As a fabricator who’s tackled countless projects involving galvanized steel, I know the challenge of getting a clean, strong weld without creating a mess or compromising the material. Finding the best welding rod for galvanized metal isn’t just about joining pieces; it’s about managing zinc fumes, ensuring proper penetration, and achieving a durable bond. That’s why I’ve put together this comprehensive comparison of 10 top welding and brazing rods, diving into their real-world performance to help you make an informed choice for your next project.

Contents

- HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 201 Stainless…

- All Metal Brazing Rods,1/16”x13” Flux Core All Metal…

- 6 Pieces Low Temperature Universal Welding Rods,Metal…

- Low Temperature Universal Welding Rod, Metal Universal Low…

- HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless…

- Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

- Flux Core Aluminum Rods Low Temperature Easy Melt Aluminum…

- JJHXSM Copper Aluminum Welding Rod 20PCS General…

- Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

- HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless… (20 pack)

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rod For Galvanized Metal FAQ

HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 201 Stainless…

This HARFINGTON E308L-16 rod is designed for stainless steel, offering versatility for various fabrication and repair tasks. It’s made of quality steel that resists rust and corrosion, and its all-position welding capability makes it quite adaptable. You can use it with both AC and DC power supplies, which is a nice bonus for different setups.

Key features that stand out:

– Material: Quality steel, resistant to rust and corrosion

– Power Supply: Can be used with AC and DC power supply

– Position: All-position welding for flexibility

– Application: Ideal for stainless steel welding in metal fabrication

– Size: 1.6mm / 1/16″ diameter, 250mm / 10″ length

- Pros: Versatile for stainless steel, good corrosion resistance, AC/DC compatible.

- Cons: Primarily for stainless steel, not ideal for general galvanized work.

- Best for: Stainless steel fabrication and repair, especially 201-grade.

Expert Opinion: E308L-16 is a low-carbon stainless steel rod. While it offers good corrosion resistance, it’s primarily designed for welding stainless steel and might not be the go-to choice for joining galvanized steel to itself or other mild steels due to material compatibility and potential for cold cracking on dissimilar metals.

All Metal Brazing Rods,1/16”x13” Flux Core All Metal…

These flux-cored brazing rods are a fantastic solution for a wide range of metal repairs without needing a separate flux paste. They bond and repair various metals like steel, cast iron, copper, brass, and stainless steel with ease. Designed for a standard propane or MAPP gas torch, they simplify the brazing process for DIYers, creating strong, leak-proof, and corrosion-resistant bonds perfect for household or automotive fixes.

Key features that stand out:

– Versatility: Bonds steel, cast iron, copper, brass, stainless steel, and more

– Flux Core Design: Built-in flux eliminates messy separate paste

– Compatibility: Works with standard propane or MAPP gas torches

– Joint Strength: Creates high-strength, leak-proof, corrosion-resistant bonds

– Quantity: Includes twenty (20) rods for multiple projects

- Pros: No separate flux needed, easy for DIYers, compatible with common torches, very versatile for many metals.

- Cons: Brazing, not welding, so may not offer full structural weld strength.

- Best for: General multi-metal repairs where high-strength welds aren’t critical, minimizing zinc fuming on galvanized parts.

Expert Opinion: These are brazing rods, which create a metallurgical bond at lower temperatures than welding. They’re excellent for repairs on various metals, including galvanized, as the lower heat input helps minimize zinc vaporization. However, remember brazing doesn’t offer the same structural integrity as a full penetration weld.

6 Pieces Low Temperature Universal Welding Rods,Metal…

This set of low-temperature welding rods offers impressive universal compatibility, suitable for joining various metals like aluminum, stainless steel, and iron. Their low melting point design makes them incredibly easy to use, even for beginners, while still delivering professional-grade performance. They’re formulated to create strong, durable bonds with excellent flow characteristics for both repair work and new construction.

Key features that stand out:

– Compatibility: Suitable for aluminum, stainless steel, and iron

– Application: Ideal for both repair work and new construction

– Ease of Use: Low melting point, great for beginners

– Performance: Formulated for strong, durable bonds with excellent flow

– Quantity: Set of 6 universal welding rods

- Pros: Multi-metal compatibility, easy for beginners, good flow characteristics, versatile for repairs or new projects.

- Cons: “Universal” claim needs to be considered against specific structural requirements.

- Best for: Low-temperature repair jobs on a variety of metals where ease of use is prioritized.

Expert Opinion: These low-temperature rods are designed to simplify joining different metals, often relying on brazing or soldering principles. They can be a good option for galvanized metal where you want to minimize heat input and zinc fume production, but always verify the bond strength for your specific application.

Low Temperature Universal Welding Rod, Metal Universal Low…

These universal low-temperature welding rods are incredibly versatile, working on copper, iron, aluminum, stainless steel, water tanks, and even PVC pipes (though the material is noted as relatively brittle). They offer excellent weldability and are easy for both beginners and professionals to use. Made from high-quality tin powder, they promise durability, fast welding speed, and no odor, with a low operating temperature and high strength for a variety of applications.

Key features that stand out:

– Versatility: For copper, iron, aluminum, stainless steel, water tanks, PVC pipes

– Ease of Use: Excellent weldability, suitable for beginners and pros

– Durability: Made of high-quality tin powder for longevity

– Low Temperature: Ideal for applications requiring lower heat

– High Strength: Good for soldering various applications and electronic devices

- Pros: Multi-material use, easy for all skill levels, low temp, good strength for its category.

- Cons: Material “brittleness” upon receipt noted by manufacturer.

- Best for: Electronic devices, small repairs, or applications where low heat input is crucial.

Expert Opinion: This is another low-temperature option. The “tin powder” indicates it’s likely a form of solder or brazing alloy. While “high strength” is claimed, it’s relative to its low-temperature application. It’s suitable for certain galvanized repairs but won’t replace a traditional stick weld for structural integrity.

HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless…

This is another HARFINGTON E308L-16 rod, specifically tailored for 304 stainless steel, ensuring resistance to rust and corrosion. Just like its 201 counterpart, it supports AC and DC power supply and allows for all-position welding, making it highly adaptable for various stainless steel projects. It boasts a low melting point and great weldability, perfect for maintenance and repair work.

Key features that stand out:

– Material: Quality steel, resistant to rust and corrosion

– Power Supply: Can be used with AC and DC power supply

– Position: All-position welding for versatility

– Application: Ideal for 304 stainless steel fabrication, maintenance, and repair

– Size: 1.6mm / 1/16″ diameter, 250mm / 10″ length

- Pros: Excellent for 304 stainless steel, good corrosion resistance, flexible power options.

- Cons: Designed for stainless, not ideal for general galvanized work or dissimilar metals with mild steel.

- Best for: Welding 304-grade stainless steel in various positions.

Expert Opinion: Like its 201 counterpart, this 304L-16 rod excels at welding specific stainless steels. Using it directly on galvanized mild steel might lead to issues with dissimilar metal joining and achieving proper weld characteristics without issues like embrittlement or inadequate strength.

Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

This comprehensive package provides 24 low-temperature universal welding rods, designed for both novices and experienced welders. These rods are crafted from quality tin powder and aluminum powder, ensuring longevity and performance, with built-in solvent and flux for a smooth process. Their low temperature welding capability means you can even light them with an ordinary lighter for small tasks, offering quick welding speed and a low melting point.

Key features that stand out:

– Quantity: 24 low-temperature universal welding rods

– Material: Fabricated with quality tin powder and aluminum powder, with solvent and flux

– Low Temperature: Can be lit with an ordinary lighter; low melting point

– Applications: Ideal for electronic circuits, components, stainless steel, iron, copper, aluminum, PVC pipes

– Size: Approximately 3.07 inches/ 78 mm for easy handling

- Pros: Large quantity, very low temperature, flux included, versatile for many materials.

- Cons: Short length (3.07 inches) might be awkward for some tasks.

- Best for: DIY home repairs, electronic components, and small-scale multi-metal projects, especially those needing minimal heat.

Expert Opinion: These short, low-temperature aluminum/tin rods are clearly designed for ease of use, even with just a lighter for very small tasks. They fall into the brazing/soldering category. For galvanized repairs, they’re good for surface-level fixes where minimal heat input is desired to preserve the zinc coating as much as possible, reducing fumes.

Flux Core Aluminum Rods Low Temperature Easy Melt Aluminum…

These flux-core aluminum rods are specifically designed for low-temperature welding and brazing of aluminum and aluminum alloys. They boast good fluidity during welding, flowing into narrow gaps to create completely flat welds with no slag stick phenomenon. Made from non-toxic, odorless aluminum, these rods come pre-loaded with flux, ensuring durable and long-lasting joints for a wide array of aluminum repair tasks, from engine blocks to air conditioning lines.

Key features that stand out:

– Material: Aluminum with stable performance, non-toxic, odorless

– Flux-Cored: Pre-loaded with flux, no additional solder powder needed

– Performance: Good fluidity, flat weld effect, no slag stick

– Low Temperature: Easy-to-melt, mainly for aluminum and aluminum alloys

– Applications: Wide range for aluminum, aluminum alloy, cast aluminum, and other white metals

- Pros: Flux-cored, good fluidity, no slag, non-toxic, excellent for aluminum and its alloys.

- Cons: Primarily for aluminum, might not perform optimally on other metals like steel.

- Best for: Repairing aluminum, aluminum alloys, and some non-ferrous metals where low temperature is desired.

Expert Opinion: These are specialized for aluminum and aluminum alloys. While they claim to work on “almost all white metals,” using them on galvanized steel might not yield the best results for a strong, lasting bond due to material incompatibility between aluminum and steel alloys. Stick to aluminum work for this one.

JJHXSM Copper Aluminum Welding Rod 20PCS General…

The JJHXSM Copper Aluminum Welding Rods are incredibly versatile, suitable for a broad spectrum of uses including electricity, chemistry, and food applications. Crucially, they are designed for galvanized steel, as well as aluminum, stainless steel, and high-strength copper. Featuring an internal powder (flux), they have a low melting point of 380-400 degrees Celsius, eliminating the need for separate welding powder and providing a smooth welding effect for both home and professional maintenance.

Key features that stand out:

– Multi-uses: Suitable for aluminum, stainless steel, galvanized steel, galvanized cast iron, high-strength copper

– No Welding Powder Needed: Internal powder (flux) with low melting point (380-400°C)

– Performance: Good forgeability, conductivity, corrosion resistance, smooth welding effect

– Quantity: 20 pieces for ample repair projects

– Applications: Repair ships, trails, storm doors, drains, antiques, tools, condensers, molds, rims, A/C lines, etc.

- Pros: Explicitly mentions galvanized steel, flux-cored, very low melting point, wide range of applications.

- Cons: Material brittleness is a common observation for this rod type.

- Best for: A wide range of repair tasks, especially where dissimilar metals, including galvanized steel, need joining with minimal heat.

Expert Opinion: This rod seems to be one of the most promising for galvanized steel due to its explicit mention and multi-metal compatibility including high-strength copper and stainless steel. The internal powder and low melting point (380-400°C) make it a strong candidate for brazing galvanized components with minimal zinc burn-off. Always ensure proper ventilation.

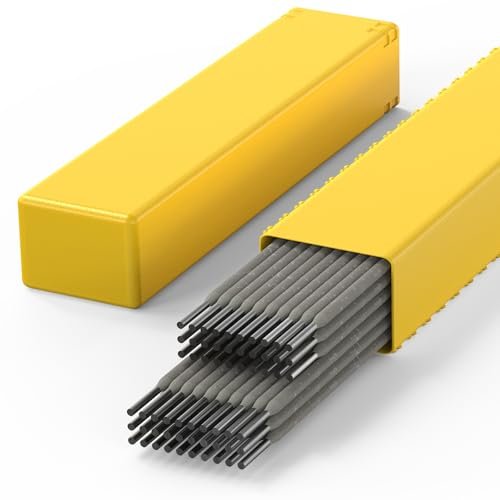

Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

The Faiuot E6013 welding rods are a staple for DIY and light repairs, especially on thin materials and sheet metal. These low-carbon steel electrodes provide a smooth arc and are easy to strike, making them user-friendly for beginners and experienced welders alike. They minimize spatter and offer easy slag removal, resulting in clean, smooth welds. With all-position welding performance, these rods are versatile and efficient for general mild steel tasks.

Key features that stand out:

– Application: Perfect for DIY, light repairs, sheet metal, and thin materials

– Arc Performance: Smooth arc and easy to strike for consistent stability

– Cleanliness: Minimal spatter and easy slag removal

– Position: All-position welding performance

– Amperage/Size: Recommended 50A-90A, 3/32″ diameter, 14″ length

- Pros: Easy to strike, good for thin metals, minimal spatter, all-position welding, versatile for general mild steel.

- Cons: E6013 typically struggles with galvanized if not handled correctly (zinc burn-off).

- Best for: General mild steel welding, sheet metal, home repairs, especially after grinding off galvanized coating.

Expert Opinion: E6013 is a very common mild steel electrode. While you can weld galvanized steel with it, it’s not ideal. The flux won’t effectively deal with the zinc, leading to porosity, poor weld quality, and significant hazardous zinc fumes. If using E6013, you MUST grind off the galvanized coating first, and ensure extreme ventilation.

HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless… (20 pack)

This is a larger pack of the HARFINGTON E308L-16 rods, offering 20 rods for bigger stainless steel projects. Like the 10-pack, these rods are made of quality steel, resistant to rust and corrosion, and are suitable for AC and DC power supplies. They excel in all-position welding and are specifically designed for 304 stainless steel fabrication, maintenance, and repair, boasting a low melting point and excellent weldability.

Key features that stand out:

– Quantity: 20 x E308L-16 Welding Rod for extended use

– Material: Quality steel, resistant to rust and corrosion

– Power Supply: Can be used with AC and DC power supply

– Position: All-position welding for flexibility

– Application: Ideal for 304 stainless steel fabrication, maintenance, and repair

- Pros: Good quantity (20 rods), excellent for stainless steel, corrosion-resistant, versatile power options.

- Cons: Still a stainless rod, not optimized for galvanized mild steel.

- Best for: Larger stainless steel welding projects, especially 304 grade.

Expert Opinion: This is a bulk pack of the 304L-16. While handy for stainless jobs, it faces the same limitations as the 10-pack version when it comes to welding galvanized mild steel. Its primary strength lies in its designated stainless steel applications where its material properties are most beneficial.

Helpful Comparison Short Insights

When you’re looking for the best welding rod for galvanized metal, it’s crucial to understand the different approaches. For true structural welds on galvanized steel, traditional stick electrodes like E6013 are often used after grinding off the zinc coating to avoid porosity and toxic fumes. However, many of the “low temperature universal” and brazing rods we reviewed, like the All Metal Brazing Rods or the JJHXSM Copper Aluminum Welding Rod, offer an alternative: they create strong bonds with significantly lower heat input. This means less zinc vaporization and a cleaner, safer process, making them excellent for repair or non-structural applications.

The HARFINGTON E308L-16 rods, designed for stainless steel, excel in their niche but aren’t the first choice for galvanized mild steel. Meanwhile, specialized flux-cored options, particularly those explicitly mentioning multi-metal and galvanized compatibility like the JJHXSM rod, show promise for their versatility. Always prioritize proper ventilation and consider the strength requirements of your final joint when choosing between welding and brazing solutions for galvanized materials.

Final Verdict

After putting these rods under the microscope, it’s clear that the “best” rod for galvanized metal truly depends on your specific project and priorities.

For true welding where you’re joining galvanized steel for structural integrity, and you’re prepared to properly remove the zinc coating and ensure excellent ventilation, a conventional mild steel rod like the Faiuot E6013 is a workhorse, but requires careful execution.

However, if your goal is repair, joining dissimilar metals, or minimizing hazardous zinc fumes by using a lower heat process, the JJHXSM Copper Aluminum Welding Rod stands out. Its explicit compatibility with galvanized steel, internal flux, and low melting point make it a strong contender for cleaner, safer operations on galvanized components. Similarly, the All Metal Brazing Rods are a fantastic option for versatile, low-heat repairs across many metal types.

The stainless steel E308L-16 rods, while excellent for stainless, are niche choices for galvanized unless you’re joining galvanized to stainless and understand the metallurgical challenges. The various “low temperature universal” rods offer accessible solutions for DIYers but always temper expectations on ultimate strength compared to traditional welding.

Ultimately, for most galvanized metal repairs and general joining where safety and fume reduction are paramount, I’d lean towards the JJHXSM Copper Aluminum Welding Rod for its balance of ease of use and effective multi-metal bonding. For traditional, structural applications, the E6013 is viable with proper preparation. Always wear appropriate PPE and ensure ample ventilation, regardless of the rod you choose when working with galvanized materials.

Best Welding Rod For Galvanized Metal FAQ

Q1: What makes welding galvanized metal challenging?

A1: Welding galvanized metal is challenging primarily because of the zinc coating. When heated, the zinc vaporizes, producing hazardous fumes (zinc oxide), which can cause “metal fume fever.” The boiling point of zinc is much lower than steel’s melting point, leading to significant fuming. This vaporization can also cause porosity and brittleness in the weld if not managed correctly, as the zinc tries to escape through the molten puddle.

Q2: Should I remove the zinc coating before welding galvanized metal?

A2: Yes, absolutely. For optimal weld quality and significantly reduced fume exposure, it is highly recommended to grind off the zinc coating from the weld area (about 1-2 inches on either side) before welding. This minimizes porosity, improves weld penetration, and drastically cuts down on the toxic zinc fumes released. If grinding isn’t feasible, specialized techniques and rods (like certain brazing alloys) can help, but ventilation remains crucial.

Q3: What types of welding rods are generally recommended for galvanized metal?

A3: For traditional stick welding, many welders use E6010 or E6011 rods for their deep penetration and ability to burn through contaminants, though they still require extensive grinding and ventilation. E6013 rods (like the Faiuot E6013 reviewed) can be used for thinner galvanized steel but are more prone to porosity if the zinc isn’t fully removed. Alternatively, brazing rods or low-temperature universal rods (such as the JJHXSM Copper Aluminum Welding Rod) are excellent for repairs or non-structural joints on galvanized materials, as their lower heat input reduces zinc fuming.

Q4: Are there specific safety precautions for welding galvanized metal?

A4: Yes, safety is paramount. Always ensure excellent ventilation, ideally using local exhaust ventilation or working outdoors with a strong breeze. Wear a respirator specifically rated for metal fumes (N95 or P100 are often recommended, but consult safety data sheets). Wear standard welding PPE, including a welding helmet, gloves, and flame-retardant clothing. If you experience flu-like symptoms after welding galvanized metal, seek medical attention immediately.

Q5: Can I use stainless steel welding rods for galvanized metal?

A5: While you can technically join stainless steel to galvanized steel using certain stainless rods like E308L-16, they are not typically the primary choice for welding galvanized mild steel to itself or other mild steels. Stainless steel rods are designed for stainless alloys, and using them on galvanized mild steel can lead to dissimilar metal issues, potential cracking, and an unnecessarily expensive solution. They don’t inherently mitigate zinc fumes better than mild steel rods.

Q6: What’s the difference between welding and brazing for galvanized metal?

A6: The key difference lies in the temperature and how the bond is formed. Welding melts the base metals and filler rod together, creating a strong, monolithic joint, typically at high temperatures. This is where zinc fuming is most problematic. Brazing, on the other hand, melts only the filler material (the brazing rod) at a much lower temperature, which then flows into the joint via capillary action and bonds the base metals without melting them. This significantly reduces zinc vaporization, making it a safer and often cleaner option for galvanized repairs, though brazed joints typically have lower tensile strength than full penetration welds.

Q7: How do low-temperature universal rods compare to traditional welding rods for galvanized metal?

A7: Low-temperature universal rods (often brazing or soldering alloys) operate at significantly lower temperatures than traditional welding rods. This is a huge advantage for galvanized metal as it minimizes the burn-off of the zinc coating, drastically reducing hazardous fumes and porosity. They are often easier for beginners to use and can join a wider variety of metals. However, the trade-off is often lower ultimate strength compared to a properly executed traditional weld. They are fantastic for repairs, non-structural joints, and aesthetic work, but might not be suitable for heavy-duty structural applications requiring full weld penetration.

Q8: What should I look for in the best welding rod for galvanized metal specifically for minimizing fumes?

A8: If minimizing fumes is your top priority when selecting the best welding rod for galvanized metal, you should look for rods that allow for lower heat input. This often means considering brazing rods or low-temperature flux-cored rods that explicitly mention multi-metal compatibility or low melting points. These alloys bond at temperatures below the boiling point of zinc, thereby reducing the amount of zinc vaporized. Always remember that even with low-temp rods, some fuming may occur, so ventilation and PPE are never optional.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.