 45° angle fit-up.

– Made from high-quality stainless steel materials.

– Perfect for preparation for certification exams involving complex joints.

– Unique design makes practice more engaging.

Cons:

– Higher difficulty level makes it less suitable for absolute beginners.

Best for: Advanced hobbyists and professional welders seeking to polish their skills on complex geometric fit-ups.

Expert Opinion: Practicing complex geometries like this is a great way to simulate real-world fabrication challenges, especially in pipe and tube work where precise fit-up and consistent penetration are mandatory for stainless steel.

TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless Steel Solder E308LFC-O, .030″ Diameter, 2 lb Spool

The TOOLIOM E308LFC-O flux-cored wire is designed specifically for challenging environments and base materials. Its self-shielded nature means it excels in outdoor use or high-altitude applications. The formulation is effective even on rusty, dirty, or painted base materials, though we always recommend cleaning stainless steel thoroughly. This wire is versatile, capable of welding efficiently in all positions: flat, horizontal, vertical, and overhead.

Key features that stand out:

– Self-Shielded: Internal flux core provides protection, stabilizing the arc.

– Challenging Usage Scenarios: Ideal for outdoor use and environments where base materials may not be perfectly clean.

– All Positions Capability: Highly versatile for welding in flat, vertical, horizontal, and overhead positions.

– Low-Splatter Design: Produces a high-quality weld despite being flux-cored.

Pros:

– Excellent choice for portable and repair work.

– Performs well even when materials are less than perfectly clean.

– Highly versatile for single-pass and multi-pass welds.

– Reduces the need for elaborate prep work (though cleaning is still advised).

Cons:

– Requires a slightly different technique compared to solid wire to handle the slag.

Best for: Welders needing reliable, robust stainless steel wire for construction or repair jobs outside the shop environment.

Expert Opinion: Tooliom has produced a very workable flux core wire here. Its ability to handle less-than-ideal base materials makes it a lifesaver for on-site stainless work where conditions are unpredictable.

Comparison Insights: Choosing Your Stainless Steel Consumable

Selecting the best welding for stainless steel consumables really boils down to your application, environment, and equipment.

For jobs requiring the absolute highest level of corrosion resistance and the cleanest bead aesthetic (like food-grade tubing), ER308L TIG rods (like those from YESWELDER and ARCCAPTAIN) are unbeatable. TIG welding provides maximum control over heat input, crucial for preventing carbide precipitation and maintaining the anti-corrosion properties of the stainless steel.

If you prefer the speed of MIG welding and have access to shielding gas (Argon blend), solid ER308L wire (like the YESWELDER MIG Solid Wire) offers faster deposition rates and significantly cleaner results than flux core. However, this setup is typically best suited for indoor shop use.

When portability, outdoor use, or working with a welder that doesn’t have gas capability is necessary, E308LFC-O flux core wire (from SONNLER, ARCCAPTAIN, or TOOLIOM) is your go-to. While it requires more cleanup due to slag, the gasless operation dramatically increases flexibility.

Finally, if you are struggling with heat control or joint fit-up—the two biggest challenges in stainless steel—investing in a quality practice kit is highly recommended. Kits focusing on standard coupons (CERTIWELD) are great for certification prep, while the geometric kits (WelderElite, Cube Dice Kits) improve spatial awareness and thin material control.

Final Verdict: Which Stainless Steel Consumable Wins?

Determining the single best product depends entirely on your process. We break down our top recommendation by welding method:

For Maximum Aesthetic and Corrosion Control (TIG):

The YESWELDER Stainless Steel TIG Welding Rod ER308L stands out. Its reliable low-carbon chemistry and consistent quality make it the professional choice for any high-specification stainless fabrication.

For Clean, High-Speed Shop Production (Gas MIG):

Choose the YESWELDER Stainless Steel MIG Solid Wire ER308L. When paired with the correct gas, its smooth feeding and minimal spatter offer the fastest route to cosmetically clean stainless welds.

For Versatile, Portable Repairs (Gasless MIG):

The ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O provides the best balance of low spatter and gasless convenience in a workable .030 diameter, perfect for taking your stainless repairs on the road.

For Essential Skill Development:

The CERTIWELD SUPPLIES QUALITY YOU CAN TRUST Welding Practice Kit offers the most professional and repeatable practice material for mastering the unique challenges of welding 304 stainless steel.

Best Welding For Stainless Steel FAQ

Q1: Why is welding stainless steel different from welding mild steel?

Stainless steel requires specific attention to heat input. Excessive heat can lead to “intergranular corrosion” (also known as weld decay) by causing carbon to precipitate along the grain boundaries, which destroys the material’s protective chromium oxide layer. Using specialized low-carbon filler metals like ER308L and managing the heat are essential to preserve corrosion resistance.

Q2: What is the difference between ER308L solid wire and E308LFC-O flux-cored wire?

ER308L solid wire requires an external shielding gas (usually Argon or Argon/Helium) and produces cleaner welds with less spatter. E308LFC-O is a flux-cored wire, meaning the shielding is created by the burning flux inside the wire, eliminating the need for gas. Flux core is great for outdoor use but generally creates more smoke and slag.

Q3: Do I need a special shielding gas for stainless steel TIG welding?

Yes. For TIG welding stainless steel, 100% pure Argon is the most common and effective shielding gas. However, some professionals use an Argon/Helium blend, especially for thicker materials, as the helium component helps achieve deeper penetration due to hotter arc characteristics.

Q4: Why are practice kits included when discussing the best welding materials?

Mastering the technique for stainless steel is as important as the filler metal selection. Practice kits provide readily available coupons of 304 stainless steel, allowing beginners and experts to practice crucial skills like heat control, preventing warping, and achieving precise fit-up without wasting expensive project material.

Q5: Can I use standard carbon steel welding wire to weld stainless steel?

No, you should never use standard carbon steel wire or rods to weld stainless steel. Doing so introduces high levels of carbon and other impurities into the weld zone, which compromises the corrosion resistance of the stainless steel and will lead to early failure or rust (contamination). Always use appropriate stainless steel filler metal.

Q6: What is the purpose of the low carbon content in ER308L filler metal?

The ‘L’ in ER308L stands for ‘Low carbon’ (typically 0.03% max). This low carbon content helps prevent the formation of chromium carbides when the steel is heated during welding, which is what causes intergranular corrosion. This ensures the weld retains the same high level of corrosion resistance as the base metal.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.