When it comes to working with manganese, I’ve learned firsthand that choosing the right welding rod isn’t just a preference—it’s absolutely critical for a strong, durable, and crack-free weld. High manganese steel is renowned for its toughness and work-hardening properties, making it fantastic for applications where abrasion and impact are a constant, but also notoriously tricky to weld. Over the years, I’ve tried various rods, and I’m excited to share my insights on the best welding rod for manganese based on real-world application and performance. This guide will walk you through seven reliable options, helping you make an informed decision for your next project, whether it’s hardfacing, repair, or fabrication.

Contents

- 1. Forney 42401 Supercote Hardfacing Welding Rod, 5/32-Inch,…

- 2. YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

- 3. ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

- 4. YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

- 5. Forney 42450 Supercote Hardfacing Welding Rod, 5/32-Inch,…

- 6. 6 Pieces Low Temperature Universal Welding Rods,Metal…

- 7. YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick…

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rod For Manganese: Your Top Questions Answered

- Q1: Why is choosing the right welding rod for manganese steel so important?

- Q2: What are the main types of welding rods generally recommended for high manganese steel?

- Q3: Do I need to preheat manganese steel before welding?

- Q4: What are the common issues to watch out for when welding manganese?

- Q5: Can I use a general-purpose rod like E6013 for manganese steel?

- Q6: What’s the importance of low hydrogen content in a welding rod for manganese?

- Q7: How does impact resistance relate to hardfacing rods for manganese?

1. Forney 42401 Supercote Hardfacing Welding Rod, 5/32-Inch,…

For those tackling moderate abrasion and low impact applications on manganese steel, the Forney 42401 is a solid, cost-effective choice. I’ve found it excellent for building up worn parts, laying down a tough surface that resists wear. It delivers a smooth arc and the slag comes off easily, which saves a lot of cleanup time. This rod is specifically designed to create crack-resistant welds, which is a major plus when dealing with manganese’s inherent challenges.

Key features that stand out:

– Excellent low cost rod for moderate abrasion and low impact

– Crack resistant weld properties

– RC 52-58 hardness for durable surfaces

– Smooth arc action and easy slag removal

– Typical applications include surface buildup on new or worn machine parts of cast steel and manganese steel

Pros:

– Cost-effective solution for hardfacing.

– Good crack resistance, vital for manganese.

– Easy to use with smooth arc and slag removal.

– Provides a durable, wear-resistant surface.

Cons:

– Best suited for moderate abrasion and low impact, not extreme conditions.

Best for: Surface buildup and hardfacing on cast and manganese steel where moderate abrasion and low impact are present.

Expert Opinion: This rod offers a good balance of affordability and performance for general hardfacing tasks on manganese. Its crack resistance is a key benefit, especially for base metals prone to weld cracking.

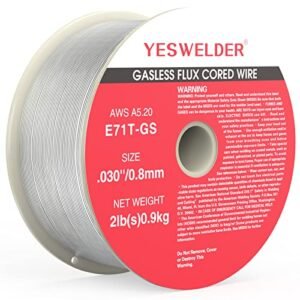

2. YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

While often associated with mild steel, the YESWELDER ER70S-6 TIG rod can be an interesting option for specific manganese applications, particularly when precise control and a clean finish are paramount. Its high manganese and silicon deoxidizer content contribute to a very smooth bead and minimal spatter, especially with 100% CO2 or an argon blend shielding gas. I’ve used this for joining lower alloy manganese components where excellent bead appearance and structural integrity are required, though it’s not a hardfacing rod.

Key features that stand out:

– ER70S-6 is a gas shield copper coated carbon steel welding rod

– Highest combination of manganese and silicon deoxidizers

– Permits higher welding currents with 100% CO2 shielding gas

– Smoother weld bead with little to zero post-weld cleanup

– Versatile application for a variety of mild and low alloy steel

Pros:

– Produces exceptionally smooth and clean welds.

– Excellent deoxidizing properties minimize porosity.

– Can be used with various shielding gases for tailored results.

– Great for applications needing precision and minimal post-weld work.

Cons:

– Requires TIG equipment and shielding gas, which adds complexity for some users.

Best for: TIG welding mild and low-alloy steels, potentially for precise joining of lower manganese components where aesthetic and structural quality are critical, and hardfacing isn’t the primary goal.

Expert Opinion: For TIG welding professionals, this rod offers superior arc stability and bead quality. While primarily for mild steel, its deoxidizer package can be beneficial in certain manganese joining situations where proper filler metal selection is carefully matched to the base metal.

3. ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

The ARCCAPTAIN E7018 rod is a staple for a reason, and when welding manganese, low hydrogen content is your best friend. This rod significantly reduces the risk of hydrogen-induced cracking, which is a common issue with manganese. I’ve found it delivers outstanding X-ray quality welds with high tensile strength. It’s an iron powder electrode that provides a smooth, stable arc with minimal spatter, making it very user-friendly across all positions.

Key features that stand out:

– E7018 is an iron powder electrode with low hydrogen content

– Delivering high-quality x-ray welds

– Suitable for welding in any position using AC or DC reverse polarity

– Outstanding X-ray values, high tensile strength, and good resistance to cracking

– High melting efficiency, a smooth and stable arc, and less spatter

Pros:

– Low hydrogen content significantly reduces cracking risks in manganese.

– Produces high-quality, strong welds suitable for critical applications.

– Works in all positions with both AC and DC current.

– Smooth arc and minimal spatter enhance user experience.

Cons:

– Requires proper storage to maintain its low hydrogen properties.

Best for: Structural welding, high-pressure pipelines, and any critical application involving manganese and high carbon steels where crack resistance and high tensile strength are paramount.

Expert Opinion: E7018 is a go-to for many challenging alloys, and its low-hydrogen properties make it invaluable for welding manganese steels, especially when preheat and controlled cooling are also observed.

4. YESWELDER E7018 1/8” 5LB Welding Rod Low Hydrogen Carbon…

Much like the ARCCAPTAIN, the YESWELDER E7018 is another excellent low-hydrogen option, but with a slightly larger 1/8” diameter for heavier applications. This rod is a workhorse for welding medium-grade carbon steels and low-alloy structurals, where manganese might be present. Its low-hydrogen composition is key for preventing porosity and cracking, especially on cold-rolled steels. I’ve used these rods for robust structural repairs and heavy fabrication where manganese steel components are involved, appreciating the steady arc and high deposition efficiency.

Key features that stand out:

– E7018 is a low-hydrogen iron powder type electrode

– Produces high quality x-ray welds

– Can be used in all positions on AC or DC reverse polarity welding current

– Recommended for welding medium grade carbon steels where no preheat is used, and on cold rolled steels normally exhibiting excessive porosity

– Steady arc, low spatter, excellent re-striking ability and high deposition efficiency

Pros:

– Low hydrogen content is crucial for preventing cracking in manganese.

– Excellent for medium to high carbon steels and structural work.

– Good for all-position welding with steady arc and low spatter.

– High deposition efficiency for faster welding of larger joints.

Cons:

– The larger diameter might be less suitable for very thin manganese sections.

Best for: Heavy structural work, offshore rigs, power plants, and general fabrication of low, medium, and high carbon steels, including robust manganese components where low hydrogen is essential.

Expert Opinion: The 1/8” E7018 is a versatile choice for thicker sections and heavy-duty applications. Its ability to perform well without preheat on some steels makes it convenient, but for high-manganese, preheat should always be considered.

5. Forney 42450 Supercote Hardfacing Welding Rod, 5/32-Inch,…

This Forney 42450 hardfacing rod is virtually identical to the 42401, offering the same fantastic benefits for moderate abrasion and low impact applications on manganese and cast steel. If you need a reliable, cost-effective solution for building up worn parts or adding a tough, wear-resistant layer to new components, this is an excellent choice. Its crack-resistant properties are a standout feature, and the smooth arc and easy slag removal make the job much more manageable. It really is a great option for extending the life of machinery.

Key features that stand out:

– Excellent low cost rod for moderate abrasion and low impact application

– Crack resistant weld

– RC 52-58 hardness

– Features smooth arc action and easy slag removal

– Typical applications include surface buildup on new or worn machine parts of cast steel and manganese steel

Pros:

– Economical choice for hardfacing applications.

– Specifically formulated for crack resistance, important for manganese.

– User-friendly with smooth arc and easy slag removal.

– Provides a good balance of hardness and impact resistance.

Cons:

– Not designed for extreme high impact or severe gouging conditions.

Best for: Economical hardfacing and surface buildup on manganese steel components requiring moderate abrasion and low impact resistance.

Expert Opinion: A dependable and affordable hardfacing rod. Its consistent performance and crack resistance make it a practical option for maintenance and repair on manganese parts.

6. 6 Pieces Low Temperature Universal Welding Rods,Metal…

These “universal” welding rods are a bit of a departure from the manganese-specific rods, being designed for low-temperature applications across various metals like aluminum, stainless steel, and iron. While they boast ease of use and a low melting point, making them attractive for beginners or general repair, their suitability for high-manganese steel is more limited. I’d consider these for minor, non-critical repairs on tools or parts that might contain some manganese but aren’t primarily high-manganese steel structures where strength and specific crack resistance are paramount. They excel in versatility for everyday shop tasks.

Key features that stand out:

– UNIVERSAL COMPATIBILITY: suitable for joining various metals including aluminum, stainless steel, and iron

– VERSATILE APPLICATION: Perfect for both repair work and new construction projects

– EASY TO USE: Low melting point design makes these welding rods ideal for beginners

– Specially formulated for strong, durable bonds with excellent flow characteristics

Pros:

– Extremely versatile for a wide range of metals.

– Low melting point makes them easy to use, especially for beginners.

– Good for general repair and multi-metal projects.

– Forms strong bonds in appropriate applications.

Cons:

– Less specialized for the unique properties of high-manganese steel, potentially lacking specific crack resistance for critical manganese welds.

Best for: General purpose repair work on a variety of metals, or non-critical repairs on parts that might incidentally contain manganese, where extreme strength or specific manganese properties aren’t the main concern.

Expert Opinion: While highly versatile for general shop use, these rods are not typically the primary recommendation for welding high-manganese steel where specific mechanical properties and crack prevention are critical. Always assess the base metal and application.

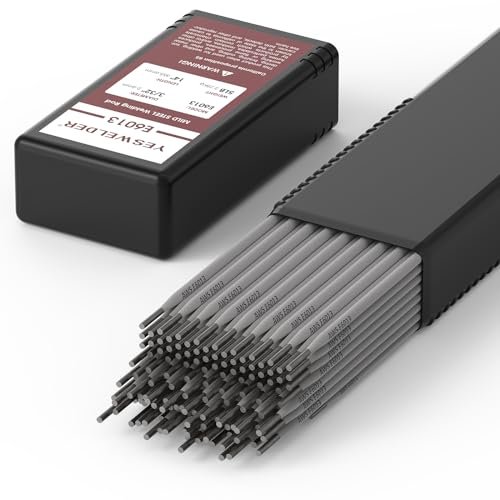

7. YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick…

The YESWELDER E6013 is a mild-steel, general-purpose rod, often a go-to for light fabrication and shallow penetration welds. It’s incredibly user-friendly, works on AC or DC, and is forgiving with poor fit-up. While excellent for sheet metal and ductwork, I have to be clear: E6013 is generally NOT the ideal choice for welding high-manganese steel. High-manganese steel requires specialized fillers to prevent cracking and maintain its properties. I’d only consider this rod for general shop tasks, very light “tack-welds” on non-critical assemblies, or projects where the base metal is primarily mild steel, and any manganese content is incidental or low. Its low spatter and easy slag removal are great, but the strength and crack resistance profile don’t typically match the demands of manganese welding.

Key features that stand out:

– E6013 is a mild-steel general purpose rod

– Operates on AC or DC welding current and works well on low voltage AC machines

– All position welding, general purpose rod for shallow penetration or in poor fitted conditions

– Low spatter and excellent slag removal, virtually self cleaning in vertical down fillets

– Use for all types of mild steel. Great for light gauge metal, sheet metal and duct work.

Pros:

– Very easy to use for beginners and general purpose work.

– Operates on both AC and DC, even low-voltage machines.

– Excellent for light gauge metal and sheet metal.

– Low spatter and easy slag removal.

Cons:

– Generally unsuitable for critical high-manganese steel applications due to lower strength and crack resistance compared to specialized rods.

Best for: Light gauge mild steel, sheet metal, ductwork, and general, non-critical shop repairs where manganese content is not significant. Not recommended as a primary rod for high-manganese steel welding.

Expert Opinion: E6013 is a fantastic general-purpose mild steel rod, but its metallurgical properties are not designed for the specific challenges of welding high-manganese steel. Always choose specialized low-hydrogen or hardfacing rods for manganese.

Helpful Comparison Short Insights

When looking at the best welding rod for manganese, a clear distinction emerges: you’re often choosing between specialized hardfacing for wear resistance and low-hydrogen rods for structural integrity and crack prevention.

For hardfacing and buildup on manganese, the Forney Supercote rods (42401, 42450) are excellent, cost-effective choices. They deliver good RC 52-58 hardness and crucial crack resistance for moderate abrasion and low impact, specifically designed for manganese steel surfaces. Their smooth arc action and easy slag removal make them user-friendly.

If your priority is high-quality structural welds with superior crack resistance on manganese or high carbon steels, the ARCCAPTAIN E7018 and YESWELDER E7018 low-hydrogen rods are indispensable. They are specifically formulated to prevent hydrogen-induced cracking, offer high tensile strength, and produce X-ray quality welds. The YESWELDER E7018, with its 1/8” diameter, is particularly suited for heavier sections and robust fabrication.

The YESWELDER ER70S-6 TIG rod steps in for those who prioritize precision, a clean finish, and minimal post-weld cleanup on mild or low-alloy steels, potentially for specific, controlled manganese applications where hardfacing isn’t the goal. Its high deoxidizer content ensures a very smooth bead.

On the other hand, the 6 Pieces Low Temperature Universal Welding Rods offer broad versatility for many metals, making them useful for general repair but less specialized for the unique demands of high-manganese steel. Similarly, the YESWELDER E6013 is a general-purpose mild steel rod that, while easy to use and excellent for light fabrication, is not recommended for primary welding of high-manganese steel due to its metallurgical properties and lower crack resistance.

In summary, for reliable manganese welding, prioritize specialized hardfacing or low-hydrogen rods over general-purpose options.

Final Verdict

Navigating the world of welding rods for manganese can feel daunting, but after reviewing these options, a few clear recommendations stand out based on common applications.

For dedicated hardfacing, surface buildup, and repair of worn manganese parts where you need good abrasion resistance and crack prevention without breaking the bank, the Forney Supercote Hardfacing Rods (42401 and 42450) are your top contenders. They consistently deliver on their promise of moderate wear resistance and good crack-resistant welds, making them a solid, economical choice.

If your project demands maximum structural integrity, high tensile strength, and superior resistance to cracking—especially for critical repairs, heavy fabrication, or joining manganese components—then the low-hydrogen E7018 rods are non-negotiable. Both the ARCCAPTAIN E7018 and YESWELDER E7018 are excellent, reliable choices that will provide the peace of mind of an X-ray quality weld. Choose the 1/8” YESWELDER for heavier sections and higher deposition.

For precision welding with TIG on lower alloy manganese steels or where aesthetic finish is paramount, the YESWELDER ER70S-6 TIG Rod offers unparalleled bead quality and deoxidizing properties, making it a specialized but effective choice.

Conversely, while versatile for general shop tasks, the 6 Pieces Low Temperature Universal Welding Rods and especially the YESWELDER E6013 are generally not suitable for primary, critical welding of high-manganese steel. Their properties don’t align with the specific demands for strength and crack resistance that high-manganese steel requires. Always remember, the right rod makes all the difference when tackling challenging alloys like manganese.

Best Welding Rod For Manganese: Your Top Questions Answered

Q1: Why is choosing the right welding rod for manganese steel so important?

A1: Manganese steel is known for its incredible toughness and work-hardening capabilities, but it’s also prone to hydrogen-induced cracking and can be difficult to weld without proper filler metal. The right welding rod, particularly low-hydrogen types or specific hardfacing rods, helps prevent these cracks, maintains the material’s properties, and ensures a strong, durable weld that can withstand the high impact and abrasion conditions manganese is designed for.

Q2: What are the main types of welding rods generally recommended for high manganese steel?

A2: For high manganese steel welding, the most common recommendations fall into two categories:

1. Low-hydrogen electrodes (like E7018): These are crucial for structural welds on manganese as they minimize hydrogen content, significantly reducing the risk of cracking. They provide high tensile strength and excellent ductility.

2. Hardfacing electrodes: Specifically designed for rebuilding worn manganese parts or adding a wear-resistant layer. These rods typically deposit an austenitic manganese alloy or other wear-resistant alloys. Examples include the Forney Supercote rods reviewed above, which offer good abrasion and moderate impact resistance.

Q3: Do I need to preheat manganese steel before welding?

A3: Yes, preheating manganese steel is highly recommended, especially for thicker sections or when welding in colder temperatures. Preheating helps to slow down the cooling rate of the weld and the surrounding base metal, which reduces thermal stresses and the likelihood of hydrogen-induced cracking. Typical preheat temperatures for manganese steel can range from 200°F to 400°F (93°C to 204°C), depending on the specific alloy and thickness.

Q4: What are the common issues to watch out for when welding manganese?

A4: The primary challenges when joining manganese include:

* Hydrogen cracking: This is the most common and serious issue, prevented by using low-hydrogen rods and proper preheat/post-weld cooling.

* Heat affected zone (HAZ) embrittlement: Excessive heat input can lead to sensitization and embrittlement in the HAZ.

* Weld metal dilution: Ensuring the filler metal properties are maintained despite dilution with the manganese base metal is important.

* Distortion: Due to high thermal expansion, distortion can be an issue.

Q5: Can I use a general-purpose rod like E6013 for manganese steel?

A5: Generally, no. E6013 is not recommended for high-manganese steel for primary or critical welds. E6013 is a mild steel general-purpose rod that has a higher hydrogen content and lower mechanical properties (strength, impact resistance, crack resistance) than specialized rods required for manganese. Using E6013 can lead to hydrogen-induced cracking, porosity, and a significantly weaker weld that won’t stand up to the demands typically placed on manganese components.

Q6: What’s the importance of low hydrogen content in a welding rod for manganese?

A6: Low hydrogen content in a welding rod is critical for manganese because hydrogen atoms can dissolve into the molten weld pool and then become trapped in the solidified metal. As the metal cools, these trapped hydrogen atoms can accumulate at grain boundaries, leading to internal pressure and microscopic cracks, particularly in the Heat Affected Zone (HAZ) of susceptible materials like high-manganese steel. Low-hydrogen rods minimize the introduction of hydrogen, thus dramatically reducing the risk of brittle fracture and hydrogen cracking in manganese welds.

Q7: How does impact resistance relate to hardfacing rods for manganese?

A7: Manganese steel is often used in applications requiring high impact resistance and wear resistance, such as in mining or construction equipment. Hardfacing rods for manganese are designed to create a surface that not only resists abrasion but also has sufficient toughness to withstand impacts without cracking or spalling. The RC hardness (e.g., RC 52-58 in the Forney rods) indicates the deposited metal’s resistance to indentation, but for manganese, the ability to absorb impact and then work-harden is equally important, meaning the filler metal needs to complement these properties of the base metal.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.