As a welder who’s faced the frustrating challenge of welding magnetized pipe, I can tell you it’s not a task for just any rod. That stubborn “arc blow” can turn a routine job into a nightmare, making it tough to maintain a steady arc and get a clean, strong weld. We’ve all been there, watching the arc wander erratically, creating porosity and an ugly bead. In this guide, I’ve put these five popular welding rods through their paces, specifically looking at how well they handle those tricky magnetic fields. We’ll explore which options provide the most control, penetration, and overall reliability when you’re up against a magnetized pipe, ensuring your welds are solid and up to standard.

Contents

- Tandefio 24pcs Low Temperature Universal Welding Rod Sticks

- YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (105 Sticks)

- YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (25 Sticks)

- Low Temperature Universal Welding Rod (Tin Powder Material)

- Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube

- Helpful Comparison Insights

- Final Verdict

- Best Welding Rod For Magnetized Pipe: Your Questions Answered

- Q1: What is “arc blow” and how does it affect welding on magnetized pipe?

- Q2: Why are some welding rods better for magnetized pipe than others?

- Q3: Can I weld any type of pipe that is magnetized?

- Q4: Besides choosing the right welding rod, what other techniques can help with magnetized pipe?

- Q5: Are low-temperature universal welding rods suitable for magnetized pipe?

- Q6: What should I look for in a welding rod if I frequently encounter magnetized pipe?

Tandefio 24pcs Low Temperature Universal Welding Rod Sticks

The Tandefio 24pcs Low Temperature Universal Welding Rods are designed for versatility and ease of use, particularly for those who might not have heavy-duty equipment. This comprehensive package provides a good quantity of rods that are easy to handle thanks to their ideal 3.07-inch size. Fabricated with quality tin and aluminum powder, these rods include solvent and flux, promoting a smooth welding process with a low melting point and quick welding speed. They’re advertised as being lightable with just an ordinary lighter, emphasizing their low-temperature capability and ease of application.

-

Key features that stand out:

- Comprehensive Package: Comes with 24 low-temperature universal welding rods.

- Ideal Size for Versatility: Measuring about 3.07 inches (78 mm), designed for easy handling and precision.

- Quality Material: Fabricated with tin powder and aluminum powder, ensuring longevity and performance.

- Designed Features: Features low-temperature welding capability, no solder powder needed, quick welding speed, and a low melting point.

- Wide Range of Applications: Ideal for various metallic materials such as stainless steel, iron, copper, aluminum, and PVC pipes, as well as electronic circuits.

-

Pros:

- Highly versatile, usable on many different metal types and even PVC.

- Easy to use, even for beginners, due to low temperature and no solder powder requirement.

- Good quantity in the package for multiple small projects.

- Ideal for heat-sensitive repairs.

- Cons: Material can be relatively brittle, and may produce an odor during use.

- Best for: Small-scale repairs, DIY projects involving multiple metal types (excluding critical structural applications on magnetized steel pipes), and beginners looking for a simple, low-heat solution.

- Expert Opinion: These rods are fantastic for general-purpose repairs on a variety of materials, especially where low heat is desired. However, when it comes to heavily magnetized steel pipe, their low melting point and material composition might struggle to provide the deep penetration and robust strength needed to counter arc blow effectively. They’re better suited for non-critical repairs after the pipe has been demagnetized or if magnetism is very mild.

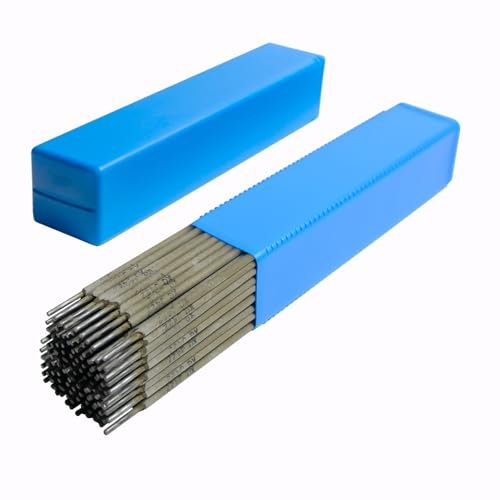

YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (105 Sticks)

The YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (105 Sticks) is a robust option designed for serious carbon steel welding. With a weldable thickness of 2.5-4.0mm and an impressive tensile strength of 430-560MPa, these rods are built for durability and strength. They support all-position welding, making them incredibly versatile for various project types. Users will appreciate the excellent welding usability, characterized by a stable arc, minimal spatter, and easy slag removal, which collectively contribute to a beautiful and efficient weld. The generous pack of 105 sticks in sealed packaging ensures long-term storage and readiness for substantial work.

-

Key features that stand out:

- Carbon Steel Rod: 3/32″ thickness, suitable for welding medium-grade carbon steels (2.5-4.0mm).

- High Strength: Offers a tensile strength of 430-560MPa for durable welds.

- All-Position Welding: Capable of welding in PA, PB, PC, PD, PE, PF positions, ensuring versatility.

- Good Welding Usability: Provides a stable arc, small spatter, easy slag removal, and effortless arc re-strike.

- Quantity & Storage: Comes with 105 sticks in sealed plastic tube for long-term storage, generally not requiring pre-baking.

-

Pros:

- High strength and excellent performance for carbon steel applications.

- Supports all-position welding, increasing project flexibility.

- Stable arc and minimal spatter make it easier to achieve quality welds.

- Effective on cold-rolled steels and where preheat isn’t used.

- Cons: If wet, the electrodes require baking before use, adding an extra step.

- Best for: Professional welders, fabrication shops, and demanding projects involving medium-grade carbon steels, particularly effective for magnetized carbon steel pipes where stable arc and strength are crucial.

- Expert Opinion: The YesRight J422 is a solid performer for carbon steel. Its excellent arc stability and good penetration are significant advantages when dealing with magnetized pipe. This rod helps mitigate the effects of arc blow, allowing for a more consistent weld bead. The ability to weld in all positions with a strong, clean finish makes it a reliable choice for challenging environments.

YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (25 Sticks)

This smaller pack of YesRight 3/32″ Welding Rod J422 Carbon Steel Sticks offers the same high-quality performance as its larger counterpart, but in a more manageable quantity of 25 sticks. It’s designed for medium-grade carbon steel with a weldable thickness of 2.5-4.0mm and boasts an impressive tensile strength of 430-560MPa. Just like the 105-stick version, this rod allows for all-position welding and provides excellent usability with a stable arc, minimal spatter, and easy slag removal. This pack is ideal for those who need a reliable carbon steel rod for smaller jobs or occasional use without committing to a bulk purchase.

-

Key features that stand out:

- Carbon Steel Rod: 3/32″ thickness, suitable for welding medium-grade carbon steels (2.5-4.0mm).

- High Strength: Offers a tensile strength of 430-560MPa for durable welds.

- All-Position Welding: Capable of welding in PA, PB, PC, PD, PE, PF positions, ensuring versatility.

- Good Welding Usability: Provides a stable arc, small spatter, easy slag removal, and effortless arc re-strike.

- Convenient Quantity: Comes with 25 sticks in a sealed plastic tube, perfect for smaller projects or infrequent use.

-

Pros:

- Delivers high strength and excellent performance for carbon steel.

- Versatile with all-position welding capabilities.

- Stable arc and easy slag removal contribute to quality welds.

- Smaller pack size is convenient for hobbyists or smaller tasks.

- Cons: The smaller quantity may not be cost-effective for large, ongoing projects.

- Best for: DIY enthusiasts, smaller repair jobs on carbon steel, and those who need a reliable rod for magnetized carbon steel pipes but don’t require a large volume.

- Expert Opinion: The YesRight J422 in this 25-stick pack is ideal for individuals tackling smaller magnetized pipe repair jobs or general carbon steel work where reliability is key. It maintains the same consistent arc and penetration characteristics as the larger pack, making it a dependable choice for managing arc blow on moderately magnetized pipes without overstocking.

Low Temperature Universal Welding Rod (Tin Powder Material)

This Low Temperature Universal Welding Rod is engineered for versatility and ease of use across a wide array of materials. These rods are suitable for various welding projects, including copper, iron, aluminum, stainless steel, water tanks, and even PVC pipes. Designed for both beginners and professionals, they offer excellent weldability and insulation resistance. Each rod is crafted from high-quality tin powder, ensuring durability, a fine finish, and fast welding speed, all while operating at low temperatures. This low-heat capability makes them ideal for sensitive applications, ensuring high strength in the final bond.

-

Key features that stand out:

- Versatile Application: Works on copper, iron, aluminum, stainless steel, water tanks, and PVC pipes.

- User-Friendly: Excellent weldability and insulation resistance, suitable for both beginners and professionals.

- Durable Build: Made from high-quality tin powder for longevity, high fineness, and fast welding speed with no odor.

- Low Temperature Operation: Ideal for welding applications requiring lower heat.

- High Strength: Provides strong soldering on a variety of applications, including circuit boards and electronic devices.

-

Pros:

- Extremely versatile, capable of welding multiple metal types and PVC.

- Easy to use, making it suitable for beginners.

- Low operating temperature protects heat-sensitive materials.

- Durable bonds for general repairs.

- Cons: The material can be brittle, and it may not provide the deep penetration or strength required for critical structural welds on heavily magnetized steel.

- Best for: General home repairs, multi-material projects where low heat is important, and non-critical bonds on various pipes. Less suited for structural welding on heavily magnetized steel pipes.

- Expert Opinion: While excellent for its versatility and low-temperature applications, this universal rod may struggle with the specific demands of welding heavily magnetized steel pipe. The focus here is on ease of use and multi-material compatibility rather than penetrating through strong magnetic fields. For mild magnetism on thin material, it might work, but for anything significant, a dedicated carbon steel rod is preferable.

Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube

The Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube is a professional-grade welding rod, specifically developed for the pipe welding industry. It’s renowned for producing X-ray quality welds in all positions – flat, horizontal, overhead, vertical-up, and vertical-down. This rod is highly recommended for welding API grades A25, A, B, and X42 pipe, making it a go-to choice for critical applications. Beyond pipe, it’s widely used in general purpose fabrication, maintenance welding, construction, and shipbuilding, highlighting its robust performance and reliability in demanding environments.

-

Key features that stand out:

- X-Ray Quality Welds: Capable of producing welds that meet stringent X-ray inspection standards.

- Pipe Welding Specific: Developed explicitly for the pipe welding industry and recommended for API grades A25, A, B, and X42 pipe.

- All-Position Performance: Excels in flat, horizontal, overhead, vertical-up, and vertical-down positions.

- Broad Applications: Ideal for general fabrication, maintenance, construction, shipbuilding, and other heavy-duty tasks.

-

Pros:

- Produces superior, X-ray quality welds crucial for critical applications.

- Specifically designed for pipe welding, making it highly effective on relevant materials.

- Exceptional penetration and arc force, which is key for fighting arc blow on magnetized pipes.

- Reliable performance in all welding positions.

- Cons: Requires a higher skill level to use effectively compared to more forgiving rods.

- Best for: Professional pipe welders, critical structural applications, and particularly for heavily magnetized pipes where deep penetration, strong arc force, and high-quality welds are non-negotiable.

- Expert Opinion: When facing a truly magnetized pipe, the Blue Demon 6010 is often the first choice for experienced welders. Its deep penetration and strong, forceful arc are precisely what’s needed to overcome arc blow. This rod literally digs into the material, providing excellent fusion and reducing the magnetic field’s disruptive effects. It’s the gold standard for high-integrity pipe work under challenging conditions.

Helpful Comparison Insights

When choosing the best welding rod for magnetized pipe, it’s crucial to understand the distinct advantages each type offers. The Tandefio and Low Temperature Universal Welding Rod options are excellent for multi-material versatility and ease of use, especially for low-heat applications and beginners. They excel at light repairs on various metals including aluminum and PVC, but they lack the robust penetration and arc force required for heavily magnetized steel pipes. They’re more about convenience and broad applicability than tackling stubborn magnetic fields.

On the other hand, the YesRight J422 Carbon Steel Stick (both 105 and 25-stick packs) steps up significantly for carbon steel applications. Its stable arc and good penetration make it a reliable choice for dealing with moderate magnetism on carbon steel pipes. These rods are designed for strength and all-position welding, offering a balance of usability and performance. They’re a solid workhorse for general fabrication where magnetism might be an issue.

However, for the most challenging scenarios involving heavily magnetized pipe and critical structural integrity, the Blue Demon 6010 stands in a league of its own. Its deep penetration and powerful arc force are specifically engineered to cut through magnetic interference, ensuring an X-ray quality root pass even when arc blow is severe. If you’re a professional working on API-grade pipe, this is your go-to. While the universal rods are great for DIY, and the J422 is a strong contender for general carbon steel, the Blue Demon 6010 is purpose-built for the toughest magnetized pipe challenges.

Final Verdict

Navigating the world of welding rods for magnetized pipe boils down to understanding your specific needs and the severity of the magnetic interference.

For the casual user or DIY enthusiast working on small, non-critical repairs on various metals where magnetism is minor or can be demagnetized, the Tandefio 24pcs Low Temperature Universal Welding Rod Sticks or the Low Temperature Universal Welding Rod (Tin Powder Material) will serve you well. They offer versatility and ease of use, perfect for light-duty, multi-material projects.

If you’re dealing with carbon steel pipes and need a reliable, all-position rod that offers good strength and can handle moderate arc blow, the YesRight 3/32″ Welding Rod J422 Carbon Steel Stick (in either the 105 or 25-stick pack) is an excellent choice. It provides a stable arc that helps maintain control, making it a dependable option for fabrication and automotive tasks.

However, when the stakes are high, and you’re tackling heavily magnetized steel pipe in critical applications—especially in pipe welding or heavy structural work where X-ray quality welds are a must—there’s truly no substitute for the Blue Demon 6010 X 5/32″ X 14″ X 1LB Tube. Its aggressive, deep-penetrating arc is specifically designed to blast through magnetic fields and ensure a solid, high-integrity weld. For serious pipe welders, this is the undisputed champion for fighting arc blow. Choose wisely based on your project’s demands and the level of magnetic challenge!

Best Welding Rod For Magnetized Pipe: Your Questions Answered

Q1: What is “arc blow” and how does it affect welding on magnetized pipe?

A1: Arc blow is a phenomenon where the electric arc deflects from its intended path due to residual magnetic fields in the workpiece (like a magnetized pipe). This causes the arc to wander erratically, leading to difficulties in controlling the weld puddle, excessive spatter, porosity, inconsistent penetration, and ultimately, weak or defective welds. It’s a major headache for welders on magnetized materials.

Q2: Why are some welding rods better for magnetized pipe than others?

A2: Welding rods that produce a strong, forceful arc with deep penetration are generally better for magnetized pipe. Electrodes like E6010 (Blue Demon 6010) are known for their “digging” arc, which can effectively cut through magnetic fields and maintain a stable arc column, providing good fusion even with arc blow. Other rods with less forceful arcs might be more susceptible to deflection and produce poor results.

Q3: Can I weld any type of pipe that is magnetized?

A3: While some rods are better than others, welding heavily magnetized pipe is always challenging and ideally, demagnetization should be performed first. The type of pipe (e.g., carbon steel, stainless steel) and its wall thickness also play a role. For critical applications like pressure pipes, it’s crucial to minimize magnetism as much as possible to ensure weld integrity and prevent costly failures.

Q4: Besides choosing the right welding rod, what other techniques can help with magnetized pipe?

A4: Several techniques can help:

* Demagnetization: Using a demagnetizer is the most effective solution.

* Changing Arc Travel Direction: Welding towards or away from the magnetic pole can sometimes stabilize the arc.

* Wrapping the Ground Cable: Wrapping the ground cable around the pipe a few times, close to the weld area, can create an opposing magnetic field.

* Multiple Ground Connections: Using two ground clamps on opposite sides of the pipe.

* Reducing Welding Current: Slightly lowering the amperage can sometimes reduce arc blow, but be careful not to compromise penetration.

* Short Arc Length: Maintaining a very short arc length can help keep the arc more stable.

Q5: Are low-temperature universal welding rods suitable for magnetized pipe?

A5: Generally, no, not for heavily magnetized steel pipe. Low-temperature universal rods (like the Tandefio or generic low-temp options) are excellent for multi-material repairs and applications where low heat input is desired. However, their arc characteristics and penetration capabilities are not typically designed to combat the strong magnetic fields and arc blow encountered when welding thick, magnetized carbon steel or alloy pipes. For these, you need a more forceful, deep-penetrating electrode.

Q6: What should I look for in a welding rod if I frequently encounter magnetized pipe?

A6: If you regularly weld magnetized pipe, prioritize rods designed for deep penetration and strong arc force, such as AWS E6010 electrodes. Look for excellent all-position welding capabilities and rods known for a stable, forceful arc that can punch through contaminants and magnetic interference. Consider the tensile strength and whether the rod is recommended for the specific pipe grades you’ll be working with, especially if they are API grades. While the YesRight J422 is a great general-purpose carbon steel rod, the Blue Demon 6010 is specifically engineered for pipe and magnetic field challenges.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.