When I first started wrenching on my own 5.9L Cummins engine, I quickly realized that reliability isn’t just about the big components; it’s about the small, crucial parts and having the right tools. Whether you’re maintaining an early VE pump engine or dialing in a legendary P7100 setup, keeping your best 12 valve cummins running strong requires using quality replacement parts and specialty tools. This guide covers five essential items—from crucial repairs like the KDP kit to necessary maintenance tools—that are vital for any serious 12V owner looking for longevity.

Contents

- Hihaha Fuel Injector/O-Ring Kit for Dodge 5.9L 12 Valve 4bt 6bt 5.9L Diesel Engines 1991.5-1998.5 / Fuel Injector Seal Ring Kit Durable/Rubber / 1 Set/Black

- Premium Silver Killer Dowel Pin KDP Repair Kit For 1989-1998 For Dodge Cummins 12 Valve Engines 5.9BT

- telfair Fuel Injection Pump Gear Puller Tool – Compatible with 1988-2012 Dodge Ram 250/350 with Cummins 5.9L/6.7L (12 Valve/VE Pump)

- KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

- MAKUANG Replacement P7100 Fuel Injector Line Set for 94-98 5.9L 12V Cummins Diesel, Stainless Steel, Solenoid Valve, 12 Ports, 1/2 in Inlet, 1/4 in Outlet, NPT Connections

- Comparison and Buying Insights

- Final Verdict

- Common Questions About Best 12 Valve Cummins

- What years are considered the best 12 valve Cummins?

- What is the Killer Dowel Pin (KDP) and why is it so important?

- How often should I consider replacing my fuel injector seals and lines?

- Are these parts compatible with both the VE Pump and the P7100 engines?

- Can I do valvetrain maintenance, like valve spring replacement, without removing the cylinder head?

- Why is the P7100 injection pump preferred by performance builders?

Hihaha Fuel Injector/O-Ring Kit for Dodge 5.9L 12 Valve 4bt 6bt 5.9L Diesel Engines 1991.5-1998.5 / Fuel Injector Seal Ring Kit Durable/Rubber / 1 Set/Black

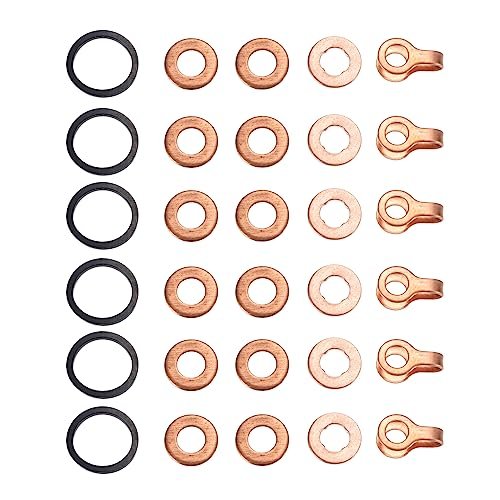

Fuel leaks around the injectors are an extremely common issue on older 12-valve platforms, often leading to performance loss and dirty engine bays. This comprehensive Hihaha O-Ring kit provides all the necessary copper washers and rubber seals needed to reseal six injectors, ensuring a tight fit and clean operation. It’s a fundamental maintenance item that directly affects the reliability of your fuel delivery, making it crucial for keeping your best 12 valve cummins engine leak-free.

Key features that stand out:

– Vehicle Compatibility: Specifically designed for Dodge 5.9L 12 Valve 4bt 6bt 5.9L Diesel Engines running from 1991.5-1998.5, accommodating 7mm injector tips.

– Comprehensive Set: Includes 12 thin copper washers, 6 standard copper washers, 6 horseshoe washers, and 6 sealing dust covers.

– Construction: Made of durable rubber and metal components designed for high heat and diesel exposure.

Pros:

– Complete kit for six injectors simplifies the purchase process.

– Direct replacement for OEM seals.

– Essential for resolving common injector drip issues.

Cons:

– Installation can be meticulous; requires careful cleaning of the injector bores.

Best for: Standard maintenance and resolving common external fuel leaks on mid-to-late 12V engines.

Expert Opinion: This kit represents critical preventative maintenance. If you pull your injectors for any reason (cleaning, replacement, or testing), always install a new set of seals and washers to prevent vacuum leaks or external drips.

Premium Silver Killer Dowel Pin KDP Repair Kit For 1989-1998 For Dodge Cummins 12 Valve Engines 5.9BT

If there is one mandatory modification for any 12-valve Cummins owner, it is addressing the Killer Dowel Pin (KDP). This dowel pin sits inside the timing cover and, if it works its way loose, can drop into the timing gears, causing catastrophic engine damage. This Premium Silver KDP Repair Kit uses a robust retainer crafted from high-quality 6061-T6 billet aluminum to physically stop the pin from backing out. It’s the definition of cheap insurance for high-cost potential failure.

Key features that stand out:

– Engine Protection: Prevents the dowel pin from dislodging and destroying the timing gears and internal components.

– Superior Material: Constructed from CNC anodized silver 6061-T6 billet aluminum for exceptional strength and corrosion resistance.

– Reversible Design: Suitable for both late P7100 engines and earlier VE pump applications.

Pros:

– Absolute necessity for engine longevity.

– High-quality, durable materials that won’t rust.

– Direct installation, engineered specifically for 5.9BT 12V engines.

Cons:

– Requires removal of the timing cover, which is time-consuming.

Best for: Every single owner of a 1989-1998 12 Valve Cummins seeking long-term engine security.

Expert Opinion: The value proposition here is unmatched. You spend a few hours installing this and eliminate the single biggest time bomb waiting in the 12-valve platform. The fact that this kit is reversible and high-grade aluminum makes it a top choice.

telfair Fuel Injection Pump Gear Puller Tool – Compatible with 1988-2012 Dodge Ram 250/350 with Cummins 5.9L/6.7L (12 Valve/VE Pump)

When performing major repairs, such as replacing the injection pump (VE or P7100), you must separate the pump gear from the driveshaft without causing damage. The telfair Fuel Injection Pump Gear Puller Tool is the specialty piece you need for this job. Forged from high-strength alloy steel, this precision-machined puller ensures a quick, damage-free removal, dramatically improving your repair speed and protecting expensive components.

Key features that stand out:

– Precision Fit: Specifically designed for 12-valve VE injection pumps and covers a wide range of Cummins models (1988-2012 5.9L/6.7L).

– Material Durability: Forged from military-grade, high-strength alloy steel, providing resistance to impact and rust.

– Efficiency Booster: CNC precision machining ensures a clean separation, making pump replacement a much smoother process.

Pros:

– Prevents damage to the injection pump or gear during removal.

– Durable construction designed for repeated professional use.

– Lightweight and easy to handle in tight engine bays.

Cons:

– Highly specialized tool only useful for injection pump services.

Best for: Mechanics and dedicated DIYers who plan to replace or upgrade their VE or P7100 injection pump.

Expert Opinion: Using improper removal methods can ruin a pump gear or worse, the pump shaft itself. This tool is non-negotiable for correct pump service. It reduces the struggle and risk inherent in these high-torque fasteners.

KSJED 5.9L Valve Spring Compressor fit for Dodge Ram 2500 3500 4500 1988-1998 Cummins 6bt 5.9L 12 Valve

Working on the valvetrain of a 12-valve Cummins often requires specialized equipment, especially if you are performing common upgrades like swapping to higher-rate valve springs or replacing valve seals. This KSJED Valve Spring Compressor is designed specifically for the 5.9L 12-valve engine, allowing you to compress the valve springs without the arduous task of removing the cylinder head. It fits snugly into the engine bay, making the job faster and less invasive.

Key features that stand out:

– Functionality: Allows for easy removal and installation of valve springs, retainers, and keepers.

– Fitment: Directly compatible with 1988-1998 Dodge Ram 2500, 3500, and 4500 models with the 5.9L 12-Valve engine.

– Robust Build: Constructed from high-quality metal that is robust and corrosion-resistant, ensuring a long service life.

Pros:

– Enables valvetrain work without removing the head.

– Essential for performance upgrades like stiffer valve springs.

– Simple, reliable operation compared to universal compressors.

Cons:

– Must ensure proper positioning to avoid damaging the valve keepers.

Best for: Individuals planning cam swaps, valve spring upgrades, or performing internal valvetrain maintenance on the 12V.

Expert Opinion: For performance owners, swapping in higher-rate valve springs is crucial for preventing valve float, especially when running higher boost. This compressor makes that job manageable in your driveway.

MAKUANG Replacement P7100 Fuel Injector Line Set for 94-98 5.9L 12V Cummins Diesel, Stainless Steel, Solenoid Valve, 12 Ports, 1/2 in Inlet, 1/4 in Outlet, NPT Connections

For owners of the highly coveted 1994-1998 P7100 (P-pump) engines, the injector lines are under immense pressure and are prone to rust, cracks, and fatigue over time. The MAKUANG Replacement Fuel Injector Line Set provides a brand-new, six-piece set of high-pressure lines to ensure consistent, reliable fuel delivery to the injectors. Using stainless steel construction, these lines are built to withstand the rigorous demands of a modified or stock P-pump system, refreshing a critical part of your best 12 valve cummins fuel system.

Key features that stand out:

– Fitment: Direct replacement for the P7100 5.9L 12V Cummins Diesel engines (1994-1998).

– Construction: Durable stainless steel ensures high burst strength and resistance to corrosion.

– Complete Set: Includes all six lines necessary for a full replacement, matching OEM specifications (superseded part numbers included for verification).

Pros:

– Eliminates risk of cracked or corroded high-pressure lines.

– Stainless steel construction is superior to aged OEM lines.

– Ensures consistent fuel flow and pressure balance across all cylinders.

Cons:

– Installation requires careful bending and routing to avoid vibration and rubbing.

Best for: P7100 12V owners (1994-1998) needing to replace aged, rusted, or damaged high-pressure fuel lines.

Expert Opinion: The P7100 pump operates at very high pressures, and line integrity is paramount. If you notice persistent leaks or suspect uneven performance, a fresh set of injector lines like this can make a significant difference.

Comparison and Buying Insights

When deciding which component is the most critical for your best 12 valve cummins, it helps to categorize them by function: prevention, repair, or maintenance.

While the KDP kit is preventative safety for every 12V engine and should be prioritized immediately, tools like the telfair gear puller and KSJED valve spring compressor are necessary investments only if you plan major component swaps or performance upgrades.

For standard operational maintenance, the Hihaha O-ring kit is critical for stopping external fuel and oil leaks around the injectors, a common issue as these trucks age. If you own a high-horsepower P-pump truck, the MAKUANG Injector Line Set offers a complete, durable solution for replacing cracked or rusted high-pressure lines, ensuring peak performance delivery.

Final Verdict

Choosing the best 12 valve cummins component often comes down to balancing preventative maintenance with necessary repairs.

If you haven’t addressed it yet, the Premium Silver Killer Dowel Pin KDP Repair Kit should be your absolute first purchase—it’s non-negotiable cheap insurance against total engine failure.

For the P7100 owners (1994-1998) looking for maximum fuel system reliability, pairing the Hihaha O-Ring Kit with the MAKUANG Injector Line Set will refresh the heart of your fuel system, ensuring consistent power delivery for years to come.

Common Questions About Best 12 Valve Cummins

What years are considered the best 12 valve Cummins?

The best 12 valve cummins engines were produced from 1989 through 1998. Within this range, the 1994-1998 models equipped with the mechanically injected Bosch P7100 (P-pump) are highly prized by enthusiasts for their immense tuning potential and robustness, often cited as the pinnacle of the 12V era.

What is the Killer Dowel Pin (KDP) and why is it so important?

The Killer Dowel Pin (KDP) is a small steel locating pin behind the timing gear cover on the 5.9L 12-valve engine. Over time, engine vibration can cause this pin to back out of its bore and fall into the rapidly spinning timing gears, which results in catastrophic engine damage. Installing a KDP repair kit is considered the single most important preventative modification.

How often should I consider replacing my fuel injector seals and lines?

While there isn’t a strict mileage interval, injector seals (O-rings and copper washers) should generally be replaced whenever the injectors are removed or if you notice fuel or oil weeping around the injector body. Fuel injector lines, especially on older trucks, should be inspected annually and replaced if any signs of rust, stress cracks, or fatigue are present.

Are these parts compatible with both the VE Pump and the P7100 engines?

Compatibility varies by part. The Killer Dowel Pin (KDP) kit is generally compatible with both VE pump (1989-1993) and P7100 pump (1994-1998) engines due to its reversible design. However, the MAKUANG Fuel Injector Line Set is explicitly designed for the P7100 setup only. Always check the specific year range listed for each product.

Can I do valvetrain maintenance, like valve spring replacement, without removing the cylinder head?

Yes, with the right specialty tool like the KSJED Valve Spring Compressor, you can perform necessary valvetrain maintenance, including valve spring or valve seal replacement, while the cylinder head remains bolted to the engine block. This saves significant time and cost.

Why is the P7100 injection pump preferred by performance builders?

The P7100 pump is completely mechanical and lacks electronic controls, making it exceptionally reliable and easy to adjust for performance. It can deliver large volumes of fuel necessary for high-horsepower applications simply by swapping internal components (like delivery valves and governors) and adjusting timing, giving it an edge in tuning flexibility compared to the earlier VE pump.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.