I’ve spent countless hours under the hood, and I know that knowing the best welding tricks isn’t just about technique—it’s about having the right tools and knowledge. Getting that perfect bead, especially in tricky positions or when laying down a long TIG pass, often comes down to specialized accessories or having a solid reference guide nearby. We’ve tested some of the most helpful products on the market, from specialized heat shields that dramatically improve your TIG welding comfort to comprehensive guides perfect for farm welding and general metal fabrication. Let’s dive into the gear that actually makes a difference in your welding efficiency.

Contents

- Weldmonger TIG Finger Heat Shield, Pocket Size, Fiberglass, Unisex

- Welding Tips & Tricks Tig Finger Heat Shield

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding goggles.

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes

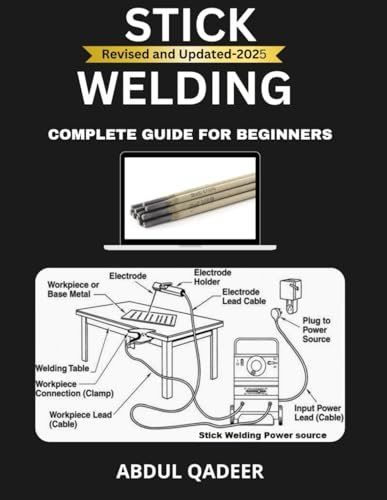

- Stick Welding: Complete Guide for beginners

- Comparison Insights on the Best Welding Tricks Gear

- Final Verdict

- Best Welding Tricks FAQ and Gear Advice

- Q1: Why is a TIG Finger considered one of the best welding tricks for beginners?

- Q2: What’s the main difference between the 6010 and 7018 electrodes mentioned in the Stick Welding guide?

- Q3: How do these guides help with increasing my overall welding efficiency?

- Q4: I mostly weld aluminum. Will a TIG Finger really make a difference?

- Q5: Is Stick welding (SMAW) really the best process for beginners to learn first?

- Q6: What safety item should I prioritize buying after my welding machine?

Weldmonger TIG Finger Heat Shield, Pocket Size, Fiberglass, Unisex

The Weldmonger TIG Finger is widely recognized as a secret weapon for professionals who need to lay long, smooth beads without stopping. I found that being able to slide your hand smoothly across hot metal surfaces dramatically reduces wrist strain and allows you to maintain a perfect pace. This simple accessory is a massive boost to welding efficiency, especially when working on stainless steel or aluminum where heat soak is a real issue. It’s small enough to keep in your pocket and durable enough to withstand continuous use in industrial settings.

Key features that stand out:

* Finish that Long Pass without Burning Your Fingers

* Pocket Size Durable Design Ideal for any TIG Job

* Increases the Lifespan of Your TIG Glove

* Great for Hobbyists and Industrial Welders

* 100% Sourced and Handmade in the USA

Pros:

* Eliminates the need for awkward prop setups on hot material

* Extremely durable fiberglass construction

* Comfortable and simple to slip on

* Essential for high-amperage, long-run TIG work

Cons:

* Can feel bulky initially until you get used to the feel.

Best for: Professional TIG welders tackling long passes on pipe or aluminum.

Expert Opinion: This is a cornerstone accessory for advanced TIG technique. If you’re struggling to finish a joint without flinching from the heat, this heat shield is a necessary upgrade, offering immediate results.

Welding Tips & Tricks Tig Finger Heat Shield

While similar in concept to the Weldmonger, the Welding Tips & Tricks version often focuses on a slightly different material blend, sometimes emphasizing a thinner profile for extremely tight corners. This specific shield aims to give you confidence when running stringers or welding internal corners where space is severely limited. I found its lighter design beneficial when I was trying to maintain precise fingertip control near the tungsten, preventing the dreaded “finger creep” away from the heat.

Key features that stand out:

* High-Temperature Silica Material for excellent heat dissipation

* Slim Profile for Tight Spots and confined access welding

* Integrated Thumb Loop for secure attachment

* Washable and Reusable Design, easy to maintain

* Designed by professional welders for practical field use

Pros:

* Excellent performance in tight quarters

* Lighter weight compared to heavier fiberglass options

* Helps reduce heat fatigue quickly

* Highly flexible material

Cons:

* May not last quite as long as the pure heavy-duty fiberglass models under extreme industrial use.

Best for: Automotive fabrication, hobbyists, or intermediate TIG welders needing a low-profile shield.

Expert Opinion: Don’t underestimate the value of heat management—it’s one of the best welding tricks there is. This shield allows you to rest your hand closer to the arc for better puddle control without worrying about immediate glove meltdown.

Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding goggles.

Sometimes the best trick is knowing your equipment inside and out. This book moves beyond technique and dives deep into the hardware, which is crucial for maximizing performance and staying safe. I appreciated the detailed sections on choosing the right machine for different types of work and the technical breakdowns of modern helmet technology, which is constantly changing. It’s perfect for beginners establishing their first workshop or experienced welders looking to purchase complex new machinery.

Key features that stand out:

* Detailed comparison charts for machine types (MIG vs TIG vs Stick)

* Safety standards breakdown for modern auto-darkening helmets

* Troubleshooting guide for common arc faults and machine issues

* Extensive photo examples of setup and calibration

* Advice on optimizing lens shading and clarity for different processes

Pros:

* Excellent resource for equipment purchasing decisions

* Demystifies complex welder specifications

* Strong focus on safety gear and standards

* Helps save money by avoiding improper equipment buys

Cons:

* Less focus on advanced welding techniques (purely gear and safety focused).

Best for: Beginners setting up their first shop, or experienced welders planning a major equipment upgrade.

Expert Opinion: Many people fail to realize that an improperly calibrated machine makes welding difficult regardless of skill level. This guide ensures your foundational knowledge about your tools is rock solid, translating directly into better weld quality.

Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes

This volume is a powerhouse of practical, heavy-duty welding knowledge designed for the rugged environment of a farm or serious home workshop. What sets this apart is its focus on structural repair and fabrication using readily available equipment, making it ideal for the general repair welder. When I was practicing, I found the extensive photo guides invaluable, especially for figuring out tricky cutting methods and dealing with large, heavy materials that require specific bracing. This book embodies the kind of hands-on, practical application often needed in metal fabrication.

Key features that stand out:

* Section on repairing thick structural steel and heavy equipment

* Projects specifically for agricultural equipment repair and construction

* Detailed plasma cutting and oxy-acetylene tutorials

* Focus on low-amp welding techniques for thin sheet metal

* Common repair mistakes and how to avoid them (critical troubleshooting)

Pros:

* Highly practical and focuses on real-world repair scenarios

* Step-by-step photos are clear and abundant

* Covers multiple processes (Stick, MIG, cutting)

* Excellent for learning how to plan large fabrication projects

Cons:

* The content can be overwhelming for someone who only wants to focus on one niche technique like TIG.

Best for: Farmers, mechanics, metal artists, and DIY enthusiasts needing robust structural repair skills.

Expert Opinion: If you are responsible for keeping heavy machinery running, this book is arguably the most valuable resource you can own. It turns theoretical knowledge into actionable, job-site repair expertise.

Stick Welding: Complete Guide for beginners

Stick welding (SMAW) is often the first process a beginner learns, and this guide provides an incredibly focused foundation. It simplifies concepts like polarity, electrode selection, and arc length, which are often sources of confusion for newcomers. I found the cheat sheets particularly helpful—no more guessing on amperage settings when switching from 6010 to 7018. If your primary goal is to master proper electrode technique and feel confident running a basic stick machine, this is the book to start with.

Key features that stand out:

* Detailed electrode selection guide (6010, 7018 explained simply)

* Step-by-step joint preparation instructions for stick welding

* Techniques for out-of-position stick welding (vertical and overhead)

* Amperage cheat sheets for various material thicknesses

* Focus on maximizing penetration and minimizing porosity

Pros:

* Extremely focused and easy to digest for true beginners

* Excellent guidance on dealing with slag inclusion

* Makes the complicated world of electrodes understandable

* Ideal for learning fundamental arc control

Cons:

* Does not cover other processes like MIG or TIG, limiting its scope for multi-process users.

Best for: Absolute beginners who have purchased a basic stick welder and need a comprehensive introduction to SMAW fundamentals.

Expert Opinion: Many people quit stick welding because they struggle to strike and maintain an arc. This guide addresses those basic hurdles head-on, ensuring a much smoother learning curve for anyone tackling their first electrode.

Comparison Insights on the Best Welding Tricks Gear

The biggest difference in this selection is between the physical aids that improve comfort and the foundational knowledge provided by the reference books. Both TIG Finger options offer significant improvements in comfort for long-pass aluminum welding and stainless work, but the Weldmonger version is specifically known for its extreme durability and heat resistance, making it the choice for high-amperage industrial work. The Welding Tips & Tricks shield is often praised for its lighter, lower-profile fit in restricted spaces.

When choosing educational materials, the Farm and Workshop book is specifically tailored for heavy-duty, practical repairs and general structural work using multiple processes. In contrast, the Stick Welding guide is the pure beginner’s bible for SMAW, focusing strictly on electrode handling and basic arc control. The Welding Tips & Tricks equipment book stands alone as the best resource for purchasing and understanding complex equipment like modern inverters and safety gear.

Final Verdict

Choosing the right tool or educational resource depends entirely on your current skill level and welding environment.

If your goal is to master TIG welding passes without stopping due to heat, the Weldmonger TIG Finger Heat Shield is an essential, inexpensive upgrade that will immediately improve your bead consistency and speed.

If you’re a beginner needing robust, real-world knowledge specifically for equipment repair and structural work that involves Stick, MIG, and cutting, the Farm and Workshop Welding book provides unparalleled value and comprehensive visual guides.

For those focusing solely on learning basic electrode selection and mastering the most forgiving process (SMAW), the Stick Welding: Complete Guide for beginners is precisely where you should start your journey to ensure you develop strong fundamentals.

Best Welding Tricks FAQ and Gear Advice

Q1: Why is a TIG Finger considered one of the best welding tricks for beginners?

A TIG Finger, like the Weldmonger or Welding Tips & Tricks models, is a massive advantage because it allows the welder to prop their hand comfortably on the hot workpiece without immediately burning through their glove. This ability to slide smoothly reduces heat fatigue and allows the beginner to focus entirely on maintaining the proper arc length and travel speed, leading to better-looking welds faster.

Q2: What’s the main difference between the 6010 and 7018 electrodes mentioned in the Stick Welding guide?

These are two common electrodes for SMAW welding. The 6010 electrode is known for deep penetration and works well on dirty or rusty steel; it’s great for root passes. The 7018 is a low-hydrogen electrode that produces superior mechanical properties (high strength and ductility). It’s typically used for structural, high-quality finishing passes where minimizing hydrogen cracking is essential.

Q3: How do these guides help with increasing my overall welding efficiency?

The educational guides, particularly Farm and Workshop Welding and the Welding Tips & Tricks equipment book, help efficiency by reducing downtime. They teach you proper joint preparation, show you how to quickly troubleshoot common machine faults, and ensure you’re using the correct machine settings and safety gear for the job, minimizing waste and rework.

Q4: I mostly weld aluminum. Will a TIG Finger really make a difference?

Absolutely. Aluminum quickly absorbs and retains a lot of heat, causing standard TIG gloves to heat up rapidly during a long pass, often forcing you to stop and re-position. Using a TIG Finger provides a critical thermal barrier, allowing you to sustain contact and complete long, continuous aluminum welding passes smoothly, which is essential for maximizing quality and appearance.

Q5: Is Stick welding (SMAW) really the best process for beginners to learn first?

Many experts recommend starting with Stick welding because it forces you to master crucial fundamentals like arc striking, maintaining arc length, and understanding metal dynamics. While modern MIG is often easier to pick up, Stick welding provides a tougher learning curve that results in a stronger understanding of proper electrode technique and overall arc control, skills that translate well to other processes later.

Q6: What safety item should I prioritize buying after my welding machine?

After a decent helmet, prioritize high-quality gloves and proper respiration. However, the educational materials reviewed here emphasize that understanding your equipment’s electrical safety features and ensuring your auto-darkening helmet meets current ANSI standards is paramount. Knowing your gear (as detailed in the equipment guide) is often the best defense against injury.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.