When I first started welding steel, I quickly realized that the rod you choose makes a massive difference – sometimes it’s the thin line between a strong, beautiful bead and a messy, weak joint. Having spent countless hours behind the hood, testing different electrodes on various steel projects, I’ve come to appreciate how critical it is to pick the right “Best Welding Rods For Steel” for the job. This isn’t just about getting the metal to stick; it’s about achieving optimal penetration, minimal spatter, and rock-solid integrity, whether you’re working on thin sheet metal or heavy structural components. We’ve put some top contenders through their paces to help you find your perfect match for welding mild steel and carbon steel.

Contents

- YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick

- YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

- YESWELDER E6013 3/32” 2LB Welding Rod Carbon Steel Stick

- ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon

- YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon

- Helpful Comparison Short Insights

- Final Verdict

- Best Welding Rods For Steel: FAQ

- What are the main types of welding rods for steel?

- When should I use an E6013 rod instead of an E7018 for steel?

- Can I use the same welding rods for mild steel and carbon steel?

- What do the numbers in “E6013” or “E7018” mean on welding rods for steel?

- Why is a low hydrogen welding rod important for certain steel applications?

- What amperage settings should I use for 3/32” welding rods for steel?

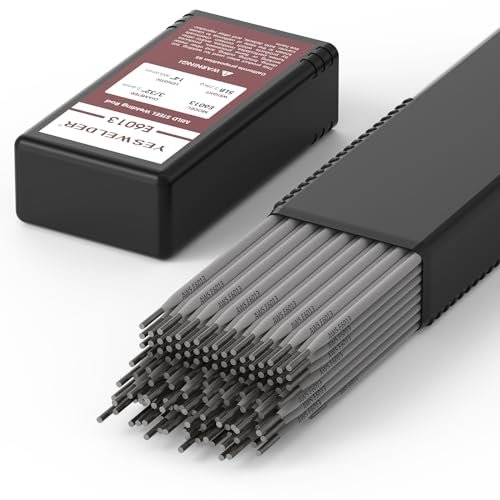

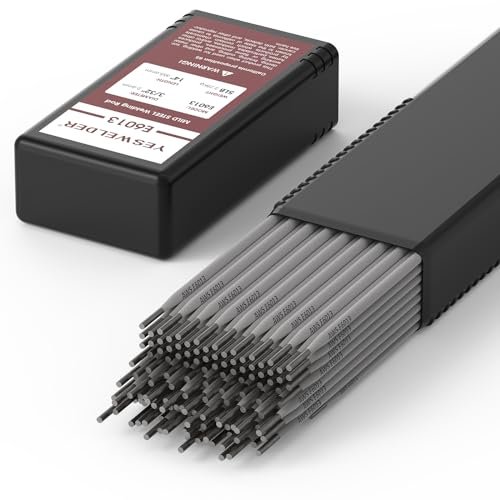

YESWELDER E6013 3/32” 5LB Welding Rod Carbon Steel Stick

The YESWELDER E6013 is a fantastic all-rounder for anyone working with mild steel, especially if you’re tackling general fabrication, light repairs, or even some sheet metal work. This rod is incredibly forgiving, making it a favorite for beginners and seasoned pros alike. I’ve found it creates a clean, consistent arc with surprisingly little spatter, which means less cleanup time after the weld. It’s a true workhorse for everyday steel projects.

Key features that stand out:

– Model: E6013 is a mild-steel, general-purpose rod.

– Versatile Current: Operates on AC or DC welding current, great for low-voltage AC machines.

– All-Position Welding: Excellent for shallow penetration or poorly fitted conditions.

– Clean Performance: Low spatter and virtually self-cleaning slag, especially in vertical down fillets.

– Usage: Ideal for all types of mild steel, light gauge metal, sheet metal, and ductwork.

Pros:

– Very easy to strike and maintain an arc.

– Produces visually appealing welds with minimal effort.

– Great for thin materials without burning through.

– Excellent slag removal, often peels off on its own.

Cons:

– Not ideal for heavy-duty structural applications requiring deep penetration.

Best for: General mild steel fabrication, sheet metal work, hobbyists, and repair jobs.

Expert Opinion: This rod is your go-to for general shop tasks. Its ease of use and clean finish make it highly reliable for non-critical welds where aesthetics and user-friendliness are key.

YESWELDER Mild Steel TIG Welding Rod ER70S-6 1/16″x16″ 5LB

While many think of “rods” as stick electrodes, if you’re a TIG welder working with mild steel, the YESWELDER ER70S-6 is an absolute standout. This specific rod is designed for TIG welding, offering exceptional control and cleanliness. I’ve used it on everything from farm implement repairs to precise fabrication, and it consistently delivers smooth, strong welds. The copper coating helps with arc stability, and the deoxidizers mean you get a cleaner bead, even with less-than-perfect base metal conditions.

Key features that stand out:

– Model: ER70S-6 is a gas-shielded, copper-coated carbon steel TIG rod.

– Superior Deoxidizers: Highest combination of manganese and silicon for cleaner welds.

– Shielding Gas Versatility: Works well with 100% CO2 or argon-rich mixes for smoother beads and less spatter.

– Broad Application: Suitable for mild and low alloy steel in construction, farm, tanks, truck bodies, and general shop use.

– Handles Imperfections: Great for applications with poor fit-up or rusty/oily plates.

Pros:

– Produces very smooth and aesthetically pleasing TIG welds.

– Excellent for achieving high-quality, precise welds on steel.

– Handles slight contaminants on the base metal better than some alternatives.

– Minimizes post-weld cleanup due to low spatter.

Cons:

– Requires a TIG welding setup and the skill set for TIG, not suitable for stick welders.

Best for: TIG welding mild and low alloy steels, precision fabrication, structural work where TIG is preferred, and situations with less-than-ideal material cleanliness.

Expert Opinion: For anyone performing TIG welding on steel, the ER70S-6 is a top-tier choice. Its ability to create strong, clean welds with minimal effort on various mild steel applications makes it indispensable.

YESWELDER E6013 3/32” 2LB Welding Rod Carbon Steel Stick

This 2LB package of YESWELDER E6013 is essentially the same excellent rod as its 5LB counterpart, but in a smaller, more convenient size. For those of us who don’t need a huge bulk supply or are just tackling smaller projects around the garage, this is a perfect option. It offers the same easy arc striking, low spatter, and excellent general-purpose performance that the E6013 is known for, making it ideal for lighter gauge metals and everyday repairs. You get the quality without the commitment to a larger box.

Key features that stand out:

– Model: E6013 is a mild-steel, general-purpose rod.

– Versatile Current: Operates on AC or DC welding current, suitable for low-voltage AC machines.

– All-Position Welding: Great for shallow penetration or in poor fitted conditions.

– Clean Performance: Low spatter and virtually self-cleaning slag, excellent for vertical down fillets.

– Usage: Ideal for all types of mild steel, light gauge metal, sheet metal, and ductwork.

Pros:

– Perfect for small projects, hobbyists, or those who need a limited supply.

– Offers the same forgiving and easy-to-use characteristics of the larger E6013.

– Excellent for general mild steel fabrication and light gauge materials.

– Produces clean, good-looking welds with easy slag removal.

Cons:

– More expensive per pound compared to the 5LB option if you frequently weld.

Best for: Home users, small workshops, students, and anyone needing E6013 performance in a more manageable quantity for occasional light steel work.

Expert Opinion: If you love the E6013 but don’t need a massive supply, this smaller package is a smart choice. It delivers the same reliable, user-friendly performance for your smaller mild steel projects.

ARCCAPTAIN E7018 Welding Rod 3/32” 5LB Low Hydrogen Carbon

When it comes to strength and critical applications, the ARCCAPTAIN E7018 is a champion among welding rods for steel. This low-hydrogen electrode is what you reach for when you need high-quality, X-ray worthy welds on structural components, high-pressure pipelines, or any project where weld integrity is paramount. I’ve found its arc to be incredibly stable, laying down a strong, dense bead with excellent penetration. It’s designed to minimize hydrogen-induced cracking, which is a huge advantage for various carbon and low-alloy steels.

Key features that stand out:

– Model: E7018 is a low-hydrogen, iron powder electrode.

– High-Quality Welds: Delivers X-ray quality welds with high tensile strength and crack resistance.

– Versatile Polarity: Suitable for all positions using AC or DC reverse polarity.

– Exceptional Performance: High melting efficiency, smooth/stable arc, less spatter, and low defect rates.

– Wide Application: Ideal for low, medium, and high carbon steels, steel structures, pipelines, ships, and power generation equipment.

Pros:

– Produces extremely strong welds with high integrity.

– Excellent for critical structural applications and thick materials.

– Low hydrogen content significantly reduces the risk of cracking.

– Very stable arc and good deposition efficiency.

Cons:

– Requires proper storage (dry) to maintain low-hydrogen properties, and can be a bit more challenging for beginners to strike an arc compared to E6013.

Best for: Structural fabrication, heavy equipment repair, pressure vessels, pipelines, and any application requiring maximum weld strength and ductility on carbon and low-alloy steels.

Expert Opinion: The E7018 is the workhorse for serious welders tackling demanding projects. Its low hydrogen properties and superior strength make it essential for critical joints where failure is not an option.

YESWELDER E7018 3/32” 5LB Welding Rod Low Hydrogen Carbon

Similar to the ARCCAPTAIN offering, the YESWELDER E7018 is another excellent choice for when you absolutely need a strong, reliable weld on steel. This low-hydrogen electrode is designed to produce high-quality, X-ray welds, making it perfect for structural work, offshore rigs, and power plants. I’ve found its arc to be exceptionally steady, leading to smooth, consistent beads with minimal spatter. Its good re-striking ability is a bonus, and the high deposition efficiency means you can lay down metal quickly and effectively when needed.

Key features that stand out:

– Model: E7018 is a low-hydrogen, iron powder type electrode.

– X-ray Quality: Produces high-quality welds, suitable for critical applications.

– All-Position Welding: Can be used in all positions on AC or DC reverse polarity.

– Excellent Performance: Steady arc, low spatter, excellent re-striking ability, and high deposition efficiency.

– Wide Application: Recommended for medium grade carbon steels (even without preheat), cold rolled steels, low-alloy structurals, offshore rigs, and power plants.

Pros:

– Delivers exceptionally strong and durable welds.

– Low hydrogen content minimizes cracking in sensitive materials.

– Steady arc and good re-strike make it user-friendly for an E7018.

– High deposition rate is efficient for filling joints.

Cons:

– Requires diligent storage in dry conditions to maintain its performance characteristics.

Best for: High-integrity welds on medium carbon steels, low-alloy structurals, heavy fabrication, and applications where strength and crack resistance are paramount.

Expert Opinion: Another solid contender for heavy-duty welding. The YESWELDER E7018 performs admirably in structural and critical applications, consistently delivering strong, low-defect welds.

Helpful Comparison Short Insights

When choosing the best welding rods for steel, it really boils down to your project’s needs and your welding process. For general-purpose welding on mild steel, especially lighter gauges, the YESWELDER E6013 (in both 5LB and 2LB sizes) is incredibly user-friendly and produces clean, appealing welds with easy slag removal. It’s the forgiving option for everyday tasks and beginners.

However, if your work demands maximum strength, crack resistance, and X-ray quality welds on medium to high carbon steels or structural components, then the ARCCAPTAIN E7018 and YESWELDER E7018 are your champions. These low-hydrogen rods are built for durability and critical applications, though they might require a bit more skill and proper storage. They shine when dealing with thicker materials and high-stress environments.

It’s crucial to remember that the YESWELDER Mild Steel TIG Welding Rod ER70S-6 operates in a different league – it’s for TIG welding. If you’re a TIG welder, this rod offers unparalleled control, cleanliness, and excellent penetration for precise work on mild and low-alloy steels, even those with poor fit-up or minor surface contaminants. It’s the choice for those prioritizing ultimate bead aesthetics and strength through the TIG process.

Ultimately, for most home projects and general repairs, the E6013 offers excellent value and ease of use. For critical infrastructure or heavy fabrication, the E7018 is non-negotiable. And for TIG aficionados, the ER70S-6 ensures top-tier results.

Final Verdict

Navigating the world of welding rods for steel can seem daunting, but it really comes down to matching the rod to your job and skill level.

For hobbyists, general repairs, and light fabrication on mild steel, the YESWELDER E6013 (whether the 5LB or 2LB pack) is our top pick. It’s incredibly forgiving, easy to use, and produces neat welds, making it ideal for learning and everyday projects.

If your projects involve heavy-duty structural work, pipelines, or any application demanding maximum strength and integrity, you absolutely need a low-hydrogen rod. Both the ARCCAPTAIN E7018 and YESWELDER E7018 deliver exceptional performance in this category, providing high-quality, crack-resistant welds for critical jobs. For the most demanding scenarios where weld failure isn’t an option, an E7018 is the only way to go.

And for those who prefer the precision and clean aesthetics of TIG welding, the YESWELDER Mild Steel TIG Welding Rod ER70S-6 is a clear winner. It ensures superior control and beautiful, strong welds on mild and low-alloy steels, setting the standard for TIG operations.

Choose wisely, and your steel projects will stand the test of time!

Best Welding Rods For Steel: FAQ

What are the main types of welding rods for steel?

The two most common types for stick welding steel are E6013 and E7018. E6013 is a general-purpose, mild steel rod known for ease of use and shallow penetration, great for light gauge metals. E7018 is a low-hydrogen rod that provides much stronger, deeper-penetrating welds, ideal for structural and critical applications. For TIG welding mild steel, ER70S-6 is a common filler metal.

When should I use an E6013 rod instead of an E7018 for steel?

Use an E6013 rod for general fabrication, light gauge metals, sheet metal, and non-critical repairs on mild steel. It’s very forgiving, easy to strike, and produces aesthetically pleasing welds. Reserve E7018 for high-strength applications, structural welding, pressure vessels, and any project where weld integrity and resistance to cracking are paramount on medium to high carbon steels.

Can I use the same welding rods for mild steel and carbon steel?

Generally, yes, with considerations. E6013 is best for mild steel. E7018 rods are excellent for low, medium, and high carbon steels, offering superior strength and crack resistance due to their low-hydrogen properties. The ER70S-6 TIG rod is also suitable for a variety of mild and low alloy steels. Always ensure your chosen rod’s specifications match the base metal composition for optimal results.

What do the numbers in “E6013” or “E7018” mean on welding rods for steel?

The “E” stands for electrode. The first two digits (e.g., “60” in E6013, “70” in E7018) indicate the minimum tensile strength in thousands of pounds per square inch (PSI) – so 60,000 PSI and 70,000 PSI, respectively. The third digit signifies the welding positions the rod can be used in (e.g., “1” means all positions). The fourth digit indicates the type of coating and current used.

Why is a low hydrogen welding rod important for certain steel applications?

Low hydrogen rods like E7018 are crucial because hydrogen can get trapped in the molten weld metal and cause cracking as it cools, especially in thicker or higher carbon steels. Low hydrogen electrodes significantly reduce the risk of this problem, leading to much stronger, more ductile, and crack-resistant welds. This is vital for critical structural components, pressure vessels, and heavy machinery.

What amperage settings should I use for 3/32” welding rods for steel?

For a 3/32” E6013 rod, a common amperage range is 45A-90A. For a 3/32” E7018 rod, you’ll typically be in the 70A-100A range. These are general guidelines; always refer to the manufacturer’s recommendations on the rod packaging and adjust based on your specific welding machine, joint configuration, and desired penetration. Experimenting on scrap metal helps dial in the perfect setting.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.