As a gearhead who loves to tinker with guitars, I’ve spent countless hours hunched over my workbench, soldering iron in hand, upgrading pickups, swapping pots, and generally trying to coax the best tone out of my instruments. Through all these projects, one thing has become crystal clear: the quality of your solder can make or break your wiring job. It’s not just about making a connection; it’s about creating a strong, reliable, and electrically sound bond that will stand the test of time and vibrations.

| IMAGE | PRODUCT NAME | AMAZON LINK |

|---|---|---|

|

ToneShaper Guitar Wiring Kit, For Fender Stratocaster, SSS2… |

View on Amazon |

|

AIM Solder LeadFree Rosin Core Solder Wire Sn99 Ag0.3… |

View on Amazon |

|

AIM Solder 60-40 Tin Lead Rosin Core Solder Wire for… |

View on Amazon |

|

Solder-It SP-7 Silver Solder Paste 7.1 Grams | Soldering… |

View on Amazon |

|

AIM Plumbing Solder Kit with solder wire, flux and brush,… |

View on Amazon |

|

2 Pack – Amerway 60/40 Solder for Glass Projects &… |

View on Amazon |

|

AIM Dura-Pure 95/5 Lead-Free 0.125inch Solid Solder Wire… |

View on Amazon |

If you’ve ever dealt with cold solder joints, scratchy pots, or mysterious signal drops, you know the frustration. That’s why choosing the right solder for guitar wiring projects is so important. I’ve personally tried a range of options, from classic leaded formulas to modern lead-free alternatives and even specialized pastes. In this guide, I’m going to share my insights on some popular solder options, highlighting what makes them good (or not so good) for your beloved axe. We’ll dive into the details, compare their strengths and weaknesses, and help you pick the best one for your next guitar mod.

Contents

- Product Reviews

- ToneShaper Guitar Wiring Kit, For Fender Stratocaster, SSS2…

- AIM Solder LeadFree Rosin Core Solder Wire Sn99 Ag0.3…

- AIM Solder 60-40 Tin Lead Rosin Core Solder Wire for…

- Solder-It SP-7 Silver Solder Paste 7.1 Grams | Soldering…

- AIM Plumbing Solder Kit with solder wire, flux and brush,…

- 2 Pack – Amerway 60/40 Solder for Glass Projects &…

- AIM Dura-Pure 95/5 Lead-Free 0.125inch Solid Solder Wire…

- Helpful Comparison Insights

- Final Verdict

- Comprehensive FAQ Section

Product Reviews

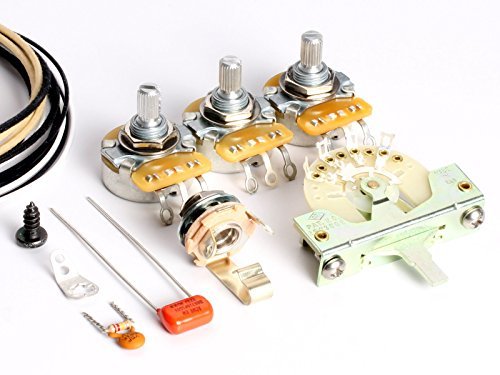

ToneShaper Guitar Wiring Kit, For Fender Stratocaster, SSS2…

While not a solder itself, this kit is an incredibly relevant option for anyone embarking on a guitar wiring project, especially for a Fender Stratocaster. It provides all the high-quality components you’d need – from the CRL 5-way switch to the pots and caps – to completely re-wire your guitar. For me, thinking about solder naturally leads to thinking about what I’m soldering, and having a top-tier component kit like this means you’re setting yourself up for success from the get-go. You’ll still need to supply your own solder, but with these components, you’ll want to use the best solder possible to ensure lasting performance. It’s designed to bring your Stratocaster’s electronics up to a professional standard, using the exact parts found in American-Series models.

- For SSS Stratocasters

- Modern wiring configures the tone controls like an American-Series Strat

- Finest OEM component brands, including USA-made CRL 5-way switch

- Professional wiring diagram – highest-quality documentation in the industry

- All hardware included and it’s the right hardware

-

Nobody knows more about guitar wiring than ToneShapers!

-

Pros:

- Provides a complete, high-quality solution for Strat wiring.

- Uses authentic, OEM-grade components for superior sound and durability.

- Includes a clear, professional wiring diagram, simplifying installation.

- Ensures compatibility and avoids guesswork with included hardware.

- Cons:

- Not a solder product itself, so you still need to purchase solder separately.

- Specific to Fender SSS Stratocasters, not versatile for other guitar types.

- Can be a higher upfront cost than just buying individual components.

- Best for: Fender SSS Stratocaster owners looking for a comprehensive, high-quality electronics overhaul, ensuring the best components for their guitar wiring project.

- User feedback summary: Users consistently praise the exceptional quality of the components and the clarity of the wiring diagrams, making what could be a daunting task much more manageable. Many note a significant improvement in their guitar’s tone and reliability after installation, highlighting that the investment in quality parts pays off.

AIM Solder LeadFree Rosin Core Solder Wire Sn99 Ag0.3…

When I’m trying to be environmentally conscious or work on projects where lead-free is a must, AIM Solder’s LeadFree Rosin Core is my go-to. This particular blend, Sn99 Ag0.3 Cu0.7, means it’s 99% tin, 0.3% silver, and 0.7% copper. The silver content is a nice touch, known for improving conductivity and strength. It flows smoothly, which is crucial for getting clean joints, especially on delicate components common in guitar wiring projects. The rosin flux core means you usually don’t need additional flux, keeping your workspace cleaner. It’s a very reputable brand in the solder world, so you can trust its quality.

- Lead-free rosin core solder wire with a diameter of 0.032″ / 0.81mm

- Alloy: 99% tin, 0.3% silver, 0.7% copper

- Low melting temperature compatible of 217°C (423°F)

- Rosin flux core is non-corrosive and non-conductive

-

Used for electrical repairs on printed circuit boards, radios, speakers, motors, applicances, wiring and other various electrical jobs.

-

Pros:

- Lead-free composition is safer for health and the environment.

- Smooth flow and low melting point for a lead-free option, making it easier to work with.

- Excellent electrical conductivity due to the tin/silver/copper alloy.

- Rosin flux core eliminates the need for external flux, simplifying the process.

- Reputable brand known for quality.

- Cons:

- Slightly higher melting point than traditional leaded solder, requiring a bit more heat.

- Can be a little less forgiving for beginners than 60/40 leaded solder.

- Best for: Environmentally conscious guitarists or those requiring lead-free compliance, and general electronics work where a reliable, lead-free solder for guitar wiring projects is needed.

- User feedback summary: Many users appreciate its excellent flow characteristics for a lead-free solder, noting it makes strong, shiny joints. They highlight its suitability for delicate electronics and its overall reliability, even for those accustomed to leaded options.

AIM Solder 60-40 Tin Lead Rosin Core Solder Wire for…

For many seasoned guitar technicians and DIY enthusiasts, myself included, 60/40 tin-lead solder is the gold standard for guitar wiring projects. This AIM Solder 60-40 wire is a fantastic example of why. The 60% tin and 40% lead alloy has a wonderfully low melting point (around 183°C-188°C), which means it flows like a dream and makes beautiful, shiny joints with minimal effort. This low temperature reduces the risk of overheating sensitive components, which is a big plus when you’re working on delicate pots or pickups. The rosin activated flux core ensures a clean joint every time. It’s incredibly forgiving and makes soldering feel almost effortless. Just remember that it contains lead, so proper ventilation is key!

- High purity leaded alloy comprised of 60% tin and 40% lead

- Melting point of 183°C-188°C (361°F-370°F)

- 2% Rosin Activated Flux Core with a diameter of 1.5mm (0.062″) and spool size of 454g (1lb)

- Great electrical and thermal conductivity, fast solder speed, low melting temperature, smooth flow and strong solder joints

- Used for electrical repairs on printed circuit boards, radios, speakers, motors, appliances, wiring and other various electrical jobs

-

WARNING: This product can expose you to chemicals including Lead…

-

Pros:

- Incredibly easy to work with due to its low melting point and excellent flow.

- Forms strong, shiny, and reliable solder joints quickly.

- Reduces risk of damaging heat-sensitive components in guitar wiring projects.

- Good electrical and thermal conductivity for optimal performance.

- Comes in a generous 1lb spool, offering great value for frequent users.

- Cons:

- Contains lead, requiring good ventilation and careful handling.

- Not suitable for applications where lead-free compliance is mandatory.

- Thicker 1.5mm diameter might be a bit much for very fine work, but good for general guitar wiring.

- Best for: Guitar wiring enthusiasts and professionals who prioritize ease of use, reliable connections, and fast soldering speeds, understanding the need for proper safety precautions with leaded solder.

- User feedback summary: Users universally praise this solder for its superb flow and ease of melting, describing it as the “go-to” for electronics work. They highlight its ability to create strong, clean joints consistently, making it a favorite for guitar wiring projects and general repairs alike.

Solder-It SP-7 Silver Solder Paste 7.1 Grams | Soldering…

This Solder-It SP-7 Silver Solder Paste is a really interesting alternative, especially for precision work or situations where you need an exceptionally strong bond. It comes in a syringe, making for a no-mess, no-waste application which I really appreciate when working on delicate components. What truly sets it apart is its incredible strength – up to 5x stronger than conventional solder wire – and its high electrical conductivity due to the silver content. It’s lead-free and boasts an “instant setting” feature which helps prevent parts from shifting while you’re soldering. This could be a game-changer for intricate guitar wiring projects where stability during cooling is critical.

- Easy to use syringe for no-mess, no-waste application

- High electrical conductivity, excellent for instrument assembly

- Corrosion-resistant, stays bright and doesn’t turn black

- Extremely tough: 10,000-25,000 PSI tensile strength, 5x stronger than conventional solder wire

- Low melting point at 430°F (221°C) and re-melts at 650°F (343°C)

-

Sets instantly, non-toxic, no lead, cadmium, antimony, or zinc

-

Pros:

- Precise, no-mess application with the syringe.

- Exceptional strength and durability makes for incredibly robust joints.

- High electrical conductivity for optimal signal transfer.

- Corrosion-resistant properties help maintain joint integrity and appearance.

- Instant setting helps prevent component movement during cooling.

- Lead-free and non-toxic formulation.

- Cons:

- Requires a different soldering technique compared to wire solder.

- Smaller quantity for the price, making it more specialized than a general-purpose solder.

- Re-melt temperature is higher than its initial flow temperature, which could complicate rework.

- Best for: Precision guitar wiring projects, small electronic components, strong structural electrical joints, or situations where maximum strength and conductivity are paramount, like delicate instrument assembly.

- User feedback summary: Users rave about the ease of application for small, intricate work and the superior strength of the resulting bonds. They often mention its clean finish and appreciate the lead-free composition for various DIY and professional tasks, especially where a strong solder option for guitar wiring projects is desired.

AIM Plumbing Solder Kit with solder wire, flux and brush,…

While AIM is a reputable solder manufacturer, this specific kit is designed for plumbing applications, and it’s important to differentiate. It contains a lead-free, silver-bearing alloy of tin, antimony, copper, and silver, and comes with flux and a brush – all geared towards sealing brass and copper plumbing joints. It complies with ASTM B32 requirements for potable water connections, which tells you its intended use. For guitar wiring projects, this product is generally not recommended. The melting point is usually quite high for plumbing solder, which could easily damage delicate guitar electronics. Plus, the included flux might not be suitable for electronics and could leave corrosive residue.

- AIM Plumbing Kit includes all the solder and solder paste flux you need.

- Silver bearing lead-free alloy comprised of tin, antimony, copper and silver

- Ideal for soldering brass and copper plumbing joints

- Complies with ASTM B32 requirements for soldering potable water connections.

-

Certified NSF and UPC

-

Pros:

- Complete kit for plumbing applications.

- Lead-free and suitable for potable water systems.

- Strong alloy for robust plumbing joints.

- Cons:

- Not suitable for guitar wiring due to a likely high melting point.

- The included flux is specifically for plumbing and not ideal for electronics.

- Risk of damaging sensitive guitar components with excessive heat.

- Overkill and incorrect formulation for delicate electrical work.

- Best for: Plumbing repairs and installations only, especially on brass and copper pipes where lead-free is required. Definitely not recommended for any guitar wiring projects.

- User feedback summary: Users confirm this kit is highly effective for its intended plumbing purpose, making secure and watertight seals. They highlight its compliance with safety standards for drinking water, but none of the feedback relates to electronics.

2 Pack – Amerway 60/40 Solder for Glass Projects &…

This Amerway 60/40 solder is another interesting case where the alloy itself (60% Tin & 40% Lead) is perfectly fine for electrical work, including guitar wiring projects. It has the classic low melting point (372°F / 189°C) that makes 60/40 so easy to work with. However, this product is designed specifically for glass artists for soldering lead caming, copper foil, and more. The key issue here for guitar wiring is the wire size: 1/8″ (3mm) diameter. That’s quite thick for the small, intricate connections typically found in guitar electronics. While you could technically use it, a thinner gauge would be much more practical and precise for your guitar’s tiny lugs and terminals. The flux type also might be optimized for glass, not electronics.

- 60/40 Solder = 60% Tin & 40% Lead

- Wire Size: 1/8″ (3mm) dia.

- Melting Point: 372°F (189°C) & Solidifies @ 361°F (183°C)

- Designed specifically for glass artists for soldering Lead Caming, Copper Foil, & more.

-

SAVE! By Purchasing 2 Rolls at a time!

-

Pros:

- Classic 60/40 tin/lead alloy, known for its ease of use and low melting point.

- Creates strong, reliable joints (alloy-wise).

- Comes in a convenient 2-pack for value.

- Cons:

- Wire diameter (3mm) is much too thick for delicate guitar wiring projects.

- Flux may be optimized for glass art, not necessarily electronics.

- Contains lead, requiring proper ventilation.

- Designed for a different application, potentially leading to messy or difficult work on guitars.

- Best for: Glass art, stained glass, and larger soldering tasks where a thick solder wire is advantageous. Not recommended for the fine detail work of guitar wiring projects.

- User feedback summary: Glass artists praise this solder for its smooth flow and consistent quality when working on stained glass and other art projects. They mention it creates nice, even beads and is reliable for its intended purpose.

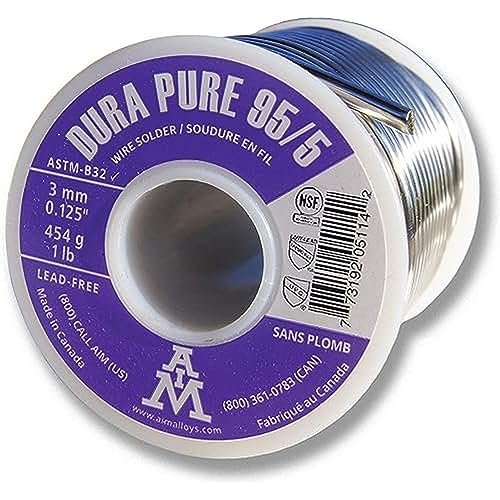

AIM Dura-Pure 95/5 Lead-Free 0.125inch Solid Solder Wire…

This is another lead-free solder from AIM, but it’s crucial to understand its specific application. The Dura-Pure 95/5 is a solid solder wire (meaning no flux core) and consists of 95% tin and 5% antimony. Like the previous plumbing kit, this product is ideal for soldering brass and copper plumbing joints and complies with ASTM B32 for potable water. Its melting range is significantly higher, at 232°C-240°C (450°F-464°F), and it boasts a very high tensile strength. For guitar wiring projects, this is a definite no-go. The high melting point is a major risk for delicate electronics, and being a solid wire means you’d need to apply external flux, adding an unnecessary step and potential mess. Its formulation and properties are simply not suited for electronics.

- Lead-free alloy comprised of 95% tin and 5% antimony

- Ideal for soldering brass and copper plumbing joints

- Melting range of 232°C-240°C (450°F-464°F)

- Ultimate tensile strength of 10,080 PSI

- Complies with ASTM B32 requirements for soldering potable water connections.

-

Certified NSF and UPC

-

Pros:

- Lead-free and environmentally friendly.

- Extremely strong tensile strength for robust joints.

- Suitable for high-stress plumbing applications and potable water.

- Cons:

- Very high melting point, highly likely to damage sensitive guitar electronics.

- Solid wire requires external flux, which adds complexity and potential for mess.

- Not formulated for electronics work, making it unsuitable for guitar wiring projects.

- Overkill and incorrect properties for delicate electrical connections.

- Best for: Heavy-duty plumbing applications and industrial uses where high strength, lead-free composition, and high melting temperatures are required. Absolutely not recommended for any guitar wiring projects.

- User feedback summary: Users confirm this solder provides exceptionally strong, durable bonds for plumbing, especially when working with copper pipes. They emphasize its lead-free nature and reliability for code-compliant installations.

Helpful Comparison Insights

When choosing the best solder options for guitar wiring projects, it really boils down to balancing ease of use, joint reliability, and personal preference (especially regarding lead).

For most guitar wiring tasks, the AIM Solder 60-40 Tin Lead Rosin Core Solder Wire stands out as the traditional champion. Its low melting point and superb flow make it incredibly forgiving and easy to achieve perfect, shiny joints. This is crucial when working on delicate components like pot lugs, switch terminals, or pickup leads, where excessive heat can cause damage. The fast solder speed means less time with the iron on your components, further reducing risk. While it contains lead, using it in a well-ventilated area with proper precautions makes it a safe and highly effective choice.

If you’re committed to a lead-free approach, the AIM Solder LeadFree Rosin Core Solder Wire Sn99 Ag0.3… is an excellent alternative. The addition of silver and copper helps it achieve great electrical conductivity and a relatively smooth flow for a lead-free option. It does require a slightly higher soldering temperature, so make sure your iron can handle it consistently without damaging components. It’s a reliable choice for those wanting to avoid lead without sacrificing too much on performance.

The Solder-It SP-7 Silver Solder Paste offers a specialized solution for precision and strength. Its syringe application is fantastic for tiny, fiddly bits, and its 5x stronger bond is impressive. However, it’s a different technique to master and might not be ideal for every connection, especially those needing quick rework. Think of it as a specialty tool for specific, high-stress joints rather than your everyday guitar wiring solder.

Now, a very important distinction: steer clear of solders designed for plumbing or glass art when it comes to guitar wiring projects. Both the AIM Plumbing Solder Kit and the AIM Dura-Pure 95/5 Lead-Free Solid Solder Wire have melting points that are far too high for sensitive guitar electronics, risking irreparable damage. Furthermore, the plumbing solders are formulated for different materials and often contain fluxes that are not suitable for electronics, or in the case of the Dura-Pure, no flux at all, requiring separate application. Similarly, while the Amerway 60/40 Solder for Glass Projects has the right alloy, its thick 3mm diameter is incredibly unwieldy for fine guitar wiring, making precise work much harder than it needs to be.

The ToneShaper Guitar Wiring Kit is a bit of an outlier here as it’s not solder, but a comprehensive component kit. If you’re doing a full Strat rewire, investing in a high-quality kit like this (and then using quality solder) ensures you have the right components that will truly maximize your guitar’s potential. It emphasizes that while solder is critical, the quality of the parts you’re connecting also plays a huge role in the final outcome of your guitar wiring project.

Ultimately, for most guitar wiring jobs, a good quality 60/40 rosin core solder in a manageable thickness (like 0.032″ to 0.062″ or 0.8mm to 1.5mm) will be your best friend. If lead is a concern, a tin/silver/copper lead-free option is a solid second choice, just be mindful of the slightly higher temperatures needed.

Final Verdict

After countless hours spent soldering and countless guitar wiring projects completed, my verdict is pretty straightforward: for the vast majority of guitarists, a good quality 60/40 tin-lead rosin core solder remains the top choice. Its low melting point, excellent flow, and ease of use are simply unmatched, making it the most forgiving and reliable option for achieving strong, clean electrical connections in your guitar. The AIM Solder 60-40 Tin Lead Rosin Core is an outstanding example of this classic workhorse.

However, if you’re committed to a lead-free environment, don’t despair! The AIM Solder LeadFree Rosin Core Solder Wire Sn99 Ag0.3… is a highly capable alternative. It provides excellent conductivity and a smooth enough flow to get the job done right, just remember to use a slightly hotter iron.

The Solder-It SP-7 Silver Solder Paste is a fantastic specialty solder for unique, high-strength applications or for very fine, delicate work where its precise application and instant setting properties truly shine. It’s not your everyday solder, but it definitely has a place in a well-equipped workshop.

Critically, avoid plumbing and glass-specific solders like the AIM Plumbing Kit, Amerway for Glass, or AIM Dura-Pure 95/5. Their properties, especially their high melting points and inappropriate wire thicknesses, make them unsuitable and potentially damaging for sensitive guitar wiring projects. Stick to solders designed for electronics, and your guitar (and your sanity) will thank you!

Comprehensive FAQ Section

1. Is leaded or lead-free solder better for guitar wiring projects?

For guitar wiring projects, many experienced technicians and hobbyists prefer leaded solder (e.g., 60/40 Tin-Lead) due to its significantly lower melting point, smoother flow, and ease of creating strong, shiny joints. This reduces the risk of overheating sensitive guitar components. However, lead-free options like tin/silver/copper alloys are excellent for those concerned about health or environmental factors, but they typically require a slightly higher soldering temperature and can be a bit less forgiving to work with initially.

2. What’s the best solder wire thickness for guitar wiring?

For most guitar wiring projects, a solder wire thickness between 0.032″ (0.8mm) and 0.062″ (1.5mm) is ideal. This range provides enough material to flow efficiently without being too thick to work with on small terminals or too thin to feed easily. Thicker wires (like 3mm) are generally too cumbersome for delicate guitar electronics.

3. Do I need flux for guitar wiring?

Most solders recommended for guitar wiring projects come with a rosin flux core, meaning the flux is already integrated into the wire. This is usually sufficient for clean joints. If you’re using solid core solder (which is generally not recommended for guitars) or encounter particularly dirty/oxidized components, you might need to apply a small amount of external rosin flux to ensure a good connection. Never use acid flux (often used for plumbing) on electronics, as it can cause corrosion.

4. What’s a good melting point for solder used in guitar wiring?

For guitar wiring projects, a solder with a melting point in the range of 183°C to 220°C (361°F to 428°F) is generally considered good. Leaded 60/40 solder melts around 183°C (361°F), making it very easy to work with. Lead-free solders often have a slightly higher melting point, usually in the 217°C to 220°C range, which is still manageable but requires a bit more heat from your iron. Avoid solders with melting points significantly above this, as they can damage delicate guitar electronics.

5. Can I use plumbing solder for guitars?

No, you should absolutely NOT use plumbing solder for guitar wiring projects. Plumbing solder typically has a much higher melting point than electronics solder and is often formulated for different materials and uses corrosive fluxes. Using it on your guitar’s sensitive components will almost certainly lead to damage, ineffective connections, and potential long-term corrosion. Always use solder specifically designed for electronics.

6. What are some safety tips for soldering guitars?

Safety is paramount when undertaking guitar wiring projects. Here are key tips:

* Ventilation: Always work in a well-ventilated area, especially when using leaded solder, or use a fume extractor to avoid inhaling solder fumes.

* Eye Protection: Wear safety glasses to protect your eyes from splashes of hot solder or flux.

* Burn Prevention: Use a soldering iron stand and be mindful of the hot iron. Avoid touching the tip or recently soldered joints.

* First Aid: Keep a first-aid kit nearby, especially for minor burns.

* Cleanliness: Wash your hands thoroughly after handling leaded solder.

* Proper Tools: Use appropriate tools like heat sinks, wire strippers, and desoldering tools to make the job safer and easier.

7. What kind of soldering iron should I use for guitar wiring?

For guitar wiring projects, a temperature-controlled soldering iron between 25-45 watts is highly recommended. This allows you to set the precise temperature needed for your chosen solder (e.g., 650-750°F or 340-400°C for leaded, slightly higher for lead-free), preventing overheating of delicate components while ensuring a strong, efficient joint. A fine-tip or chisel-tip iron will give you the precision needed for small terminals.

Affiliate Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this site.