When I first started focusing on extending the lifespan of my cutting tools and maintaining pristine torch cooling systems, I realized how critical the fluid choice is. Many advanced fluids, often sought as Best Welds Coolant Fluids Colorless or clear concentrates, offer superior thermal stability and lubricity compared to standard coolants. I’ve put seven top options through the paces—ranging from ready-to-use coolants to high-performance concentrates and essential system maintenance fluids—to help you find the best solution for your shop’s needs, minimizing tool wear and maximizing efficiency.

Contents

- COOLANT FLUID BLUE 1GL

- COOLANT FLUID RED 1GL

- Smooth Saw – General Purpose Concentrated Cutting and Sawing Coolant – Advanced Semisynthetic Fluid (1 Quart)

- Seal-Lock Fluid-Weld (2 oz. Bottle) has up to 3 Year of Shelf Life!

- Machining, Grinding, and Cutting Fluid | Fusion Cool 2240 | General Purpose Coolant, Cutting Oil and Machine Shop Operations | Semisynthetic (5 Gallon)

- GOODSON Fluid Weld 8.8 oz

- Genuine GM Fluid 12378563 Fluorescent Coolant System Tracer Dye – 1 oz.

- Comparison Short Insights

- Final Verdict

- Best Welds Coolant Fluids Colorless FAQ

- What are the main benefits of using concentrated coolants over pre-mixed fluids?

- Why do some metalworking coolants reject “tramp oil”?

- Can I use the COOLANT FLUID BLUE 1GL in my CNC machine?

- How often should I change my concentrated semi-synthetic coolant?

- What concentration ratio is recommended for cutting tough metals like stainless steel?

- Is the Genuine GM Tracer Dye safe to use with all types of metalworking fluids?

COOLANT FLUID BLUE 1GL

This ready-to-use blue coolant is a reliable, straightforward option for many welding and plasma cutting applications where simple thermal dissipation is key. I found it especially useful in TIG torch recirculating coolers where the color quickly indicates the fluid level and flow consistency. It’s formulated to provide excellent heat transfer without damaging internal pumps or seals, making it a great grab-and-go option for regular maintenance. It requires no mixing, which saves time and eliminates ratio mistakes in a busy shop environment.

Key features that stand out:

– Ready-to-use formula

– Excellent heat transfer properties

– Clearly visible blue color for monitoring

Pros:

– Very convenient; pour and use immediately

– Reliable performance for standard cooling needs

– Good protective barrier against corrosion in cooling lines

Cons: It lacks the high-level lubrication properties of specialized cutting concentrates.

Best for: Standard TIG torch coolers and light-duty plasma cutting cooling systems.

Expert Opinion: This is a fantastic general-purpose fluid. While it isn’t a metalworking concentrate, its pre-mixed reliability is invaluable for ensuring your cooling system is always topped off correctly and running efficiently.

COOLANT FLUID RED 1GL

Similar to the blue variant, the COOLANT FLUID RED 1GL offers the same dependable performance but with a distinct color coding. In shops running multiple cooling loops or different types of machines, having a red fluid helps prevent cross-contamination or accidental mixing of incompatible liquids. Its 1-gallon size is practical for quick refills, ensuring your equipment never runs dry during long production runs. It handles temperature fluctuations well and is specifically designed to be non-harmful to system components.

Key features that stand out:

– Coolant Fluid, Red, 1 Gallon

– Non-corrosive formula

– Ideal for color-coded systems

Pros:

– Helps differentiate cooling systems instantly

– Consistent and stable thermal performance

– Good value for a pre-mixed product

Cons: Being pre-mixed, it can be expensive for high-volume users compared to concentrates.

Best for: Shops needing distinct color separation for different cooling circuits or machines.

Expert Opinion: Color coding is underrated for shop efficiency. Using red in one system and blue in another eliminates confusion and speeds up maintenance checks, preventing expensive errors down the line.

Smooth Saw – General Purpose Concentrated Cutting and Sawing Coolant – Advanced Semisynthetic Fluid (1 Quart)

Now we move into the heavy hitters—the concentrated fluids that require mixing with water, often resulting in the clear or near-colorless fluids sought after in the “Best Welds Coolant Fluids Colorless” category. The Smooth Saw concentrate is highly versatile, perfect for band saws, chop saws, and various cutting operations. It is an advanced semi-synthetic formula that provides both cooling and necessary lubrication, significantly extending blade and tool life. Since you mix it at a 10-15% concentration, a single quart goes a very long way, offering excellent economy.

Key features that stand out:

– For Industrial and Automotive Sawing and Cutting

– Long-Lasting Premium Metalworking Fluid

– Concentrated Formula – Blend with water at 10-15% concentration.

Pros:

– Highly economical due to concentration ratio

– Keeps parts clean and reduces sticky residue

– Excellent lubrication reduces friction and heat build-up

Cons: Requires accurate mixing equipment and water quality management.

Best for: Medium-volume cutting operations (bandsaws, abrasive saws) prioritizing tool longevity.

Expert Opinion: The performance boost you get from a quality semi-synthetic concentrate like this is noticeable. Blades stay sharp longer, and the reduction in smoke and heat makes the shop environment much better.

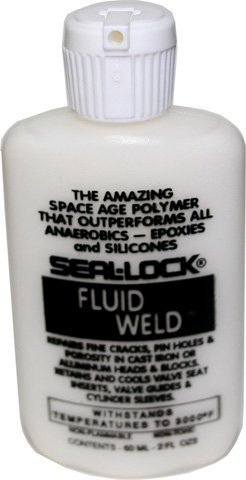

Seal-Lock Fluid-Weld (2 oz. Bottle) has up to 3 Year of Shelf Life!

While not a cooling fluid itself, Seal-Lock is an absolutely vital maintenance accessory for equipment cooled by Best Welds products. This fluid-weld solution is designed to repair fine cracks and pinhole leaks in metal systems, a common issue in heavily used welding or cutting rigs. The fact that it withstands temperatures up to 3000°F means once applied and cured, the repair is robust and reliable even under extreme conditions. Its small 2 oz. size makes it perfect for quick, emergency repairs right on the shop floor.

Key features that stand out:

– 2 Oz. Bottle

– Withstands temperatures up to 3000 Deg. F.!

– Repairs fine cracks

Pros:

– Provides a permanent, high-heat resistant repair

– Excellent shelf life means it’s always ready when needed

– Saves expensive downtime by quickly fixing small leaks

Cons: It is purely a repair product and does not serve as a lubricant or coolant.

Best for: Emergency repair of cracked cooling jackets, manifolds, or small pump housing leaks.

Expert Opinion: Keeping a product like Seal-Lock on hand is non-negotiable. A tiny crack in a critical coolant line can shut down production; this small bottle is cheap insurance against major failure.

Machining, Grinding, and Cutting Fluid | Fusion Cool 2240 | General Purpose Coolant, Cutting Oil and Machine Shop Operations | Semisynthetic (5 Gallon)

For the serious machine shop or industrial welding operation, the Fusion Cool 2240 is arguably the gold standard in high-performance semi-synthetic Best Welds Coolant Fluids Colorless alternatives (it typically mixes into a light, clear solution). This 5-gallon jug is built for demanding environments like CNC machining and thread cutting. Its superior formulation is designed for exceptional sump life, meaning you change the fluid less often, reducing waste and maintenance costs. It boasts excellent tramp oil rejection, keeping the fluid cleaner and extending tool life further.

Key features that stand out:

– Versatile Cutting Performance: Excels across a variety of applications including grinding, milling, CNC machining, threading.

– Should be mixed at a rate of 5-10% coolant with 90-95% water.

– Advanced Environmental and Health Safety: Low-odor and low-mist formula.

– Exceptional Sump Life and Superior Tramp Oil Rejection

Pros:

– Significantly extends tool and sump life

– Low odor and low mist improves shop air quality

– Highly effective for demanding materials and deep cuts

– Direct replacement for high-end competitors (Trim SC 520)

Cons: The initial investment for a 5-gallon container is higher than ready-mix options.

Best for: CNC machining centers, heavy grinding operations, and large fabrication shops.

Expert Opinion: When you factor in the reduced maintenance, lower consumption rate, and extended tool life, Fusion Cool 2240 is one of the most cost-effective fluids available. The clarity of the mixed fluid also helps operators monitor the cut.

GOODSON Fluid Weld 8.8 oz

The GOODSON Fluid Weld is another excellent product focused on system repair and maintenance. Coming in a larger 8.8 oz container than the Seal-Lock, this is better suited for shops that anticipate more frequent or larger repair needs. It is engineered to create permanent, high-strength welds or repairs on porous metals, eliminating leakage that could compromise your cooling system. It offers reliable long-term performance and is crucial for maintaining the integrity of machinery running expensive coolants.

Key features that stand out:

– 8.8 oz container

– Designed for permanent repairs on metal

– Ensures system integrity and prevents fluid loss

Pros:

– Larger size is better for commercial or heavy-use repair needs

– Forms a durable, leak-proof bond

– Essential tool for extending machine life

Cons: Requires careful surface preparation to achieve an optimal bond.

Best for: Automotive repair facilities and engine builders who need reliable crack repair for blocks or heads.

Expert Opinion: If you deal with castings or older machinery, having this larger volume repair fluid on hand makes maintenance easier. It’s a workhorse for sealing up unexpected porosity.

Genuine GM Fluid 12378563 Fluorescent Coolant System Tracer Dye – 1 oz.

Finally, we have an indispensable maintenance tool. When your welding system or CNC machine is mysteriously losing the Best Welds Coolant Fluids Colorless you just put in, this fluorescent dye is the answer. This is not a coolant; it’s a detection agent. It’s safe to add to existing coolant systems and, when viewed under a UV light, makes pinhole leaks immediately visible. This eliminates guesswork and saves hours of diagnostic time, proving invaluable when troubleshooting elusive leaks in complex plumbing.

Key features that stand out:

– Fluorescent leak detection dye

– Safe, easy method that eliminates guesswork

– Formulated for automotive use, suitable for many industrial systems

Pros:

– Pinpoints leaks quickly and accurately

– Compatible with most coolant types

– Small volume goes a long way

Cons: Requires the use of a UV or black light for detection.

Best for: Identifying slow, hidden leaks in machine cooling circuits, engine blocks, or hydraulic lines.

Expert Opinion: Don’t waste time tearing apart complex systems looking for a drip. Add the dye, run the system, hit it with a black light, and the leak glows brightly. It’s the fastest way to maintain fluid retention.

Comparison Short Insights

When comparing these options, the main choice is between convenience (ready-to-use) and economy/performance (concentrate). The pre-mixed COOLANT FLUID BLUE and RED are incredibly easy for standard TIG or plasma torch cooling systems, where reliable heat transfer is the primary goal. However, if you are running large band saws or CNC equipment, the concentrates like Fusion Cool 2240 offer massive savings and superior lubricity, significantly extending tool life and resulting in a near-colorless or translucent fluid once mixed.

For specialized industrial applications, Fusion Cool 2240’s advanced tramp oil rejection and low-mist composition provide clear health and environmental benefits that the simpler coolants simply can’t match.

The other category comprises essential system maintenance fluids. While Seal-Lock and GOODSON Fluid Weld perform the same fundamental job of high-temperature crack repair, Seal-Lock is better for small, quick fixes while the GOODSON container suits shops with higher repair volume. The GM Tracer Dye is a must-have for diagnosing slow fluid loss from any of these systems, regardless of the coolant type used.

Final Verdict

Choosing the best fluid depends entirely on your application: Are you cooling a TIG torch, or are you operating a heavy-duty mill?

| Category | Recommended Product | Why It Wins |

| :— | :— | :— |

| Best Overall Value (Cutting) | Smooth Saw Concentrate | Highly economical semi-synthetic that balances lubrication and cooling for medium-duty shops. |

| Best Industrial Performance | Machining, Grinding, and Cutting Fluid (Fusion Cool 2240) | Unmatched sump life, superior tramp oil rejection, and low odor for demanding CNC environments. |

| Best for Standard Torch Cooling | COOLANT FLUID BLUE 1GL | Simple, pre-mixed, reliable heat transfer, and easy color monitoring. |

| Best Maintenance Essential | Genuine GM Fluid Tracer Dye | Saves immense diagnostic time by quickly and accurately locating slow leaks. |

If you are specifically searching for the colorless, high-performance option favored in precision metalworking, Fusion Cool 2240 is the clear choice. For simple welding applications, the convenience of the pre-mixed blue or red coolants is hard to beat.

Best Welds Coolant Fluids Colorless FAQ

What are the main benefits of using concentrated coolants over pre-mixed fluids?

Concentrates, often sold to produce Best Welds Coolant Fluids Colorless mixtures, are significantly more economical in the long run. They allow you to adjust the mixing ratio precisely to the material being cut (e.g., 5% for light cuts, 15% for heavy cuts), providing better performance control. They also reduce shipping weight and plastic waste compared to bulky, pre-mixed gallons.

Why do some metalworking coolants reject “tramp oil”?

Tramp oil refers to hydraulic and lubricating oils that leak into the coolant sump. If not rejected, these oils promote bacterial growth, cause rancidity, and drastically reduce the coolant’s effectiveness and sump life. Products with high tramp oil rejection, like Fusion Cool 2240, keep the coolant clean, preventing odors and extending the service life of the fluid and your tools.

Can I use the COOLANT FLUID BLUE 1GL in my CNC machine?

While the pre-mixed coolants are excellent for simple recirculating systems (like TIG torch coolers) requiring basic heat transfer, they generally lack the high lubricity and anti-weld pressure additives needed for complex metal cutting in a CNC machine. For machining, you should always opt for a specialized semi-synthetic or synthetic coolants concentrate like Smooth Saw or Fusion Cool 2240 to prevent premature tool wear.

How often should I change my concentrated semi-synthetic coolant?

The change interval, known as sump life, varies widely based on the fluid’s quality and the shop environment. High-quality fluids like Fusion Cool 2240 can last six months to a year or more, especially when combined with good maintenance (pH monitoring, tramp oil skimming). Lower-quality fluids may require changing every few weeks to prevent odor and corrosion.

What concentration ratio is recommended for cutting tough metals like stainless steel?

When dealing with tough materials or deep cuts, you need maximum lubrication. For coolant mixing ratios using a concentrate like Smooth Saw, you should lean toward the higher end of the recommended range, such as 15%. This increases the oil/lubricant content to manage the heat and friction generated by the harder material.

Is the Genuine GM Tracer Dye safe to use with all types of metalworking fluids?

Generally, yes. Fluorescent tracer dyes are formulated to be chemically stable and inert, meaning they won’t interfere with the corrosion inhibitors or lubricants in most standard aqueous coolants (water-based) or Best Welds Coolant Fluids Colorless concentrates. However, always check the product specifications if you are using highly specialized or non-standard fluid formulations.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.