When I first started tackling stainless steel projects, I quickly realized it wasn’t quite like welding mild steel. The unique properties of stainless steel demand a more nuanced approach, and getting those clean, strong, corrosion-resistant welds requires the right technique, the proper consumables, and a lot of practice. I’ve spent countless hours in the shop, experimenting with different wires, rods, and practice setups to truly understand what makes a difference when welding stainless steel. That’s why I’ve put together this guide, drawing from my own experience to help you find the best tools and resources to master the art of welding stainless steel, whether you’re a beginner or looking to refine your skills.

Contents

- CERTIWELD SUPPLIES QUALITY YOU CAN TRUST Welding Practice Coupons

- Stainless Steel Welding Practice Kit, 2pcs Cube Dice

- E308LFC-O .035-Diameter Stainless Flux Core Welding Wire

- Welding Of Stainless Steels And Other Joining Methods

- Blue Demon ER308L X .030 X 2LB Spool stainless steel

- WelderElite 14pcs 201 Stainless Steel Laser Cut Welding Wolf Head Kit

- WelderElite Welding Coupons Vases, 17 Gauge Welding Practice

- TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless

- YESWELDER Stainless Steel TIG Welding Rod ER308L 1/16″x16″

- ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O

- Comparison Insights: Finding Your Best Welding Method For Stainless Steel Supplies

- Final Verdict: Equipping Yourself for the Best Stainless Steel Welds

- Best Welding Method For Stainless Steel: FAQ Section

- Q1: What is the best welding method for stainless steel for beginners?

- Q2: Is TIG or MIG better for welding stainless steel?

- Q3: What kind of filler metal should I use for 304L stainless steel?

- Q4: Can I weld stainless steel with a regular MIG welder?

- Q5: Why is welding stainless steel harder than mild steel?

- Q6: What practice materials are best for stainless steel welding?

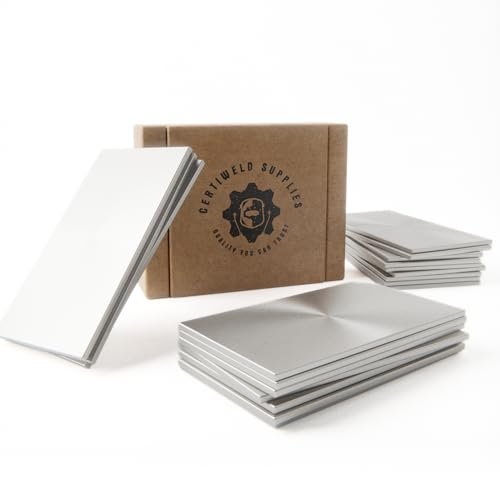

CERTIWELD SUPPLIES QUALITY YOU CAN TRUST Welding Practice Coupons

If you’re serious about honing your stainless steel welding skills, consistent practice is key. These Certiweld Supply welding coupons offer a fantastic, standardized way to practice MIG, TIG, and stick welding on stainless steel. I found the uniformity super helpful for consistent training and testing, allowing me to focus purely on my technique without worrying about material inconsistencies. They come in different material options, including stainless steel, making them incredibly versatile for various learning curves and project types.

Key features that stand out:

* Standard Size Welding Coupons: Designed for uniformity in instruction, testing, and practice.

* 3 Different Materials: Available in steel, stainless steel, and aluminum.

* Compatible with Most Welding Methods: Suitable for MIG, TIG, and stick welding.

* Quality You Can Trust: Made in the USA with high-grade, rust-resistant materials.

Pros:

* Provides a standardized platform for consistent practice.

* Versatile for multiple welding methods and materials, including stainless steel.

* High-quality, rust-resistant material ensures durability.

* Great for beginners and seasoned welders alike.

Cons:

* You’ll need a separate welding machine and consumables.

Best for: Welders seeking a consistent, high-quality material for practicing their stainless steel welding techniques across various methods.

Expert Opinion: Expert Opinion: These coupons are an excellent foundation for skill development. Their consistent quality lets you focus on mastering arc control and puddle manipulation specifically for stainless steel.

Stainless Steel Welding Practice Kit, 2pcs Cube Dice

This little practice kit is a creative way to turn welding practice into a fun project, especially when you’re just starting out with stainless steel. The idea of welding a dice or cube from smaller pieces encourages precision and careful heat management – crucial skills for thin-gauge stainless steel. It’s a durable kit made from high-quality steel that provides a tangible goal, which can be really motivating.

Key features that stand out:

* Premium welding kit training steel: Makes one dice and one cube.

* High Quality: Welding coupons made of high-quality steel.

* Mutil-purpose: Helps practice welding skills and encourages innovation.

* SIZE: 2.36″x2.36″x2.36″ Cube.

Pros:

* Engaging and fun way to practice welding skills.

* Encourages precision and attention to detail.

* Durable materials for repeated practice or a lasting keepsake.

* Great as a gift for aspiring welders.

Cons:

* Limited in scope compared to larger practice coupons.

Best for: Beginners looking for a fun, project-based approach to learning stainless steel welding and improving fine motor control.

Expert Opinion: Expert Opinion: This kit is fantastic for building confidence. The smaller, intricate pieces really push you to refine your control, which directly translates to better welds on more complex stainless steel projects.

E308LFC-O .035-Diameter Stainless Flux Core Welding Wire

When it comes to MIG welding stainless steel without shielding gas, this E308LFC-O flux core wire from SONNLER is a real contender. I’ve found it incredibly convenient for outdoor or job-site repairs where gas bottles aren’t practical. It performs well on various stainless steel types like 304, 304L, and 308L, offering good slag coverage and surprisingly minimal spatter. The vacuum packaging is a smart touch, ensuring the wire stays moisture-free until you use it.

Key features that stand out:

* E308LFC-O Application: Suitable for 304, 304L, 308, 308L, 321, and 347 stainless steels.

* NO NEED GAS: Improves welding efficiency for gasless MIG welding.

* PROFESSIONAL PACKAGING: Individually vacuum packed for waterproof and moisture-proof protection.

* EXCELLENT & STABLE PERFORMANCE: Great slag coverage, minimal spatter, almost no cleanup.

Pros:

* Eliminates the need for shielding gas, making it convenient for outdoor use.

* Excellent performance on various stainless steel grades.

* Minimizes spatter and cleanup, saving time.

* Vacuum packaging ensures product integrity and longevity.

Cons:

* Flux core wires generally produce more smoke than solid wire with gas.

Best for: Welders needing a gasless MIG welding solution for stainless steel projects, especially outdoors or in challenging environments, who prioritize efficiency and ease of use.

Expert Opinion: Expert Opinion: This flux core wire offers a practical alternative for field work. While it won’t give you the mirror finish of TIG, its ability to produce solid welds without gas is a huge advantage for many stainless steel applications.

Welding Of Stainless Steels And Other Joining Methods

While not a physical welding product, this book is an absolutely essential resource for anyone serious about mastering stainless steel welding. It’s the kind of comprehensive guide I wish I had when I started, diving deep into the metallurgy, various joining methods (including TIG, MIG, and Stick), and common issues specific to stainless steel. It bridges the gap between hands-on practice and the theoretical knowledge needed to truly understand why certain techniques work best.

Key features that stand out:

* Comprehensive Coverage: In-depth insights into various stainless steel welding methods.

* Metallurgical Understanding: Explores the properties and behaviors of stainless steels during welding.

* Troubleshooting Guides: Offers solutions to common problems encountered during stainless steel fabrication.

* Practical Applications: Focuses on real-world scenarios and best practices.

Pros:

* Provides invaluable theoretical knowledge to complement practical skills.

* Covers a wide range of welding methods and their application to stainless steel.

* Helps diagnose and solve complex welding challenges.

* An excellent reference for both beginners and experienced professionals.

Cons:

* Requires dedicated reading and study, isn’t a hands-on tool.

Best for: Welders looking to deepen their theoretical understanding of stainless steel metallurgy and optimal welding methods, ensuring higher quality and more consistent results.

Expert Opinion: Expert Opinion: This book is an indispensable guide for anyone serious about mastering stainless steel welding, offering the foundational knowledge often overlooked in hands-on practice. It’s truly a must-have for your technical library.

Blue Demon ER308L X .030 X 2LB Spool stainless steel

For those of us who prefer MIG welding stainless steel with shielding gas, the Blue Demon ER308L solid wire is a go-to choice. I’ve used this wire extensively for welding common stainless grades like 304L and 308L, and it consistently delivers smooth, clean welds with excellent penetration. The low carbon content helps prevent intergranular corrosion, which is a major concern with stainless steel. It’s also suitable for applications requiring good performance at cryogenic temperatures, adding to its versatility.

Key features that stand out:

* Requires Shielding Gas: Designed for MIG welding with gas for superior results.

* Versatile Application: Used for welding types 304, 304L, 308, 308L, 321, and 347 stainless steels.

* Cryogenic Applications: Suitable for use in environments requiring performance at low temperatures.

* Low Carbon Content (ER308L): Helps prevent carbide precipitation and intergranular corrosion.

Pros:

* Produces high-quality, clean welds with proper shielding gas.

* Excellent corrosion resistance due to low carbon content.

* Versatile across a broad range of stainless steel types.

* Reliable performance for critical applications.

Cons:

* Requires the use of an external shielding gas, which adds to cost and complexity.

Best for: Professional welders and fabricators who regularly MIG weld various grades of stainless steel and require high-quality, corrosion-resistant joints using shielding gas.

Expert Opinion: Expert Opinion: When gas-shielded MIG welding stainless, this ER308L wire is a benchmark. Its consistent feed and excellent arc characteristics make it a reliable choice for critical applications where weld integrity is paramount.

WelderElite 14pcs 201 Stainless Steel Laser Cut Welding Wolf Head Kit

This WelderElite kit takes welding practice to a whole new artistic level. Building a wolf head sculpture from laser-cut 201 stainless steel pieces is an incredibly engaging way to develop skills like fit-up, precision welding, and heat control on thin stainless. It supports multiple welding methods including MIG, TIG, Arc, Spot, and Gas welding, but I found it particularly effective for refining my TIG skills due to the intricate nature of the pieces. The finished sculpture is not just a practice piece but a unique artistic item.

Key features that stand out:

* Fun DIY Project: Create a metal wolf head sculpture from 14 laser-cut pieces.

* Multi-Method Practice: Helps practice MIG, TIG, Arc, Spot, and Gas welding skills.

* Skill Building: Develops skill in fitting and welding thin stainless steel coupons.

* Unique Output: Completed sculpture makes a great gift, decor, or portfolio piece.

Pros:

* Highly engaging and creative way to practice welding.

* Excellent for developing precision and heat management on thin stainless steel.

* Supports multiple welding methods.

* Results in a unique and tangible art piece.

Cons:

* Requires patience and a good eye for detail.

Best for: Welding enthusiasts and professionals seeking a challenging and artistic project to practice intricate stainless steel welding with a focus on fine detail and thin materials.

Expert Opinion: Expert Opinion: Projects like this are fantastic for forcing welders to think about heat input and fit-up on thin stainless. The complexity significantly boosts problem-solving skills, especially with TIG.

WelderElite Welding Coupons Vases, 17 Gauge Welding Practice

Another innovative practice kit from WelderElite, these 17-gauge 304 stainless steel coupons are designed to be welded into a functional vase, pen holder, or tool container. Working with 17-gauge stainless steel is a great way to practice managing distortion and achieving visually appealing welds on thinner materials. The laser-cut precision ensures good fit-up, letting you focus entirely on your welding technique. Plus, you end up with a durable, corrosion-resistant item for your home or workshop!

Key features that stand out:

* Versatile Use: Weld into a 304 stainless steel vase, pen holder, or tool container.

* Precision Cutting: Laser-cut for excellent dimensional accuracy and easy fit-up.

* Durable Material: 304 stainless steel resists corrosion, perfect for outdoor use.

* Skill Development: Ideal for sharpening your thin stainless steel welding skills.

Pros:

* Practices welding on a practical, functional project.

* Excellent for learning to manage thin-gauge stainless steel.

* High-quality, corrosion-resistant 304 stainless steel.

* Laser-cut pieces ensure accurate fit-up.

Cons:

* Primarily focused on a single type of project.

Best for: Welders who want to practice joining thinner 304 stainless steel and create a functional item while sharpening their precision welding skills.

Expert Opinion: Expert Opinion: These vase coupons are brilliant for practicing consistent, clean welds on thin stainless. The 17-gauge material really pushes you to perfect your heat control, leading to stronger, prettier welds.

TOOLIOM Gasless Flux-Cored MIG Welding Wire, Stainless

This TOOLIOM flux-cored MIG wire is another solid choice for gasless stainless steel welding, especially in challenging conditions. What impressed me was its ability to handle rusty, dirty, or even painted materials with good resistance to oil, making it perfect for those less-than-ideal field conditions. The internal flux core creates a stable arc with less spatter, which means less cleanup time. Its all-position capability is a huge bonus for versatility in different project setups.

Key features that stand out:

* Flux Core Design: Stabilizes the arc, enhances performance, and reduces spatter for high-quality welds.

* Usage Scenarios: Ideal for welding rusty, dirty, and painted materials; excellent oil resistance.

* ALL POSITIONS CAPABILITY: Versatile for flat, horizontal, vertical, and overhead welding.

* Self-Shielded: Eliminates the need for external shielding gas.

Pros:

* Exceptional for challenging environments and dirty materials.

* Stable arc and reduced spatter enhance weld quality and reduce cleanup.

* All-position welding capability for maximum flexibility.

* Gasless operation simplifies setup and increases portability.

Cons:

* Still produces more fumes than solid wire with gas.

Best for: Welders needing a reliable gasless MIG welding wire for stainless steel in outdoor, high-altitude, or less-than-clean environments, prioritizing versatility and robust performance.

Expert Opinion: Expert Opinion: For utility and robustness, this gasless flux-cored wire is excellent. Its tolerance for imperfect base metals makes it a practical choice for repair work where ideal conditions aren’t available.

YESWELDER Stainless Steel TIG Welding Rod ER308L 1/16″x16″

When I’m aiming for the highest quality, most precise welds on stainless steel, I reach for a TIG setup, and the YESWELDER ER308L TIG rod is a fantastic choice. This is my go-to for general-purpose TIG welding of stainless steels like 304L and 308L, especially where aesthetics and corrosion resistance are critical. The low carbon content significantly increases its resistance to intergranular corrosion, which is a major advantage for durability. Remember, 100% Argon or Argon/Helium is essential for optimal results with TIG.

Key features that stand out:

* ER308L: Most popular stainless rod for general-purpose applications and cryogenic temperatures.

* SHIELD GAS: Requires 100% Argon or Argon/Helium for greater penetration and speeds.

* CORROSION RESISTANCE: Low carbon content (0.03% max) increases resistance to intergranular corrosion.

* APPLICATION: Filler metal for TIG welding process in stainless steel 304, 304L, 308, 308L, 321, and 347.

Pros:

* Produces exceptionally clean, high-quality, and aesthetically pleasing welds.

* Superior corrosion resistance due to low carbon content.

* Versatile for a wide range of stainless steel grades.

* Ideal for critical applications like food processing and medical equipment.

Cons:

* TIG welding generally requires more skill and a slower pace than MIG.

Best for: Welders prioritizing precision, aesthetic quality, and superior corrosion resistance in TIG welded stainless steel projects, including demanding applications like petrochemical and food processing.

Expert Opinion: Expert Opinion: For the discerning welder, ER308L TIG rods are the benchmark for quality stainless steel welds. They allow for unparalleled control, yielding beautiful and robust joints, especially when paired with pure argon.

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O

The ARCCAPTAIN E308LFC-O flux-cored wire is another reliable option for gasless MIG welding of stainless steel. I’ve found that its internal flux core really helps to stabilize the arc, making for a smoother welding experience with minimal spatter. This wire is designed for consistent performance across all positions and is compatible with a wide range of stainless steel grades, much like other quality E308LFC-O wires. The careful vacuum packaging also assures you’re getting a fresh, moisture-free product, which is crucial for good flux core performance.

Key features that stand out:

* Enhanced Arc Stability: Internal flux core stabilizes the arc, enhancing performance and providing protection for gasless MIG.

* Consistent Performance: Minimizes spatter and delivers excellent weld formation in all positions.

* Versatile Application: Compatible with 304, 304L, 308, 308L, 321, and 347 stainless steel grades.

* Premium Packaging: Vacuum packed for waterproof and moisture-proof protection, ensuring optimal performance.

Pros:

* Eliminates the need for shielding gas, improving portability and efficiency.

* Provides stable arc and consistent, low-spatter welds.

* Compatible with a broad range of stainless steel types.

* High-quality packaging protects the wire from environmental degradation.

Cons:

* Produces more fumes and requires more cleanup than solid wire with gas.

Best for: Welders looking for a reliable, all-position gasless flux-cored wire for MIG welding various stainless steel grades, especially for field work or where gas is impractical.

Expert Opinion: Expert Opinion: ARCCAPTAIN’s flux-cored wire is a solid performer for gasless stainless MIG. Its stable arc and consistent bead make it a great choice for both professional and hobby welders tackling diverse stainless projects.

Comparison Insights: Finding Your Best Welding Method For Stainless Steel Supplies

When choosing the best welding method for stainless steel and the supplies that support it, consider your specific needs. If precision and aesthetics are your top priority, especially for thin-gauge stainless steel or critical applications, TIG welding with rods like the YESWELDER ER308L is unmatched. It demands more skill and is slower, but the results are beautiful, strong, and highly corrosion-resistant.

For faster fabrication or outdoor/field work, MIG welding is often the most efficient choice. You then have a decision: solid wire with shielding gas (like the Blue Demon ER308L) for cleaner welds and less cleanup, or gasless flux-cored wire (like the SONNLER E308LFC-O, TOOLIOM, or ARCCAPTAIN options) for convenience and versatility in less-than-ideal conditions. Flux-cored wires are great for rusty or dirty materials but produce more smoke and spatter.

Practice is fundamental regardless of your chosen method. Kits like the CERTIWELD SUPPLIES coupons, Stainless Steel Cube Dice, WelderElite Wolf Head, or WelderElite Vases provide excellent opportunities to hone your skills on actual stainless steel. They are crucial for developing the muscle memory and heat control necessary for successful stainless steel fabrication. Finally, don’t underestimate the power of knowledge; a resource like “Welding Of Stainless Steels And Other Joining Methods” can elevate your understanding of welding stainless steel significantly, helping you troubleshoot and optimize your techniques. Each product here offers unique benefits to help you master welding stainless steel.

Final Verdict: Equipping Yourself for the Best Stainless Steel Welds

After years of hands-on experience and trying various approaches, it’s clear there isn’t a single “best welding method for stainless steel” that fits all scenarios. Instead, it’s about having the right tools and knowledge for the specific job. For unparalleled precision and a pristine finish, the YESWELDER Stainless Steel TIG Welding Rod ER308L combined with dedicated practice on something like the WelderElite Laser Cut Wolf Head Kit is the winning combination. If speed and portability are your main concerns, especially for general fabrication or repairs, then a quality gasless flux-cored MIG wire like the SONNLER E308LFC-O or TOOLIOM Gasless Flux-Cored MIG Welding Wire will serve you well. For those who prioritize a balance of speed and weld quality in a shop setting, the Blue Demon ER308L solid wire with shielding gas is a superb choice. Don’t forget that consistent practice on the CERTIWELD SUPPLIES Quality Coupons and a deep dive into the theoretical aspects with “Welding Of Stainless Steels And Other Joining Methods” are the cornerstones of truly mastering stainless steel welding, no matter your chosen method.

Best Welding Method For Stainless Steel: FAQ Section

Q1: What is the best welding method for stainless steel for beginners?

A1: For beginners, MIG welding stainless steel with flux-cored wire (like the E308LFC-O options reviewed) can be a good starting point due to its relative ease of learning, especially gasless versions. However, TIG welding offers more control and cleaner results, making practice kits designed for TIG (like the WelderElite Wolf Head) excellent for skill development, though it has a steeper learning curve.

Q2: Is TIG or MIG better for welding stainless steel?

A2: It depends on your priorities. TIG welding is generally considered superior for stainless steel due to its precision, cleaner welds, better aesthetic finish, and stronger resistance to corrosion and distortion. It’s ideal for thinner materials and critical applications. MIG welding, on the other hand, is faster and more efficient for thicker materials and production work, especially with solid wire and shielding gas, or with flux-cored wire for outdoor portability.

Q3: What kind of filler metal should I use for 304L stainless steel?

A3: For 304L stainless steel, the most common filler metals are ER308L (for TIG and solid MIG) or E308LFC-O (for flux-cored MIG). The “L” in 304L and 308L stands for “low carbon,” which helps prevent carbide precipitation and intergranular corrosion, ensuring the weld metal matches the base metal’s corrosion resistance.

Q4: Can I weld stainless steel with a regular MIG welder?

A4: Yes, you can weld stainless steel with a regular MIG welder, but you’ll need the correct consumables and shielding gas. This typically means using stainless steel wire like ER308L and a specific shielding gas mixture, usually 98% Argon and 2% CO2, or 100% Argon. If using flux-cored wire like E308LFC-O, no external shielding gas is needed.

Q5: Why is welding stainless steel harder than mild steel?

A5: Welding stainless steel is harder because it has a higher thermal expansion rate, which leads to more distortion and warping. It also has lower thermal conductivity, meaning heat builds up quickly and can lead to overheating and carbide precipitation (which reduces corrosion resistance). Proper heat management, faster travel speeds, and appropriate filler metals are crucial for successful stainless steel fabrication.

Q6: What practice materials are best for stainless steel welding?

A6: Dedicated stainless steel welding coupons are the best practice materials. Products like the CERTIWELD SUPPLIES Quality Coupons or the WelderElite Vases made of 304 stainless steel are excellent. They allow you to practice on the actual material you’ll be working with, helping you understand its unique heat characteristics and how to achieve quality stainless steel joints. Project-based kits also provide a fun, engaging way to learn precision.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.