Welding aluminum can feel like a bit of a dance – it’s tricky, fast, and needs the right technique. I’ve spent my fair share of hours in the shop, wrestling with different aluminum welding methods and materials. From patching up a boat to fabricating custom parts, finding the best welding method for aluminum isn’t just about grabbing any torch; it’s about matching the right tools and filler metals to the job. This guide dives into 10 popular options, offering a hands-on look at what works best for various aluminum welding techniques and projects, helping you achieve strong, clean welds every time.

Contents

- 1. 50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

- 2. ARCCAPTAIN Magnesium Aluminum Welding Wire ER5356 .035″ MIG…

- 3. 6 Pieces Low Temperature Universal Welding Rods,Metal…

- 4. YESWELDER Magnesium Aluminum Welding Wire, ER5356 .030-Inch…

- 5. Aircraft Aluminum Gas Welding The Method Revised

- 6. Biscuits Welding Practice Aluminum Parts- 5052 Aluminum -…

- 7. Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons…

- 8. YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

- 9. 45pcs Aluminum Brazing Rods, Aluminum Welding Rods,…

- 10. 20 Pack 6061 T6 Aluminum Sheet Welding Kit 1/8” Thick…

- Comparison Short Insights

- Final Verdict

- Best Welding Method For Aluminum: Frequently Asked Questions

- Q1: What is generally considered the best welding method for aluminum?

- Q2: Can I weld aluminum with a stick welder?

- Q3: What’s the difference between ER4043 and ER5356 aluminum filler metals?

- Q4: Are flux-cored aluminum rods good for beginners?

- Q5: What shielding gas is used for aluminum welding?

- Q6: What are common challenges when welding aluminum?

- Q7: How important is cleaning aluminum before welding?

1. 50 Pieces Flux Core Aluminum Rods Low Temperature Easy…

These flux-cored aluminum rods are a fantastic option for those looking for a straightforward welding solution without the need for additional solder powder. They’re designed for low-temperature applications, making them quite forgiving and accessible for various repair tasks. You’ll appreciate their ability to create strong bonds with minimal fuss, especially on common aluminum alloys.

Key features that stand out:

– NO SOLDER POWDER NEEDED: Flux cored design simplifies the process.

– HIGH QUALITY MATERIAL: Made from non-toxic, odorless, and durable aluminum.

– PERFECT WELDING EFFECT: Offers low melting point, great weldability, and corrosion resistance.

– WIDELY USE: Suitable for aluminum, aluminum alloy, and aluminum-magnesium alloy.

Pros:

– Extremely easy to use, even for beginners.

– No need for external flux or solder powder.

– Achieves strong, corrosion-resistant welds.

– Versatile for various white metals.

Cons:

– May not provide the same precision as TIG welding for critical applications.

Best for: Quick repairs, DIY projects, and those new to aluminum welding looking for simplicity.

Expert Opinion: These rods are a great entry point into aluminum repair. The self-fluxing nature drastically reduces complexity, allowing even hobbyists to achieve decent results without specialized equipment.

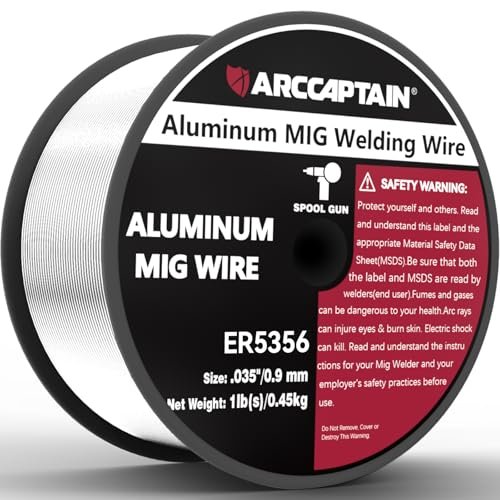

2. ARCCAPTAIN Magnesium Aluminum Welding Wire ER5356 .035″ MIG…

When you’re dealing with demanding applications, especially those exposed to corrosive environments like saltwater, ARCCAPTAIN’s ER5356 aluminum MIG wire is a strong contender. Its 5% magnesium content ensures superior corrosion resistance and provides a smooth, stable arc that experienced welders will appreciate. This wire is specifically formulated for high-strength aluminum-magnesium alloys.

Key features that stand out:

– Smooth Welding Experience: Stable arc characteristics for excellent weld bead appearance.

– ER5356 Aluminum Welding Wire: 5.0% magnesium content for excellent resistance to seawater and salt spray corrosion.

– Versatile Application: Ideal for 5xxx series aluminum-magnesium alloys (5052, 5083, 5356, etc.).

– Melting Range and Density: Melting point 950 °F to 1175 °F, density 0.097 lbs/cubic inch.

Pros:

– Exceptional corrosion resistance, especially in marine environments.

– Smooth and stable arc for clean, professional welds.

– Excellent for high-magnesium aluminum alloys.

– Produces a bright white finish after anodizing.

Cons:

– Requires a MIG welder set up for aluminum, which can be an investment.

Best for: Marine applications, structural components, and welding 5xxx series aluminum alloys where corrosion resistance is paramount.

Expert Opinion: The ER5356 is a workhorse for applications needing strength and superior corrosion resistance. Its smooth feed and stable arc make it a go-to for many professional fabricators working with relevant alloys.

3. 6 Pieces Low Temperature Universal Welding Rods,Metal…

These universal welding rods offer broad compatibility, making them a handy addition to any workshop. They’re designed with a low melting point, which not only makes them easier to use but also ideal for a range of repair jobs involving different metals. Whether you’re a beginner or just need a versatile rod for mixed-metal projects, these can be quite effective.

Key features that stand out:

– UNIVERSAL COMPATIBILITY: Suitable for aluminum, stainless steel, and iron.

– VERSATILE APPLICATION: Great for repair work and new construction on different metal combinations.

– EASY TO USE: Low melting point makes them beginner-friendly.

– COMPLETE SET: Package includes 6 rods for immediate use.

Pros:

– Works across multiple metal types, including aluminum, stainless steel, and iron.

– Beginner-friendly due to low melting point.

– Provides strong, durable bonds.

– Excellent flow characteristics for consistent welds.

Cons:

– Universal compatibility might mean slightly less specialized performance for pure aluminum projects.

Best for: General metal repairs, DIY projects involving mixed metals, and beginners seeking a versatile welding rod.

Expert Opinion: Their universal nature is a huge plus for small shops or home users who encounter various metal types. While not a substitute for specialized MIG or TIG, they excel at quick, effective repairs.

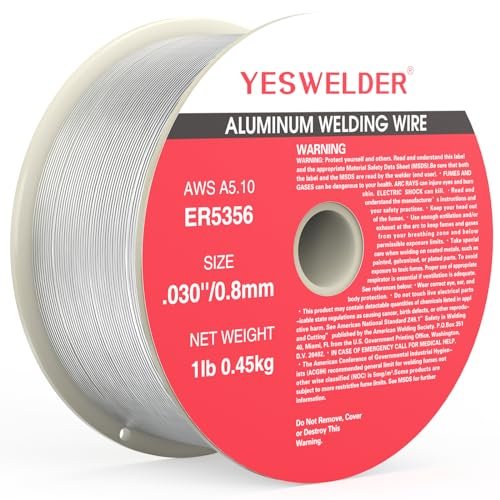

4. YESWELDER Magnesium Aluminum Welding Wire, ER5356 .030-Inch…

YESWELDER’s ER5356 MIG wire is another excellent choice for those focused on durability and corrosion resistance. Similar to the ARCCAPTAIN ER5356, this wire is specifically formulated with 5% magnesium, making it perfect for welding 5000 series aluminum. Its ability to maintain a clean, white color after anodizing is a significant advantage for aesthetic applications.

Key features that stand out:

– ER5356 WELDING WIRE: 5% magnesium aluminum filler metal for MIG welding.

– EXCELLENT PERFORMANCE: Enhanced corrosion resistance, higher shear strength, and a clean, white color after anodizing.

– VERSATILE APPLICATIONS: Ideal for metal fabrication, auto repair, equipment maintenance, and DIY projects.

– MATERIAL COMPATIBILITY: Recommended for 5000 series aluminum base metals (5050, 5052, 5083, etc.).

Pros:

– Superior corrosion resistance, particularly in saltwater.

– High shear strength for durable welds.

– Excellent color match after anodizing, maintaining aesthetics.

– Robust spool ensures reliable feeding and durability.

Cons:

– Requires a well-tuned MIG welder and potentially a spool gun for optimal feeding.

Best for: Marine environments, auto body repair, and any application where corrosion resistance and aesthetic finish on 5000 series aluminum are important.

Expert Opinion: The consistency of YESWELDER’s ER5356 wire, combined with its resistance to corrosion and excellent anodizing match, makes it a reliable option for both professional fabrication and serious hobbyists.

5. Aircraft Aluminum Gas Welding The Method Revised

This product isn’t a physical welding material or machine, but a valuable resource for anyone serious about learning the nuances of aircraft aluminum gas welding. For historical context or specific repair methodologies, having a detailed guide can be incredibly insightful. It delves into the traditional methods that were once standard for high-stakes aluminum applications.

Key features that stand out:

– Detailed Guide: Offers in-depth knowledge on aircraft aluminum gas welding.

– Revised Edition: Updated information for better understanding.

– Historical Context: Provides insights into traditional welding techniques.

– Specialized Focus: Concentrates on methods relevant to aircraft-grade aluminum.

Pros:

– Provides comprehensive theoretical and practical knowledge.

– Essential for understanding older repair techniques or specific niche applications.

– Great for historical research or specialized restoration projects.

– Can complement hands-on training with foundational principles.

Cons:

– Not a consumable product; requires separate welding equipment.

– Gas welding is generally slower and less common for aluminum than MIG or TIG today.

Best for: Aviation enthusiasts, historical aircraft restorers, students of welding history, or those looking to master traditional gas welding techniques for aluminum.

Expert Opinion: While TIG and MIG dominate modern aluminum welding, understanding gas welding, especially for aircraft applications, offers invaluable insight into metallurgy and heat control. This book serves as an excellent reference.

6. Biscuits Welding Practice Aluminum Parts- 5052 Aluminum -…

Mastering aluminum welding requires practice, and these 5052 aluminum welding coupons are specifically designed for that. Cut to a practical size, they provide an excellent surface for beginners to hone their skills across various welding methods. Using quality material for practice ensures that what you learn on these coupons translates effectively to real-world projects.

Key features that stand out:

– Material: High-quality 5052 Aluminum Welding Coupons.

– Size: 2 inches * 4 inches * 0.125 thickness, ideal for handling.

– Quantity: Generous pack of 24 pieces for extensive practice.

– Versatile Practice: Suitable for MIG, TIG, Stick, Arc, Gas, and Brazing.

Pros:

– Perfect for beginners to develop and refine aluminum welding skills.

– High-quality 5052 aluminum provides a realistic practice experience.

– Ample quantity allows for continuous improvement.

– Compatible with all major welding methods.

Cons:

– Not a consumable welding material for actual repairs, only for practice.

Best for: Welding students, apprentices, and anyone looking to improve their proficiency in aluminum welding techniques across various processes.

Expert Opinion: You can’t emphasize practice enough in welding, especially with aluminum. These coupons provide a consistent, quality material that allows welders to focus on technique without worrying about material inconsistencies.

7. Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons…

This small kit of aluminum welding coupons from Therwen offers a unique approach to practice with its varied shapes. While smaller, the square and triangular dice provide different angles and joint configurations to tackle, pushing your skill development beyond flat plates. Made from durable aluminum, these coupons are designed to withstand repeated practice sessions.

Key features that stand out:

– Complete Set for Practice: Includes 3 coupons with 2 square dice and 1 triangular dice.

– Aluminum Structure: Constructed with quality aluminum for durability.

– Ideal Tool for Beginners: Helps to learn, train, and practice welding skills.

– Convenient and User Friendly Design: Simplified design for easy handling and position holding.

Pros:

– Varied shapes allow practice on different joint types and angles.

– Durable aluminum construction ensures longevity for repeated use.

– Excellent for beginners to improve precision and control.

– Can be repurposed as decorative items after practice.

Cons:

– Only 3 pieces, which might limit extensive practice compared to larger packs.

Best for: Beginners looking for diverse practice geometries, or experienced welders wanting to refine specific joint welding techniques on aluminum.

Expert Opinion: Practicing on different shapes, like these dice, challenges a welder to adapt their torch angle and travel speed, which is crucial for real-world projects. A thoughtful addition to a practice regimen.

8. YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

For TIG welding aluminum, the ER4043 rod is a classic and widely respected choice. YESWELDER’s offering in this category provides a 5% silicon content, which significantly improves fluidity and reduces sensitivity to weld cracking. This makes it a preferred filler for general-purpose applications and compatible with a wide range of common aluminum alloys.

Key features that stand out:

– ER4043: 5% silicon content (AlSi5) for general-purpose aluminum welding.

– SHIELDING GAS: Typically requires 100% Argon, Helium, or a mix.

– EXCELLENCE: Silicon additions improve fluidity, reduce cracking sensitivity, and produce brighter welds.

– MULTIPLE USAGE: Can be used where base metal requires thermal treatment and for welding various aluminum grades (3003, 5052, 6061, etc.).

Pros:

– Excellent fluidity for smooth, clean welds.

– Reduced cracking sensitivity, leading to more robust joints.

– Versatile, compatible with many common aluminum alloys.

– Produces bright, aesthetically pleasing weld beads.

Cons:

– Not suitable for high-magnesium alloys (e.g., 5083, 5456) that require ER5356.

Best for: General TIG welding of aluminum, particularly 3000 and 6000 series alloys, and where good fluidity and crack resistance are desired.

Expert Opinion: The ER4043 is the bread and butter of TIG aluminum. Its silicon content makes it incredibly forgiving and easy to work with, producing consistent, strong welds on the most commonly encountered aluminum grades.

9. 45pcs Aluminum Brazing Rods, Aluminum Welding Rods,…

This generous pack of 45 aluminum brazing rods offers a convenient and effective way to tackle aluminum repairs without complex equipment. Like other flux-cored options, these eliminate the need for external flux or solder powder, simplifying the process significantly. Their low melting point and excellent weld strength make them ideal for various home and auto repair tasks.

Key features that stand out:

– No Flux or Solder Powder Needed: Flux cored design for straightforward use.

– High Quality Aluminum Welding Rods: Crafted from premium non-toxic, odorless, and durable aluminum.

– Low Melting Point & Excellent Weld Strength: Delivers corrosion resistance and high thermal/electrical conductivity.

– Aluminum Welding Rods for Versatile Applications: Works for aluminum, aluminum alloy, aluminum-magnesium alloy, and other white metals.

Pros:

– User-friendly, requiring only a torch and basic cleaning.

– Creates strong, clean welds with good electrical and thermal conductivity.

– High-quality, durable material suitable for indoor and outdoor use.

– Large quantity ensures plenty of rods for multiple projects.

Cons:

– Requires precise torch control to avoid melting the base metal, especially on thin pieces.

Best for: Extensive DIY repairs, automotive aluminum component fixes, and anyone needing a large supply of easy-to-use aluminum repair rods.

Expert Opinion: The value proposition here is huge. For frequent, small-to-medium aluminum repairs, these rods provide a cost-effective and relatively easy solution, especially when TIG or MIG isn’t feasible or available.

10. 20 Pack 6061 T6 Aluminum Sheet Welding Kit 1/8” Thick…

For serious welding practice, especially in educational settings or for specific certifications, these Certiweld Supplies welding coupons are an excellent choice. Made from high-grade 6061 T6 aluminum, they offer a realistic simulation of common structural aluminum. Their consistent size and quality make them ideal for perfecting techniques across MIG, TIG, and stick welding.

Key features that stand out:

– Standard Size Welding Coupons: Uniformity for instruction, testing, and practice.

– 3 Different Materials: Available in steel, stainless steel, and aluminum (this specific product is 6061 T6 Aluminum).

– Compatible with Most Welding Methods: Suitable for MIG, TIG, and stick welding.

– Quality You Can Trust: Made in the USA with highest grade materials, rust-resistant.

Pros:

– High-grade 6061 T6 aluminum provides realistic practice for structural applications.

– Standardized size ensures consistent training and testing conditions.

– Versatile for use with MIG, TIG, and stick welding methods.

– Made in the USA, ensuring quality and precise manufacturing.

Cons:

– A significant investment if you only need a few pieces for casual practice.

Best for: Welding schools, professional welders needing to maintain or certify skills, and serious hobbyists aiming for precision on common structural aluminum.

Expert Opinion: Practicing on 6061 T6 is crucial for many applications, as it’s a very common structural alloy. These coupons provide an excellent, consistent platform to master the specific challenges of welding this material.

Comparison Short Insights

When looking for the best welding method for aluminum, you’ll quickly see a distinction between filler materials and practice tools. For small, non-critical repairs or DIY projects, the flux-cored rods like the 50 Pieces Flux Core Aluminum Rods or the 45pcs Aluminum Brazing Rods are incredibly convenient. They simplify the process by eliminating the need for separate flux and often only require a propane or oxygen-acetylene torch, making them highly beginner-friendly. The 6 Pieces Low Temperature Universal Welding Rods offer even broader compatibility, suitable for aluminum, stainless steel, and iron, which is handy for general repair shops.

However, for structural integrity, corrosion resistance, and precision, especially in applications like marine or automotive, dedicated MIG or TIG methods with specific filler wires are superior. Both the ARCCAPTAIN ER5356 and YESWELDER ER5356 magnesium-aluminum MIG wires excel here, offering excellent corrosion resistance (critical for saltwater environments) and high shear strength for 5xxx series alloys. For TIG welding, the YESWELDER ER4043 rod is a go-to for its fluidity and crack resistance on 3xxx and 6xxx series aluminum. Choosing between ER5356 and ER4043 depends heavily on the base metal alloy you’re working with.

Finally, you can’t weld well without practice. Products like the Biscuits Welding Practice Aluminum Parts and Therwen 3 Pcs Welding Kit are essential for skill development. They provide a consistent medium to master torch control, travel speed, and puddle manipulation across various methods like MIG, TIG, and even gas welding. The 20 Pack 6061 T6 Aluminum Sheet Welding Kit offers a more professional-grade practice material for specific certifications or high-stakes fabrication. And for those interested in the historical or theoretical aspects of aluminum welding, the Aircraft Aluminum Gas Welding The Method Revised book provides invaluable foundational knowledge.

Final Verdict

Choosing the “best” welding method for aluminum truly boils down to your project’s specific demands, your skill level, and the equipment you have available.

For beginners and DIY enthusiasts tackling minor repairs or hobby projects, the flux-cored aluminum rods (like the 50 Pieces Flux Core Aluminum Rods or the 45pcs Aluminum Brazing Rods) are your easiest entry point. They demand less specialized equipment and simplify the process considerably.

If you’re delving into MIG welding aluminum, especially for applications requiring high strength and superior corrosion resistance, the ER5356 magnesium-aluminum wires (from ARCCAPTAIN or YESWELDER) are unparalleled. They’re fantastic for marine environments and 5xxx series alloys.

For TIG welding, which offers the highest precision and control, the YESWELDER ER4043 rods are a classic choice, perfect for a wide range of common aluminum alloys, especially 3xxx and 6xxx series, offering excellent fluidity and crack resistance.

And no matter your chosen method, practice is non-negotiable. The various welding practice coupons (from Biscuits, Therwen, or Certiweld Supplies) are invaluable tools to hone your skills, build confidence, and ensure your actual welds are strong and clean. Remember, investing in quality practice materials is an investment in your welding proficiency.

Ultimately, assess your project, match the filler metal to your base material, and commit to consistent practice – that’s the real secret to mastering aluminum welding.

Best Welding Method For Aluminum: Frequently Asked Questions

Q1: What is generally considered the best welding method for aluminum?

A1: For most precision and critical applications, TIG (Tungsten Inert Gas) welding is widely considered the best method for aluminum. It offers superior control over heat input, penetration, and bead appearance, resulting in very clean and strong welds. MIG (Metal Inert Gas) welding with a spool gun is also an excellent and faster option for thicker aluminum and production work, though it might not offer the same level of precision as TIG.

Q2: Can I weld aluminum with a stick welder?

A2: While technically possible to stick weld aluminum using specialized aluminum electrodes, it’s generally not recommended for beginners or for applications requiring high strength or aesthetics. Aluminum stick welding is challenging due produces more spatter, requires more specific electrodes, and results in rougher, less consistent welds compared to TIG or MIG. It’s often seen as a last resort for field repairs when other methods aren’t available.

Q3: What’s the difference between ER4043 and ER5356 aluminum filler metals?

A3: The main difference lies in their chemical composition and suitability for different aluminum alloys. ER4043 contains 5% silicon, which improves fluidity and reduces cracking, making it ideal for welding 3xxx and 6xxx series aluminum (like 6061). It’s also suitable for some casting alloys. ER5356 contains 5% magnesium, offering higher tensile strength and excellent corrosion resistance, especially in saltwater environments. It’s the preferred choice for welding 5xxx series aluminum-magnesium alloys (like 5052, 5083), which are known for their strength and corrosion resistance.

Q4: Are flux-cored aluminum rods good for beginners?

A4: Yes, flux-cored aluminum rods are often a great starting point for beginners. They simplify the welding process significantly because they don’t require external flux or expensive shielding gas equipment. Their low melting point also makes them more forgiving. They’re excellent for small repairs and DIY projects, but generally offer less precision and strength than TIG or MIG welds.

Q5: What shielding gas is used for aluminum welding?

A5: For both MIG and TIG welding aluminum, 100% Argon is the most common and recommended shielding gas. Argon provides excellent arc stability, good penetration, and a clean weld. For thicker aluminum or faster travel speeds, a mix of Argon and Helium (typically 75% Argon / 25% Helium) can be used to increase heat input and penetration.

Q6: What are common challenges when welding aluminum?

A6: Welding aluminum presents several unique challenges. Firstly, aluminum has a low melting point but high thermal conductivity, meaning it heats up and cools down quickly, making heat control tricky (“burn-through”). Secondly, aluminum forms an oxide layer (aluminum oxide) that has a much higher melting point than the base metal, requiring thorough cleaning and effective shielding gas to prevent contamination. Thirdly, aluminum’s susceptibility to porosity and cracking needs careful filler metal selection and technique.

Q7: How important is cleaning aluminum before welding?

A7: Cleaning aluminum before welding is critically important and often the most overlooked step. Aluminum quickly forms an invisible oxide layer that has a much higher melting point than the base metal. If not removed, this oxide layer can lead to poor penetration, porosity, contamination, and weak welds. Always use a stainless steel brush, acetone, or a suitable solvent to remove oxides and contaminants immediately before welding.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.