I’ve spent countless hours under the hood, and if there’s one thing I’ve learned, it’s that your welding lens is everything. A blurry or slow lens doesn’t just cause eye strain; it fundamentally ruins your bead quality and slows down your productivity. Finding the best welding lenses means balancing speed, optical clarity, and cost. I recently put 10 top contenders—including both fixed and high-end auto-darkening lenses—to the test to see which ones offered the best puddle visibility and protection. This comprehensive guide will walk you through the options, helping you upgrade your gear for safer, better, and faster results.

Contents

- The King 1.0 | Shade 5-13 Adjustable Gold Auto Darkening Welding Lens | 2″ x 4 1/4″ x 0.33″ | Adjusts From Shades 5-13 (9 Lenses In 1) | Gold Front – Deep Blue Weld View | Ridge Products Royal Series

- Ridge Products 10 Pack of 2×4.25 Clear Welding Lenses, Replacement Clear Welding Lens 2×4 1/4, Welding Hood Clear Lenses, Top Protection For Welding Lens And Eyes, Lightweight, 0.04″ Thick

- 4.5″ X 5.25″ Welding Helmet Cover Lens, 10 Pcs Outside Replacement Clear Lens Covers for Solar Auto Darkening Welding Helmet.

- Best Welds Cover Lens for Welding Hoods – 2″ X 4 1/4″ Premium Quality Clear Plastic Cover Lenses

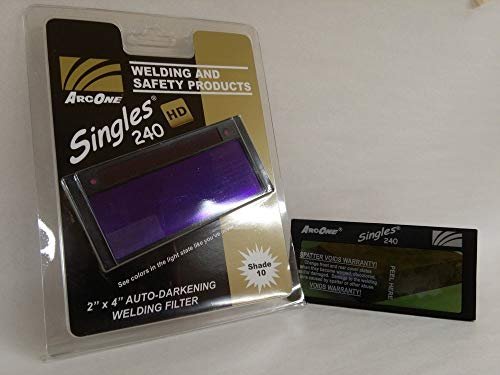

- ArcOne S240-10 Horizontal Single Auto-Darkening Filter for Welding, 2 x 4, Shade 10

- The King Single 1.0 | Shade 10 Gold Auto Darkening Welding Lens | 2″ x 4 1/4″ x 0.2″ | Darkens Automatically And Ultra Clear | Gold Front – Deep Blue Weld View | Ridge Products Royal Series

- Tefuawe 2×4 1/4 Gold Automatic Welding Lens, 2 Amp TIG Rating, Variable Shade with Multiple Settings, For Stick Mig Tig

- TrueArc Blue Auto-Darkening Welding Lens – High Definition Blue Hue Filter- Fits 2″ x 4-1/4″ Welding Hoods – Shade 10

- Gold Shade 10 2×4 1/4 Auto Darkening Welding Lens, Cool Blue Puddle Technology 2×4 Welding Lens, Welding Lens Auto Darkening Replacement for a Sugar Scoop Welding Hood or Pancake Welding Hood

- The King | Shade 10 Gold Welding Lens 2×4 1/4 | Aqua Colored Glass Welding Lens | Shade 10 Welding Lens 2×4 1/4, Perfect Size For a Sugar Scoop Welding Hood, or Pancake Welding Hood | Ridge Products

- Practical Comparison: Short Insights on Best Welding Lenses

- Final Verdict

- Frequently Asked Questions About Best Welding Lenses

- Why is ADF switching speed so important?

- What is “True Color Technology” and does it actually improve welding?

- What does the TIG amperage rating on a lens mean?

- How often should I replace the clear cover plates?

- What is the advantage of a gold-coated welding lens?

- Are fixed-shade glass lenses still a viable option compared to ADFs?

The King 1.0 | Shade 5-13 Adjustable Gold Auto Darkening Welding Lens | 2″ x 4 1/4″ x 0.33″ | Adjusts From Shades 5-13 (9 Lenses In 1) | Gold Front – Deep Blue Weld View | Ridge Products Royal Series

If versatility is your top priority, this lens is a powerful option. The King 1.0 acts as essentially nine lenses in one, adjustable across shades 5 through 13. The gold front coating reflects radiant heat, while the lens provides a crystal-clear, deep blue view of the weld puddle. It’s designed for extreme clarity, promising to eliminate the common “double vision” often seen in cheaper lenses, offering a true 10/10 welding experience.

Key features that stand out:

– Adjustability: Wide range from 5-13, adjustable from the back without removing the hood (using special adjustable clear lenses).

– Clarity and Color: Improved screens and alignment ensure high clarity and a unique deep blue weld view.

– Coverage: Suitable for all welding processes (MIG, Stick, Plasma) and cutting torches.

Pros:

– Extremely versatile due to the wide shade range.

– Comes with strong 90-day money-back guarantee and 1-year warranty.

– Exceptional optical clarity and alignment.

Cons:

– Not ideal for exclusive low-amperage TIG welding below 70A.

Best for: Professional welders who switch processes and amperage frequently.

Expert Opinion: This lens is a fantastic high-end upgrade for standard hoods, offering premium features usually reserved for full-face high-cost helmets. Just be mindful of the low-amp TIG limitation.

Ridge Products 10 Pack of 2×4.25 Clear Welding Lenses, Replacement Clear Welding Lens 2×4 1/4, Welding Hood Clear Lenses, Top Protection For Welding Lens And Eyes, Lightweight, 0.04″ Thick

Cover lenses are the unsung heroes of welding protection, and this 10-pack provides durable, reliable clarity. Keeping your main auto-darkening filter protected is essential, and replacing the covers when they get dirty prevents eye strain and ensures the AD lens sensors aren’t blocked, which can cause flashing. These are standard size, fitting most conventional welding helmets with ease.

Key features that stand out:

– Clarity: Manufactured to be ultra-clear, avoiding warping or creasing.

– Safety Standard: Meets Z87.1 STD, ensuring eye safety even though they are just covers.

– Protection: Includes four layers of protective film to prevent scratches during shipping and storage.

Pros:

– High-quality, standard-sized replacement lenses.

– Essential for prolonging the life of expensive inner lenses.

– Economical 10-pack provides great value.

Cons:

– These are external consumables, not the main auto-darkening lens.

Best for: Maintaining the longevity and clarity of any standard 2×4.25 auto-darkening lens.

Expert Opinion: You can’t afford to skip these. Running a high-end lens without a clean cover is like driving a sports car with flat tires. This pack is a solid, reliable choice for standard hoods.

4.5″ X 5.25″ Welding Helmet Cover Lens, 10 Pcs Outside Replacement Clear Lens Covers for Solar Auto Darkening Welding Helmet.

Not all hoods use the smaller 2×4.25 standard lens size. If your welding helmet uses the larger 4.5″ x 5.25″ viewing area, this 10-piece set is exactly what you need. Made from premium polycarbonate, these covers are designed to withstand the splatter and grime of heavy-duty welding. Remember to peel off the protective film on both sides before fitting them into your helmet frame!

Key features that stand out:

– Sizing: Large 4.5″ X 5.25″ dimensions suitable for larger view helmets.

– Material: Made of durable Premium Polycarbonate.

– Value: Comes in an economical package of 10 pieces.

Pros:

– Fits standard large-format welding hoods.

– High-quality, protective material.

– Keeps your larger ADF investment safe from damage.

Cons:

– Ensure you measure your helmet accurately, as this size is not universal.

Best for: Welders using wide-view or specific large-format helmets that require 4.5″ x 5.25″ covers.

Expert Opinion: These large covers protect a significantly bigger viewing area, which is vital for safety and visibility in large-format helmets. Regularly changing these improves both clarity and the reliability of your hood.

Best Welds Cover Lens for Welding Hoods – 2″ X 4 1/4″ Premium Quality Clear Plastic Cover Lenses

Sometimes, simplicity and reliability are all you need. These premium quality clear plastic cover lenses from Best Welds adhere to the standard 2″ X 4 1/4″ sizing, making them a universally reliable choice for most traditional welding helmets. They provide the necessary physical barrier against sparks and slag, ensuring the auto-darkening filter underneath remains unscratched and fully functional.

Key features that stand out:

– Compatibility: Standard 2″ X 4 1/4″ size ensures wide compatibility.

– Quality: Premium plastic construction for durability.

– Function: Serves as the first line of defense against spatter.

Pros:

– Trusted brand name reliability.

– Perfect fit for standard pancake and pipeliner hoods.

– Keeps the inner lens clean and protected.

Cons:

– May need to be purchased in bulk separately for continuous use.

Best for: Welders who prefer established brands for their essential consumables.

Expert Opinion: A good, straightforward cover lens. Investing in high-quality covers prevents the frustrating experience of minor scratches obscuring your view.

ArcOne S240-10 Horizontal Single Auto-Darkening Filter for Welding, 2 x 4, Shade 10

The ArcOne S240-10 is a solid, fixed-shade auto-darkening filter (ADF) designed for reliability and speed. If you primarily stick weld or MIG weld at consistent amperages where Shade 10 is appropriate, this lens provides great performance without the complexity of variable shades. It boasts high-definition clear view technology and a rapid switching speed of 0.5 milliseconds, offering quick protection in a compact 2×4 standard size.

Key features that stand out:

– Response Time: Fast switching speed of 0.5 milliseconds.

– Fixed Shade: Reliable Shade 10 setting.

– Durability: Water and dust resistant build quality.

– Clarity: High Definition clear view technology.

Pros:

– Extremely reliable fixed shade ADF.

– Very fast response time for eye protection.

– Compact design fits standard 2″ x 4″ hoods.

Cons:

– Lack of adjustability limits its use across different processes.

Best for: Dedicated welders focusing on MIG or Stick processes that consistently require a Shade 10 filter.

Expert Opinion: Sometimes, variable shades are overkill. This ArcOne unit is perfect for the dedicated pipe welder or fabricator who knows exactly what shade they need and values consistency over features.

The King Single 1.0 | Shade 10 Gold Auto Darkening Welding Lens | 2″ x 4 1/4″ x 0.2″ | Darkens Automatically And Ultra Clear | Gold Front – Deep Blue Weld View | Ridge Products Royal Series

If you loved the clarity of the adjustable King 1.0 but need a simpler, thinner option, The King Single 1.0 is the answer. This fixed Shade 10 ADF maintains the signature gold front coating and the deep blue weld view, which significantly enhances puddle visibility. It’s ultra-clear and built with tight tolerances to prevent alignment issues. A key benefit of this model is that it’s solar-powered (charged by the weld arc), providing long battery life.

Key features that stand out:

– Clarity and Color: Gold front combined with a clear, deep blue view.

– Power Source: Solar-powered and self-recharging via the welding arc.

– Build Quality: Improved construction for tight tolerances, eliminating double vision.

Pros:

– Excellent optical quality and alignment.

– Solar charging means less worry about manual battery replacement.

– Comes with strong warranty and guarantee protections.

Cons:

– Not recommended for TIG welding below 90A.

Best for: Welders prioritizing high-definition clarity in a dedicated Shade 10 ADF, particularly for MIG and higher-amp Stick welding.

Expert Opinion: The optical clarity is genuinely impressive. For a fixed Shade 10, this is one of the clearest auto-darkening options available on the market today.

Tefuawe 2×4 1/4 Gold Automatic Welding Lens, 2 Amp TIG Rating, Variable Shade with Multiple Settings, For Stick Mig Tig

The Tefuawe Gold Automatic Lens is specifically engineered to address the challenges of low-amperage welding. Its stand-out feature is the 2 Amp TIG Rating, making it highly reliable for demanding, low-current TIG work where cheaper lenses often flash. The real gold coating is functional, reflecting 99% of UV/IR and radiant heat, leading to cooler operation and less eye strain during extended sessions.

Key features that stand out:

– TIG Performance: Excellent 2 Amp TIG rating for reliable low-amperage welding.

– Heat Management: Gold coating reflects radiant heat for cooler use.

– Design: Ultralight and thin (0.19″ thickness) for compatibility with all 2″ X 4-1/4″ helmets.

– Innovation: Includes an optional Hand Gesture function to switch between Weld and Grind mode.

Pros:

– Exceptional performance for low-amp TIG.

– Superior heat reflection reduces user fatigue.

– Very thin profile allows for easy fitting.

Cons:

– Hand Gesture function may not be reliable for outdoor use.

Best for: Precision TIG welders who often work below 10 amps and require maximum protection against flashing.

Expert Opinion: If TIG is your main game, the low-amperage rating on this Tefuawe lens makes it a must-have. Reliable darkening speed at the lowest amps is crucial for eye safety.

TrueArc Blue Auto-Darkening Welding Lens – High Definition Blue Hue Filter- Fits 2″ x 4-1/4″ Welding Hoods – Shade 10

The TrueArc Blue lens leverages specialized blue hue technology to enhance contrast and puddle visibility. For many welders, the traditional green tint can mask important details; the blue hue filter delivers a calming view that reduces glare and eye strain, allowing for longer, more comfortable welding sessions. This is a solar-powered, fast-acting Shade 10 ADF that fits most standard hoods, including popular Pancake and Pipeliner models.

Key features that stand out:

– Blue Hue Technology: High-definition filter provides enhanced contrast and clearer puddle visibility.

– Comfort: Reduces glare and eye strain for extended use.

– Speed: Darkens instantly (under 0.5 milliseconds) for quick protection.

Pros:

– Superior comfort and clarity during long welding sessions.

– Blue tint preferred by many for improved contrast.

– Universal fit for most standard 2×4.25 helmets.

Cons:

– Only recommended the premium VPro model for heavy TIG use.

Best for: Welders suffering from eye strain using traditional green lenses who need a fast, reliable Shade 10 ADF.

Expert Opinion: The move to “true color” or specific color hues like blue is a huge trend, and TrueArc does it well. If you struggle to see the edge of the puddle clearly, this blue filter could be the solution.

Gold Shade 10 2×4 1/4 Auto Darkening Welding Lens, Cool Blue Puddle Technology 2×4 Welding Lens, Welding Lens Auto Darkening Replacement for a Sugar Scoop Welding Hood or Pancake Welding Hood

This PRERUNER lens is built on speed and innovation. Its standout feature is an incredibly rapid 0.01 millisecond auto-darkening speed, providing near-instantaneous eye protection against arc flash. Beyond speed, it utilizes Cool Blue Puddle Technology and a gold coating that allows up to seven true colors, offering a view far superior to traditional yellow-green filters, enhancing visibility in both bright and dark environments.

Key features that stand out:

– Ultra-Fast Response: 0.01 milliseconds darkening speed (one of the fastest available).

– True Color: Allows up to 7 true colors for superior environmental and puddle clarity.

– Design: Gold coated to block UV/IR rays and enhance durability.

Pros:

– Fastest darkening speed ensures maximum eye safety.

– Exceptional clarity thanks to multi-color technology.

– Standard 2×4.25 size fits most conventional hoods.

Cons:

– The 0.33″ thickness might require minor modifications in some older hoods.

Best for: Safety-conscious welders who demand the absolute fastest arc response time and superior true color representation.

Expert Opinion: The speed of this lens is unbeatable for safety. If arc eye is a concern, this lens minimizes exposure time dramatically, making it a great long-term investment.

The King | Shade 10 Gold Welding Lens 2×4 1/4 | Aqua Colored Glass Welding Lens | Shade 10 Welding Lens 2×4 1/4, Perfect Size For a Sugar Scoop Welding Hood, or Pancake Welding Hood | Ridge Products

For welders who prefer the reliability and consistency of a fixed, non-auto-darkening glass lens, The King fixed Shade 10 is an exceptional choice. Unlike standard passive lenses, this features an aqua-colored glass and a gold coating. The aqua tint provides a cool blue viewing effect, which is highly praised for reducing eye fatigue and improving focus, especially during demanding TIG applications where clarity is paramount.

Key features that stand out:

– Fixed Clarity: Consistent Shade 10 protection without reliance on electronics.

– Aqua/Cool Blue Tint: HD clarity designed specifically to improve TIG and MIG work quality.

– Eye Protection: Gold coating blocks harmful rays and reduces strain.

Pros:

– Ideal for high-definition TIG welding clarity.

– No batteries or sensors to worry about; pure reliability.

– Excellent at reducing glare and eye strain compared to standard passive glass.

Cons:

– Requires the user to nod down or flip the hood manually.

Best for: TIG welders who prefer the reliability and superior clarity of a high-end, fixed-shade glass lens.

Expert Opinion: If you use a pancake or pipeliner hood and primarily focus on TIG, the passive aqua glass provides a level of depth and clarity that many ADFs still struggle to match. It’s a true specialist’s lens.

Practical Comparison: Short Insights on Best Welding Lenses

When upgrading your lens, understanding the practical differences between these top-tier options is key:

- Adjustability vs. Fixed: For workshops doing high-amp Stick, low-amp TIG, and plasma cutting, the The King 1.0 Adjustable offers unparalleled versatility (Shades 5-13). However, if you stick to one process, fixed-shade options like the ArcOne S240-10 or The King Single 1.0 provide simpler, reliable performance with less bulk and potential points of failure.

- TIG Performance: TIG welding is the true test of an ADF. If you consistently weld below 70 amps, you must choose a lens rated for extremely low amperage. The Tefuawe Gold Automatic Lens with its 2 Amp TIG Rating stands out as the best electronic option for delicate TIG work, where others might flash.

- Speed and Safety: While 0.5 milliseconds is fast, the PRERUNER Gold Shade 10 boasts a game-changing 0.01 millisecond response time. If you work in environments with frequent, sudden arc strikes or prioritize safety above all else, that ultra-fast response offers superior protection.

- Clarity and Color: Modern lenses move beyond the old green tint. Welders seeking enhanced puddle visibility and comfort will love the specialized hues. The TrueArc Blue and the Ridge Products gold/deep blue filters (like The King Single 1.0) significantly reduce eye fatigue compared to basic lenses.

- Consumables: Regardless of which ADF you choose, don’t skimp on cover plates. Using clear, standardized options like the Ridge Products 10 Pack or 4.5″ X 5.25″ Helmet Cover Lens is essential to protect the expensive electronic components underneath.

Final Verdict

Choosing the right lens often comes down to matching the lens to your primary work demands.

The Winner for Versatility and Features: The King 1.0 Adjustable takes the crown. Its wide shade range (5-13) and improved clarity make it the perfect all-in-one ADF upgrade for any multi-process welder.

The Best for Precision TIG Work: If you frequently work with low amperage TIG, the Tefuawe Gold Automatic Lens is your safest bet. Its certified 2 Amp rating guarantees reliable darkening exactly when you need it most.

The Best Budget-Conscious Upgrade: For reliable performance in a fixed shade, the The King Single 1.0 offers exceptional optical clarity and solar recharging in a proven 2×4.25 format, giving you a premium view without the premium variable price tag.

Frequently Asked Questions About Best Welding Lenses

Why is ADF switching speed so important?

The switching speed, measured in milliseconds (ms), determines how quickly the lens darkens when the arc strikes. Faster speeds (like 0.5ms or 0.01ms) significantly reduce the brief flash of light the eye is exposed to. This instantaneous protection is crucial for preventing “arc eye” (photokeratitis) and minimizing long-term eye strain, especially during repetitive tack welding.

What is “True Color Technology” and does it actually improve welding?

“True Color Technology” (or high-definition clarity) allows more natural colors from the environment to pass through the lens in the light state (and dark state). Unlike older green or yellow lenses, which distort colors, true color lenses offer improved puddle visibility because the arc and molten metal appear in their natural, discernible hues, enhancing contrast and allowing for better control of the bead edges.

What does the TIG amperage rating on a lens mean?

The TIG amperage rating indicates the lowest amperage at which the auto-darkening lens can reliably detect the arc and darken instantly. TIG welding, particularly on thin material, uses very low currents (often below 10 amps). If a lens isn’t rated for low amps, it may “flash” or fail to darken during the initial arc start, leading to eye strain or injury. Look for ratings like “2 Amp TIG rated” for the best performance.

How often should I replace the clear cover plates?

You should replace the clear outer and inner cover plate replacement lenses whenever they become significantly scratched, foggy, or covered in spatter. A dirty cover lens not only reduces your puddle visibility but can also interfere with the ADF sensors, causing the lens to flash and risk your eye safety.

What is the advantage of a gold-coated welding lens?

Gold coatings offer two main practical benefits. First, gold is highly reflective, effectively rejecting radiant heat (infrared light) generated by the arc. This keeps the lens cartridge and the area around your face cooler during long, high-amperage welds. Second, many gold coatings are combined with specific LCD screens to produce unique, high-contrast colors (like deep blue or aqua) that enhance clarity.

Are fixed-shade glass lenses still a viable option compared to ADFs?

Yes, absolutely. High-quality fixed-shade glass lenses, such as The King Aqua Colored Glass, are highly valued by precision welders (especially those using pancake hoods) because they offer superior, unwavering optical clarity that doesn’t rely on batteries or sensor speed. While they require manual hood flipping, their reliability and optical quality are often preferred for critical, low-amperage TIG applications.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.