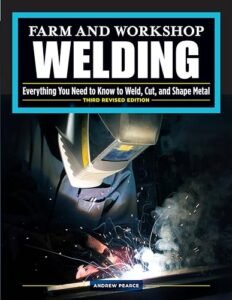

Welding sheet metal can feel like a delicate dance – too much heat and you’re patching holes, too little and your welds are weak. I’ve personally spent countless hours in the shop trying to get that perfect bead on thin gauge steel for automotive repairs and home projects. It really comes down to having the best welding rod for sheet metal that’s forgiving, easy to run, and minimizes burn-through. In this guide, we’ll dive into the top electrodes that make working with thin metals a whole lot easier, whether you’re a seasoned pro or just starting out.

Contents

- Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel

- Eastwood 3 Lb 120 Rods Stick Welding Electrode Rod 1/16

- All Metal Brazing Rods, 1/16”x13” Flux Core All Metal

- PLOWIC E6013 Welding Rods 3/32″: Carbon Steel Stick

- 6 Pieces Low Temperature Universal Welding Rods, Metal

- Comparison Insights for Best Welding Rod For Sheet Metal

- Final Verdict

- Best Welding Rod For Sheet Metal: FAQ Section

- What is the best welding rod for sheet metal to prevent burn-through?

- Can beginners weld sheet metal with stick welders?

- What amperage should I use for welding sheet metal with E6013 rods?

- Are brazing rods a good alternative to traditional welding for sheet metal?

- What are LSI keywords for “Best Welding Rod For Sheet Metal”?

- What rod type is best for different kinds of sheet metal (e.g., aluminum, stainless steel, mild steel)?

Faiuot E6013 Welding Rods 3/32”: 14” Low-Carbon Steel

These Faiuot E6013 welding rods are a fantastic all-rounder, especially when you’re tackling lighter gauge metals. I’ve found them incredibly forgiving, making them a go-to for home repairs, light metal fabrication, and intricate sheet metal work. The consistent arc and minimal spatter mean you spend less time grinding and more time admiring your clean, smooth welds – a huge plus for thin materials where cleanup can be tricky. They truly shine when you need reliability without fuss.

Key features that stand out:

– Perfect for DIY & Light Repairs: Ideal for home repairs, light metal fabrication, and sheet metal welding.

– Smooth Arc & Easy to Strike: Provides consistent arc stability for easier and more efficient welding.

– Minimal Spatter & Easy Slag Removal: Ensures clean, smooth welds, especially useful for sheet metal work.

– All-Position Welding Performance: Versatile for flat, horizontal, vertical, and overhead welding.

– Ideal Choice for Thin Metal Welding: Recommended amperage: 50A-90A, 3/32″ diameter.

- Pros: Excellent arc stability, very low spatter, easy slag removal, versatile for all positions, great for thin metals.

- Cons: Might not be robust enough for heavy structural work.

- Best for: DIY enthusiasts, light fabrication, automotive panel repairs, ductwork.

Expert Opinion: For general purpose sheet metal welding, especially in a home shop setting, the Faiuot E6013 3/32″ rods are an excellent choice. Their easy handling characteristics significantly reduce the learning curve for beginners and improve efficiency for experienced welders working on thin stock.

Eastwood 3 Lb 120 Rods Stick Welding Electrode Rod 1/16

When you’re dealing with truly delicate sheet metal, a smaller diameter rod like this Eastwood 6013 1/16-inch option is essential. This pack is specifically designed for welding light sheet metal up to 3/16-inch steel, providing the precision you need to avoid burn-through. The smaller rod allows for lower amperage settings, which is critical for controlling heat input on thin materials. It’s truly a game-changer when you’re trying to achieve clean, controlled welds without blowing holes in your project.

Key features that stand out:

– Ideal For Welding Light Sheet Metal: Specifically designed for sheet metal applications.

– Perfect for Thin Gauge Steel: Suitable for materials up to 3/16 inch thick.

– Small 1/16 inch Rod Size: Allows for precise heat control and lower amperage.

– Generous 3 Lb Pack: Provides approximately 120 rods for multiple projects.

- Pros: Excellent for very thin sheet metal, prevents burn-through, great for precise work, good quantity.

- Cons: Requires a steady hand due to its smaller diameter.

- Best for: Extremely thin sheet metal, intricate repairs, hobbyists working with delicate materials.

Expert Opinion: The 1/16-inch diameter of these Eastwood 6013 rods is invaluable for precision work on very thin sheet metal. It’s often overlooked how critical rod diameter is for heat management, and this size helps mitigate the common issue of burn-through that plagues less experienced welders on thin stock.

All Metal Brazing Rods, 1/16”x13” Flux Core All Metal

Now, for something a bit different! These All Metal Brazing Rods aren’t traditional welding electrodes, but they offer an incredibly versatile solution for joining and repairing a wide range of metals without complex welding equipment. I’ve used these for plumbing fixes and automotive patch-ups where traditional stick welding wasn’t feasible or desired. The flux core design is a major convenience, saving you from messy separate flux, and the ability to use a simple propane torch makes it super accessible for DIYers.

Key features that stand out:

– VERSATILE ALL-METAL REPAIR: Bonds steel, cast iron, copper, brass, stainless steel, and more.

– CONVENIENT FLUX CORE DESIGN: Eliminates the need for separate flux paste, simplifying the process.

– WORKS WITH PROPANE TORCH: Designed for use with standard handheld propane or MAPP gas torches.

– STRONG & DURABLE BRAZED JOINTS: Creates high-strength, leak-proof, and corrosion-resistant bonds.

– IDEAL FOR MULTIPLE REPAIRS (20 RODS): Ample material for numerous repair projects.

- Pros: No expensive welding equipment needed, works with a propane torch, versatile for many metals, flux-cored for ease of use, strong joints.

- Cons: Not a true fusion weld, so it has different mechanical properties.

- Best for: Repairs on various metals, plumbing, automotive, home repairs where traditional welding isn’t an option.

Expert Opinion: While not “welding” in the strictest sense, these flux-core brazing rods are an absolute lifesaver for sheet metal repairs, especially when working with dissimilar metals or when a full arc welder isn’t available or practical. Their ease of use and versatility make them a valuable addition to any DIY toolkit for thin metal fixes.

PLOWIC E6013 Welding Rods 3/32″: Carbon Steel Stick

Another excellent E6013 option, the PLOWIC 3/32″ rods are tailored for those seeking ease of use and clean results on small to medium projects. I particularly appreciate their stable arc and low spatter, which are critical for maintaining control and minimizing post-weld cleanup on sheet metal. They’re super beginner-friendly thanks to the easy striking and consistent performance, making them a great choice for tackling anything from auto body repair to general maintenance tasks where thin metals are involved.

Key features that stand out:

– Stable Arc for Smooth Welding: Provides consistently stable arc with easy striking.

– Low Spatter and Easy Slag Removal: Produces minimal spatter for cleaner beads and less cleanup.

– All-Position Welding Capability: Versatile for flat, horizontal, vertical, and overhead welding.

– AC/DC Compatibility for Flexible Use: Delivers reliable performance with both AC and DC welders.

– Ideal for Small to Medium Projects: 3/32″ rods deliver precise heat control for thin metal.

- Pros: Very stable arc, low spatter, easy slag removal, versatile for all positions, works with AC/DC welders, excellent for beginners.

- Cons: Not designed for heavy industrial applications.

- Best for: Auto body repair, ductwork, general maintenance, beginners learning to weld sheet metal.

Expert Opinion: The PLOWIC E6013 rods stand out for their exceptional user-friendliness. The combination of a stable arc, low spatter, and easy slag removal makes them particularly forgiving for those learning to weld sheet metal, where precision and heat control are paramount.

6 Pieces Low Temperature Universal Welding Rods, Metal

These Low Temperature Universal Welding Rods offer a specialized solution for joining various metals, often without the need for high-heat arc welding. I’ve found them incredibly handy for delicate repairs or when working with metals that are prone to warping. Their low melting point simplifies the process, making them accessible even for beginners, and the universal compatibility means you can tackle different metal combinations with just one type of rod. They provide strong, durable bonds with good flow characteristics, which is key for a clean finish on sheet metal.

Key features that stand out:

– UNIVERSAL COMPATIBILITY: Suitable for joining various metals including aluminum, stainless steel, and iron.

– VERSATILE APPLICATION: Perfect for both repair work and new construction projects.

– EASY TO USE: Low melting point design ideal for beginners.

– COMPLETE SET: Package includes 6 universal welding rods ready for immediate use.

– PERFORMANCE: Specially formulated for strong, durable bonds with excellent flow characteristics.

- Pros: Joins multiple metal types, low melting point (prevents warping), beginner-friendly, strong bonds, good flow.

- Cons: Requires a very clean surface for best results.

- Best for: Aluminum repairs, dissimilar metal joining, beginners, delicate sheet metal work where low heat input is critical.

Expert Opinion: These low-temperature rods represent a different approach to joining thin metals, often ideal for situations where traditional high-heat arc welding might cause excessive distortion or be impractical. Their universal compatibility and ease of use make them a valuable problem-solver for specific sheet metal challenges, particularly with aluminum.

Comparison Insights for Best Welding Rod For Sheet Metal

When choosing the best welding rod for sheet metal, your decision often boils down to the type of process and the specific metals you’re working with. For traditional stick welding of carbon steel sheet metal, E6013 rods are generally the top recommendation due to their smooth arc, easy slag removal, and suitability for thin materials. Both the Faiuot and PLOWIC E6013 3/32″ rods offer excellent performance for general-purpose sheet metal work, with PLOWIC being particularly beginner-friendly due to its stable arc.

If you’re dealing with extremely thin sheet metal and battling burn-through, the Eastwood 1/16″ E6013 rod is an absolute must-have. Its smaller diameter allows for much finer heat control.

However, if you’re exploring alternatives to traditional arc welding or need to join dissimilar metals like aluminum or stainless steel without a full welder, the All Metal Brazing Rods and Low Temperature Universal Welding Rods offer fantastic solutions. The brazing rods are perfect for home repairs with a propane torch, while the low-temperature universal rods excel at delicate, multi-metal repairs where heat input is a major concern.

Final Verdict

Choosing the right welding rod for sheet metal truly depends on your specific needs, skill level, and equipment.

If you’re a beginner or a DIY enthusiast primarily working with carbon steel sheet metal and have an arc welder, I’d lean towards the PLOWIC E6013 3/32″ rods for their exceptional ease of use and low spatter. They’re incredibly forgiving.

For those needing a workhorse rod for various light fabrication and repair tasks on steel, the Faiuot E6013 3/32″ rods are a solid, reliable choice that delivers consistent results.

When the material gets critically thin and burn-through is a constant worry, the Eastwood 1/16″ 6013 rods are your best friend, offering the precision needed to tackle those delicate jobs.

Lastly, for non-traditional repairs, joining dissimilar metals, or working without an arc welder, both the All Metal Brazing Rods (with a torch) and the Low Temperature Universal Welding Rods offer innovative and highly effective solutions to keep your projects moving forward.

Best Welding Rod For Sheet Metal: FAQ Section

What is the best welding rod for sheet metal to prevent burn-through?

The Eastwood 1/16″ 6013 welding rod is excellent for preventing burn-through on sheet metal due to its smaller diameter, which allows for lower amperage settings and more precise heat control. Generally, smaller diameter E6013 rods (like 1/16″ or 3/32″) are preferred for thin gauge metal.

Can beginners weld sheet metal with stick welders?

Yes, beginners can definitely weld sheet metal with stick welders, especially with the right electrodes. E6013 rods like the Faiuot or PLOWIC 3/32″ are highly recommended for their easy arc striking, smooth performance, and forgiving nature, making the process much easier for newcomers to control heat input on thin materials.

What amperage should I use for welding sheet metal with E6013 rods?

For 3/32″ E6013 rods on sheet metal, a good starting point is typically between 50-90 amps. For 1/16″ rods, you’ll want to go even lower, sometimes as low as 30-60 amps. Always test your settings on a scrap piece of the same thickness before welding your actual project to find the optimal heat for your specific machine and material.

Are brazing rods a good alternative to traditional welding for sheet metal?

Yes, brazing rods can be a fantastic alternative for certain sheet metal applications, particularly for repairs, joining dissimilar metals (like copper to steel), or when you don’t have access to a traditional arc welder. Products like the All Metal Flux Core Brazing Rods are convenient as they can be used with a standard propane torch and create strong, leak-proof joints without the high heat of arc welding, reducing warping.

What are LSI keywords for “Best Welding Rod For Sheet Metal”?

Relevant LSI (Latent Semantic Indexing) keywords for “Best Welding Rod For Sheet Metal” include: thin gauge metal welding, low amperage electrodes, E6013 rods for thin metal, automotive sheet metal repair, minimizing burn-through, stick welding thin steel, arc welding sheet metal, flux-cored brazing rods, low temperature metal joining, electrode selection for delicate work, welding mild steel sheet, thin metal fabrication, heat control in welding.

What rod type is best for different kinds of sheet metal (e.g., aluminum, stainless steel, mild steel)?

For mild steel sheet metal, E6013 electrodes (like the 3/32″ or 1/16″ options reviewed) are generally the best welding rod for sheet metal due to their versatility and ease of use. For aluminum sheet metal, specialized aluminum welding rods (often requiring TIG or MIG) or low temperature universal welding rods (like the 6 Pieces Universal Rods) used with lower heat can be effective for repairs. For stainless steel sheet metal, specific stainless steel electrodes (e.g., E308L-16) or the universal low-temperature rods can be used, depending on the application and equipment available.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.