When I’m tackling a tubular steel project, whether it’s building a custom roll cage or repairing a structural frame, choosing the best welding rod for tubular steel is absolutely crucial. You need something that delivers strong, reliable welds, especially when working on pipes or complex geometries where structural integrity is paramount. I’ve spent countless hours laying beads on various tubular steel configurations, and I know firsthand that the right electrode selection can make all the difference between a high-quality, defect-free joint and a frustrating, re-do situation. This guide comes from that hands-on experience, focusing on tested options to help you achieve excellent results.

Contents

- YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon…

- YESWELDER E7018 5/32” 10LB Welding Rod Low Hydrogen Carbon…

- YESWELDER E7018 3/32” 10LB Welding Rod Low Hydrogen Carbon…

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

- 6 Pieces Low Temperature Universal Welding Rods, Metal…

- UNIFAMILY 50pcs Stainless Steel TIG Welding Rod ER308L,…

- Blue Demon ER308L X 1/16″ X 36″ X 1LB Tube…

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rod For Tubular Steel: Your FAQ Answered

- Q1: Why is E7018 often recommended as the best welding rod for tubular steel?

- Q2: Can I use other types of electrodes for welding tubular carbon steel besides E7018?

- Q3: What’s the difference between 3/32″ and 5/32″ E7018 rods for tubular steel welding?

- Q4: When should I choose TIG welding rods (like ER308L) for tubular steel instead of stick welding rods?

- Q5: Are low-temperature universal welding rods suitable for structural tubular steel projects?

- Q6: How should I store welding rods to maintain their quality, especially E7018 for tubular steel?

- Q7: What are LSI keywords and why are they relevant to “Best Welding Rod For Tubular Steel”?

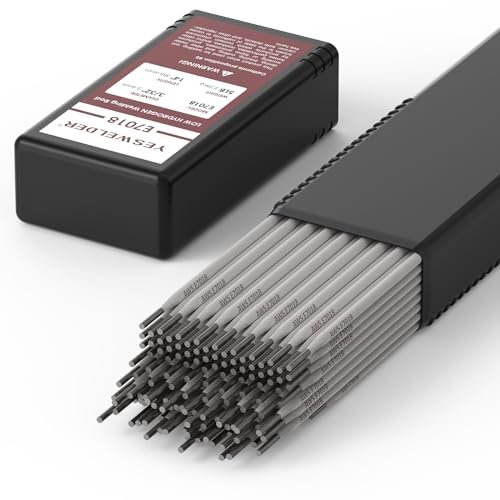

YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon…

This 3/32” E7018 rod from YESWELDER is a fantastic choice for many tubular steel applications, particularly when you’re aiming for high-quality, X-ray worthy welds. Its low-hydrogen formulation significantly reduces the risk of hydrogen-induced cracking, which is a common concern in critical structural applications. I’ve found it consistently delivers a steady arc with minimal spatter, making it easier to maintain control, especially when you’re navigating the curves and tight spots of tubular joints. It’s truly versatile, performing well in all welding positions, which is often a necessity when working with complex tubular structures.

Key features that stand out:

* Model E7018: A widely trusted low-hydrogen iron powder electrode for demanding applications.

* All Position Welding: Excellent for overhead, vertical, and horizontal tubular joints.

* Steady Arc, Low Spatter: Ensures easier control and a cleaner weld puddle.

* High Deposition Efficiency: Helps lay down more metal faster without sacrificing quality.

* Recommended Amperages: 70A-100A: Ideal for general purpose and medium thickness tubular steel.

Pros:

* Produces high-quality, X-ray standard welds

* Excellent for structural integrity due to low hydrogen content

* Good arc stability and minimal cleanup

* Versatile for various welding positions and carbon steels

Cons:

* Requires proper storage to maintain low hydrogen properties.

Best for: General fabrication and repair of medium-carbon tubular steel where high strength and X-ray quality are required, especially for intricate, multi-position work.

Expert Opinion: For smaller diameter tubular steel or root passes on thicker sections, this 3/32″ E7018 is a workhorse. Its low hydrogen nature is crucial for avoiding cracks in stressed tubular joints, and the consistent arc makes it very forgiving.

YESWELDER E7018 5/32” 10LB Welding Rod Low Hydrogen Carbon…

When you’re dealing with thicker-walled tubular steel or need to fill larger gaps efficiently, this 5/32” YESWELDER E7018 rod steps up to the plate. Like its smaller sibling, it’s a low-hydrogen, iron powder type electrode, designed for superior weld quality and resistance to cracking. The larger diameter means it’s built for higher amperage and can lay down more metal per pass, which is a real time-saver on heavier tubular steel projects. Its excellent re-striking ability is a handy feature, especially if you’re frequently stopping and starting on long seams or complex assemblies.

Key features that stand out:

* Model E7018: Provides high-quality, X-ray welds suitable for critical applications.

* All Position Welding: Maintains versatility across different welding orientations.

* High Deposition Efficiency: Speeds up welding on thicker materials.

* Recommended Amperages: 150A-220A: Perfect for heavier gauge tubular steel.

* Suitable for Low to High Carbon Steels: Broad application range.

Pros:

* Ideal for heavy-duty tubular steel and thick sections

* High deposition rate for faster welding

* Excellent mechanical properties for strong welds

* Resistant to porosity and cracking

Cons:

* May be too large for thin-walled tubing or precise root passes.

Best for: Welding heavier gauge tubular steel, structural frameworks, and situations requiring high deposition rates and strong, reliable welds on medium to high carbon steels.

Expert Opinion: The 5/32″ E7018 is my go-to for fill and cap passes on structural tubular steel. Its ability to handle higher amperages and lay down a significant amount of metal quickly, while maintaining excellent properties, makes it indispensable for robust fabrication.

YESWELDER E7018 3/32” 10LB Welding Rod Low Hydrogen Carbon…

This is essentially the same reliable 3/32” E7018 rod as the first one reviewed, but in a more generous 10LB package. For welders who frequently work with tubular steel and consume rods regularly, this larger quantity is a practical and economical choice. You still get all the benefits: the low-hydrogen formulation for crack resistance, all-position capability for challenging tubular geometries, and that consistent, steady arc with low spatter. It’s the kind of rod you can depend on for producing high-quality, X-ray welds on a range of carbon steels.

Key features that stand out:

* Model E7018: A dependable low-hydrogen electrode for structural integrity.

* All Position Welding: Ensures flexibility for various tubular joint orientations.

* Steady Arc, Low Spatter: Facilitates cleaner welds and easier puddle control.

* 10LB Package: More rods for continuous work on tubular steel projects.

* Recommended Amperages: 70A-100A: Optimal for medium-thickness tubular components.

Pros:

* Larger quantity offers better value for regular users

* Delivers strong, crack-resistant welds

* Great for all positions, especially on tubular work

* Consistent performance across various carbon steels

Cons:

* Still requires careful storage to prevent moisture absorption.

Best for: Welders and fabricators who regularly perform critical structural welding on medium-carbon tubular steel and prefer to buy in bulk for efficiency and cost-effectiveness.

Expert Opinion: Buying E7018 in a 10lb can is smart if you’re doing a lot of tubular fabrication. This 3/32″ diameter is incredibly versatile for root passes and smaller tubing, providing those critical low-hydrogen properties we look for in structural work.

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon…

The ARCCAPTAIN E7018 welding rod offers another excellent option for tubular steel applications, emphasizing its outstanding X-ray values and high tensile strength. This 3/32” rod, like others of its type, is an iron powder electrode with low hydrogen content, which is key to preventing cracking in critical welds. I’ve found ARCCAPTAIN rods often provide a smooth and stable arc with less spatter, which contributes to a cleaner weld and less post-weld cleanup. Its suitability for a wide range of structural components, including high-pressure pipelines and marine structures, makes it a reliable choice for demanding tubular projects.

Key features that stand out:

* E7018 Welding Rod: Renowned for high-quality, X-ray welds and robust performance.

* Advantages: Boasts outstanding X-ray values, high tensile strength, and good resistance to cracking.

* Performance: Features high melting efficiency, a smooth and stable arc, and less spatter.

* Low Hydrogen Content: Minimizes defects and ensures weld integrity.

* Widely Used: Ideal for various carbon steels and critical structural components like pipelines and steel bridges.

Pros:

* Produces exceptionally clean, high-strength welds

* Excellent arc stability and minimal spatter for ease of use

* Superior crack resistance due to low hydrogen

* Suitable for critical applications including high-pressure tubular structures

Cons:

* No significant drawbacks for its intended E7018 application.

Best for: High-pressure tubular structures, critical steel framing, and any application where maximum weld integrity, crack resistance, and X-ray quality are non-negotiable.

Expert Opinion: ARCCAPTAIN’s E7018 is a solid contender when you need dependable performance on tubular steel. The emphasis on high X-ray values and crack resistance directly translates to safer, more durable structures, which is paramount in our field.

6 Pieces Low Temperature Universal Welding Rods, Metal…

This set of low-temperature universal welding rods presents a very different approach to working with tubular steel, especially for repair or light fabrication where ease of use and multi-metal compatibility are priorities. Unlike the E7018 rods, these are designed for versatility, capable of joining various metals including aluminum, stainless steel, and iron. Their low melting point makes them incredibly user-friendly, ideal for beginners or quick repairs on thinner tubular sections without requiring complex equipment or settings. They’re great for situations where you might be connecting dissimilar tubular metals or simply need a simple, strong bond for non-critical repairs.

Key features that stand out:

* Universal Compatibility: Suitable for joining diverse metals like aluminum, stainless steel, and iron tubing.

* Versatile Application: Effective for both repair work and new construction projects on different metal combinations.

* Easy to Use: Low melting point design makes them accessible for beginners.

* Professional-Grade Performance: Delivers strong, durable bonds despite ease of use.

* Excellent Flow Characteristics: Ensures good penetration and a smooth finish.

Pros:

* Extremely versatile for multi-metal applications

* Beginner-friendly due to low melting point

* Good for quick repairs on various tubular materials

* No special equipment needed, works with standard arc welders

Cons:

* Not intended for high-stress structural tubular applications requiring E7018 strength.

Best for: Repairing thinner-walled tubular components of various metals (aluminum, stainless, iron), hobby projects, and beginners looking for a straightforward welding solution for less critical applications.

Expert Opinion: While not a substitute for E7018 on heavy structural steel, these universal rods are surprisingly effective for small repairs on exhaust tubing, fence posts, or light-duty frames where you might encounter different metals. The low temperature is a huge advantage for preventing warp on thinner sections.

UNIFAMILY 50pcs Stainless Steel TIG Welding Rod ER308L,…

When your tubular steel project involves stainless steel, these UNIFAMILY ER308L TIG welding rods are an excellent choice. Made from low carbon stainless steel, they’re designed to resist rust and provide smooth, high-quality welds on stainless and even mild/low alloy steels. TIG welding offers superior control and precision, which is a huge advantage when you’re working on thin-walled stainless steel tubing for applications like exhaust systems, food-grade piping, or intricate architectural elements. The smooth weld seams and minimal cleanup are major benefits for aesthetic and hygienic finishes.

Key features that stand out:

* High Quality ER308L: Low carbon stainless steel material, resistant to rust.

* Applicable Sizes: 1/16 inch diameter, 16 inches long, suitable for various TIG machines.

* Easy to Use: Provides a smooth weld seam and eliminates the need for extensive cleanup.

* Stable Arc, Less Spatter: Ideal for high-current welding with excellent control.

* Wide Application: Perfect for small diameter pipes and tubes, automotive parts, and construction involving stainless steel.

Pros:

* Specifically designed for high-quality stainless steel welding

* Provides clean, smooth welds with minimal spatter and cleanup

* Excellent for precise work on thin-walled tubing

* Reliable for applications requiring aesthetic appeal and corrosion resistance

Cons:

* Requires TIG welding equipment and a higher skill level than stick welding.

Best for: Precision welding of stainless steel tubular components, thin-walled stainless steel pipes, exhaust systems, and applications where a clean, aesthetically pleasing, and corrosion-resistant weld is critical.

Expert Opinion: If you’re TIG welding stainless steel tubing, ER308L is the standard. This UNIFAMILY offering provides a good quantity of reliable rod. The ability to create super clean, smooth welds without spatter is paramount for stainless work, especially when appearance and sanitation are factors.

Blue Demon ER308L X 1/16″ X 36″ X 1LB Tube…

Another top-tier option for stainless steel tubular welding is the Blue Demon ER308L TIG rod. Known for their quality, Blue Demon provides these 1/16″ rods in a convenient 1LB tube. This rod is not only excellent for standard stainless steel welding (like types 304, 308) but is also specifically recommended for types 321 and 347, offering versatility for a broader range of stainless alloys found in tubular structures. Its suitability for cryogenic temperatures highlights its superior metallurgical properties, making it a reliable choice for demanding applications. When you need consistent, high-integrity welds on stainless steel tubing, Blue Demon is a brand you can trust.

Key features that stand out:

* ER308L Stainless Steel: Ideal for welding common stainless steel grades and more specialized types (321, 347).

* Cryogenic Applications: Suitable for welding tubular components that will operate in extremely low-temperature environments.

* AWS A5.9 Standard: Meets industry standards for quality and performance.

* Welding Current DCEN: Optimized for direct current electrode negative TIG welding.

* 1/16″ Diameter: Excellent for precision control on thin to medium-walled stainless steel tubing.

Pros:

* High-quality weld for various stainless steel types

* Excellent performance in demanding environments, including cryogenic

* Reliable brand reputation for consistency

* Ensures strong, corrosion-resistant welds on stainless tubular

Cons:

* Requires specific TIG setup and technique.

Best for: High-performance stainless steel tubular fabrication, chemical processing pipelines, food service equipment, and any critical application requiring superior stainless steel TIG welds, especially those exposed to extreme temperatures.

Expert Opinion: Blue Demon’s ER308L is a premium choice for TIG welding stainless steel tubing. The fact that it’s good for 321 and 347, plus cryogenic applications, tells you it’s a high-grade rod. For critical stainless tubular joints where absolutely no compromise on quality or integrity is acceptable, this is a winner.

Helpful Comparison Short Insights

When picking the best welding rod for tubular steel, understanding the nuances between these options is key. For general carbon steel tubular projects, especially those requiring structural integrity and X-ray quality, E7018 rods are truly the industry standard. The YESWELDER E7018 (3/32” and 5/32”) and ARCCAPTAIN E7018 (3/32”) are top contenders here, offering robust, low-hydrogen welds. The 3/32” diameter is fantastic for root passes on thinner tubing or when you need precise control, while the 5/32” shines for heavier fill and cap passes on thicker-walled tubular components.

If you’re dealing with stainless steel tubing, your go-to options are the ER308L TIG rods, like the UNIFAMILY and Blue Demon offerings. TIG welding with ER308L provides superior aesthetic and metallurgical quality, crucial for applications where appearance, corrosion resistance, or specific alloys (like 321 and 347 with Blue Demon) are paramount. The 1/16″ diameter of these TIG rods is perfect for the precision needed on stainless tubular.

For quick fixes, hobby work, or joining dissimilar metals in non-critical tubular applications, the 6 Pieces Low Temperature Universal Welding Rods offer unmatched versatility and ease of use. They’re a great “emergency” or “beginner” option but remember they don’t provide the same structural strength or X-ray quality as E7018 or ER308L for demanding tubular projects.

Final Verdict

Choosing the best welding rod for tubular steel ultimately depends on your specific project, material, and skill level.

- For robust structural carbon steel tubular projects demanding X-ray quality and superior crack resistance, the YESWELDER E7018 (in either 3/32″ or 5/32″ depending on thickness) and the ARCCAPTAIN E7018 (3/32″) are your undisputed champions. These low-hydrogen rods offer the strength and integrity you need for critical applications like roll cages, chassis, or heavy-duty frameworks.

- When working with stainless steel tubular components, especially where aesthetics, corrosion resistance, and precise control are essential, the UNIFAMILY ER308L and Blue Demon ER308L TIG rods are the standout performers. Their ability to create clean, high-quality welds makes them ideal for exhaust systems, sanitary piping, or custom stainless fabrications.

- For casual repairs, multi-metal joining, or beginners tackling non-critical tubular work, the 6 Pieces Low Temperature Universal Welding Rods provide a simple and versatile solution. They’re a great addition to any workshop for quick fixes but shouldn’t be relied upon for structural integrity.

No matter which you choose, proper technique and appropriate amperage settings will always be key to achieving the best results on your tubular steel welding endeavors.

Best Welding Rod For Tubular Steel: Your FAQ Answered

Q1: Why is E7018 often recommended as the best welding rod for tubular steel?

A1: E7018 rods are low-hydrogen electrodes, which means they produce welds with very little hydrogen content. This is crucial for tubular steel, especially in structural applications, because hydrogen can cause cracking (hydrogen-induced cracking or delayed cracking) in the weld, compromising its integrity. E7018 also offers excellent tensile strength, good impact resistance, and can be used in all positions, which is common for tubular welding.

Q2: Can I use other types of electrodes for welding tubular carbon steel besides E7018?

A2: Yes, you can. For less critical, general-purpose welding on mild carbon steel tubing, E6010 or E6011 rods are often used for root passes due to their deep penetration and ability to handle contaminated surfaces. E6013 is good for thin-walled tubing and offers a smooth, cosmetic bead. However, for structural integrity and critical applications, E7018 is generally preferred because of its superior mechanical properties and low hydrogen content.

Q3: What’s the difference between 3/32″ and 5/32″ E7018 rods for tubular steel welding?

A3: The diameter dictates the amperage range and the amount of filler metal deposited. A 3/32″ E7018 rod uses lower amperage (e.g., 70-100A) and is excellent for root passes, welding thinner-walled tubing, or making precise welds in tight spaces. A 5/32″ E7018 rod uses higher amperage (e.g., 150-220A) and is better suited for filling larger gaps, cap passes, or welding thicker-walled tubular sections where high deposition rates are needed.

Q4: When should I choose TIG welding rods (like ER308L) for tubular steel instead of stick welding rods?

A4: You should choose TIG welding rods, specifically ER308L, when you are welding stainless steel tubular components (e.g., exhaust pipes, food-grade tubing, architectural elements). TIG welding provides superior control, precision, and produces extremely clean, high-quality, and aesthetically pleasing welds with minimal spatter and cleanup. It’s ideal for thin-walled tubing where warpage is a concern and for applications where corrosion resistance is paramount.

Q5: Are low-temperature universal welding rods suitable for structural tubular steel projects?

A5: No, generally not. While low-temperature universal welding rods are excellent for beginners, quick repairs, or joining dissimilar metals in non-critical applications (like light hobby projects or minor automotive repairs), they typically do not provide the same tensile strength, crack resistance, or X-ray quality that E7018 electrodes offer for structural tubular steel. Always use E7018 or other specific structural electrodes for critical load-bearing tubular components.

Q6: How should I store welding rods to maintain their quality, especially E7018 for tubular steel?

A6: Proper storage is crucial for maintaining the quality of welding rods, especially low-hydrogen E7018. These rods are susceptible to moisture absorption, which can introduce hydrogen into the weld metal and lead to cracking. Store them in a dry, airtight container or a heated rod oven to keep them free from moisture. If rods have been exposed to humidity, they might need to be re-baked according to the manufacturer’s specifications before use on critical tubular steel applications.

Q7: What are LSI keywords and why are they relevant to “Best Welding Rod For Tubular Steel”?

A7: LSI (Latent Semantic Indexing) keywords are conceptually related terms that help search engines understand the broader context and relevance of your content. For “Best Welding Rod For Tubular Steel,” LSI keywords like “electrode types,” “low hydrogen,” “arc stability,” “material compatibility,” “welding positions,” “structural welding,” “pipe welding,” and “crack resistance” ensure that the article comprehensively covers the topic, making it more informative and discoverable by users searching for related information.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.