I’ve been in the workshop long enough to know the headache of joining two different types of metal. It’s not as simple as sticking two pieces of the same material together; you need the right filler. Over the years, I’ve tested countless welding rods, and let me tell you, finding the best welding rod for dissimilar metals can make or break your project. This guide is built from that hands-on experience, walking you through options that really perform when you’re trying to weld things like stainless steel to mild steel, or copper to aluminum, ensuring strong, reliable bonds.

Contents

- 1. 6 Pieces Low Temperature Universal Welding Rods,Metal…

- 2. All Metal Brazing Rods,1/16”x13” Flux Core All Metal…

- 3. Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

- 4. Low Temperature Universal Welding Rod, Metal Universal Low…

- 5. Stainless Steel E309L-16 Welding Electrode Rod For TIG MIG…

- 6. Stainless Steel E309L-16 Welding Electrode Rod For TIG MIG…

- 7. 50Pcs Metal Universal Welding Wire easy to use Flux Core…

- 8. Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

- 9. Solderweld SW-MS09306K – Multi Sol Low Temp Dissimilar…

- 10. Blue Demon Alloy 3000 X 3/32″ X 14″ X POP…

- Comparison Short Insights

- Final Verdict

- Best Welding Rod For Dissimilar Metals FAQ

- Q1: What makes welding dissimilar metals so challenging?

- Q2: Can I use a regular welding rod for dissimilar metals?

- Q3: What’s the difference between welding and brazing when joining dissimilar metals?

- Q4: When should I choose a low-temperature welding rod for dissimilar metals?

- Q5: What type of rod is best for welding stainless steel to carbon steel?

- Q6: Are there any universal welding rods for all dissimilar metals?

- Q7: What are LSI keywords and why are they important for understanding the best welding rod for dissimilar metals?

- Q8: Can I use an E6013 rod for dissimilar metals?

1. 6 Pieces Low Temperature Universal Welding Rods,Metal…

These universal welding rods are a fantastic starter option for anyone tackling diverse metal projects. They operate at a low melting point, which makes them incredibly forgiving for beginners, yet they deliver a professional-grade bond. I found them particularly useful for quick repairs where I needed to join a mix of common metals like aluminum, stainless steel, or even iron without a complicated setup.

Key features that stand out:

– UNIVERSAL COMPATIBILITY: Works on aluminum, stainless steel, iron, and more.

– EASY TO USE: Low melting point design makes them ideal for beginners.

– VERSATILE APPLICATION: Great for both repair work and new construction.

– COMPLETE SET: Comes with 6 rods, ready for immediate use.

– PERFORMANCE: Ensures strong, durable bonds with excellent flow.

Pros:

– Super easy for beginners to pick up and use.

– Compatible with a wide array of common metals.

– Creates strong, lasting bonds at lower temperatures.

– Good for general repair and small projects.

Cons:

– The small quantity might not be enough for larger projects.

Best for: Beginners and DIYers needing to tackle small, multi-metal repair jobs.

Expert Opinion: These rods are a go-to for hobbyists and those new to welding dissimilar metals, offering surprising versatility and ease of use without specialized equipment.

2. All Metal Brazing Rods,1/16”x13” Flux Core All Metal…

If you’re more into brazing than traditional welding for dissimilar metals, these flux-core rods are a real time-saver. The built-in flux means you don’t have to fuss with separate pastes, which makes the whole process cleaner and quicker. I’ve used them for everything from plumbing fixes to automotive repairs, and the ability to work with just a propane torch is a huge plus for home workshops. They create really strong, leak-proof joints.

Key features that stand out:

– VERSATILE ALL-METAL REPAIR: Bonds steel, cast iron, copper, brass, stainless steel, and more.

– CONVENIENT FLUX CORE DESIGN: Eliminates the need for separate flux paste.

– WORKS WITH PROPANE TORCH: Accessible for DIYers without complex welding gear.

– STRONG & DURABLE BRAZED JOINTS: Creates high-strength, leak-proof, and corrosion-resistant bonds.

– IDEAL FOR MULTIPLE REPAIRS (20 RODS): Ample material for numerous projects.

Pros:

– Eliminates the need for separate flux, simplifying the process.

– Works with a standard propane torch, very accessible.

– Creates strong, durable, and corrosion-resistant bonds.

– Comes in a generous pack of 20 rods for multiple uses.

Cons:

– It’s a brazing solution, not a high-heat welding rod, so results differ.

Best for: DIYers and home users looking for an easy, effective brazing solution for a wide range of metal repairs with basic equipment.

Expert Opinion: For accessible, strong, and flux-free brazing of various metals, these rods are hard to beat, especially for those without a full welding setup.

3. Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

The Tandefio 24-piece kit is a comprehensive package for low-temperature welding, especially useful for diverse projects. I appreciate the generous quantity of rods, which means less worrying about running out mid-project. They’re designed for easy handling and have a very low melting point, making them incredibly convenient. What surprised me was their effectiveness on such a broad range of materials, including even PVC pipes for specific joining needs, though metal-to-metal is where they really shine for dissimilar work.

Key features that stand out:

– Comprehensive Welding Package: 24 low temperature universal welding rods.

– Ideal Size for Versatility: 3.07 inches/78 mm for easy handling and precision.

– Quality Material: Fabricated with quality tin powder and aluminum powder.

– Designed Features: Low temperature, no solder powder needed, quick welding speed.

– Wide Range of Applications: Ideal for stainless steel, iron, copper, aluminum, and even PVC.

Pros:

– Large quantity provides great value for multiple projects.

– Easy to handle and manipulate for precise welds.

– Low melting point and quick welding speed for convenience.

– Extremely broad application range, including some non-metals.

Cons:

– The material can be brittle, so careful handling is needed to prevent breakage.

Best for: Those needing a bulk supply of low-temperature rods for diverse, light-duty repair projects across many material types.

Expert Opinion: This kit offers incredible versatility for low-temperature bonding across a surprising array of materials, making it a valuable asset for any multi-material repair enthusiast.

4. Low Temperature Universal Welding Rod, Metal Universal Low…

These low-temperature universal welding rods are another solid contender for tackling dissimilar metals. Their straightforward nature and excellent weldability mean they’re forgiving enough for beginners but still deliver reliable results for pros. I found them particularly useful for joining common shop metals and even some electronic components. The durability from the high-quality tin powder ensures your welds will last, and the low-temperature operation is a huge plus for sensitive materials.

Key features that stand out:

– Versatile: Usable on copper, iron, aluminum, stainless steel, water tanks, and PVC pipes.

– Easy to use: Excellent weldability and insulation resistance for all skill levels.

– Durable: Made of high-quality tin powder for longevity and performance.

– Low temperature: Ideal for applications requiring lower heat.

– High strength: Creates strong bonds for various applications.

Pros:

– Broad compatibility with many common metals.

– Very easy to use, great for beginners.

– Durable construction leads to long-lasting welds.

– Low heat input is beneficial for sensitive projects.

Cons:

– Like similar low-temp rods, they can be brittle.

Best for: General purpose low-temperature repairs, especially for mixed metals, circuit boards, and other applications needing controlled heat.

Expert Opinion: A reliable, easy-to-use option that provides strong, durable bonds across a good range of materials, perfect for general workshop use.

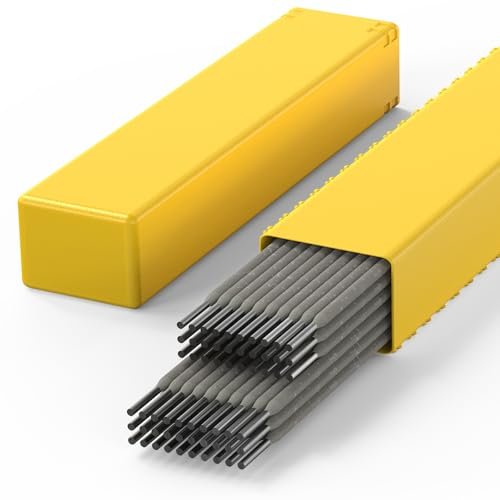

5. Stainless Steel E309L-16 Welding Electrode Rod For TIG MIG…

When I’m joining stainless steel to carbon steel or low alloy steels, the E309L-16 is my go-to. This isn’t your average universal rod; it’s specifically designed for these demanding dissimilar metal applications. The low carbon content is a huge benefit, preventing intergranular corrosion and ensuring the integrity of the weld, especially in high-heat environments. It creates a stable arc with minimal spatter, which means less cleanup and a cleaner finish on important fabrication projects. Just remember the pre-baking!

Key features that stand out:

– High Compatibility For Stainless And Carbon Steel: Specifically engineered for dissimilar steel joins.

– Low Carbon Content For Better Resistance: Improves resistance to intergranular attack.

– Versatile Size Range And Current Specs: Available in various diameters with specified amperage ranges.

– Stable And Low Spatter: Easy-to-control arc with minimal spatter for cleaner welds.

– Preparation And Usage Guidelines: Requires pre-baking and DC power for optimal performance.

Pros:

– Excellent for robust welds between stainless and mild/low alloy steels.

– Reduced carbon content enhances corrosion resistance.

– Provides a stable arc with minimal spatter, making it easier to control.

– Delivers strong, reliable, and aesthetically pleasing welds.

Cons:

– Requires specific pre-baking and DC power, adding to preparation time.

Best for: Professional welders needing to join stainless steel to carbon or low alloy steels with high strength and corrosion resistance.

Expert Opinion: This electrode is a must-have for critical dissimilar steel welding, offering superior performance and metallurgical integrity when used correctly.

6. Stainless Steel E309L-16 Welding Electrode Rod For TIG MIG…

You know a product is good when you see it listed more than once! This E309L-16 electrode reinforces its position as a top choice for welding dissimilar stainless and carbon steels. What truly stands out is its consistent performance in creating high-quality, corrosion-resistant bonds. I’ve relied on these for industrial repairs and fabrication where the joint absolutely has to hold up under stress and varying temperatures. The minimal spatter and stable arc make the job smoother, ensuring a professional finish every time you follow the proper procedure.

Key features that stand out:

– High Compatibility For Stainless And Carbon Steel: Ideal for joining stainless steel to carbon and low alloy steels.

– Low Carbon Content For Better Resistance: Enhanced protection against intergranular attack in welded areas.

– Versatile Size Range And Current Specs: Various diameters to match different welding machines and applications.

– Stable And Low Spatter: Promotes cleaner welds with less post-weld grinding.

– Preparation And Usage Guidelines: Emphasizes electrode baking and DC power for optimum results.

Pros:

– Provides highly reliable and strong welds for stainless to carbon steel.

– Excellent resistance to intergranular corrosion.

– Stable arc and low spatter contribute to cleaner, more efficient work.

– Versatile in size for different project needs.

Cons:

– Requires careful adherence to pre-use guidelines (baking) for best results.

Best for: Any professional or serious hobbyist consistently needing strong, corrosion-resistant welds between stainless and carbon/low alloy steels.

Expert Opinion: The E309L-16 is a proven workhorse for specific dissimilar metal combinations, delivering consistent, high-integrity welds that are vital in demanding applications.

7. 50Pcs Metal Universal Welding Wire easy to use Flux Core…

This bulk pack of 50 flux-cored welding rods is a dream for anyone working extensively with aluminum and its alloys, especially when joining them to other non-ferrous metals where compatible. The key benefit here is the “no solder powder” design; the flux is built right into the core, making the welding process incredibly convenient and clean. I’ve achieved full, smooth welds with these, noting their excellent thermal and electrical conductivity. For high-volume aluminum repair or fabrication involving dissimilar metals, these are a strong contender.

Key features that stand out:

– No Need Solder Powder: Flux-cored design eliminates external flux.

– Solution Welding Flux-cored Rods: High-quality rods for welding/brazing aluminum and aluminum alloys, and some other non-ferrous metals.

– Perfect Welding Effect: Achieves full and smooth welds with internal powder.

– Strong Welding: Suitable for various materials including aluminum, aluminum alloys, cast aluminum, and stainless steel.

– High Quality Safe and Stable: 33cm (13inch) length, 1.6mm diameter for consistent performance.

Pros:

– Self-fluxing for extreme convenience and clean operations.

– Produces very smooth and complete welds.

– Strong, durable bonds that resist cracking.

– Comes in a large quantity, excellent for ongoing projects.

Cons:

– While versatile, it’s primarily optimized for aluminum and aluminum alloys, not truly universal for all dissimilar metals.

Best for: Users frequently welding or brazing aluminum and its alloys, especially when dealing with aluminum-based dissimilar metal projects.

Expert Opinion: For anyone tackling numerous aluminum or aluminum alloy joining tasks, these flux-cored rods offer superb convenience and consistent, strong results.

8. Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

While primarily known for low-carbon steel, the E6013 rods deserve a mention for their versatility in specific light-duty dissimilar metal contexts, particularly when one of the metals is mild steel. These are a favorite among DIYers and beginners because they strike an arc easily and produce minimal spatter, making for cleaner welds and less cleanup. I’ve used them for sheet metal work and light repairs where the combination might be mild steel to a similar low-alloy steel. Their all-position capability is a bonus, making them quite adaptable for various home projects.

Key features that stand out:

– Perfect for DIY & Light Repairs: Ideal for home repairs and light metal fabrication.

– Smooth Arc & Easy to Strike: Consistent arc stability for easier welding.

– Minimal Spatter & Easy Slag Removal: Ensures clean, smooth welds with less cleanup.

– All-Position Welding Performance: Versatile for flat, horizontal, vertical, and overhead welding.

– Ideal Choice for Thin Metal Welding: Recommended amperage for ductwork, automotive panels, etc.

Pros:

– Very beginner-friendly with easy arc striking and stable performance.

– Low spatter and easy slag removal save time on cleanup.

– Works in all positions, increasing versatility for awkward repairs.

– Excellent for thin materials and light fabrication involving mild steel.

Cons:

– Primarily designed for low-carbon steel, so its application for truly dissimilar metals is more limited compared to specialized rods.

Best for: DIYers and beginners tackling light repairs on low-carbon steel or specific mild steel to mild steel variants where ease of use is paramount.

Expert Opinion: Although not a universal dissimilar metal rod, its ease of use and clean results make it a great gateway for beginners, and it can handle certain light-duty dissimilar steel applications effectively.

9. Solderweld SW-MS09306K – Multi Sol Low Temp Dissimilar…

The Solderweld SW-MS09306K is a specialized low-temperature solder designed specifically for bonding dissimilar metals like aluminum to copper, and brass to copper. This isn’t a traditional welding rod; it’s a multi-purpose tin-zinc-cadmium solder that creates strong joints without the high heat of a welder. I found these rods incredibly effective for HVAC work, refrigeration lines, and other applications where you need to join these specific material combinations without risking damage from excessive heat. The 18-inch length also gives you plenty of material to work with.

Key features that stand out:

– Multi Sol Low Temp Dissimilar Metals Bonding: Specifically formulated for lower temperature joining.

– Tin-Zinc-Cadmium multipurpose solder: Unique alloy for specialized bonds.

– Join and repair Aluminum, Aluminum/Copper, Brass/Copper: Targeted compatibility for key dissimilar pairs.

– Six 18 inch Rods per Package: Good length and quantity for specialized work.

Pros:

– Excellent for specific low-temperature dissimilar metal combinations (Al/Cu, Brass/Cu).

– Creates strong bonds without the need for high-heat welding equipment.

– Long rods provide ample material for several jobs.

– Very effective for HVAC and refrigeration repairs.

Cons:

– Contains cadmium, so proper ventilation is crucial during use.

– Limited to specific metal combinations, not a general-purpose solution.

Best for: HVAC technicians, plumbers, and hobbyists needing to join aluminum to copper or brass to copper at low temperatures.

Expert Opinion: For its niche, this multi-sol solder is exceptionally effective at creating strong, low-temperature bonds between its specified dissimilar metals, making it invaluable for certain repair fields.

10. Blue Demon Alloy 3000 X 3/32″ X 14″ X POP…

The Blue Demon Alloy 3000 is truly a “problem solver” rod when you’re faced with unknown metals or need maximum versatility for dissimilar joints. What truly sets it apart for me is its ability to produce smooth, porosity-free welds without undercut or splatter, even on metals you can’t quite identify. The special ferrite-balanced chemistry means it’s also fantastic as a “stud pulling” electrode, which is a lifesaver for removing broken bolts or drills. This rod is suitable for all positions on AC or DC, making it incredibly adaptable for various professional repair and fabrication tasks.

Key features that stand out:

– Welds dissimilar or unknown metals: Highly versatile for challenging combinations.

– Smooth, porosity free welds: Delivers high-quality, clean results.

– Special ferrite balanced chemistry (Stud Pulling electrode): Unique capability to remove broken fasteners.

– Typical applications: Wide range including tool repair, rebuilding shafts, and general dissimilar metal welding.

– All positions AC or DC+: Flexible for various welding setups and orientations.

Pros:

– Unmatched versatility for welding unknown or highly dissimilar metals.

– Produces exceptionally clean, high-quality welds.

– Unique stud-pulling feature is incredibly practical.

– Works with both AC and DC current in all positions.

Cons:

– Its specialized nature and high performance might come at a higher cost compared to basic rods.

Best for: Professional repair shops, fabricators dealing with unknown materials, and any application requiring a high-strength, versatile solution for complex dissimilar metal joining.

Expert Opinion: If you need one rod that can handle almost anything, especially when the base metals are a mystery, the Blue Demon Alloy 3000 is an unparalleled choice for its versatility and exceptional weld quality.

Comparison Short Insights

When picking the best welding rod for dissimilar metals, your project’s specific needs really guide the choice. For beginners and light DIY tasks, the 6 Pieces Low Temperature Universal Welding Rods or the Tandefio 24pcs Low Temperature Universal Welding Rod Sticks are fantastic starting points due to their ease of use and broad compatibility with common metals like aluminum and iron. If you’re looking for a flux-cored brazing solution that works with a propane torch, the All Metal Brazing Rods shine, simplifying repairs for copper, brass, and steel without a full welding setup.

For professional applications involving stainless steel to carbon steel, the Stainless Steel E309L-16 Welding Electrode Rod (both listings!) is an absolute essential, delivering high-strength, corrosion-resistant welds. Meanwhile, for high-volume aluminum or aluminum alloy work, the 50Pcs Metal Universal Welding Wire with its self-fluxing core is incredibly efficient. If your work involves specific low-temperature soldering of aluminum/copper or brass/copper, the Solderweld SW-MS09306K is tailored for those precise combinations. And for the ultimate all-around problem solver, especially with unknown metals, the Blue Demon Alloy 3000 stands out with its exceptional versatility and unique capabilities. Finally, for basic, light-duty carbon steel work that might occasionally touch on simple dissimilar steel joints, the Faiuot E6013 Welding Rods offer a beginner-friendly approach.

Final Verdict

Navigating the world of welding rods for dissimilar metals can feel like a maze, but armed with the right knowledge, it becomes much clearer. For me, the Blue Demon Alloy 3000 truly rises above as the most versatile “problem solver,” capable of tackling unknown metals with excellent results, making it an invaluable tool for any professional. However, for those consistent, high-stakes stainless-to-carbon steel jobs, the E309L-16 rods are non-negotiable for their specialized performance.

If you’re a DIYer, don’t overlook the ease and affordability of the low-temperature universal rods like the 6-piece or 24-piece sets – they’re perfect for small, varied repairs. And for specific brazing needs, the flux-core all-metal rods offer a simple, effective solution. Ultimately, the “best” rod boils down to the specific metals you’re joining, your equipment, and your skill level. Consider your most frequent projects, and pick the rod that empowers you to create strong, lasting bonds with confidence.

Best Welding Rod For Dissimilar Metals FAQ

Q1: What makes welding dissimilar metals so challenging?

A1: Welding dissimilar metals is tricky because different metals have varying melting points, thermal expansion rates, and chemical compositions. These differences can lead to issues like cracking, porosity, and galvanic corrosion if the wrong filler material or technique is used. Specialized welding rods are designed to bridge these gaps, creating a compatible interface between the two materials.

Q2: Can I use a regular welding rod for dissimilar metals?

A2: Generally, no. Using a standard rod meant for a single type of metal (like a typical mild steel rod) on dissimilar metals often results in a weak, brittle, or cracked weld. It’s crucial to use a rod specifically formulated for joining different metal types, as they contain alloys that can accommodate the varying properties of the base metals.

Q3: What’s the difference between welding and brazing when joining dissimilar metals?

A3: Welding involves melting the base metals and the filler material to form a strong metallurgical bond. Brazing, on the other hand, melts only the filler material (often at a lower temperature than the base metals), which then flows into the joint by capillary action to create a bond. Brazing is often simpler for dissimilar metals, especially for thinner materials or those sensitive to high heat, like some aluminum to copper joints. Flux-cored brazing rods are great for this.

Q4: When should I choose a low-temperature welding rod for dissimilar metals?

A4: Low-temperature welding rods are ideal for situations where you want to minimize heat input, such as when working with thin materials, heat-sensitive components, or metals prone to warping. They are also very user-friendly for beginners and can join a wide variety of common metals like aluminum, stainless steel, and iron without needing a powerful welding machine.

Q5: What type of rod is best for welding stainless steel to carbon steel?

A5: For welding stainless steel to carbon steel or low alloy steels, an E309L-16 electrode is widely recommended. The “L” signifies low carbon content, which helps prevent carbide precipitation and intergranular corrosion in the heat-affected zone, ensuring a strong and durable bond between these two very different types of steel.

Q6: Are there any universal welding rods for all dissimilar metals?

A6: While some rods are marketed as “universal” and work on a broad range of common metals (like the low-temperature options reviewed), no single rod can truly weld every conceivable dissimilar metal combination. Highly specialized alloys, like the Blue Demon Alloy 3000, come close by being designed for unknown or highly varied metals, but specific critical applications will always benefit from a rod precisely tailored to the materials in question.

Q7: What are LSI keywords and why are they important for understanding the best welding rod for dissimilar metals?

A7: LSI (Latent Semantic Indexing) keywords are related terms and phrases that Google uses to understand the overall context and meaning of content. For “Best Welding Rod For Dissimilar Metals,” LSI keywords like dissimilar metal welding techniques, welding aluminum to steel, flux core welding rods, and E309L-16 electrode help search engines know that the article comprehensively covers the topic, providing a richer, more relevant resource for users.

Q8: Can I use an E6013 rod for dissimilar metals?

A8: An E6013 welding rod is primarily designed for mild steel and low-carbon steel. While it’s very user-friendly and great for light repairs, its suitability for truly dissimilar metal combinations is limited. It might work for certain light-duty steel-to-steel dissimilar applications if the metallurgical compatibility is sufficient, but it’s not a general-purpose solution for diverse metal types like welding copper to brass or aluminum to steel. For complex dissimilar metal joints, specialized rods are always preferred.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.