When I first started tackling galvanized steel projects, I quickly learned it’s not like welding regular mild steel. The zinc coating brings its own challenges, especially with those notorious fumes and the potential for a weakened weld if you don’t use the right approach. Through trial and error, and a fair bit of research, I’ve found that picking the best welding rod for galvanized steel is crucial for getting strong, clean, and safe results. It’s all about balancing effective zinc burn-off with good penetration and minimal porosity. This guide is based on my experience and what truly works, aiming to help you choose the ideal rod for your next galvanized welding job.

Contents

- 6 Pieces Low Temperature Universal Welding Rods, Metal…

- 50Pcs Metal Universal Welding Wire easy to use Flux Core…

- HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 201 Stainless…

- HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless…

- JJHXSM Copper Aluminum Welding Rod 20PCS General…

- Helpful Comparison Insights

- Final Verdict

- FAQs: Best Welding Rod To Use For Galvanized Steel

- Q1: Why is welding galvanized steel different from welding regular steel?

- Q2: What type of welding rod is generally recommended for galvanized steel?

- Q3: Do I need special precautions when welding galvanized steel?

- Q4: Can I use universal welding rods on galvanized steel effectively?

- Q5: What’s the difference between flux-cored and solid rods for welding galvanized?

- Q6: What about post-welding treatment for galvanized steel?

6 Pieces Low Temperature Universal Welding Rods, Metal…

These low-temperature universal welding rods are a fantastic pick for anyone looking for versatility, especially if you’re working on various metals alongside galvanized steel. I’ve found them incredibly user-friendly, making them a great option for beginners or those who don’t want to mess with specific rods for every metal type. Their low melting point is a key benefit, allowing for easier manipulation and helping to minimize excessive zinc burn-off when dealing with galvanized surfaces, which translates to a cleaner weld and less fumes. They create strong, durable bonds across different combinations of metals.

- UNIVERSAL COMPATIBILITY: Works with aluminum, stainless steel, iron, and other metal combinations.

- VERSATILE APPLICATION: Suitable for both repair work and new construction projects.

- EASY TO USE: Low melting point design makes them ideal for beginners.

- COMPLETE SET: Comes with 6 rods, ready for immediate use.

- PERFORMANCE: Formulated for strong, durable bonds with excellent flow characteristics.

Pros:

– Extremely versatile, reducing the need for multiple rod types.

– Low melting point helps with easier welding and less heat distortion.

– Great for beginners due to their ease of use.

– Produces strong and reliable joints.

Cons:

– May not offer the specialized strength or alloy compatibility required for heavy-duty industrial or structural applications.

Best for: Hobbyists, DIY enthusiasts, and general home repairs involving a mix of metals, including lighter gauge galvanized steel.

Expert Opinion: These rods truly shine for their universal application and low-temperature characteristics, making them forgiving and versatile. They’re particularly good for smaller repairs on galvanized items where precise heat control is beneficial to manage zinc fuming.

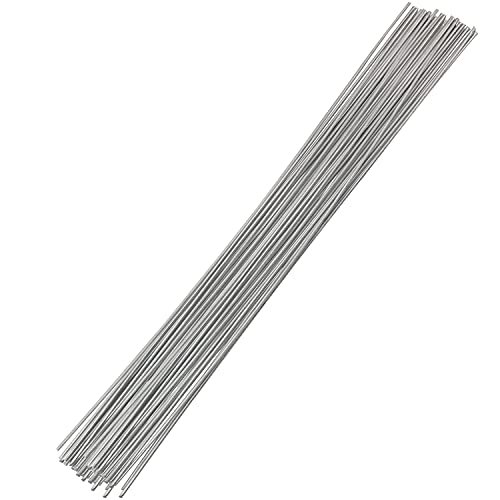

50Pcs Metal Universal Welding Wire easy to use Flux Core…

If you’re looking for extreme convenience and a strong focus on “white metals” which often includes lighter galvanized materials, this 50-piece flux-cored welding wire set is a standout. The most impressive feature for me is that you don’t need additional solder powder, as the flux is conveniently integrated into the core. This makes the welding process much cleaner and quicker. They’re primarily designed for aluminum and its alloys but are also quite capable with other non-ferrous metals, making them a solid choice for certain galvanized applications where aluminum is also present or for the zinc coating itself. The welds come out full and smooth, showing excellent corrosion resistance.

- No Need Solder Powder: Flux-cored design eliminates the need for external flux powder.

- Solution Welding Flux-cored Rods: High-quality rods for welding/brazing aluminum and its alloys, also non-ferrous metals.

- Perfect Welding Effect: Achieves full and smooth welds with great weldability and corrosion resistance.

- Strong Welding: Can weld almost all white metals, including aluminum, aluminum alloys, cast aluminum, aluminum-magnesium alloys, and some stainless steel.

- High Quality Safe and Stable: Each piece is 33cm (13inch) long with a 1.6mm diameter.

Pros:

– Self-fluxing design greatly simplifies the welding process.

– Produces very clean, smooth, and corrosion-resistant welds.

– Excellent for a wide range of aluminum and white metal applications.

– Strong bonding ensures durability.

Cons:

– While versatile, its primary strength lies with aluminum, which might not be ideal if your base galvanized material is steel requiring specific steel-welding rods.

Best for: Repairing aluminum structures, appliances, or components that might be galvanized, where ease of use and a clean finish are top priorities.

Expert Opinion: The flux-cored design for aluminum and white metals is a game-changer for speed and ease. For galvanized applications, especially if the galvanized coating is what you’re primarily fusing or repairing, these rods offer a smooth, clean bond with minimal fuss.

HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 201 Stainless…

When your project specifically calls for welding 201 grade stainless steel, which might be found in some galvanized setups or adjacent to galvanized components, the HARFINGTON E308L-16 is a robust choice. These rods are made from quality steel, offering excellent resistance to rust and corrosion, which is a critical factor when dealing with materials like galvanized steel that are designed for corrosion protection. I appreciate their AC and DC power supply compatibility and their ability to perform well in all-position welding, offering great flexibility in various work scenarios. They ensure strong, durable joints on stainless steel.

- Size: Diameter: 1.6mm (1/16″), Length: 250mm (10″); 10 x E308L-16 Welding Rods included.

- Material: Made of quality steel, resistant to rust and corrosion.

- Feature: Welding electrodes E308L-16 rods for stainless steel welding in metal fabrication, maintenance, and repair work.

- Application: Low melting point, great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

- Note: Keep as dry as possible; heating and cooling should be done slowly.

Pros:

– Specifically formulated for 201 stainless steel, ensuring optimal material compatibility.

– Excellent corrosion and rust resistance.

– Compatible with both AC and DC power supplies.

– Allows for all-position welding, enhancing versatility.

Cons:

– Its specific application for 201 stainless steel means it’s not a general-purpose rod for mild galvanized steel.

Best for: Projects requiring welding of 201 stainless steel components, especially in environments where corrosion resistance is paramount, or when joining 201 stainless to other compatible metals that might be galvanized.

Expert Opinion: The E308L-16 designation is key here, pointing to its specialized use for stainless steel. While not a direct “galvanized steel” rod, its properties for stainless make it valuable for assemblies where 201 stainless meets galvanized parts, offering a strong, corrosion-resistant stainless joint.

HARFINGTON E308L-16 Welding Rod 1/16″ x 10″ 304 Stainless…

Much like its 201 counterpart, the HARFINGTON E308L-16 for 304 stainless steel is another specialized, high-quality option. If your project involves the highly popular 304 grade stainless steel, these rods provide optimal performance and material integrity. They excel in applications requiring high resistance to corrosion and wear, which is often a consideration when working with or near galvanized materials. The AC and DC power compatibility coupled with all-position welding makes these rods incredibly adaptable for various fabrication, maintenance, and repair tasks on 304 stainless components.

- Size: Diameter: 1.6mm (1/16″), Length: 250mm (10″); 10 x E308L-16 Welding Rods included.

- Material: Made of quality steel, resistant to rust and corrosion.

- Feature: Welding electrodes E308L-16 rods for stainless steel welding in metal fabrication, maintenance, and repair work.

- Application: Low melting point, great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

- Note: Keep as dry as possible; heating and cooling should be done slowly.

Pros:

– Specifically designed for optimal welding of 304 stainless steel.

– Offers excellent corrosion and rust resistance, vital for durability.

– Versatile with AC/DC compatibility and all-position welding.

– Ensures high-quality, strong welds on 304 stainless.

Cons:

– Not a suitable choice for welding mild steel or other base metals commonly found in galvanized applications.

Best for: Fabrication and repair of 304 stainless steel components, especially in food service, chemical, or architectural applications where 304 stainless is the primary material, or where it interfaces with galvanized elements.

Expert Opinion: The precision for 304 stainless steel is this rod’s main draw. In complex structures where galvanized elements are joined to 304 stainless, using the correct rod for the stainless portion is crucial for maintaining the assembly’s integrity and corrosion resistance.

JJHXSM Copper Aluminum Welding Rod 20PCS General…

This 20-piece set of JJHXSM Copper Aluminum Welding Rods truly stands out for its explicit mention of suitability for galvanized steel and galvanized cast iron, alongside a broad range of other metals including aluminum, stainless steel, and high-strength copper. This versatility makes it an incredibly practical choice for general repair work around the home or workshop. I particularly like the integrated powder core design, which means no separate welding powder is needed, simplifying the process and making it more efficient. The low melting point (380-400 degrees Celsius) contributes to good forgeability, conductivity, and corrosion resistance, resulting in a smooth welding effect.

- Multiple uses: Widely applicable in electricity, chemistry, food use; suitable for aluminum, stainless steel, galvanized steel, galvanized cast iron, high-strength copper.

- No need for welding powder: Multifunctional copper-aluminum welding wire with internal powder and low melting point (380-400 degrees Celsius).

- Good performance: Powder core design provides good forgeability, conductivity, and corrosion resistance, ensuring a smooth welding effect.

- Size information: 1.6 mm / 0.06 inches diameter and 33 cm / 13 inches length.

- Aluminum welding rods can repair or manufacture almost anything made of aluminum, pot metal or galvanized steel, as well as heterogeneous welding between the above metals.

Pros:

– Specifically listed as suitable for galvanized steel and galvanized cast iron.

– Incredibly versatile for a wide range of metals including copper, aluminum, and stainless steel.

– Self-fluxing (no separate welding powder needed) for ease of use.

– Low melting point for better control and reduced material stress.

– Excellent for general maintenance and diverse repair scenarios.

Cons:

– The “general purpose” nature might mean it doesn’t offer the peak performance of highly specialized rods for single material types.

Best for: Anyone needing a truly multi-purpose welding rod, especially if you’re frequently working with galvanized steel, aluminum, copper, and stainless steel in various repair and maintenance tasks.

Expert Opinion: The direct mention of “galvanized steel” as a primary application makes this an extremely relevant option for our focus. Its flux-cored, low-temperature, and multi-metal capabilities make it a strong contender for anyone needing a reliable, general-purpose rod that can handle the zinc coating effectively.

Helpful Comparison Insights

When looking at the best welding rod to use for galvanized steel, it’s clear there are different approaches depending on your project. For general home use and diverse repairs, the “6 Pieces Low Temperature Universal Welding Rods” and the “JJHXSM Copper Aluminum Welding Rod” stand out. Both offer universal compatibility and low melting points, which are excellent for managing the zinc coating on galvanized surfaces. The JJHXSM rod specifically calls out galvanized steel, making it a highly confident choice for those applications.

If convenience and a clean finish on aluminum and related “white metals” are your main concern, even if those are galvanized, then the “50Pcs Metal Universal Welding Wire easy to use Flux Core” is an impressive option due to its self-fluxing core and smooth results. However, remember its primary strength is aluminum.

For tasks that involve specific grades of stainless steel in conjunction with or near galvanized components, the HARFINGTON E308L-16 rods (both 201 and 304 versions) are your go-to. They are highly specialized for stainless steel, ensuring proper alloy compatibility and corrosion resistance, though they aren’t meant for welding the galvanized mild steel itself. Choosing between the 201 and 304 versions simply depends on the exact grade of stainless steel you’re working with.

Consider your base metal and the primary goal: Are you welding galvanized mild steel, or welding another metal to a galvanized component? The universal low-temp options are best for the former, while the stainless-specific rods are for the latter.

Final Verdict

Navigating the world of welding rods for galvanized steel can feel a bit overwhelming, but after looking at these options, a clear picture emerges.

For me, the JJHXSM Copper Aluminum Welding Rod (Product 5) truly takes the top spot as the overall best welding rod to use for galvanized steel in a general-purpose scenario. Its explicit mention of “galvanized steel,” combined with its multi-metal compatibility and convenient flux-cored design, makes it an incredibly practical and effective choice for a wide range of repairs and fabrication projects where galvanized materials are present. It offers that crucial low melting point and ease of use without sacrificing strength.

If your projects lean heavily towards aluminum and other white metals, and you prioritize a super clean, no-fuss process, the 50Pcs Metal Universal Welding Wire easy to use Flux Core (Product 2) is an excellent runner-up. Its self-fluxing nature is fantastic for speed and quality on those specific materials.

For those just starting out or needing a truly broad-spectrum solution for light-duty repairs on various metals including galvanized, the 6 Pieces Low Temperature Universal Welding Rods (Product 1) are a very forgiving and user-friendly option.

Lastly, if your work involves specific stainless steel grades (201 or 304) that are part of a galvanized assembly, then the HARFINGTON E308L-16 rods (Products 3 & 4) are indispensable for maintaining the integrity and corrosion resistance of those stainless components. Just remember they’re not for welding the underlying mild steel of the galvanized piece.

Ultimately, by considering the specific needs of your project and the base metals involved, you can confidently choose the right rod to ensure strong, durable, and safe welds on galvanized steel.

FAQs: Best Welding Rod To Use For Galvanized Steel

Q1: Why is welding galvanized steel different from welding regular steel?

A1: Welding galvanized steel is trickier because of its zinc coating. When heated, the zinc vaporizes, producing toxic zinc fumes that are hazardous to breathe (often called “metal fume fever”). This vaporization also creates gas that can lead to porosity and embrittlement in the weld, weakening the joint. Proper ventilation and specific rod choices are crucial to minimize these issues.

Q2: What type of welding rod is generally recommended for galvanized steel?

A2: For arc welding (SMAW) on galvanized steel, rods that offer good penetration and are designed to handle contaminants are often preferred. Common choices include E6010 and E6011 (cellulose-coated rods) because their digging arc helps burn off the zinc coating and minimize porosity. Some low-temperature, flux-cored rods designed for multi-metal or low-fume applications, like some reviewed above, can also be excellent, especially for thinner materials.

Q3: Do I need special precautions when welding galvanized steel?

A3: Absolutely. Excellent ventilation is paramount to disperse the toxic zinc fumes. Always use Personal Protective Equipment (PPE), including a respirator (preferably a powered air-purifying respirator, PAPR, or at least an N95 or P100 mask designed for metal fumes) and standard welding gear. If possible, it’s recommended to grind off the galvanized coating 1-2 inches around the weld area to reduce fume exposure and improve weld quality.

Q4: Can I use universal welding rods on galvanized steel effectively?

A4: Yes, many universal welding rods, especially those designed for low-temperature applications and with flux-cored capabilities, can be quite effective on galvanized steel. The low melting point helps manage the zinc vaporization, and the flux can help scavenge impurities. Always check the product description, like with the JJHXSM rods, for explicit mention of galvanized steel compatibility.

Q5: What’s the difference between flux-cored and solid rods for welding galvanized?

A5: Solid rods (like E6010/E6011) rely on their arc characteristics to burn off the zinc. Flux-cored rods, on the other hand, have a core that contains fluxing agents. This internal flux can help clean the molten puddle, deoxidize the weld, and sometimes even reduce fuming by incorporating the zinc into the slag, leading to smoother, less porous welds on galvanized surfaces. Some multi-metal flux-cored wires are specifically formulated for this challenge.

Q6: What about post-welding treatment for galvanized steel?

A6: After welding galvanized steel, the area immediately around the weld will have lost its zinc coating, making it susceptible to corrosion. It’s crucial to recoat the exposed area to restore corrosion protection. Options include applying a zinc-rich paint, cold galvanizing compound, or other protective coatings designed for metal. This step is vital for the long-term durability of your repaired or fabricated galvanized structure.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.