If you’ve ever faced a welding project where the metal is less than pristine – perhaps caked with rust, paint, or grease – you know the headache it can cause. I’ve certainly been there, trying to coax a decent bead out of an unwilling, corroded surface. The truth is, choosing the best welding rod for rusty metal isn’t just about picking any rod; it’s about finding one that can cut through the imperfections, create a stable arc, and ultimately deliver a strong, lasting bond even in challenging conditions. After years of tackling various repair jobs, I’ve narrowed down some reliable options that truly make a difference when you’re up against rust. Let’s dive into some picks that can help you conquer those stubborn, rusty repairs.

Contents

- 6 Pieces Low Temperature Universal Welding Rods, Metal…

- All Metal Brazing Rods, 1/16”x13” Flux Core All Metal…

- Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

- Fox Alloy 40pcs Brass Brazing Rods HS221 1/2 lb Diameter…

- Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rod for Rusty Metal: Your Questions Answered

- Q1: Can I weld directly over rust?

- Q2: What’s the best way to prepare rusty metal for welding?

- Q3: Are flux-cored welding rods better for rusty metal than solid wire?

- Q4: Why is a low-temperature welding rod or brazing sometimes preferred for rusty metal?

- Q5: What kind of safety precautions should I take when welding rusty metal?

- Q6: How much rust is too much to weld over?

- Q7: Can I use stainless steel rods to weld rusty carbon steel?

- Q8: Does the diameter of the welding rod matter for rusty metal?

6 Pieces Low Temperature Universal Welding Rods, Metal…

These universal welding rods are a fantastic option for those who deal with diverse metal types and aren’t always working with perfectly clean surfaces. Their low melting point and excellent flow characteristics make them surprisingly forgiving, which is a huge advantage when you’re trying to join something like rusty iron to a cleaner piece of aluminum. They’re designed for a strong, durable bond across various metals, meaning you’re not constantly switching rods for different projects.

Key features that stand out:

– UNIVERSAL COMPATIBILITY: Works with aluminum, stainless steel, iron, and other metal combinations.

– EASY TO USE: Low melting point simplifies the process, great for beginners.

– VERSATILE APPLICATION: Suitable for both repair work and new construction projects.

– STRONG, DURABLE BONDS: Formulated for excellent flow characteristics and robust joints.

Pros:

– Extremely versatile for various metal types.

– Low melting point makes them user-friendly, even for beginners.

– Creates strong, reliable bonds.

– Good for both repair and new projects.

Cons:

– Might not be suitable for heavy-duty structural applications requiring specific high-strength alloys.

Best for: Multi-metal repairs, general fabrication where different metals are involved, and beginners tackling light to medium-duty rusty metal work.

Expert Opinion: These rods are a go-to for situations where you’re unsure of the exact metal composition or when dealing with moderate rust that’s been wire-brushed. Their low temperature profile reduces the risk of burning through thinner, rust-compromised sections.

All Metal Brazing Rods, 1/16”x13” Flux Core All Metal…

When traditional welding is tricky due to rust or thin material, brazing can be a lifesaver, and these flux core all-metal brazing rods are excellent for that. The key benefit here is the convenient flux core design, which eliminates the messy step of applying separate flux – a huge time-saver, especially on fiddly repairs. They bond a wide range of metals like steel, cast iron, copper, and stainless steel, and are designed to work with a standard propane torch, making them accessible for DIYers without specialized welding gear.

Key features that stand out:

– CONVENIENT FLUX CORE DESIGN: Eliminates the need for separate flux paste, simplifying the process.

– VERSATILE ALL-METAL REPAIR: Bonds steel, cast iron, copper, brass, stainless steel, and more.

– WORKS WITH PROPANE TORCH: Accessible for DIYers, no expensive welding equipment needed.

– STRONG & DURABLE BRAZED JOINTS: Creates leak-proof, corrosion-resistant bonds that withstand stress.

Pros:

– Built-in flux saves time and ensures clean joints.

– Exceptional versatility across many metal types.

– Only requires a propane torch, highly accessible.

– Produces strong, lasting, and corrosion-resistant bonds.

Cons:

– Brazing creates a bond on the surface, which is different from a full-penetration weld.

Best for: Automotive panel repairs, plumbing fixes, household items, and thin metals where a strong, surface-level bond is preferred over traditional welding.

Expert Opinion: These are excellent for rusty metal where you want to avoid high heat input or where the metal is too thin for arc welding. The flux core handles minor surface impurities, making it forgiving on less-than-perfect surfaces, but good cleaning is always recommended.

Tandefio 24pcs Low Temperature Universal Welding Rod Sticks…

This generous pack of low temperature universal welding rod sticks is designed for extreme ease of use and broad application. What truly stands out is their low temperature welding capability – you can even light them up with an ordinary lighter for small repairs, thanks to the self-contained solvent and flux. Made with quality tin and aluminum powder, they offer a quick welding speed and low melting point, making them very forgiving on thin or delicate materials that might be compromised by rust.

Key features that stand out:

– COMPREHENSIVE WELDING PACKAGE: 24 rods included, great for multiple projects.

– QUALITY MATERIAL: Fabricated with tin and aluminum powder for longevity and performance.

– LOW TEMPERATURE WELDING CAPABILITY: Can be lit with an ordinary lighter for convenience.

– WIDE RANGE OF APPLICATIONS: Ideal for electronic circuits, water tanks, oil tanks, and various metallic materials like stainless steel, iron, copper, aluminum, and PVC pipes.

Pros:

– Extremely easy to use with a very low melting point.

– Self-fluxing, simplifying the process.

– Excellent for small, quick repairs without heavy equipment.

– Versatile for many materials, including thin metals and pipes.

Cons:

– The rods can be relatively brittle, requiring careful handling.

Best for: Delicate repairs, joining thin or dissimilar metals, hobbyists, quick fixes on small rusty areas, and situations where minimal heat input is crucial.

Expert Opinion: These are more for brazing-type applications than traditional fusion welding, but their ease of use and low-temp approach make them highly effective for filling small holes or joining thin rusty sections where traditional welding would be overkill or cause blow-through.

Fox Alloy 40pcs Brass Brazing Rods HS221 1/2 lb Diameter…

For robust brazing applications, especially with copper and copper alloys, the Fox Alloy Brass Brazing Rods HS221 are a fantastic choice. These Phos-copper brazing rods are air self-fluxing, meaning the phosphorus acts as the brazing agent when working with copper, eliminating the need for separate flux. They boast good fluidity and a moderate melting point, making them ideal for high-strength, conductive joints. While not a traditional welding rod, brazing is an excellent alternative for joining metals that might be difficult to weld due to rust or differing compositions.

Key features that stand out:

– SELF FLUXING WELDING: Phosphorus in the alloy acts as the brazing agent when joining copper to copper.

– RECIPE OPTIMIZATION: Conforms to AWS A5.8, ensuring quality and consistent performance.

– ADVANTAGE: Moderate melting point, high fluidity, perfect for gas flame, induction, furnace brazing.

– WIDE APPLICATION: Suitable for resistance brazing, flame brazing, high-frequency brazing, especially copper and copper alloys.

Pros:

– Excellent for strong, conductive copper-to-copper bonds.

– Self-fluxing feature for copper, simplifying the process.

– Good fluidity allows molten metal to flow into small gaps.

– Versatile with various heat sources (MAPP, propane, oxygen acetylene, TIG).

Cons:

– Primarily suited for copper and copper alloys, limiting its universal application for all rusty metals.

Best for: Refrigeration systems, HVAC, plumbing, electrical work, and any applications primarily involving copper and copper alloys where a strong, leak-proof bond is critical.

Expert Opinion: While specialized for copper, its brazing capabilities make it useful when joining copper to other metals that might have surface imperfections. For rusty steel or iron, a different rod would be more appropriate, but for specific rusty copper repairs, this is top-tier.

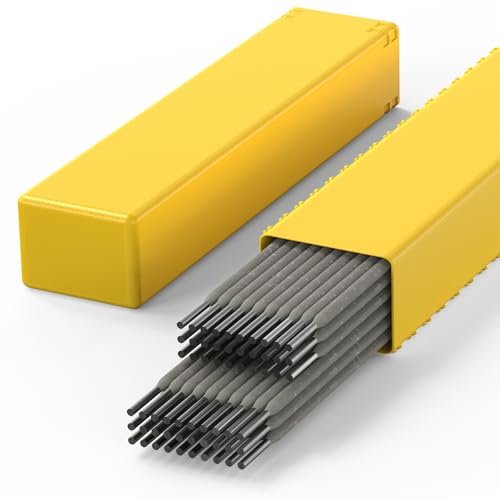

Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel…

The Faiuot E6013 Welding Rods are a classic choice for general-purpose welding, and they shine when dealing with light repairs and thinner low-carbon steel, even with less-than-ideal surfaces. The E6013’s smooth arc and easy strike make it incredibly user-friendly for both beginners and experienced welders. Its special flux coating significantly reduces spatter and allows for easy slag removal, which is a huge benefit when you’re trying to get a clean finish on sheet metal or slightly rusty material. This rod is versatile for all-position welding and works well on low-voltage AC/DC welders.

Key features that stand out:

– SMOOTH ARC & EASY TO STRIKE: Provides consistent arc stability for easier welding.

– MINIMAL SPATTER & EASY SLAG REMOVAL: Special flux coating ensures cleaner welds.

– ALL-POSITION WELDING PERFORMANCE: Suitable for flat, horizontal, vertical, and overhead welding.

– IDEAL CHOICE FOR THIN METAL WELDING: Perfect for DIY, light metal fabrication, and sheet metal repairs.

Pros:

– Excellent for beginners due to easy arc strike and stability.

– Handles slight surface imperfections well.

– Low spatter and easy slag removal result in cleaner welds.

– Versatile for all welding positions and AC/DC welders.

Cons:

– While forgiving, heavily rusted or dirty metal will still require substantial prep work for a strong weld.

Best for: DIY projects, automotive panel repairs, ductwork, light metal fabrication, and general repairs on low-carbon steel where the metal might have minor rust or paint.

Expert Opinion: E6013 is often dubbed a “dirty rod” for a reason – it handles impurities better than many other electrodes. For lightly rusted low-carbon steel, especially thin gauge, this is an excellent choice, offering a cosmetically pleasing bead with minimal fuss.

Helpful Comparison Short Insights

When picking the best welding rod for rusty metal, versatility and ease of use are key. For ultimate multi-metal versatility and forgiving low-temperature joining, the 6 Pieces Low Temperature Universal Welding Rods or the Tandefio 24pcs Low Temperature Universal Welding Rod Sticks are stellar. They shine where you’re unsure of the exact metal or dealing with very thin, rust-compromised sections.

If brazing is your preferred method for strong, leak-proof bonds on a variety of metals, especially with accessible tools, the All Metal Brazing Rods with their flux core design are fantastic. They simplify the process immensely by removing the need for separate flux. For specialized work primarily with copper and copper alloys, the Fox Alloy Brass Brazing Rods HS221 are purpose-built for high-strength, self-fluxing brazes, but remember their material limitation.

Finally, for traditional arc welding on lightly rusted low-carbon steel, especially for DIYers and light fabrication, the Faiuot E6013 Welding Rods are a dependable workhorse. They offer a smooth arc and handle minor surface issues well, making them a forgiving option for common repair scenarios. Remember, while these rods are more tolerant of rust, proper metal preparation always yields the best results.

Final Verdict

Choosing the absolute best welding rod for rusty metal really depends on your specific project, the types of metal, and your equipment.

- For the DIYer or professional needing maximum versatility and ease with various metals and light rust: I lean towards the 6 Pieces Low Temperature Universal Welding Rods. They’re incredibly forgiving and work across the board.

- If you’re looking for an accessible brazing solution for multi-metal repairs, especially without a full welding setup: The All Metal Brazing Rods, Flux Core are a standout. The built-in flux is a game-changer.

- For classic arc welding on mild steel that’s a bit rusty, especially for thinner gauges: The Faiuot E6013 Welding Rods remain a strong contender due to their smooth arc and tolerance for minor surface impurities.

Ultimately, while some rods are more forgiving, remember that the cleaner the metal, the stronger and more reliable your weld will be. But when clean isn’t an option, these tested picks will definitely give you the best fighting chance.

Best Welding Rod for Rusty Metal: Your Questions Answered

Q1: Can I weld directly over rust?

A1: While some welding rods (like E6013 or certain flux-cored wires) are more forgiving of minor surface impurities, it’s generally not recommended to weld directly over rust. Rust creates contaminants in the weld pool, leading to porosity, weak bonds, and an overall poor-quality weld. Always aim to remove as much rust, paint, and grease as possible before welding.

Q2: What’s the best way to prepare rusty metal for welding?

A2: The best preparation involves mechanical removal. Use a wire brush (manual or grinder-mounted), sanding discs, or grinding wheels to get down to bare, shiny metal in the area you plan to weld. For heavy rust, a grinder is essential. After mechanical cleaning, a quick wipe with a degreaser (like acetone or rubbing alcohol) can remove any remaining oils.

Q3: Are flux-cored welding rods better for rusty metal than solid wire?

A3: Generally, yes. Flux-cored welding wires and rods contain deoxidizers within their core, which help to clean up impurities in the weld puddle. This makes them more tolerant of rust, paint, and mill scale compared to solid wires, which require a cleaner surface and external shielding gas.

Q4: Why is a low-temperature welding rod or brazing sometimes preferred for rusty metal?

A4: Low-temperature rods and brazing methods are often preferred for rusty or thin metal because they introduce less heat into the base material. High heat on thin, rust-compromised metal can cause blow-through or further weakening. Brazing also creates a strong metallurgical bond without fully melting the base metals, which can be beneficial for dissimilar metals or materials with difficult-to-clean surfaces.

Q5: What kind of safety precautions should I take when welding rusty metal?

A5: Always wear appropriate Personal Protective Equipment (PPE): welding helmet with the correct shade, flame-retardant jacket/sleeves, heavy gloves, and steel-toed boots. When grinding or welding rusty material, be aware that grinding dust can be an irritant, and fumes from burning rust or coatings can be harmful. Ensure good ventilation and consider a respirator, especially in enclosed spaces.

Q6: How much rust is too much to weld over?

A6: If the rust has significantly pitted the metal, caused thinning of the material, or created holes, it’s generally too much to weld over effectively. Welding over heavily corroded material won’t create a strong, lasting bond, and you’ll likely just be welding to more rust. In such cases, it’s often better to cut out the rusted section and weld in a patch of new, clean metal.

Q7: Can I use stainless steel rods to weld rusty carbon steel?

A7: While some stainless steel electrodes (like E309L) can be used for welding dissimilar metals or for joining stainless to carbon steel, using them specifically to “deal with” rust on carbon steel isn’t their primary benefit. They still require a reasonably clean surface for a strong weld. For rusty carbon steel, an E6013 or a flux-cored rod is often a more practical and cost-effective choice after proper cleaning.

Q8: Does the diameter of the welding rod matter for rusty metal?

A8: Yes, the diameter matters. For thinner, rusty sheet metal, a smaller diameter rod (e.g., 3/32″ or 2.5mm) is usually better to prevent blow-through. For thicker, structural components that might have surface rust (after cleaning), a larger diameter rod can be used to achieve deeper penetration and a stronger weld.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.