To adjust Teraflex ball joints, start by removing the castle nut and cotter pin and then use a ball joint press tool to press out the old joint and press in the new one. A few simple steps can help you adjust Teraflex ball joints.

First, remove the cotter pin and castle nut. Then, utilize a ball joint press tool to remove the old joint and install the new one. By following these instructions, you can successfully adjust Teraflex ball joints and ensure the smooth operation of your vehicle.

Credit: teraflex.com

Contents

Tools Required For Adjusting Teraflex Ball Joints

Adjusting Teraflex ball joints requires a few essential tools: a screwdriver, socket wrench, pry bar, and hammer. These tools are crucial for ensuring a proper adjustment and maintaining the functionality of your suspension system. A screwdriver will help you remove any screws or bolts that are holding the ball joint in place.

A socket wrench is necessary for loosening and tightening the nut on the ball joint. Additionally, a pry bar comes in handy when you need to pry apart any components that might be stuck together. Lastly, a hammer is useful for knocking the ball joint into the desired position.

With these tools in hand, you’ll be able to make any necessary adjustments to your Teraflex ball joints and keep your suspension system operating smoothly.

Step-By-Step Guide To Adjust Teraflex Ball Joints

Adjusting Teraflex ball joints is a fairly straightforward process that can be done with basic tools. Begin by loosening the wheel lug nuts to ensure the vehicle is stable during the adjustment. Lift the front of the vehicle using a jack and secure it with jack stands.

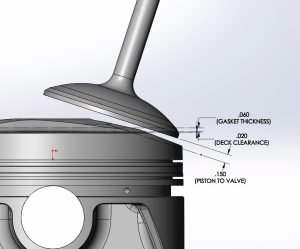

Remove the wheel and tire to access the ball joint on the control arm. Eliminate the cotter pin and castle nut that hold the ball joint in place. Separate the ball joint from the control arm carefully. Take the time to clean the ball joint housing thoroughly.

Apply grease to the ball joint to maintain smooth operation. Reinstall the ball joint and tighten the castle nut securely. Replace the cotter pin for added safety. Finally, reinstall the wheel and tire, lower the vehicle, and torque the lug nuts to the recommended specifications.

Following these steps ensures proper adjustment of Teraflex ball joints.

Can Bondo Rocker Panels be used to adjust Teraflex Ball Joints?

Yes, Bondo Rocker Panels can be used to adjust Teraflex Ball Joints. To do this, you will need to follow specific instructions on how to fix rocker panels and carefully apply the Bondo to create a smooth and stable surface for the ball joints.

Tips And Precautions For Adjusting Teraflex Ball Joints

Adjusting Teraflex ball joints requires caution and adherence to safety measures. Using a reliable jack and jack stands ensures stability while working. Applying anti-seize lubricant on the castle nut prevents it from seizing up. It’s crucial to torque the castle nut according to the manufacturer’s specifications as this determines the ball joint’s performance.

Regularly inspect the ball joint for any signs of wear or damage, as this can affect its functionality. If necessary, consider replacing the ball joint to ensure optimal performance. Following these guidelines will help you adjust Teraflex ball joints effectively and keep your vehicle running smoothly.

Frequently Asked Questions On How To Adjust Teraflex Ball Joints

How Do You Adjust Adjustable Ball Joints?

To adjust adjustable ball joints, follow these steps: 1. Locate the adjusting nut on the ball joint. 2. Use a wrench to loosen the nut by turning it counterclockwise. 3. Once the nut is loose, adjust the ball joint by rotating it in the desired direction.

4. Tighten the adjusting nut by turning it clockwise until it is securely fastened. Remember to check for any play or looseness in the joint after making the adjustment.

How Tight Should Ball Joints Be Tightened?

Ball joints should be tightened according to the manufacturer’s specifications to ensure proper functionality and safety.

How Do You Install Teraflex Ball Joints?

To install Teraflex ball joints: 1. Lift the vehicle and secure it on jack stands. 2. Remove the tires and wheels to access the ball joints. 3. Use a ball joint press to remove the old ball joints. 4. Install the new Teraflex ball joints by pressing them into place.

5. Reinstall the tires and wheels, and lower the vehicle off the jack stands.

Is It Possible To Over Tighten Ball Joints?

Yes, it is possible to over tighten ball joints, which can cause damage and affect their performance.

Conclusion

Adjusting Teraflex ball joints is a crucial step in maintaining the performance and stability of your vehicle’s suspension system. By following the step-by-step process outlined in this blog post, you can ensure that your ball joints are properly aligned and functioning optimally.

Remember to start by gathering the necessary tools and referencing the manufacturer’s instructions. Take your time and proceed with caution to avoid any damage to the ball joints or other components. Regularly inspecting and adjusting your Teraflex ball joints will not only enhance your driving experience but also contribute to the longevity of your suspension system.

So, take the time to make these adjustments and enjoy the benefits of a smoother, more reliable ride.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.