As a welder who spends serious time behind the hood, I know choosing the right welding rod can make or break a project. I’ve spent hours testing different stick electrodes and specialty filler metals to figure out which ones deliver reliable performance, whether I’m working on heavy structural steel or delicate sheet metal. This guide dives into 7 of the top contenders, helping you find the best welding rod brand that fits your machine and specific job requirements, ensuring you get strong, high-quality welds every time.

Contents

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon Steel Welding Sticks Electrodes, Welding Rods ARC Welding Equipment

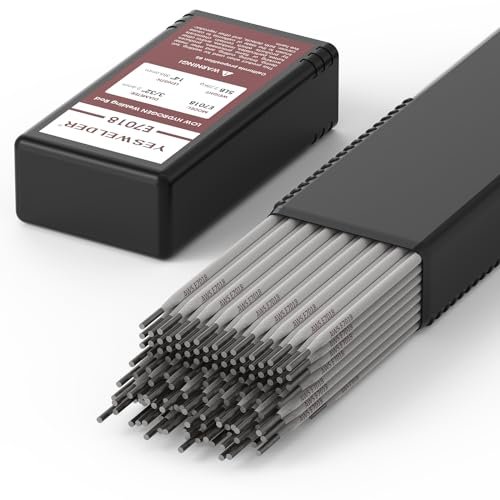

- YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon Steel Stick Electrodes

- YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick Electrodes

- YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

- WISUNO Welding Rods,E7018 3/32’’ 1LB,Carbon Steel Stick Electrodes

- 50 Pieces Flux Core Aluminum Rods Low Temperature Easy Melt Aluminum Welding Rods Welding Sticks

- 6 Pieces Low Temperature Universal Welding Rods,Metal Welding Arc Equipment, Easy Melt Aluminum Rods,Arc Welding Equipment and Accessories for Stainless Steel Iron, Beginner and Pro

- Comparison Short Insights on the Best Welding Rod Brand Options

- Final Verdict

- Best Welding Rod Brand: Comprehensive FAQ

- Q1: What does the designation E7018 mean, and why is it so highly recommended?

- Q2: Can I use E6013 rods for heavy-duty structural steel?

- Q3: How should I store low hydrogen rods like E7018 to maintain quality?

- Q4: Are the low-temperature aluminum flux rods suitable for use with a standard stick welder (ARC machine)?

- Q5: What is the ideal amperage range for 3/32″ E7018 welding rods?

- Q6: What is the key difference between stick electrode TIG filler rods?

- Q7: If I’m welding mild steel, why should I choose E7018 over E6013?

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon Steel Welding Sticks Electrodes, Welding Rods ARC Welding Equipment

If you’re tackling critical structural work that demands the highest quality, you can’t go wrong with the ARCCAPTAIN E7018. This low hydrogen electrode is designed to minimize cracking and porosity, making it perfect for pressure vessels, pipelines, and heavy construction. I found the arc stable and the slag easily managed, producing welds that hold up to rigorous inspection. The high tensile strength and low hydrogen content make these the go-to rods for professional use.

Key features that stand out:

– E7018 Low Hydrogen: Essential for high-quality, X-ray standard welds.

– Versatile Polarity: Suitable for welding in any position using AC or DC reverse polarity.

– High Melting Efficiency: Offers quick deposition, saving time on larger projects.

Pros:

– Produces exceptional X-ray quality welds.

– Excellent resistance to cracking and defects.

– Very stable arc characteristics.

Cons:

– Requires proper storage (rod oven) due to low hydrogen properties.

Best for: High-stress structural components, pressure piping, and code-work where weld integrity is paramount.

Expert Opinion: This rod offers everything a professional expects from an E7018. If your fabrication must meet specific engineering codes, the reliability and low-hydrogen properties of this ARCCAPTAIN rod make it a top choice among welding stick electrodes.

YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon Steel Stick Electrodes

YESWELDER is known for providing quality materials at a practical price point, and their E7018 stick electrode continues that trend. Like its competitor, this is a low-hydrogen rod built for high-integrity welding across all positions. What stood out during testing was its excellent re-striking ability—a huge time saver when you’re doing short welds or tacking. It performs admirably on medium carbon steels, especially where preheating isn’t possible, often preventing the porosity issues typical with conventional electrodes.

Key features that stand out:

– All Position Welding: Highly flexible for complex joints and positions.

– Excellent Re-striking Ability: Minimizes frustration and downtime mid-weld.

– High Deposition Efficiency: Gets metal where it needs to be quickly and cleanly.

Pros:

– Strong performance on steels where preheat isn’t used.

– Steady, predictable arc behavior.

– Good value for a low-hydrogen electrode.

Cons:

– Slag can sometimes be slightly harder to chip compared to premium options.

Best for: General fabrication of medium carbon steel structures, field repairs, and offshore rig maintenance.

Expert Opinion: The YESWELDER E7018 is a solid workhorse rod. If you need a reliable E7018 for high-strength requirements without the premium price tag, this is a fantastic choice for professional and serious hobby welders alike.

YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick Electrodes

The E6013 is arguably the most user-friendly general-purpose rod available, and the YESWELDER version excels in ease of use. If you are a beginner, or frequently work on light gauge materials, sheet metal, or ductwork, this rod offers superb shallow penetration and runs smoothly on low voltage AC machines. The key benefit here is the virtually self-cleaning slag, which often peels right off, saving huge amounts of post-weld cleanup time, especially when running vertical down fillets.

Key features that stand out:

– General Purpose: Ideal for a wide range of mild steel applications.

– Excellent Slag Removal: Virtually self-cleaning, leading to beautiful welds with minimal chipping.

– Low Spatter: Keeps the workspace cleaner and reduces finishing time.

Pros:

– Runs well on low amperage/AC machines.

– Extremely easy arc initiation and operation.

– Great for aesthetic passes and poor-fit conditions.

Cons:

– Not suitable for high-stress, critical structural applications due to lower tensile strength than E7018.

Best for: Light gauge metals, DIY projects, farm equipment repair, and beginner welders mastering basic techniques.

Expert Opinion: Every stick welder should keep E6013 in their inventory. This particular rod offers excellent welding performance for surface passes and thin materials. It’s the easiest rod to use when prioritizing bead appearance and minimizing penetration.

YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

Stepping away from stick welding, if your precision work requires Tungsten Inert Gas (TIG) welding, the ER70S-6 is the industry standard filler metal for mild steel. This copper-coated rod is specifically formulated with high manganese and silicon deoxidizers. This is crucial because it allows you to use 100% CO2 shielding gas (or Argon mixes) while maintaining a smooth bead profile and minimal cleanup. The copper coating ensures stable current transfer and protection against corrosion before use.

Key features that stand out:

– ER70S-6 TIG Filler: Specifically for TIG welding mild steel fabrication.

– High Deoxidizers: Manages impurities, even when welding rusty or oily plates.

– Multiple Usage: Excellent for tanks, shaft buildup, and high-quality shop fabrication.

Pros:

– Produces exceptionally smooth weld beads with low spatter (when TIG welding).

– Great flow characteristics for precise control.

– Compatible with various shielding gases, including cheaper CO2.

Cons:

– Requires a TIG setup; not compatible with standard stick welders.

Best for: Precision mild steel fabrication, TIG welding pipe, and clean, high-visual-standard repairs.

Expert Opinion: For anyone running a shop focused on TIG work, the quality of the ER70S-6 filler metal is non-negotiable. This YESWELDER option offers excellent control and minimizes post-weld grinding, making it highly efficient.

WISUNO Welding Rods,E7018 3/32’’ 1LB,Carbon Steel Stick Electrodes

While many commercial E7018 rods come in large 5LB or 10LB boxes, the WISUNO option provides a convenient 1LB size. This is ideal if you only need a small quantity for a specific project or are trying out different diameters before committing to a larger purchase. This rod delivers excellent E7018 welding performance—super stable arc, easy slag removal, and beautiful weld seams. It’s surprisingly effective even for thin plate small parts, despite being an E7018, thanks to its reliable arc starting.

Key features that stand out:

– Convenient 1LB Package: Perfect for small jobs, maintenance, or testing.

– Easy Arc Initiation: Beginner-friendly characteristics, despite being a heavy-duty rod type.

– Strict Quality Control: Chemical composition is controlled for consistent mechanical strength.

Pros:

– Great for hobbyists who don’t need bulk storage.

– Stable arc across both AC and DC current.

– Produces smooth, high-quality weld surfaces.

Cons:

– Higher cost per pound than bulk options.

Best for: Hobbyists, maintenance technicians needing small quantities, and cover passes that require a smooth finish.

Expert Opinion: This rod offers the quality of E7018 in a manageable quantity. It’s highly adaptable, making it a great emergency rod to keep in your toolbox, and the performance on thin plates is commendable.

50 Pieces Flux Core Aluminum Rods Low Temperature Easy Melt Aluminum Welding Rods Welding Sticks

When you need to repair aluminum but don’t have access to a spool gun or TIG setup, these flux core aluminum rods are a practical solution. The major advantage here is that no external solder powder is needed; the flux is already integrated into the core. These rods melt at a low temperature, which is essential when working with aluminum’s delicate heat characteristics. They provide high thermal and electric conductivity, making them excellent for fixing HVAC lines, thin aluminum frames, or small castings.

Key features that stand out:

– Flux Cored Design: Eliminates the need for separate solder powder or external flux.

– Low Melting Point: Easier and safer to work with aluminum materials.

– Great Weldability: Produces strong, corrosion-resistant bonds.

Pros:

– Highly versatile for various aluminum alloys (magnesium alloy included).

– Very easy to use; requires only a torch or high heat source.

– Excellent for small, precise aluminum repairs.

Cons:

– Requires extremely clean base metal for best results.

Best for: Low-temperature aluminum brazing and repairing white metals without complex welding equipment.

Expert Opinion: These are specialty rods designed for brazing and soldering aluminum, not traditional arc welding. They are invaluable for quick repairs on damaged aluminum components where a strong, clean bond is required without specialized AC/DC TIG machines.

6 Pieces Low Temperature Universal Welding Rods,Metal Welding Arc Equipment, Easy Melt Aluminum Rods,Arc Welding Equipment and Accessories for Stainless Steel Iron, Beginner and Pro

If versatility is your primary goal, these low-temperature universal rods offer an impressive ability to join dissimilar metals, including aluminum, stainless steel, and iron. This rod is designed with a low melting point and excellent flow characteristics, making it easy for even beginners to achieve professional-grade performance. They are particularly useful in situations where you might need to bond two different types of metal, such as an iron bracket to a stainless steel component.

Key features that stand out:

– Universal Compatibility: Joins aluminum, stainless steel, and iron effectively.

– Low Melting Point: Simplifies the process and reduces the chances of warping.

– Excellent Flow Characteristics: Ensures strong, durable bonds across different materials.

Pros:

– Perfect for multi-metal repair work.

– Easy to use for beginners due to the low melt temperature.

– Ready for immediate use with standard arc equipment.

Cons:

– Weld strength may not match high-tensile carbon steel stick electrodes.

Best for: Automotive repair, prototyping, and general shop tasks involving multiple metal types where ease of use is prioritized.

Expert Opinion: These rods are more of a specialized brazing/bonding solution than a heavy-duty stick electrode. For beginners, they are a fantastic way to quickly and easily achieve strong bonds on tricky metal combinations.

Comparison Short Insights on the Best Welding Rod Brand Options

When looking for the best welding rod brand, your choice depends heavily on the application. The E7018 options (ARCCAPTAIN and YESWELDER) are the kings of strength and structural integrity; they are necessary for code-work because they offer low hydrogen content and superb mechanical properties.

In contrast, the YESWELDER E6013 is the generalist—a phenomenal rod for cosmetic work and thin material due to its shallow penetration and effortless slag removal. If you’re just learning, start here.

It’s crucial to note the difference between stick electrodes and specialty rods. The YESWELDER ER70S-6 is strictly a TIG welding rod and requires a different machine and process. Similarly, the Flux Core Aluminum Rods and the Universal Welding Rods are low-temperature fillers/brazing materials, not meant for high-amperage stick welding, but they offer the best way to tackle specialty metals like aluminum without expensive equipment.

Finally, the WISUNO E7018 1LB is an excellent option for those who need E7018 performance but in a small, easily storable quantity.

Final Verdict

Choosing the right rod is all about matching the rod to the job’s demands:

For Professional Structural Work & Highest Strength: Choose the ARCCAPTAIN E7018 for its proven X-ray quality and reliable low-hydrogen performance.

For General Shop Use & Best Value 7018: The YESWELDER E7018 offers professional performance at a very competitive price point and features exceptional re-striking ability.

For Beginners, Thin Metal, or Cosmetic Welds: Go with the YESWELDER E6013. It’s the easiest rod to run and clean up.

For Specialized Aluminum Repairs (Non-Arc): The 50 Pieces Flux Core Aluminum Rods are indispensable for fast, strong low-temperature aluminum bonding.

Best Welding Rod Brand: Comprehensive FAQ

Q1: What does the designation E7018 mean, and why is it so highly recommended?

A: The designation E7018 is standard in the industry. The ‘E’ stands for electrode, ’70’ means the deposited weld metal has a minimum tensile strength of 70,000 pounds per square inch (PSI), the ‘1’ means it can be welded in all positions (flat, horizontal, vertical, overhead), and the ‘8’ indicates a low hydrogen coating, usually iron powder. E7018 is highly recommended because it offers superior strength and reduces the risk of hydrogen-induced cracking, crucial for critical structural welds.

Q2: Can I use E6013 rods for heavy-duty structural steel?

A: E6013 rods are generally rated for 60,000 PSI tensile strength and provide very shallow penetration. While you can weld heavier steel with them, they are not recommended for critical structural loads or heavy equipment where high integrity and deeply penetrating welds are required. For structural work, always opt for the best welding rod brand offering E7018 or similar high-strength, low-hydrogen stick electrodes.

Q3: How should I store low hydrogen rods like E7018 to maintain quality?

A: Low hydrogen rods must be kept dry because moisture absorption compromises their low hydrogen properties, potentially leading to cracking. The best practice is to store them in a temperature-controlled rod oven or dry cabinet. If they have been exposed to moisture, they often need to be rebaked according to the manufacturer’s specifications to restore their integrity before use.

Q4: Are the low-temperature aluminum flux rods suitable for use with a standard stick welder (ARC machine)?

A: No, the low-temperature aluminum flux core rods (like those reviewed) are typically designed for brazing, requiring heat from an external source like a propane, MAPP, or oxy-acetylene torch, not the high amperage output of a traditional arc welding machine. Using them in a stick welder would likely destroy the rod quickly without achieving a proper bond. They are a great solution for easy melt aluminum repairs.

Q5: What is the ideal amperage range for 3/32″ E7018 welding rods?

A: The ideal amperage range can vary slightly between manufacturers and specific machines, but generally, a 3/32″ E7018 stick electrode runs well between 70A and 100A (as seen in the YESWELDER specifications). Always start on the lower end and increase the heat until you achieve a smooth, stable arc and proper penetration for the material thickness you are working with.

Q6: What is the key difference between stick electrode TIG filler rods?

A: Stick electrodes (like E6013 or E7018) are consumable, flux-coated rods that create their own shielding gas and slag when melted by the arc. TIG filler rods (like the ER70S-6 TIG welding rod) have no flux coating; they rely entirely on an external inert shielding gas (usually Argon) fed through the torch to protect the molten weld pool.

Q7: If I’m welding mild steel, why should I choose E7018 over E6013?

A: While E6013 is easier to run, E7018 offers higher tensile strength (70,000 PSI vs. 60,000 PSI) and low hydrogen content. E7018 provides better resistance to cracking and defects, especially on thicker or high-carbon materials, making it the preferred choice when welding performance and structural integrity are paramount.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.