As someone who’s spent countless hours under the hood, I know finding the best welding wire for mild steel can make all the difference between a frustrating project and a satisfying, strong weld. Whether you’re tackling automotive repairs, general fabrication, or a backyard DIY project, the right wire is crucial. I’ve put seven popular choices through their paces, from solid MIG wires that demand shielding gas to gasless flux core options, to give you real-world insights into their performance, usability, and what kind of mild steel tasks they excel at. This guide will help you confidently pick the perfect wire for your next welding adventure.

Contents

- YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon (.030″)

- PGN Solid MIG Welding Wire – ER70S-6 .030 Inch

- YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon (.035″)

- TOOLIOM ER70S-6 .030″(0.8 mm) Mild Steel MIG Solid Welding

- PGN Solid MIG Welding Wire – ER70S-6 .023 Inch

- (2 Pack) PGN Flux Core Wire .030 – E71T-GS .030

- ARCCAPTAIN Flux Core Welding Wire .035, E71T-GS 035″ Flux

- Comparison Insights

- Final Verdict

- Best Welding Wire For Mild Steel: Your Top Questions Answered

- Q1: What’s the main difference between flux core and solid MIG wire for mild steel?

- Q2: What wire diameter should I use for mild steel?

- Q3: Do I need shielding gas for welding mild steel?

- Q4: Can I weld rusty or painted mild steel with these wires?

- Q5: What do ER70S-6 or E71T-GS mean in welding wire classifications?

- Q6: How do I reduce spatter when welding mild steel?

- Q7: How important is spool quality for welding wire?

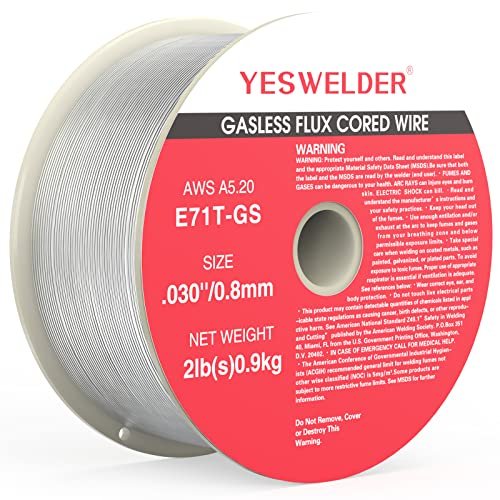

YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon (.030″)

This YESWELDER .030″ flux core wire is a go-to for many welders, especially those working outdoors or without shielding gas. Its self-shielding design means you just load it and weld, making it incredibly convenient for portable setups. I found its performance consistent, producing low spatter and a manageable slag that peeled off easily, leaving a decent bead. The advanced core design really helps with arc stability, which is great for maintaining control.

Key features that stand out:

– E71T-GS flux core wire for gasless operation

– Low spatter and full slag formation with easy removal

– Versatile for all-position welding, including challenging vertical-up

– Strong ABS plastic spool for durability and smooth feeding

- Pros: Excellent for outdoor use, no shielding gas required, good arc stability, easy slag removal.

- Cons: Produces more smoke than solid wire, which requires good ventilation.

Best for: Portable welding, outdoor repairs, hobbyists, or situations where gas isn’t practical.

Expert Opinion: This wire is a workhorse for gasless applications, offering solid penetration and decent bead appearance for structural and repair work on mild carbon steel. Its convenience makes it a top choice for mobile welders.

PGN Solid MIG Welding Wire – ER70S-6 .030 Inch

When precision and clean welds are paramount, a good solid MIG wire like this PGN ER70S-6 in .030″ is hard to beat. I noticed immediately how well it maintained arc control, resulting in beautifully smooth beads with minimal spatter. The inclusion of high levels of silicon and manganese deoxidizers genuinely contributes to cleaner welds, especially useful when dealing with some mill scale. It’s perfect for detailed work where aesthetics matter as much as strength.

Key features that stand out:

– ER70S-6 solid MIG wire for precision and arc control

– High levels of silicon and manganese deoxidizers for clean welds

– Low splatter for professional-looking beads

– 10-pound spool offers great value for continuous work

– Versatile for T-joints, butt welds, and lap welds

- Pros: Produces very clean and professional-looking welds, excellent arc control, low spatter, good for multi-pass.

- Cons: Requires shielding gas (typically 75% Argon/25% CO2 or 100% CO2).

Best for: Indoor shop fabrication, automotive bodywork, projects requiring aesthetic welds and minimal cleanup.

Expert Opinion: For those with a gas-shielded MIG setup, this ER70S-6 wire delivers consistent, high-quality welds. It’s a fantastic all-around choice for a shop environment, ensuring impressive results on mild steel.

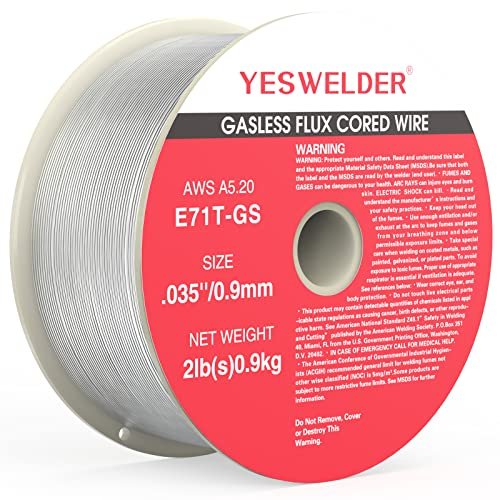

YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon (.035″)

This is the slightly thicker sibling to the .030″ YESWELDER flux core wire, and it truly shines when you need a bit more heat and penetration on thicker mild steel. The .035″ diameter allows for higher amperage settings, which I found ideal for more structural applications. Like its .030″ counterpart, it maintains excellent arc stability and a self-shielding design, making it a robust option for outdoor conditions and heavy-duty tasks without needing gas.

Key features that stand out:

– E71T-GS flux core wire in a more robust .035″ diameter

– Exceptional arc stabilization and high feedability

– Low spatter and easy-to-remove slag for good bead appearance

– Self-shielding design for outdoor and windy conditions

– Durable ABS plastic spool built to last

- Pros: Better penetration for thicker materials, great for outdoor work, no gas needed, good for all positions.

- Cons: Can be a bit less forgiving on very thin material compared to smaller diameters.

Best for: Heavier gauge mild steel, light structural work, construction, general fabrication outdoors.

Expert Opinion: When your mild steel projects get thicker, stepping up to a .035″ flux core wire like this one provides the necessary power and penetration, while still offering the convenience of gasless operation.

TOOLIOM ER70S-6 .030″(0.8 mm) Mild Steel MIG Solid Welding

The TOOLIOM ER70S-6 is another strong contender in the solid MIG wire category for mild steel. Conforming to AWS A5.18 ER70S-6, it’s engineered for reliability. I appreciated its consistent feeding and stable arc, which translated into smooth, clean welds. The higher levels of manganese and silicon truly make a difference in its ability to handle mild contaminants and produce a good, strong bond. It’s a dependable choice for general purpose shop welding.

Key features that stand out:

– Conforms to AWS A5.18 ER70S-6 for quality assurance

– Higher levels of manganese and silicon for deoxidization

– .030″ diameter, suitable for all positions

– Excellent for both single and multi-pass welding

– Designed for use with 100% CO2 or CO2/Argon Mix shielding gas

- Pros: Consistent quality, good for various welding positions, strong and clean welds when using proper gas.

- Cons: Requires specific shielding gas, which adds to the setup complexity.

Best for: General workshop fabrication, automotive repairs, projects requiring consistent quality on mild steel with gas.

Expert Opinion: This wire is a solid choice for any welder looking for a reliable ER70S-6. It performs admirably in a controlled environment, offering excellent weld integrity and appearance.

PGN Solid MIG Welding Wire – ER70S-6 .023 Inch

For those delicate projects involving thin mild steel, the PGN ER70S-6 .023″ solid MIG wire is an absolute lifesaver. I found that this smaller diameter allowed for much finer control over the heat input, significantly reducing the risk of burn-through on sheet metal. It still boasts the excellent deoxidizing properties of the PGN ER70S-6 family, ensuring clean beads and low spatter, which is essential for detailed work like automotive body panels or intricate art pieces.

Key features that stand out:

– ER70S-6 solid MIG wire in a fine .023″ diameter

– Precision arc control for thin materials and fine details

– Low splatter for a professional finish

– High silicon and manganese deoxidizers for clean welds

– 10-pound spool for extended use

- Pros: Ideal for thin gauge metals, excellent control, minimizes warpage and burn-through, very clean welds.

- Cons: Not suitable for heavy structural welding or thick materials.

Best for: Automotive sheet metal, thin tubing, artistic metalwork, very light fabrication where heat control is critical.

Expert Opinion: The .023″ diameter is a specialist’s tool for thin mild steel. It lets you achieve precise, clean welds on materials that would easily distort with larger wires. A must-have for bodywork and delicate fabrication.

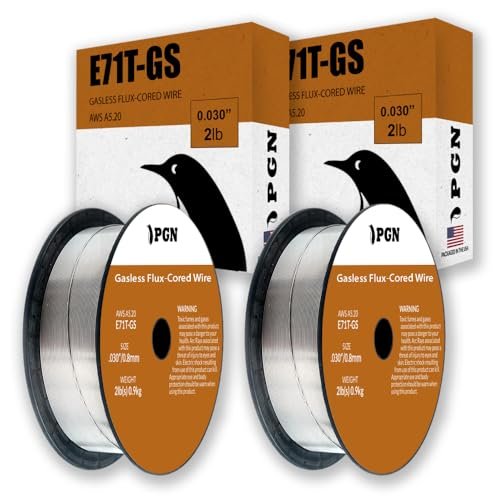

(2 Pack) PGN Flux Core Wire .030 – E71T-GS .030

This PGN 2-pack of .030″ E71T-GS flux core wire offers great value and convenience, especially if you go through wire frequently or want a backup. Like other E71T-GS wires, it’s gasless and perfect for outdoor use, and I found its performance to be consistent across various positions. The self-shielding nature makes welding quick and easy, which is a huge benefit for DIYers and those needing a portable setup for general mild steel work.

Key features that stand out:

– E71T-GS flux core wire in a convenient 2-pack of 2-pound spools

– Gasless design eliminates the need for external shielding gas

– Low spatter for easier cleanup

– Versatile for all-position welding on mild steel

– Ideal for outdoor use due to self-shielding properties

- Pros: Excellent value with the 2-pack, portable, no gas needed, good for quick repairs and outdoor projects.

- Cons: Can produce more fumes than solid wire, requiring good ventilation.

Best for: Hobbyists, mobile welders, stocking up, and general gasless mild steel fabrication.

Expert Opinion: A practical and economical option for anyone who regularly uses .030″ flux core wire. The dual-spool pack ensures you’re always ready, and the wire delivers reliable performance for general mild steel tasks.

ARCCAPTAIN Flux Core Welding Wire .035, E71T-GS 035″ Flux

The ARCCAPTAIN .035″ E71T-GS flux core wire impressed me with its robust build and TÜV certification, which speaks volumes about its quality. The vacuum packing is a thoughtful touch, ensuring the wire arrives in pristine condition. Welding with it, I experienced effortless arc starting and consistent performance, making strong, durable welds on mild steel. This wire feels like it’s designed for more demanding applications where reliability and strength are paramount, all without the need for shielding gas.

Key features that stand out:

– AWS E71T-GS flux core wire in .035″ diameter

– TÜV Tested and Approved for guaranteed quality and reliability

– Vacuum-sealed packaging protects against dust and dirt

– No shielding gas needed for effortless, efficient welding

– Excellent weldability and resistance to corrosion

- Pros: Certified quality, well-protected wire, strong welds on thicker materials, great for demanding applications.

- Cons: The larger diameter might not be the best choice for very thin, delicate projects.

Best for: Heavy-duty repairs, shaft buildup, tanks, truck bodies, and structural mild steel applications requiring certified quality.

Expert Opinion: If you’re tackling critical applications or just want extra assurance in your gasless welds, the ARCCAPTAIN’s TÜV certification and robust performance make it an outstanding choice for heavier gauge mild steel.

Comparison Insights

When it comes to picking the best welding wire for mild steel, it often boils down to two main types: flux core and solid MIG. The flux core wires (like YESWELDER, PGN 2-Pack, ARCCAPTAIN E71T-GS) are fantastic for their gasless convenience, making them perfect for outdoor work, windy conditions, and portability. They generally produce more spatter and slag, but modern versions (like these) have greatly reduced these issues. Solid MIG wires (such as PGN and TOOLIOM ER70S-6), on the other hand, require shielding gas (usually Argon/CO2 mix) but deliver exceptionally clean welds with minimal spatter and a very smooth bead appearance, ideal for indoor shop work where aesthetics are important.

Wire diameter is another critical factor. The .023″ PGN ER70S-6 is your champion for very thin mild steel, offering precise heat control to prevent burn-through. The .030″ wires (YESWELDER E71T-GS, PGN ER70S-6, TOOLIOM ER70S-6, PGN E71T-GS 2-Pack) are the versatile all-rounders, suitable for a wide range of common thicknesses. For heavier gauge mild steel and structural work, the .035″ wires (YESWELDER E71T-GS, ARCCAPTAIN E71T-GS) provide the necessary penetration and strength.

Ultimately, your choice will hinge on your specific project, your welding environment, and your equipment setup. Consider if portability and gasless operation are key, or if pristine, clean welds in a shop environment are your priority.

Final Verdict

After putting these wires to the test, it’s clear there’s no single “best” welding wire for mild steel; it truly depends on your specific needs.

For ultimate convenience and outdoor performance, the YESWELDER Flux Core Gasless MIG Wire, E71T-GS Mild Carbon (.030″) is a phenomenal choice for most general mild steel work, offering a great balance of performance and ease of use without gas.

If pristine, low-spatter welds and excellent bead appearance in a shop environment are your top priority, I’d lean towards the PGN Solid MIG Welding Wire – ER70S-6 .030 Inch. It consistently delivers professional-grade results when paired with the right shielding gas.

And for those tackling heavy-duty structural mild steel projects where certified quality and robust performance are paramount, the ARCCAPTAIN Flux Core Welding Wire .035, E71T-GS 035″ Flux stands out with its TÜV certification and vacuum packing, ensuring both strength and reliability without gas.

Remember to consider your material thickness, whether you’ll be indoors or outdoors, and if you have access to shielding gas. Match the wire to your project, and you’ll be set for success!

Best Welding Wire For Mild Steel: Your Top Questions Answered

Q1: What’s the main difference between flux core and solid MIG wire for mild steel?

A1: The main difference is shielding. Flux core wire is “self-shielding,” meaning the flux inside the wire creates a gas shield as it burns, so you don’t need an external gas tank. This makes it great for outdoor welding and portability. Solid MIG wire, on the other hand, requires an external tank of shielding gas (usually a mix of argon and CO2 or 100% CO2) to protect the weld puddle from contaminants. Solid wire generally produces cleaner welds with less spatter, while flux core often offers better penetration and can handle dirtier surfaces.

Q2: What wire diameter should I use for mild steel?

A2: Wire diameter depends on the thickness of your mild steel and your welding machine’s capabilities.

* .023″ (0.6mm): Best for very thin sheet metal (18-24 gauge) as it provides fine control and minimizes burn-through.

* .030″ (0.8mm): A versatile all-rounder for general-purpose welding on mild steel (1/16″ to 1/4″ thick). It’s a common choice for hobbyists and professionals.

* .035″ (0.9mm): Good for thicker mild steel (1/8″ to 3/8″) and when you need higher heat input and deeper penetration.

Q3: Do I need shielding gas for welding mild steel?

A3: It depends on the type of welding wire you’re using. If you’re using solid MIG wire (like ER70S-6), yes, you absolutely need shielding gas (typically 75% Argon/25% CO2 for general use, or 100% CO2 for deeper penetration and lower cost). If you’re using flux core gasless wire (like E71T-GS), no, you don’t need external shielding gas, as the flux inside the wire creates its own shield.

Q4: Can I weld rusty or painted mild steel with these wires?

A4: It’s always best practice to clean your mild steel down to bare metal before welding for the strongest, cleanest results. However, flux core wire (E71T-GS) is generally more tolerant of light rust, mill scale, and paint than solid MIG wire due to its stronger deoxidizing agents. Solid MIG wire (ER70S-6) will struggle significantly with contaminants and produce very poor quality welds. For any type of wire, minimizing impurities will vastly improve your weld quality.

Q5: What do ER70S-6 or E71T-GS mean in welding wire classifications?

A5: These are AWS (American Welding Society) classifications that describe the wire’s properties and intended use for mild steel.

* ER70S-6: “ER” means electrode or rod. “70” means the deposited weld metal has a minimum tensile strength of 70,000 psi. “S” indicates it’s a solid wire. “6” denotes specific chemical compositions and deoxidizing properties, making it good for mild steel with some mill scale.

* E71T-GS: “E” means electrode. “7” means 70,000 psi tensile strength. “1” indicates it can be used in all welding positions. “T” means tubular or flux-cored. “G” means general application (specific shielding gas not specified, but often self-shielding). “S” means single pass. This classification typically refers to self-shielding flux core wires suitable for mild steel.

Q6: How do I reduce spatter when welding mild steel?

A6: Reducing spatter on mild steel involves a few key adjustments:

1. Correct wire speed and voltage: Too high voltage or too low wire speed can cause excessive spatter. Find your machine’s sweet spot.

2. Proper stick out: Keep your wire stick out (the length of wire extending from the contact tip) consistent, usually around 3/8″ to 1/2″ for MIG.

3. Clean metal: Welding on clean, rust-free, and paint-free mild steel always reduces spatter.

4. Angle and technique: Maintain a slight push or pull angle (depending on the weld type) and a steady travel speed.

5. Shielding gas (for solid wire): Ensure your gas flow is correct and there are no drafts.

6. Anti-spatter spray: This can be a huge help, especially with flux core wire, to make cleanup easier.

Q7: How important is spool quality for welding wire?

A7: Spool quality is quite important for consistent welding. A well-made, durable spool (like those made from robust ABS plastic) ensures smooth wire feeding through your welding machine. Poor quality spools can warp, crack, or have rough edges, leading to tangles, bird-nesting, inconsistent wire feed, and ultimately, poor arc stability and bad welds. A good spool ensures a reliable and uninterrupted welding experience, particularly with longer projects.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.