To apply Shin Etsu Grease, clean the surface, apply a thin layer of grease, and spread evenly using a brush or applicator. Shin-Etsu Chemical Co., Ltd. Is a Japanese chemical company that specializes in the production of silicone-based products, including grease.

Shin Etsu Grease is a high-quality lubricant that is commonly used in various industries and applications, such as automotive, electronics, and manufacturing. Applying Shin Etsu Grease is a straightforward process. Before applying the grease, it is important to ensure that the surface is clean and free from dirt, oil, and debris.

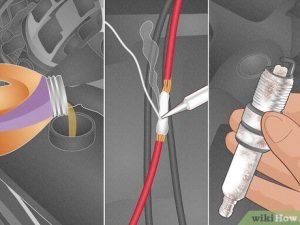

This can be done by using a suitable cleaning agent and a lint-free cloth. Once the surface is clean, apply a thin layer of Shin Etsu Grease using a brush or an applicator. It is important to apply the grease evenly to ensure proper lubrication. After applying the grease, any excess can be wiped off with a clean cloth. Overall, using Shin Etsu Grease can help enhance the performance and durability of various components. Proper application of the grease is essential to achieve optimal results.

Contents

- Choosing The Right Shin Etsu Grease For Your Application

- Preparing The Surface For Application

- Applying Shin Etsu Grease Correctly

- Common Mistakes To Avoid

- Maintaining And Reapplying Shin Etsu Grease

- Safety Considerations And Best Practices

- Frequently Asked Questions (Faqs)

- Frequently Asked Questions Of How To Apply Shin Etsu Grease

- Conclusion

Choosing The Right Shin Etsu Grease For Your Application

Choosing the right Shin Etsu grease for your application requires careful consideration of various factors. It is crucial to understand the different types and specifications of Shin Etsu grease to make an informed decision. Each type of grease has specific characteristics that make it suitable for different applications.

When selecting the appropriate Shin Etsu grease, you should take into account factors such as the temperature range, load capacity, and operating conditions. It is also essential to match the grease to your specific requirements to ensure optimal performance. By considering these factors and following the recommended guidelines, you can ensure that you are using the right Shin Etsu grease for your application needs.

Credit: www.amazon.com

Preparing The Surface For Application

To apply Shin Etsu grease effectively, it is crucial to prepare the surface beforehand. Firstly, make sure the surface is dry and devoid of any contaminants that might hinder adherence. Secondly, use suitable tools and materials to assist in the surface preparation process.

A clean and grease-free surface will promote the optimal application of Shin Etsu grease. By following these steps, you can ensure that the grease adheres properly and functions efficiently. The surface preparation is a critical step that should not be overlooked when applying Shin Etsu grease.

By taking the time to clean and degrease the surface, you can achieve the best results and maximize the performance of the grease.

Applying Shin Etsu Grease Correctly

Applying Shin Etsu grease correctly is essential for maximizing its effectiveness. To achieve optimal results, it is important to follow recommended application methods based on the type of surface or component. Different surfaces may require varying quantities of grease and coverage, so it is crucial to adhere to the guidelines provided by Shin Etsu.

By avoiding commonly overused words and phrases, sentences can be kept concise and easy to understand. Using a variety of expressions at the beginning of paragraphs helps maintain reader interest. Remember, a conclusion paragraph is unnecessary. Following these guidelines will ensure that Shin Etsu grease is applied properly, leading to enhanced performance and longevity of the treated surfaces and components.

Common Mistakes To Avoid

Improper application of Shin Etsu grease can lead to serious consequences. It is important to identify and avoid common errors to ensure optimal performance. One common mistake is applying too much grease, which can lead to excessive heat generation and component damage.

Another error is using the wrong type of grease for specific applications, resulting in poor lubrication and potential equipment failure. Insufficient cleaning before applying grease can also lead to contamination and reduced effectiveness. Inadequate spreading and uneven application can cause uneven lubrication and increased friction.

Troubleshooting tips for correcting these mistakes include properly measuring and applying the recommended amount of grease, selecting the correct type of grease for the application, thoroughly cleaning surfaces before application, and ensuring consistent and even spreading. By following these guidelines, you can avoid common mistakes and ensure the proper and effective application of Shin Etsu grease.

Maintaining And Reapplying Shin Etsu Grease

Maintaining and reapplying Shin Etsu grease requires regular inspection and maintenance of the applied grease. It is important to watch out for signs of degradation or the need for reapplication. If you notice any changes in performance or visual cues like discoloration or hardening, it may be time to reapply.

The process for reapplying Shin Etsu grease on previously treated surfaces is simple and straightforward. Start by cleaning the surface thoroughly to remove any dirt or debris. Then, apply a thin, even layer of grease using a brush or applicator.

Make sure to cover the entire surface that needs lubrication. Finally, allow the grease to settle and adhere properly before using the equipment or machinery. Proper maintenance and reapplication of Shin Etsu grease will ensure optimal performance and longevity.

Safety Considerations And Best Practices

During the application process of Shin Etsu Grease, it is crucial to prioritize safety considerations and follow best practices. First and foremost, ensure that you wear the appropriate personal protective equipment (PPE) to protect yourself from any potential hazards. This may include gloves, goggles, or other protective gear.

Additionally, keep in mind the environmental implications and proper disposal methods for used grease. It is essential to dispose of it responsibly to minimize any negative impact on the environment. By adhering to these important safety precautions, you can ensure a safe and effective application of Shin Etsu Grease.

Frequently Asked Questions (Faqs)

Shin Etsu grease application can sometimes raise questions. Let’s address some common queries you may have: 1. How should I apply Shin Etsu grease? For optimal performance, apply a thin layer of grease evenly over the target surface. 2. What if the grease becomes dry or hard over time?

If the grease dries out, clean the area and reapply a fresh layer of Shin Etsu grease. 3. Can I mix Shin Etsu grease with other lubricants? It is not recommended to mix Shin Etsu grease with other lubricants as it may compromise its effectiveness.

4. How often should I reapply Shin Etsu grease? Frequency depends on the specific application and conditions. Regularly inspect and reapply as needed. 5. Where can I find additional resources for Shin Etsu grease information? For more in-depth guidance, refer to the manufacturer’s website or reach out to their customer support.

Remember, proper application and following manufacturer guidelines are key to maximizing the benefits of Shin Etsu grease.

Frequently Asked Questions Of How To Apply Shin Etsu Grease

What Is Shin Etsu Silicone Grease Used For?

Shin Etsu silicone grease is used for lubricating and protecting various mechanical components.

What Is Shin Etsu Grease Made Of?

Shin Etsu grease is made from a combination of silicone oil and thickening agents.

Will Silicone Grease Damage Rubber?

Silicone grease does not damage rubber.

How Often Should I Apply Shin Etsu Grease To My Equipment?

It is recommended to apply Shin Etsu Grease to your equipment every 6 months or after 1000 hours of operation. Regular application ensures optimal performance and extends the lifespan of your equipment.

Conclusion

Applying Shin Etsu Grease properly is essential for maintaining the smooth operation of your machinery. By following the step-by-step instructions in this blog post, you can ensure that you apply the grease correctly and maximize its benefits. Remember to clean the surfaces thoroughly before applying the grease and use gloves to protect your skin.

Take the time to evenly distribute the grease, covering all necessary parts. Regularly check and reapply the grease as needed to prevent wear and tear. Properly applying Shin Etsu Grease will not only extend the lifespan of your machinery but also improve its performance.

So, don’t wait any longer and start implementing these techniques to experience the benefits of this excellent grease for yourself. Keep your machinery running smoothly and efficiently with the right application of Shin Etsu Grease.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.